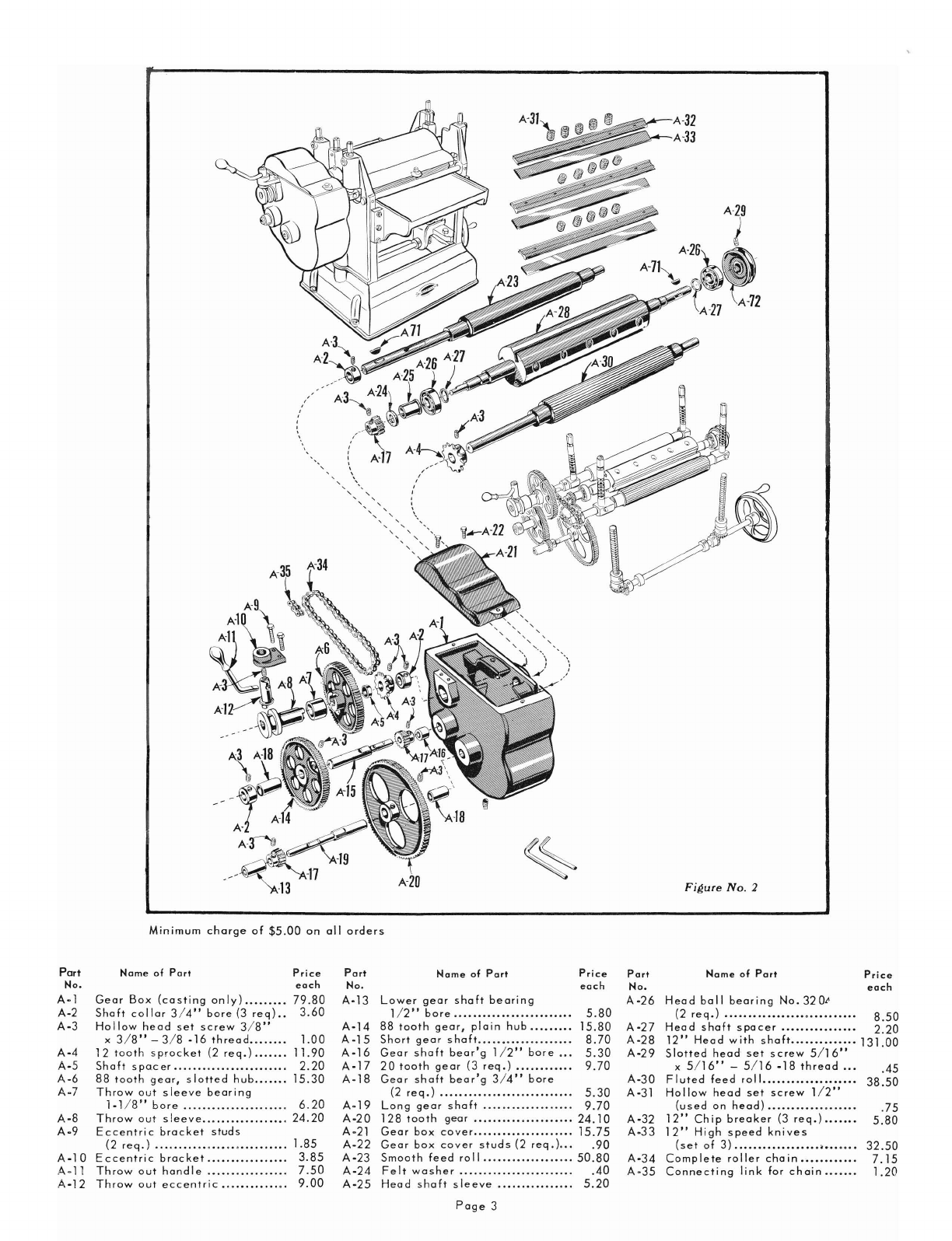

Figure

No.2

Minimum

charge

of

$5.00

on

all

orders

Part

Name

of

Part

Price

Part

Name

of

Part

Price

Part

Name

of

Part

Price

No.

each

No.

each

No.

each

A-l

Gear

Box

{casting

only)

..••.••.•

79.80

A-J3

Lower

gear

shaft

bearing

A

-26

Head

ball

bearing

No.

320"

A-2

Shaft

collar

3/4"

bore

(3

req)

..

3.60

1/2"

bore

...•••.••.••••.••••.•.•..

5.80

(2

req.)

.....••..•••••.••••••..•.•.•

8.50

A-3

Hollow

head

set

screw

3/8"

A-14

88

tooth

gear,

plain

hub

••.••..••

15.80

A-27

Head

shaft

spacer

.••••.•••.••.•.•

2.20

x

3/8"

-

3/8

-16

thread

.•.•.•.•

1.00

A-15

Short

gear

shaft

•..•••...•......•.•.

8.70

A-28

12"

Head

with

shaft

•••••••.••••••

131.00

A-4

12

tooth

sprocket

(2

req.)

.

11.90

A-16

Gear

shaft

bear'g

1/2"

bore

•.•

5.30

A-29

Slotted

head

set

screw

5/16"

A-5

Shaft

spacer

................•.......

2.20

A-17

20

tooth

gear

(3

req.)

••.•••.•••••

9.70

x

5/16"

-

5/16

-18

thread

...

.45

A-6

88

tooth

gear,

slotted

hub

.

15.30

A-18

Gear

shaft

bear'g

3/4"

bore

A-30

Fluted

feed

roil

••.••.••.•••.•••••••

38.50

A-7

Throw

out

sleeve

bearing

(2

req.)

••••........•..........••..•

5.30

A-31

Hollow

head

set

screw

1/2"

1-1/8"

bore

.............•......•.

6.20

A-19

Long

gear

shaft

..••..•••••.•••.•..

9.70

(used

on

head)

.•.........•••.•.••

.75

A-8

Throw

out

sleeve

...............••.

24.20

A-20

128

tooth

gear

.•.••••.•...•..•••.••

24.10

A-32

12"

Chip

breaker

{3

req.).......

5.80

A-9 E

ccentri

c

brocket

studs

A-21

Gear

box

cover

..••.••.••.•.••••.•••

15.75

A-33

12"

High

speed

knives

(2

req.)

...•..•..•••.•••.•..••..•...

1.85

A-22

Gear

box

cover

studs

(2

req.)...

.90

(set

of 3)

..••.••••.••.•.•••••••••••

32.50

A-10

Eccentric

brocket

..••.•••.••..•...

3.85

A-23

Smooth

feed

roil

•••.•.•.•.•...••..•

50.80

A-34

Complete

roller

chain

•.••••.•.••.

7.15

A-11

Throw

out

handle

7.50

A-24

Felt

washer

••••••.••..••••••..••••.

.40

A-35

Connecting

link

for

chain

.

1.20

A-12

Throw

out

eccentric

.•..•..•.•..•.

9.00

A-25

Head

shaft

sleeve

•.•••••••....•••

5.20

Page

3