007-91090047-003 MSS - MASTER SPECIFICATION SYSTEM

MASTER SPECIFICATION SECTION -

SUBMITTALS

01340 - 2

1Equipment Data and Spare Parts Summary Page 2 of 3

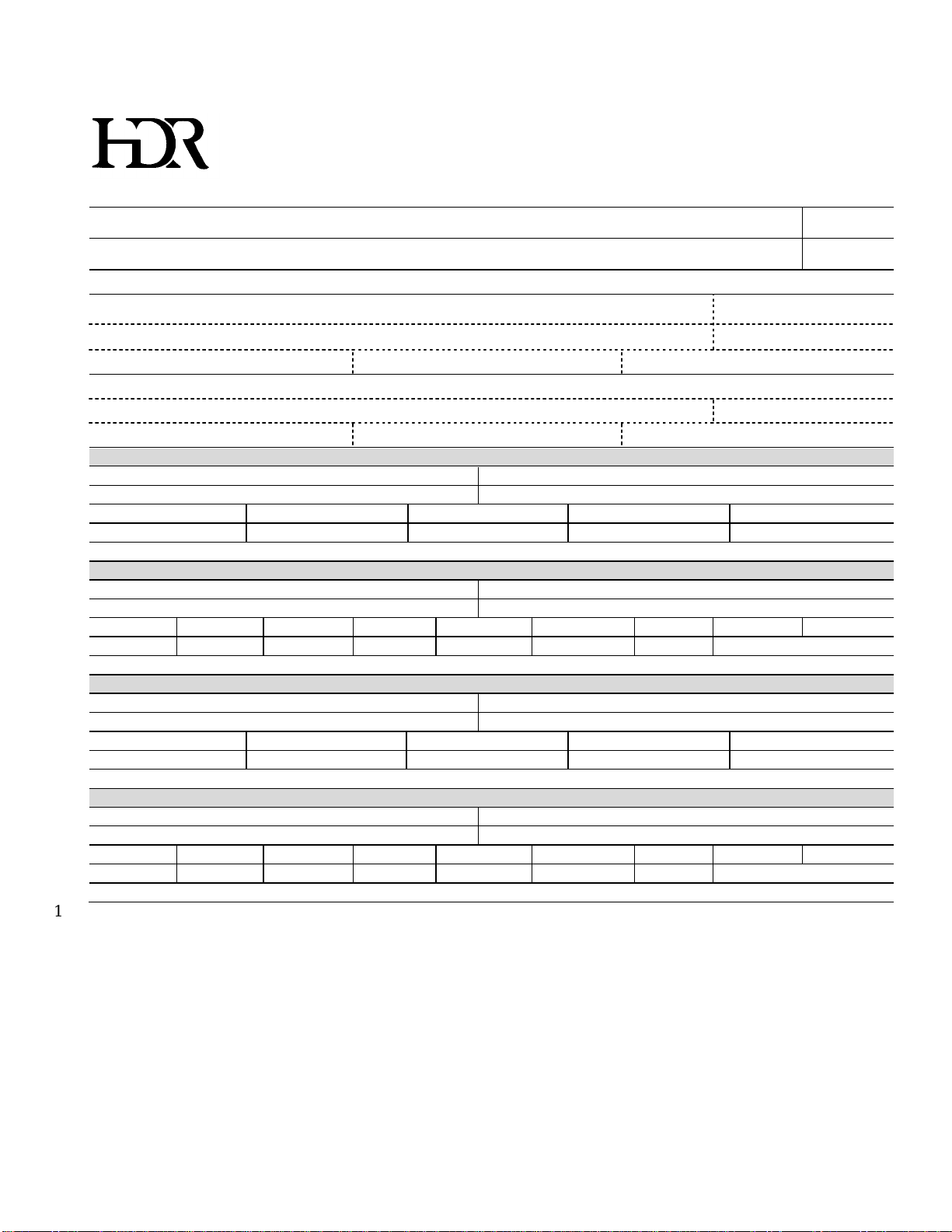

MECHANICAL NAMEPLATE DATA

Equip. BOOSTER PUMP Serial No.

Make BURKS Model No. ES8M-AB 1x1-1/4”

ID No. N/A Frame No. N/A HP RPM Cap.

Size TDH Imp. Sz. CFM PSI

Other:

ELECTRICAL NAMEPLATE DATA

Equip. BOOSTER PUMP MOTOR Serial No. F1007282578

Make BALDOR Model No.

ID No. N/A Frame No. N/A HP 5 V. 460 Amp. 6 HZ 60 PH 3 RPM 3600 SF 1.15

Duty CONT Code A Ins. Cl. F Type SEV.DUTY NEMA C Amb. Temp. Rise Rating

Other:

MECHANICAL NAMEPLATE DATA

Equip. DRUM GEAR REDUCER Serial No. 850049143.10.10.002

Make SEW EURODRIVE Model No. 77DRP112M4DH

ID No. N/A Frame No. N/A HP RPM 1765 Cap.

Size TDH Imp. Sz. CFM PSI

Other:

ELECTRICAL NAMEPLATE DATA

Equip. DRUM GEAR MOTOR Serial No. 850049143.10.10.002

Make SEW EURODRIVE Model No. DRP112M4DH

ID No. N/A Frame No. N/A HP 3 V. 266A/460Y Amp. 6.50 HZ 60 PH 3 RPM 1765 SF 1.15

Duty CONT Code B Ins. Cl. F Type NEMA C Amb. 40°C Temp. Rise Rating

Other: MOBIL 660XP 220 OIL

MECHANICAL NAMEPLATE DATA

Equip. FLOC GEAR REDUCER Serial No. 8500049148.10.10.002

Make SEW EURODRIVE Model No. RF37DT80K4-KS

ID No. N/A Frame No. N/A HP RPM 1700 Cap.

Size TDH Imp. Sz. CFM PSI

Other:

ELECTRICAL NAMEPLATE DATA

Equip. FLOC GEAR MOTOR Serial No. 8500049148.10.10.002

Make SEW EURODRIVE Model No. DFT80K4-KS

ID No. N/A Frame No. N/A HP 0.5 V. 123YY/460Y Amp. 1.76 HZ 60 PH 3 RPM 1700 SF 1.15

Duty CONT Code B Ins. Cl. F Type NEMA C Amb. 40°C Temp. Rise Rating

Other: MOBIL 660XP 220

MECHANICAL NAMEPLATE DATA

Equip. BOOSTER PUMP Serial No.

Make BURKS Model No. ES8M-AB 1x1-1/4”

ID No. Frame No. HP RPM Cap.

Size TDH Imp. Sz. CFM PSI

Other:

ELECTRICAL NAMEPLATE DATA

Equip. BOOSTER PUMP MOTOR Serial No. F1008255484

Make BALDOR Model No.

ID No. N/A Frame No. N/A HP 5 V. 460 Amp. 6 HZ 60 PH 3 RPM 3600 SF 1.15

Duty CONT Code A Ins. Cl.F Type SEV. DUTY NEMA C Amb. Temp. Rise Rating

Other:

2