Plunger Cart Usage

2

012-14781A

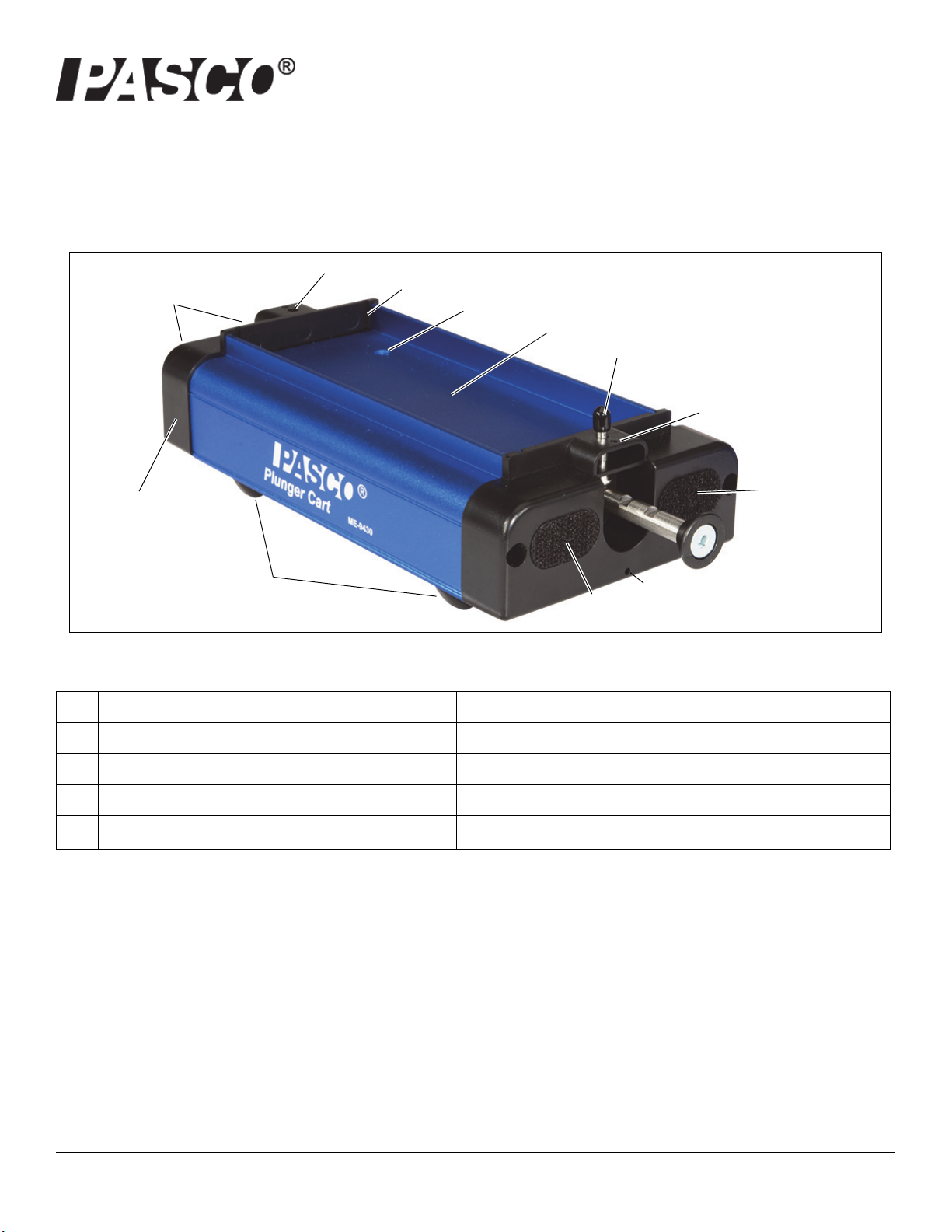

that can hold extra masses. The tray has threaded holes

for attaching PASCO accessories such as a Cart Adapter

that can be used to mount a Motion Sensor, and slots for

holding a Cart Picket Fence.

Other Features

The Plunger Cart has ball-bearing wheels that are

designed with narrow edges to minimize friction. The cart

has a spring suspension system that prevents damage to

the wheels and internal components if the cart is dropped

or stepped on. Plunger Carts can be stacked for easy stor-

age.

Plunger Operation

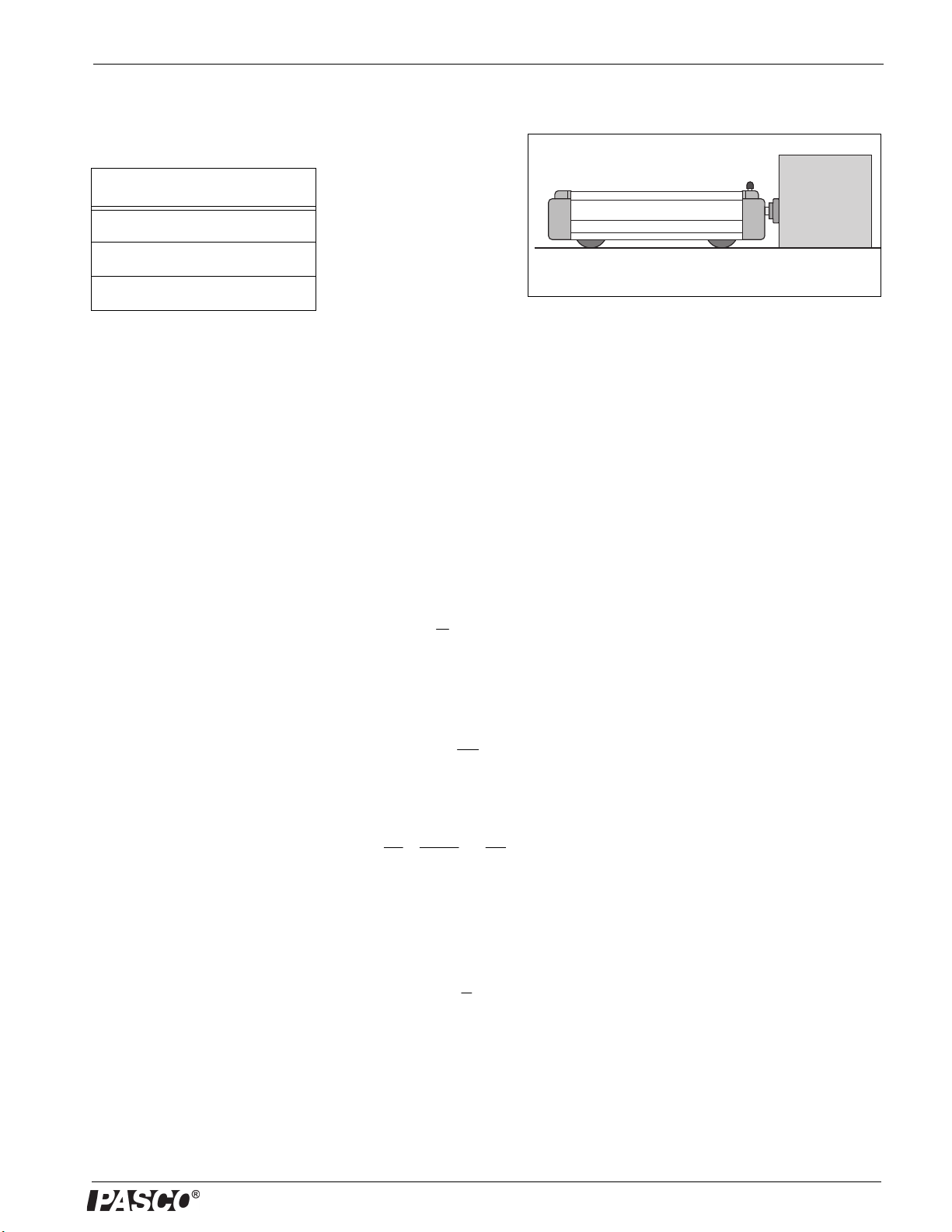

The plunger has three indentations on the top side that you

can see when the plunger is fully extended. Inside the cart

is a Retention Bar located above the plunger. When the

plunger is pushed in far enough so that an indentation lines

up with the Retention Bar, the plunger will be held in that

position until the Plunger Trigger is pushed down. If the end

of the plunger is next to an object such as a heavy book,

the Plunger Cart will accelerate away from the object when

the Plunger Trigger is pushed down and the plunger

applies a force.

Positions #1 and #2

Apply a slight upward force on the end of the plunger, Push

the plunger into the Plunger Cart until you hear or feel the

first “click” (Position #1) as the indentation on the plunger

lines up with the Retention Bar. Lower the end of the

plunger slightly to disengage it from the Retention Bar, and

push the plunger a little farther into the Plunger Cart.

Slightly raise the end of the plunger and push the plunger

until you hear or feel the second “click” (Position #2). To

release the plunger, push down on the Plunger Trigger.

CAUTION: The plunger comes out rapidly, so be prepared.

For example, do not hold the plunger end of the Plunger

Cart against your eye (or anything else that would be

harmed) if the plunger is released.

Position #3

Apply a slight upward force on the end of the plunger. Push

the plunger all the way into the Plunger Cart until the Posi-

tion #3 indentation catches on the Retention Bar. The end

of the plunger will be flush with the end cap of the Plunger

Cart. The plunger pushes outward with maximum force

when it is released from Position #3. This is also the posi-

tion used when doing inelastic collisions with the Velcro

bumpers.

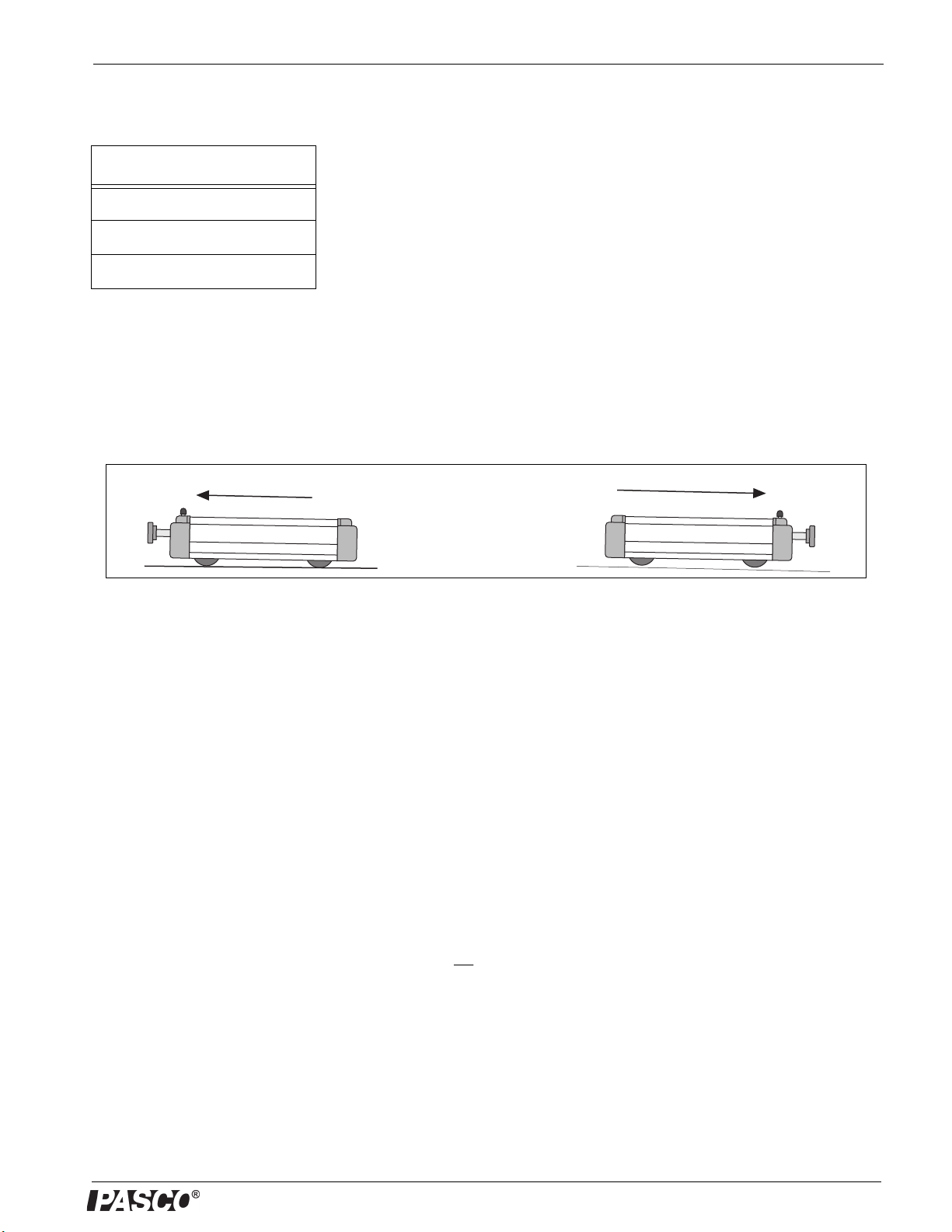

Usage

The following illustrations show a few of the ways that the

Plunger Cart is used. See the PASCO web site at

www.pasco.com for more information.

Collision Cart

The PASCO ME-9454 Collision Cart is a “twin” of the

Plunger Cart but it is red and does not have a spring

plunger. The different colors make it easier to keep track of

the carts in collisions studies.

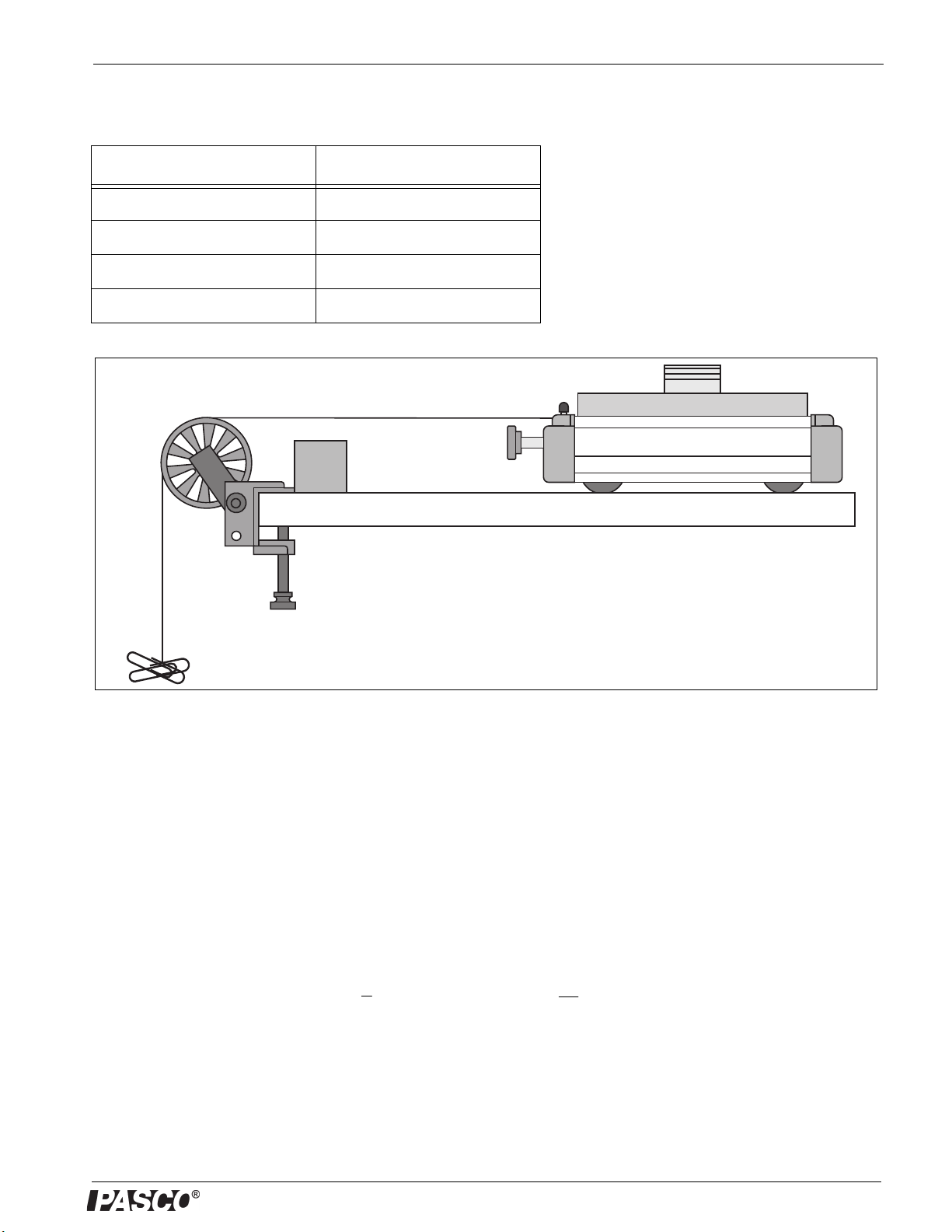

Plunger Cart Dynamics Systems

Plunger Carts are included in bundles with tracks, adjust-

able feet, end stops, a track pivot clamp a friction block,

and other accessories such as mass bars, springs, photo-

gate brackets, “cart picket fences”, and a pulley with clamp.

.

Plunger Trigger

Approximate Position of

Plunger Retention Bar

Position #1

Position #2

Position #3