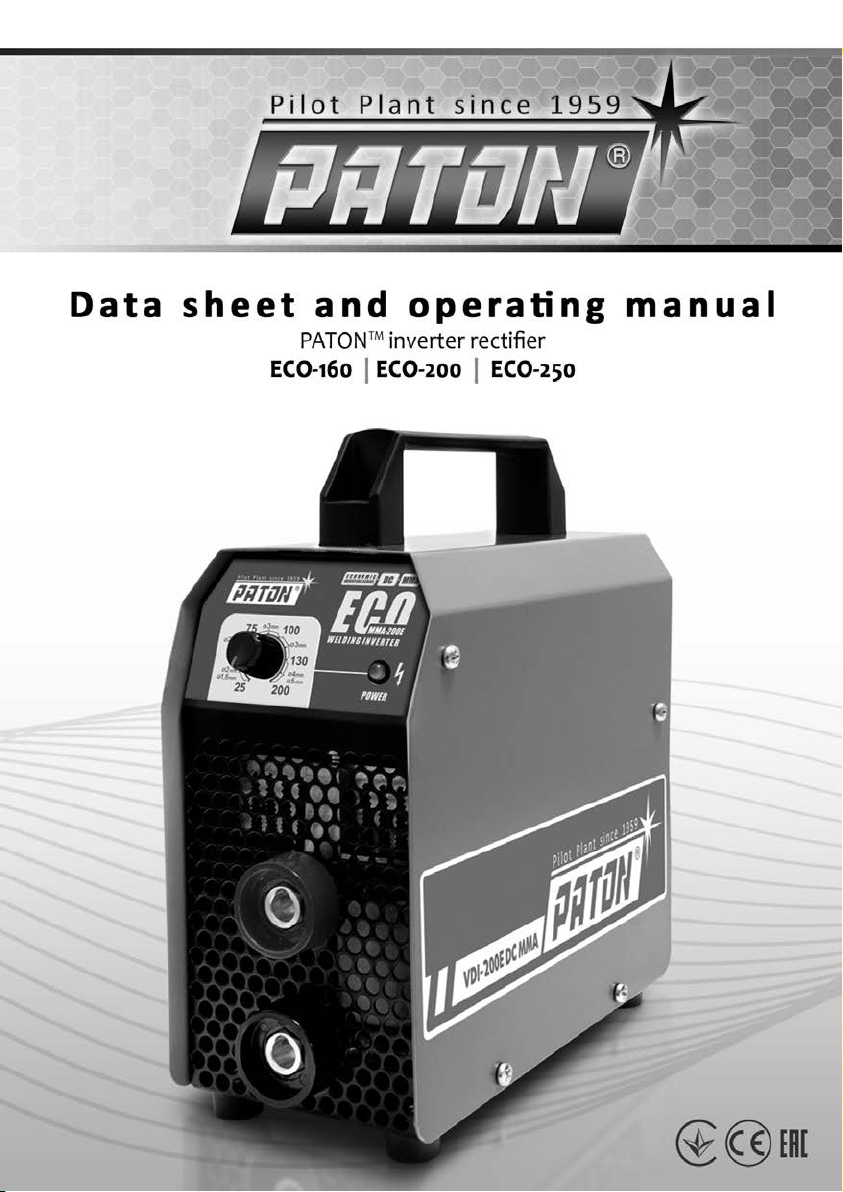

Paton ECO-160 Instruction Manual

PATON ECO-series DC MMA

- 2 -

CONTENTS

1. Generalprovisions4

2. Start‐up 7

2.1.Intendeduse7

2.2.Installation requirements 7

2.3.Powerconnection8

2.4.Mainsplugconnection8

3. Weldingwithstickelectrodes(MMA) 8

3.1.HotStartfunction9

3.2.ArcForcefunction9

3.3.Anti‐Stickfunction10

4. Attendanceandtechnicalmaintenance 10

5. Generatoroperationmode 11

6. Storagerules 11

7. Transportation 11

8. Technicalspecifications 11

9. Deliveryset 12

10. Troubleshooting 12

11. Safetyrules 13

12. Schematicelectricaldiagramofthesource 15

13. Warrantyliabilities 16

14. Acceptancecertificate 17

- 3 -

PATON ECO-series DC MMA

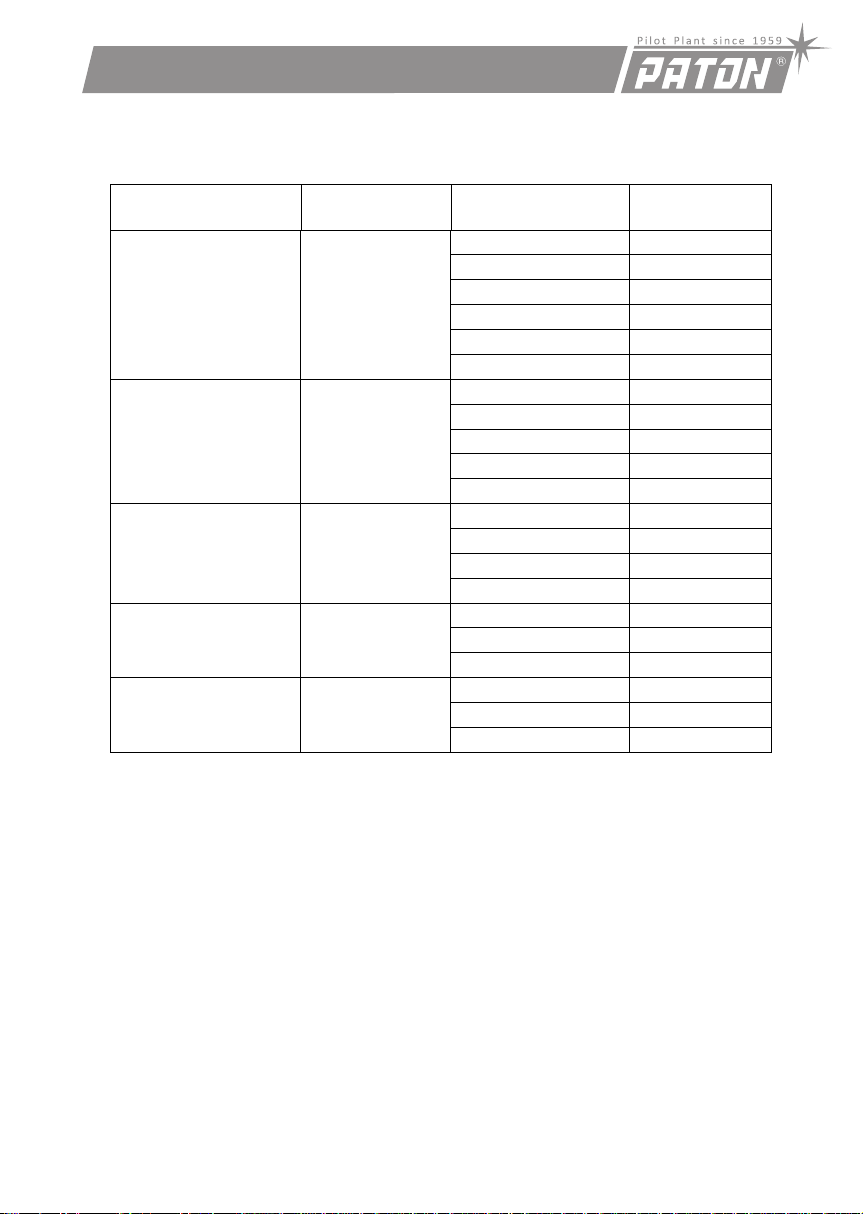

Connectiontopowermains/powerboard(at25ºС):

ATTENTION:Makeprovisionforcablesroutedinthewallsandotherextensioncords!

ElectrodeusedSetcurrentvalue

Powercablecross‐

section,sq.mm

Maximumcable

length,m

Ф2mm80Aatmost

1.0

120

1.5

180

2.0

240

2.5

300

4.0

480

6.0

720

Ф3mm120Aatmost

1.5

120

2.0

160

2.5

200

4.0

320

6.0

480

Ф4mm160Aatmost

2.0

120

2.5

150

4.0

240

6.0

360

Ф5mm,low‐melting200Aatmost

2.5

120

4.0

190

6.0

290

Ф5mm,

high‐melting250Aatmost

2.5

100

4.0

150

6.0

230

ATTENTION:Supplybuttonontherearpanelofthemachineisnotapower

button,soitdoesnotprovidecompletede‐energizationofinternalelectronic

parts,whenthemachineisswitchedoff.Therefore,inaccordancewithsafety

rules,disconnecttheplugfromthemainsaftercompletionofwelding.

PATON ECO-series DC MMA

- 4 -

1. GENERALPROVISIONS

InverterrectifiersPATONECO‐160,ECO‐200,ECO‐250aredesignedfordirect

currentmanualarcwelding(MMA).ThisEcoseriesisintendedfordemandingusers,

who need the most compact and powerful machine with full rated current of 160

A/200A/250Arespectively.Thiscurrentisenoughtoworkwithanyelectrodesfrom

Ф1.6mmtoФ5mmindiameter,includinghigh‐meltingelectrodes.Atthesametime,

its load duration is 40% and higher, which is more than enough for most

applications more demanding than household use (workshops, motor transport

servicesetc.).

All brand PATON™ ECO models produced by PATON are equipped

with a built‐in undervoltageprotectionunit.

Duetoincreasedfrequencyofvoltagesuppliedtothetransformer,the

transformercanbemadetenfoldsmaller.That’swhyweightandoveralldimensionsof

thismachineisseveraltimessmallerthanthoseofregularequipmentwithidentical

outputparameters.

Mainadvantages:

1. Inadditiontovoltagesurgeprotection,themachineisequippedwithastabilization

systemforlargelong‐termvoltagevariationsinthesupplymainsfrom170Vto260

V.However,minimumvoltageof170Vallowsweldingwithanelectrodenotmore

thanФ3mmindiameter.

2. Themachinefitsstandarddomesticpowermains.Duetohighefficiencyfactor,the

sourceprovidestwicelowerpowerconsumptioncomparedtoregularsources.

3. Convenientuseduetohighloadduration(LD)atratedcurrent,whichenables

continuousweldingwithФ3mmelectrodesattheirratedcurrent.

4. Increasedmachinereliabilityindustyproductionenvironment.

5. Allelectronicpartsofthemachineareimpregnatedwithtwolayersofhigh‐quality

varnishwhichensuresproductreliabilityduringtheentireservicelife.

6. Smoothadjustmentofarccurrent.

7. Enhancedarcingstability.

- 5 -

PATON ECO-series DC MMA

PARAMETERS

ECO–160ECO–200ECO–250

Ratedvoltageof50Hzsupply

mains,V220220220

Ratedcurrentconsumptionfrom

mains,A202532

Ratedarccurrent,A

160

200

250

Maximumroot‐mean‐square

current,A190240300

Loadduration(LD)40%at160A

100%at101A

40%at200A

100%at126A

40%at250А

100%at158A

Mainsvoltagevariationrange,V

170~260

170~260

170~260

Arccurrentadjustmentrange,A

20~160

25~200

32~250

HotStart

yes

yes

yes

ArcForce

yes

yes

yes

Anti‐Stick

yes

yes

yes

Open‐circuitvoltage,V

80

80

80

Arcstrikingvoltage,V

110

110

110

Ratedpowerconsumption,kW

4.4

5.5

7.0

Maximumpowerconsumption,

kW5.56.98.8

Efficiencyfactor,%

90

90

90

Cooling

forced

Operatingtemperaturerange

–

25…+45ºС

–

25…+45ºС–25…+45ºС

Overalldimensions(length,

width,height)245х100х200270х110х200270х110х200

Weight,kg

3.75

3.95

4.30

Ingressprotectionclass*

IP21

IP21

IP21

*ForEcoseriesmachines,theirframeprotectsthemfromingressofobjectsmorethan5.5

mmindiameter,andverticallydrippingwaterdoesnotinfringethemachineoperation

Fig.1Controlelementsandindication

PATON ECO-series DC MMA

- 6 -

Recommendedlengthofpowerweldingcablesduringwelding:

Machinemodel

Cablelength,m

(oneway)

Cross‐section

area,sq.mmCablegrade

ECO–160

1…4

8

КГ1х8

2…5

10

КГ1х10

3…8

16

КГ1х16

ECO–200

1…4

10

КГ1х10

2…6.5

16

КГ1х16

3…10

25

КГ1х25

ECO–250

1…5

16

КГ1х16

2…8

25

КГ1х25

3…11

35

КГ1х35

- 7 -

PATON ECO-series DC MMA

1–Arccurrentcontroller,allowsforsmoothadjustmentofarccurrent.

2–Statusindicator:

a) permanentgreenlight–themachineisreadyforoperation;

b) flashingyellowlightduringstriking–mainsvoltageisnotsufficient;

c) permanentyellowlight–thesourceisoverheated;

d) nolight–nopowersupply.

3–Mainsswitch(doesnotlightup,thecolourisadoptedfordesignpurposes).

А–Powercurrentsocket"+"ofbayonettype:

incaseofMMAwelding–forconnectionofelectrodecable(veryoccasionally

"earth"cablecanbeconnected,ifspecialelectrodesareused).

B–Powercurrentsocket"‐"ofbayonettype:

incaseofMMAwelding–forconnectionof"earth"cable(veryoccasionally

electrodecablecanbeconnected,ifspecialelectrodesareused).

2. START‐UP

ATTENTION:Beforestart‐up,readthechapter"Safetyrules",paragraph11.

2.1INTENDEDUSE

Theweldingmachineisdesignedsolelyformanualarcweldingwithastick

electrode,aswellasforargonwelding.

Otheruseofthemachineisconsideredundue.Themanufacturerisnot

responsiblefordamagecausebyundueuseofthemachine.

Intendeduseofthemachineimpliesadherencetoinstructionsofthisoperating

manual.

ATTENTION:Donotusetheweldingmachineforpipesdefrosting.

2.2INSTALLATION REQUIREMENTS

Theweldingmachineisprotectedfromingressofforeignsolidobjectsofmore

than5.5mmindiameter.

Theweldingmachinecanbeplacedandoperatedoutdoors.Internalelectricpartsof

themachineareprotectedagainstdirectmoistureimpact.

ATTENTION:Donotswitchthemachineoffimmediatelyaftercompletionof

weldingworksinhotweatherorintenseweldingworksinanyweatherconditions!

Electronicpartsmustbeallowedtocooldownfor5minutes.

ATTENTION:Whenthemachineisswitchedoffandcoolsdownafteroperation

incoldseason,condensateformsinsideofit,sodonotswitchthemachineonagain

inlessthan3...4hours!!!

Therefore,don'tswitchthemachineoffincoldseason,ifyouaregoingtoswitchit

onwithin4hours.

ATTENTION:Themachinemaybelife‐threateningafterahardfall.Soplaceit

onstablesolidsurface.

PATON ECO-series DC MMA

- 8 -

Themachinemustbeplacedsoastoensurefreeinletandoutletofcoolingair

throughventholesonthefrontandtherearpanels.Takecarethatmetaldust(for

example,duringemerygrinding)doesdrawndirectlyintothemachinebythecooling

fan.

2.3POWERCONNECTION

Theweldingmachineofseriesdesignisratedformainsvoltageof220V(‐23%

+18%).

ATTENTION:Allmanufacturer'swarrantyliabilitiesbecomevoidifthe

machineisusedwithsupplyvoltageexceeding270V!

Mainsconnector,cross‐sectionsofpowersupplycablesandsupply‐linefuses

mustbeselectedonthebasisoftechnicalspecificationsofthemachine.

2.4MAINSPLUGCONNECTION

ATTENTION:Mainsplugshallcorrespondtosupplyvoltageandcurrent

consumptionoftheweldingmachine(seetechnicaldata).Inaccordancewithsafety

practices,usereceptacleswithguaranteedearthing!!!

3. WELDINGWITHSTICKELECTRODES(MMA)

‐inserttheelectrodecableintothesourcesocketА"+";

‐insertthe"earth"cableintothesourcesocketB"‐";

‐connectthe"earth"cabletotheworkpiece;

‐connectthemainsplugtothesupplymains;

‐setpowerswitch3ontherearpaneltoposition"I";

Fig.2.Machineconnectiondiagramforweldingwithstickelectrodes

ATTENTION:Oncethepowerswitch3issettoposition"I",thestickelectrode

becomesenergized.Donottouchconductiveorearthedobjects,suchas,for

example,weldingmachineframeetc.,withtheelectrode.

- 9 -

PATON ECO-series DC MMA

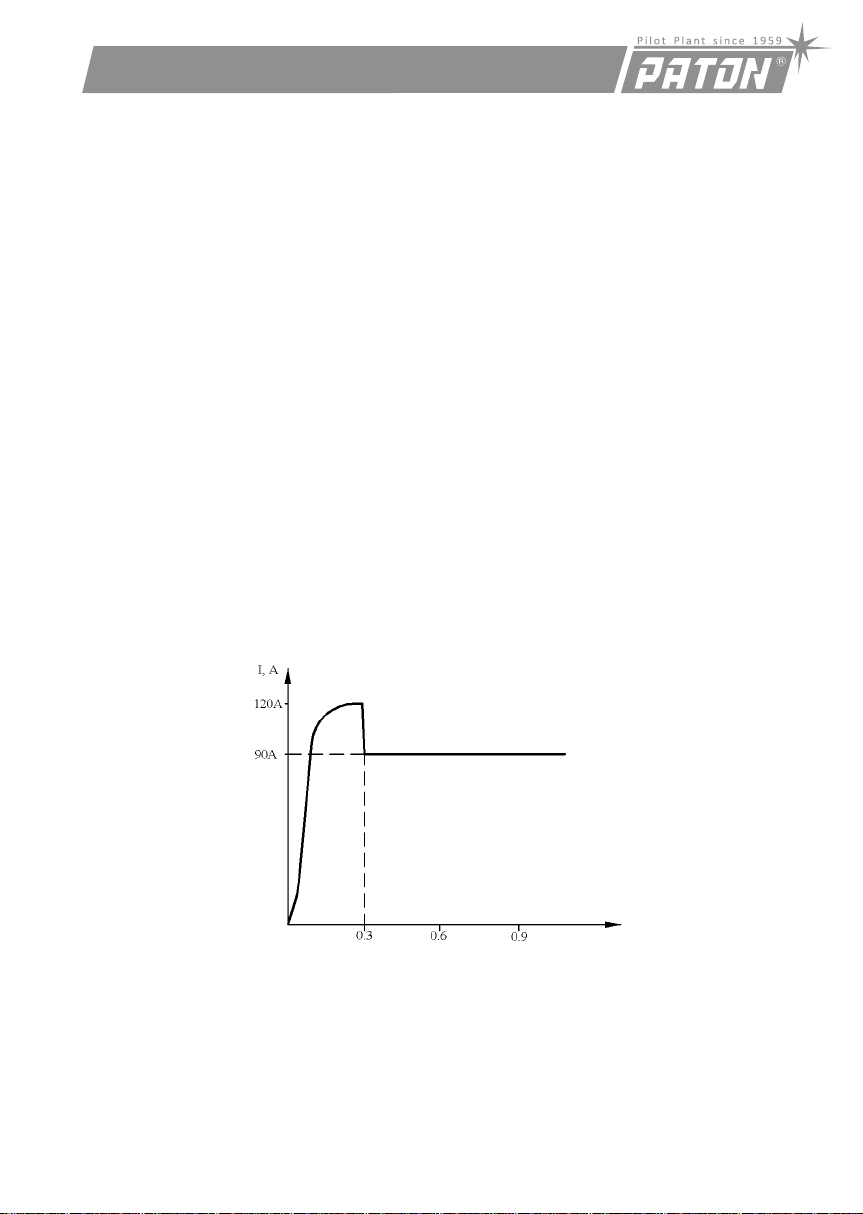

3.1HOTSTARTFUNCTION

Advantages:

‐improvedstrikingevenwhenusingelectrodeswithbadstrikingproperties;

‐betterpenetrationofbasematerialduringstrikingand,consequently,less

poorpenetrations;

‐preventionofslaginclusions.

Theresultisachievedbythefollowingmeans:

Inthemomentofarcstriking,arccurrentincreasesby33%ofthesetarccurrent

valueforashorttime(Fig.3).

Example:weldingwithanelectrodeofФ3mmindiameter.

Arccurrentvalue,whichissetusingthecontroller,is90A.

Hotstartcurrentis90A+33%=120A.

3.2ARCFORCEFUNCTION

Advantages:

‐enhancedshort‐arcweldingstability;

‐bettertransferofmetaldropsintotheweldpool;

‐betterarcstriking;

‐reducedriskofelectrodesticking.

Theresultisachievedbythefollowingmeans:

Duetoreductionofarcvoltagebelowtheminimumpermissiblevoltageof

stablearcburning,arccurrentincreasesby30%ofthesetvalue(Fig.4).

Fig.3.HOTSTARTfunction

t,

s

PATON ECO-series DC MMA

- 10 -

Fig.4.ARCFORCEfunction

3.3ANTI‐STICKFUNCTION

Duringinitialarcstriking,theelectrodecanstickorbetackedtotheworkpiece,

firstleadingtooverheatingandeventuallytodamageoftheelectrode.

Iftheelectrodehasstucktotheworkpiece,themachinereducesarccurrent

within0.6...0.8s.Thisfunctionhelpstheweldingoperatortoseparate(detach)the

electrodefromtheworkpiecewithoutrisktoburnhiseyeswithaccidentalarcstriking.

Oncetheelectrodeisdetachedfromtheworkpiece,theprocessofweldingcanbe

readilyresumed.

4. ATTENDANCEANDTECHNICALMAINTENANCE

ATTENTION:Beforeopeningthemachine,switchitoffanddisconnectthe

mainsplug.Waituntilinternalcircuitsofthemachinede‐energize(about5

minutes),andonlythenproceedwithotheractions.Whenleavingthemachine,

installarestrictiveplatewhichprohibitsswitchingthemachineon.

Inordertoensureproperoperationofthemachineformanyyears,adhereto

severalrules:

- conductinspectioninaccordancewithsafetypracticeswithintheestablished

timeintervals(see"Safetyrules"chapter);

- ifthemachineissubjecttoheavyuse,itisrecommendedtopurgeitwithdry

compressedaironcepersixmonth.Attention:Ifthemachineispurgedfroma

veryshortdistance,electroniccomponentsmaybedamaged;

- ifthemachineisverydust‐laden,cleanchannelsofthecoolingsystem

manually.

130

- 11 -

PATON ECO-series DC MMA

5. GENERATOROPERATIONMODE

Thepowersourcecanbeoperatedfromageneratoruponthefollowingcondition:

Whenworkingwith

electrodes

Setcurrentvalue

Minimumgenerator

power,kVA

Ф280Aatmost2.6

Ф3120Aatmost4.1

Ф4160Aatmost5.5

Ф5,low‐melting200Aatmost6.9

Ф5,high‐melting250Aatmost8.8

ATTENTION:Inordertoensuretrouble‐freeoperation,outputvoltageofthe

generatorshallnotfallbeyondthepermissiblerangeof170~260V!

6. STORAGERULES

Apreservedandpackagedsourceshallbestoredinstorageconditions4asper

GOST15150‐69for5years.

Ade‐preservedsourceshallbestoredindryclosedroomsatairtemperaturenot

lowerthanplus5°С.Theroomsmustbefreefromacidvapoursandotheractive

substances.

7. TRANSPORTATION

Apackagedsourcecanbetransportedbyanymeansoftransportation,which

provideitsintegrity,complyingwithalltransportationrulesestablishedforthistypeof

transport.

8. TECHNICALSPECIFICATIONS

ATTENTION:Ifasourceisdesignedforspecialsupplyvoltage,itstechnical

specificationsareprovidedontheidentificationplateonthefrontortherearpanel.

Inthiscase,mainsplugandmainscableshallbeselectedaccordingtothevoltage

used.

Parameters

ECO‐160 ECO‐200 ECO‐250

Ratedvoltageofmains50/60Hz,V

~220

~220

~220

Mainsvoltagevariationrange,V

170~260

170~260

170~260

Efficiencyfactor,%909090

Arccurrentadjustmentrange,A20~16025~20032~250

Arc

currentat:

5min./45%LD

5min./100%LD

160A

101A

200A

126A

250A

158A

Maximumpowerconsumption,kVA5.56.98.8

Normaloperatingvoltage:

‐MMAstickelectrode20.4~26V20.4~26.5V20.4~27.0V

PATON ECO-series DC MMA

- 12 -

9. DELIVERYSET

1. Weldingarcsupplysourcewithamainscable – 1pce.

2. Shouldercarryingstrap – 1pce.

3. PATONbrandcorrugatedbox – 1pce.

4. 3mweldingcablewithanelectrodeholder – 1pce.

5. 3mweldingcablewithearthterminal – 1pce.

6. Operatingmanual – 1pce.

10. TROUBLESHOOTING

FaultCauseCorrection

Noarccurrent

Themainsswitchison,

butthestatusindicator

isnotlit.

Mainscablebreak

Checkthemainscable.

Supplymainsvoltageis

lowerthan155V

Disconnectthemachineand

connectittothemainswith

propersupplyvoltage

Supplymainsvoltage

exceedsthepermissible

valueof260V

Disconnectthemachineand

connectittothemainswith

propersupplyvoltage

Internalsourcesupply

unithasfailed

Contacttheservicefacility

Noarccurrent

Themainsswitchison,

thesourcestatus

indicatorlightsgreen

Weldingcablesare

disconnected

Checkplugconnection

Earthisnotconnectedor

connectedpoorly

Establishreliableconnectionof

theearthcablewiththework

piece

Noarccurrent

Themainsswitchison,

thesourcestatus

indicatorlightsyellow

Temperaturesensorhas

beenactuated

Waituntilthemachinecools

down;thenitwillswitchonagain

automatically

Insufficientcoolingair

supply

Providesufficientairinflow

Temperaturesensor

is

faulty

Contacttheservicefacility

Badstrikingduring

weldingwithastick

electrode,thesource

statusindicatorflashes

greenforshortperiods

Supplymainsvoltageat

thestartofloadingis

neartheminimum

permissiblevalueof

165V.

Ifitisimpossibletoincrease

cross‐sectionoffeedingmains

cables,tryreducingtheset

currentvalue,untilitwillallowfor

strikingthearc.Thenusean

electrodecorrespondingtothe

currentvalue.

Continuationoftableonpage14.

- 13 - PATON ECO-series DC MMA

Continuationoftablestartedonpage13.

11. SAFETYRULES

GENERALPROVISIONS

Theweldingmachineismanufacturedinaccordancewithtechnicalstandardsand

establishedsafetyrules.However,incorrecthandlingresultsinthefollowingdangers:

‐injuryofmaintenancepersonnelorthirdpersons;

‐damageofthemachineorpropertyoftheenterprise;

‐derangementofefficientworkingprocess.

Allpersonsdealingwithstart‐up,operation,attendanceandmaintenanceofthe

machinemust:

‐undergorelevantqualifyingexamination;

‐haveknowledgeaboutwelding;

‐carefullyfollowtheseinstructions.

Malfunctionsthatcanreducesafetymustbeeliminatedimmediately.

USER'SRESPONSIBILITIES

Toensureindividualprotection,adheretothefollowingrules:

‐wearrobustfootwear,whichretainsinsulatingpropertiesinmoistconditionsaswell;

‐protectthehandswithinsulatinggloves;

‐protecttheeyeswithaheadshield,withisequippedwithablack‐lightfiltercomplying

withsafetystandards;

‐wearonlyproperlow‐flammableclothes.

INDIVIDUALPROTECTIVEEQUIPMENT

Toensureindividualprotection,adheretothefollowingrules:

‐wearrobustfootwear,whichretainsinsulatingpropertiesinmoistconditionsaswell;

‐protectthehandswithinsulatinggloves;

‐protecttheeyeswithaheadshield,withisequippedwithablack‐lightfiltercomplying

withsafetystandards;

‐wearonlyproperlow‐flammableclothes.

Fault

Cause

Correction

Sporadicarc

extinctionoccurs

duringwelding

Arcburningvoltageis

toohighforthe

electrodeused

Ifpossible,useotherelectrodes

oranotherweldingmachine

designedforhigherpower

Stickelectrodeis

stickingtothework

piece

Arccurrentvalueistoo

low

Setarccurrenttoahighervalue

Badweldingquality

(intensesplashing)

Incorrectpolarityofthe

electrode

Changepolarityoftheelectrode

(inaccordancewithdataofthe

electrodesmanufacturer)

Poorcontactwithearth

Connectearthterminalasclose

totheweldingzoneaspossible

PATON ECO-series DC MMA

- 14 -

DANGEROFHAZARDOUSGASESANDVAPOURS

‐ ifsmokeandhazardousgasesemergeintheoperatingzone,removethemwith

specialmeans;

‐providesufficientfreshairinflow;

‐arcradiationfieldmustbefreefromsolventvapours.

DANGEROFSPARKING

‐removeflammableobjectsfromtheoperatingzone;

‐itisnotallowedtoweldvesselswheregases,fueloroilproductsarestoredorusedto

bestored.Residuesoftheseproductsmayexplode;

‐ whenworkinginfire‐dangerousorexplosion‐dangerousrooms,adheretospecial

rulesincompliancewithnationalandinternationalregulations.

DANGEROFMAINSANDARCCURRENT

‐electricshockcanleadtodeath;

‐ magneticfieldscreatedbythismachinecanhaveadverseeffectonoperabilityof

electricalappliances(suchascardiacpacemakers).Peoplewhousesuchappliancesshall

consultwithadoctorbeforeapproachingtheoperatingweldingarea;

‐weldingcablemustberobust,intactandinsulated.Looseconnectionsanddamaged

cablesmustbeimmediatelyreplaced.Mainscablesandcablesoftheweldingmachinemust

becheckedforinsulationintegritybyanelectricalengineeronaregularbasis;

‐whenusingthemachine,neverremoveitsoutercase.

INFORMALSAFETYMEASURES

‐themanualmustbealwaysstoredneartheplacewheretheweldingmachineisused;

‐ inadditionaltothemanual,adheretogeneralandlocalsafetyandenvironmental

rules;

‐allinstructionsontheweldingmachineshallbekeptreadable.

STRAYWELDINGCURRENTS

‐makesurethattheearthcableterminalissecurelyconnectedtotheworkpiece;

‐ifpossible,avoidinstallingtheweldingmachinedirectlyontheconductivecoatingof

floororworktable,useinsulatingpads.

SAFETYMEASURESINNORMALCONDITIONS

Checkthemachineforexternaldamagesandperformanceofsafetydevicesatleat

onceaweek.

- 15 -

PATON ECO-series DC MMA

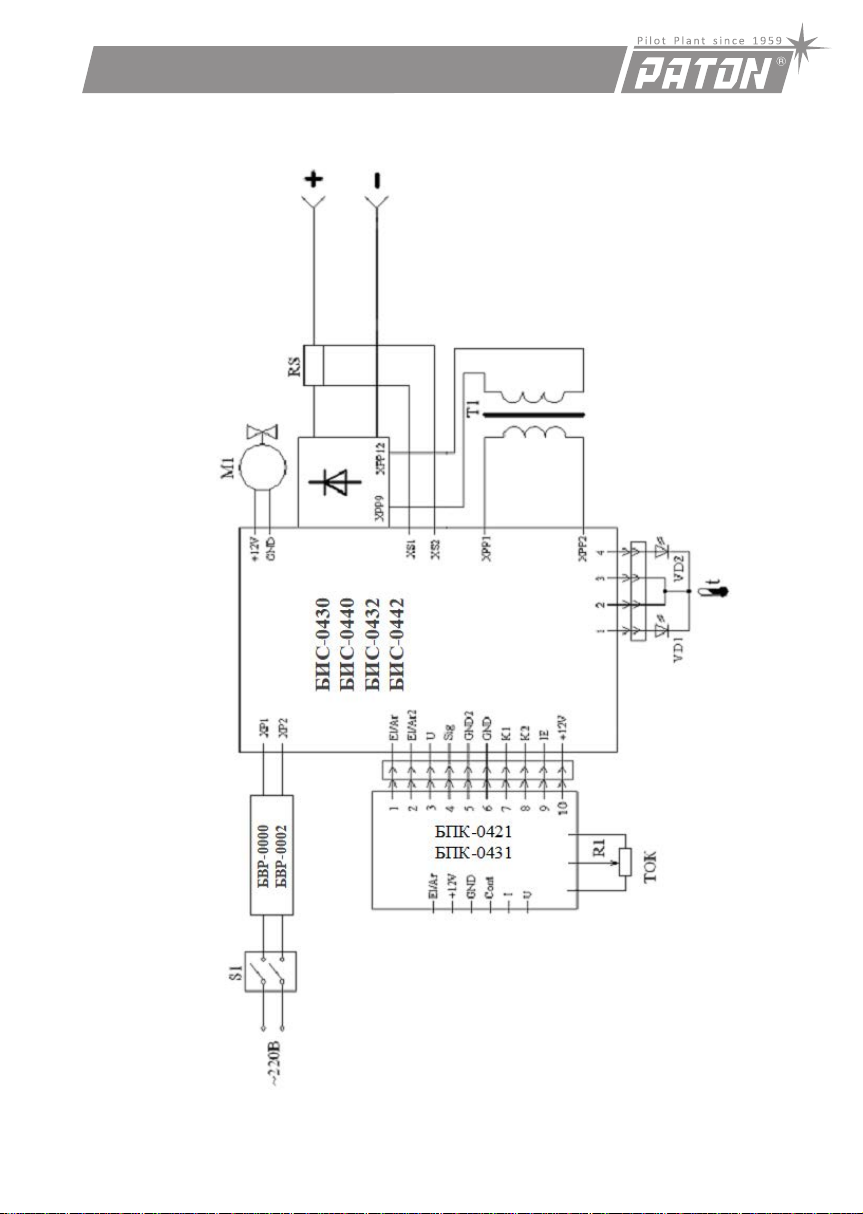

12. SCHEMATICELECTRICALDIAGRAMOFTHESOURCE

Schematicelectricaldiagram

oftheSourceECO‐160/200/250DCММА

PATON ECO-series DC MMA

- 16 -

13. WARRANTYLIABILITIES

PilotPlantofWeldingEquipmentnamedafterYe.O.Patonguaranteesproper

operationofthesupplysource,providedthattheconsumerobservesoperating,storageand

transportationconditions.

ATTENTION:Freewarrantyservicingisnotprovidediftheweldingmachineis

mechanicallydamaged!

BasicwarrantyperiodforweldinginvertersofEseriesis__years.Basicwarranty

periodiscalculatedfromthedateofsaleoftheinverterequipmenttotheultimatebuyer.

Duringthebasicwarrantyperiod,thevendorisobligedtoprovidetheownerofPATON

TMinverterequipmentwiththefollowingservicesforfree:

‐performdiagnosticsandrevealthecauseoffault;

‐provideunitsandelementsnecessarytoperformtherepair;

‐replacebrokendownelementsandunit;

‐conducttestingoftherepairedequipment.

Basicwarrantyliabilitiesdonotapplytoequipment:

‐whichhasmechanicaldamagesaffectingoperabilityofthemachine(deformationofthe

frameanddetailsduetofallfromheightordropofheavyobjectsontheequipment,

buttonsandslotsfallingout);

‐withevidenceofcorrosionwhichcauseditsnon‐operability;

‐brokendownduetoexcessmoistureaffectingitspowerandelectronicelements;

‐brokendownduetoaccumulationofconductivedust(coaldust,metalchips,etc.)insideof

themachine;

‐iftheuserattemptedtorepairtheunitsofthemachineand/orreplaceitselectronic

elementsathisowndiscretion;

‐dependingonoperatingconditions,itisrecommendedtocleaninternalelementsandunits

ofthisequipmentwithcompressedaironcepersixmonths,inordertopreventbreak‐down

ofthemachine.Beforecleaningthemachine,removetheprotectivecover.Cleaningshall

beperformedcarefully,withcompressorhoseheldfarenoughfromthemachinesoasnot

todamagethesolderingofelectronicelementsandmechanicalparts.

Inaddition,basicwarrantyliabilitiesdonotapplytobrokendownexternalelementsof

theequipment,whicharesubjecttophysicalcontact,andassociated/consumablematerials

whichcanbeclaimedtwoweeksafterthesaledateatthelatest:

‐ONandOFFbutton,

‐weldingparametersadjustingknobs,

‐slotsforconnectionofcablesandhoses,

‐controlslots,

‐mainscableandmainscableplug,

‐carryinghandle,shoulderstrap,case,box,

‐electrodeholder,earthterminal,weldingcablesandhoses.

Thevendorretainstherighttorefusetoperformwarrantyrepair,ortosetthewarranty

liabilitiesstartdaytomonthandyearoftheequipmentmanufacture(theycanbedetermined

fromtheserialnumber):

‐iftheownerhaslostthedatasheet;

‐ifthevendordidnotfillinthedatasheetorfilleditincorrectlywhensellingtheequipment,

- 17 -

PATON ECO-series DC MMA

‐warrantyperiodisextendedbytheperiodofwarrantyservicingoftheequipmentatthe

servicefacility.

14. ACCEPTANCECERTIFICATE

ArcinverterrectifierPATONECO‐_______Е

Serialnumber__________________ЕcomplieswithGOST13821‐77

andhasbeenapprovedforoperation.

Dateofsale”_______”_____________20____

Stamphere ________________________

(vendorsignature)

PATON ECO-series DC MMA

- 18 -

Dateofreceiptforrepair”_____”_________________20____

__________________

(signature)

Symptomsofnon‐operability:

____________________________________________________________________

Cause:______________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

================================================================

Dateofreceiptforrepair”_____”_________________20____

__________________

(signature)

Symptomsofnon‐operability:

____________________________________________________________________

Cause:______________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

This manual suits for next models

2

Table of contents

Other Paton Inverter manuals

Popular Inverter manuals by other brands

Samil Power

Samil Power SolarLake 12000TL-PM installation guide

Fusion

Fusion 25512 Use and care guide

Universal Motors

Universal Motors UMP0 IP55 Operation manual

inergy

inergy MPPT SUPERCHARGER quick start guide

Silverline

Silverline 868853 user manual

SolarEdge

SolarEdge Home Hub Inverter Three Phase Product guide