Paton PSI 270 PRO 400 V User manual

0 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

1 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

TABLE OF CONTENTS

1.

GENERAL INFORMATION ......................................................................................

4

1.1.

TECHNICAL CHARACTERISTICS ..........................................................................

6

1.2.

CONTROLS AND CONNECTORS ...........................................................................

7

2.

SETTING THE WELDING UNIT INTO OPERATION ............................................

9

2.1

PROPER USE ..............................................................................................................

9

2.2

REQUIREMENTS FOR INSTALLATION ................................................................

10

2.3.

CONNECTION TO A POWER SUPPLY SYSTEM ..................................................

10

2.4.

REQUIREMENTS FOR AN ELECTRICAL OUTLET .............................................

10

3.

MANUAL COVERED-ELECTRODE ARC WELDING PROCESS (MMA) ....

11

3.1

PREPARING THE WELDING UNIT FOR OPERATION ........................................

11

3.2

OPERATIONAL CYCLE OF THE MANUAL ARC WELDING PROCESS ...........

11

3.3.

INCREASED-CURRENT ARC STARTING .............................................................

12

3.4.

REDUCED-VOLTAGE WELDING MODE ..............................................................

12

3.5.

PROTECTION AGAINST ELECTRODE STICKING ..............................................

13

3.6.

SETTING THE SLOPE OF THE VOLT-AMPERE CHARACTERISTIC OF THE

WELDING UNIT ........................................................................................................

13

3.7.

SHORT ARC WELDING MODE ...............................................................................

14

3.8.

REDUCTION OF OPEN-CIRCUIT VOLTAGE ........................................................

14

3.9.

WELDING AT PULSE WELDING CURRENT ........................................................

14

4.

ARGON ARC WELDING PROCESS (TIG) ..........................................................

15

4.1.

PREPARING THE WELDING UNIT FOR OPERATION TIG –LIFT ....................

15

4.2

OPERATIONAL CYCLE OF THE WELDING PROCESS TIG –LIFT ...................

17

4.2.1

TIG-LIFT CONTACT ARC STARTING FUNCTION ..............................................

17

4.3

OPERATIONAL CYCLE OF THE WELDING PROCESS WITH TIG-2T ..............

18

4.3.1

OPERATIONAL CYCLE OF THE WELDING PROCESS WITH TIG-2T ..............

18

4.3.2

TIG-2T CONTACTLESS ARC STARTING FUNCTION .........................................

19

4.4.

PREPARING THE WELDING UNIT FOR OPERATION TIG –4T ........................

20

4.4.1

OPERATIONAL CYCLE OF THE WELDING PROCESS WITH TIG-4T ..............

20

4.4.2

TIG-4T CONTACTLESS ARC STARTING FUNCTION .........................................

21

4.5

INITIAL CURRENT (PILOT ARC CURRENT) SETTING ......................................

21

4.6

LINEAR INCREASE OF WELDING CURRENT .....................................................

21

4.7.

LINEAR DECREASE OF WELDING CURRENT ....................................................

22

4.8.

WELDING CRATER CURRENT ...............................................................................

22

4.9.

WELDING AT PULSE WELDING CURRENT ........................................................

22

5.

SEMIAUTOMATIC ARC WELDING PROCESS (MIG/MAG) .........................

23

5.1.

PREPARING THE WELDING UNIT FOR OPERATION ........................................

24

2 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

5.2.

OPERATIONAL CYCLE OF THE WELDING PROCESS - MIG/MAG .................

25

5.2.1

OPERATIONAL CYCLE OF THE WELDING PROCESS - MIG / MAG 2T ..........

26

5.2.2

CYCLE WELDING PROCESS - MIG / MAG FUNCTION 4T& 4T_ ......................

26

5.3

FUNCTION OF PRETREATMENT GAS CLEANING ............................................

27

5.4

FUNCTION OF INCREASES THE WIRE FEED SPEED ........................................

27

5.5

FUNCTION OF BURNING OUT AT THE END OF WELDING .............................

28

5.6

FUNCTION OF POSTWELD GAS CLEANING .......................................................

28

5.7

INDUCTANCE CONTROL FUNCTION ...................................................................

28

5.8.

WELDING AT PULSE WELDING VOLTAGE ........................................................

28

6.

SETTING THE WELDING UNIT ..............................................................................

29

6.1.

SWITCHING TO THE REQUIRED FUNCTION ......................................................

30

6.2

CHOOSING A LANGUAGE ON THE DEVICE .......................................................

30

6.3.

SWITCHING TO THE REQUIRED WELDING PROCESS .....................................

30

6.4.

RESETTING ALL FUNCTIONS CURRENT WELDING METHOD ......................

30

7.

GENERAL LIST OF FUNCTION SEQUENCES ..................................................

31

7.1

MANUAL ARC WELDING PROCESS (MMA) .......................................................

31

7.2

ARGON SHIELDED TUNGSTEN-ARC WELDING PROCESS (TIG) ...................

31

7.3.

SEMIAUTOMATIC ARC WELDING PROCESS (MIG/MAG) ...............................

32

7.3.1.

WIRE FEEDER FUNCTION WELDING PROCESS (MIG/MAG) ..........................

33

8.

MAINTENANCE ........................................................................................................

33

9.

OPERATION WITH AN ELECTRIC GENERATOR ...............................................

34

10.

STORAGE ...................................................................................................................

34

11.

TRANSPORTATION ..................................................................................................

34

12.

SPECIFICATION DATA ............................................................................................

34

13.

DELIVERY SET ..........................................................................................................

35

14.

WARRANTY ...............................................................................................................

35

15.

WASTE ELECTRICAL & ELECTRONIC EQUIPMENT .........................................

37

16.

SAFETY INSTRUCTIONS .........................................................................................

37

17.

ELECTRICAL SCHEMATIC DIAGRAM .................................................................

40

18.

ACCEPTANCE CERTIFICATE .................................................................................

41

19.

WARRANTY CARD ..................................................................................................

42

3 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

EC Declaration of Conformity

The following products have been tested by us with the listed standards

and found in compliance with the European Community Low Voltage

Directive 2014/35/EU and Electromagnetic Compatibility Directive

2014/30/EU.

AUTHORISED

REPRESENTATIVE:

MASTERWELD Sp. z o.o., Poland

Przemysłowa 14 st.,

PL35105 Rzeszów

Ust.ID. PL8133751525

MANUFACTURER

ADDRESS

Limited Liability Company “Pilot Plant of Welding

Equipment of Electric Welding Institute named after

E.O. Paton”

Ukraine, 03045, Kyiv, 66 Novopyrohivska St.

PRODUCT:

DIGITAL SEMIAUTOMATIC INVERTER

PATON PSI 270 PRO / 350 PRO 400V

DC MIG/MAG TIG/MMA

The statement is based on a single evaluation of one sample of above mentioned products. It

does not imply an assessment of the whole production. The manufacturer should ensure that all

product in series production are in conformity with the product

sample detailed in this report.

The applicant should hold the whole technical report at

disposal of the competent all the right.

Applied EC Directives:

2014/35/EU (Low Voltage)

2014/30/EU (Electromagnetic Compatibility)

Applied Standards:

EN 60204-1:2006. Safety of machinery - Electrical equipment of

machines –Part 1: General requirements; EN 60974-1:2012 Are

welding equipment –Part 1: Welding power sources; EN 60974-

10:2014 Are welding equipment –Part 10: Electromagnetic

compatibility (EMC) –requirements.

Issued Date: 12 September 2017

Expiry Date: 11 September 2022

General Manager

We, MASTERWELD Sp. z o. o., hereby declare that specified above conforms covering

European Parliament and Council Directives, 2014/35/EC Low Voltage Directive of 26

February 2014 and 2014/30/EU Electromagnetic Compatibility of 26 February 2014.

The CE mark above can be used under the responsibility of manufacturer. After completion of an EC

declaration of conformity and compliance with all relevant EU Directives.

4 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

ATTENTION!When connecting the welding unit to the power distribution

board (at a temperature of 25 ºC), take into account through-the-wall wiring

and the lengths of extension cables.

Electrode

diameter for a

MMA welding

process (mm)

Set current in

MMA and TIG

welding

processes (A)

Electrode wire

diameter for a

MIG/MAG

welding process

(mm)

Cross-section

area of the power

cable conductor

(mm2)

Maximum cable

length (m)

PSI 270 PRO 400 V

Ф3 mm

Not more than

120 А

Not more than

Ф0,8 mm

1,5

75

2

105

2,5

130

4

205

6

310

Ф4 mm

Not more than

160 A

Not more than

Ф1,0 mm

2

75

2,5

95

4

155

6

230

Ф5 mm, Ф6 mm

niskotopliwe

Not more than

270 A

Up to

Ф1,2 mm

2,5

58

4

92

6

138

PSI 350 PRO 400 V

Ф3 mm

Not more than

120 А

Not more than

Ф0,8 mm

1,5

75

2

105

2,5

130

4

205

6

310

Ф4 mm

Not more than

160 А

Not more than

Ф1,0 mm

2

75

2,5

95

4

155

6

230

Ф5 mm

Not more than

220 А

2,5

68

4

114

6

168

Ф6 mm

niskotopliwe

Not more than

250 A

Not more than

Ф1,2 mm

2,5

60

4

100

6

150

Ф6 mm

Up

350 A

Not more than

Ф1,4 mm

2,5

41

4

66

6

100

1. GENERAL INFORMATION

The digitally controlled invertor-rectifier welding units PATON®PSI 270 РRO / 350 PRO - 400Vare

designed for direct-current gas-shielded welding according to such welding processes as a manual arc

welding process (MMA), an argon arc welding process (TIG), and a semiautomatic arc welding

process (MIG/MAG). The digital controller used in these welding units ensures significant advantages

for the welding unit as compared with multifunctional analog controllers, as the analog controllers are

5 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

designed for the specific operating modes of controlled equipment and are not optimal in all operating

modes. The digital controller of the MIG welding units allows all the capabilities of the welding unit,

up to its capabilities at full power, to be used in all the operating modes of the unit.

The MIG welding units pertain to the Professional Series equipment and are designed for industrial

use. The operation of the welding unit is possible separately from an electrode wire feeding unit. This

operational mode is reasonable in order to provide the ease of use of the unit and compliance of the

unit with safety requirements. The additional adjustment operations provided for the welding unit

make it possible to set the optimal values of the operating parameters of the unit in various operating

modes characterized by a high load factor at a rated current of up to 315 A or 400 A. The welding units

can be used for manual arc welding with standard electrodes 1.6 … 6 mm in diameter and free-melting

electrodes up to 6.0 mm in diameter and for semiautomatic arc welding with solid electrode wire 0.6

… 1.6 mm in diameter. The function of reduction of open-circuit voltage in the manual arc welding

process (MMA), with the possibility for this function to be switched on and off, allows the welding

unit to be operated in unsafe environment.

The distinctive feature of the welding units is the availability of a high-quality electrode wire feeding

unit and a KZ-2 euro type style connector, which allows the operator to replace welding torches at his

option. The welding unit contains a module for protection against excess and low power supply

voltage.

Due to the increased frequency of the input voltage of the rectifier transformer of the welding

unit, the weight and overall dimensions of the transformer are significantly reduced as compared with

other welding units with similar characteristics.

The basic advantages of the PATON®welding units are the following:

1. The possibility to adjust welding parameters in wide ranges

a) 1 (basic parameter) + 10 (additional parameters) for the manual arc welding process

(MMA)

b) 1 (basic parameter) + 10 (additional parameters) for the argon arc welding process (TIG)

c) 2 (basic parameter) + 9 (additional parameters) for the semiautomatic arc welding

process (MIG/MAG)

2. The availability of the adjustable pulse welding mode for all the welding processes

3. The welding unit is protected against long-time fluctuations of power supply voltage and

ensures welding arc stabilization when the input voltage of the unit changes in the range of

320 V through 440 V.

4. The welding unit is rated for operation with a standard power supply system. Due to the higher

efficiency coefficient of the unit, the power consumed by the unit is reduced by 50% as

compared with other similar welding units.

5. The rotation frequency of the driving motor of the ventilator of the welding unit can be

automatically varied depending on the temperature inside the unit. This feature allows the

service life of the ventilator and driving motor to be increased and, additionally, dust content

inside the unit to be reduced.

6. Comfortable use due to the long duty cycle at the rated current, which enables virtually

uninterrupted welding using electrodes Ф6 mm.

7. The enhanced reliability of the welding unit in operation in dusty environment

8. The welding unit contains an electronic thermal protection system for protecting all the heat-

generating components of the welding unit against overheating.

9. All the printed-circuit boards with electronic elements are impregnated with two layers of high-

quality varnish in order to provide the high reliability of the welding unit within its service life.

10. Improved arc flash stability which in practice eliminates electrode adhesion.

11. Easy replacement of fuses due to their location outside the device.

12. When the source is separated from the wire feeder, it provides small dimensions and makes the

device mobile, which simplifies welding in hard-to-reach places.

6 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

1.1. TECHNICAL CHARACTERISTICS

PARAMETRY

PSI 270 PRO 400 V

PSI 350 PRO 400 V

Rated power supply voltage 50/60 Hz, V

3x400 V

3x400 V

Rated power supply current

12,0 … 13,0

16,0 … 18,0

Rated welding current

270

350

Maximum operating current,

350

450

Operating load factor, %

70% at 270А

100% at 220A

70% at 350А

100% at 290A

Power supply voltage range

±15%

±15%

Welding current control range

14 –270

16 –350

Welding voltage control, V range

12 –29

12 –30

Diameter of a stick electrode

1,6 –6,0

1,6 –6,0

Diameter of electrode wire

0,6 –1,2

0,6 –1,4

Maximum weight of the reel,

5 –18 kg

5 –18 kg

Number of pressure rolls

2 or 4

2 or 4

Welding processes with pulse welding modes

MMA: 0,2 … 500Hz

TIG: 0,2 … 500Hz

MIG/MAG: 0,2 … 500Hz

Increased-current arc starting function of the

manual arc welding process

Adjustable

Adjustable

Reduced-voltage welding function of the

manual arc welding process

Adjustable

Adjustable.

Protection against electrode sticking

Automatic

Automatic

Reduction of open-circuit voltage

ON/OFF

ON/OFF

Open-circuit voltage in the manual arc

welding process

12 / 75

12 / 75

Welding arc starting voltage

110

110

Rated consumed power

7.9 … 8.6

10,5 … 11,8

Maximum consumed power

11,0

15,0

Efficiency coefficient

90

90

Cooling

Forced

Forced

Operating temperature range

–25 … +45 ºС

–25 … +45 ºС

7 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

Overall dimensions (length width height)

540 х 360 х 400

540 х 360 х 400

Weight without the coil and accessories

23,5

23,9

Protection class*

IP 33

IP 33

*These Professional Series welding units are protected against ingress of foreign particles more than 2.5 mm

in size and against rain drops if the rain drops fall at an angle to the vertical surfaces of the welding unit not

more than 60 degrees.

THE RECOMMENDED LENGTHS OF THE WELDING CABLES ARE INDICATED

BELOW.

Model urządzenia

Cable length

Cross-section area of

the cable conductor

Cable

designation

PSI 270 PRO 400 V

2 … 14 m

35 mm2

KG 1х35

3 … 19 m

50 mm2

KG 1х50

PSI 350 PRO 400 V

2 … 10 m

35 mm2

KG 1х35

3 … 14 m

50 mm2

KG 1х50

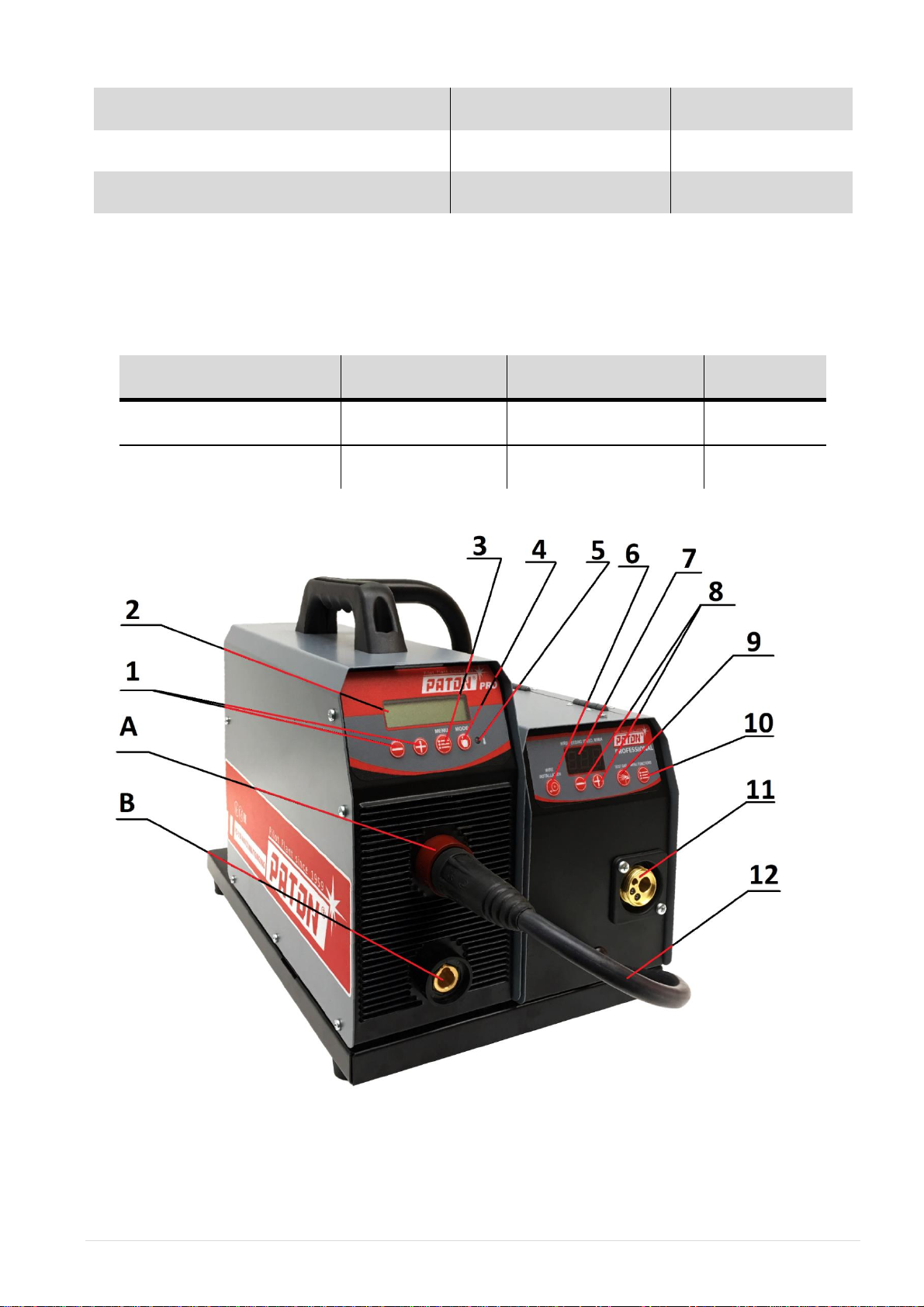

1.2. CONTROLS AND CONNECTRORS

8 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

1. Buttons for adjusting the welding current setting and parameters of the welding machine

function;

2. Digital display showing the current value and welding functions;

3. Button for adjusting the function of the selected welding method

4. Button for selecting welding method:

a) Manual covered electrode arc welding (MMA)

b) Argon arc welding with a no consumable electrode (TIG)

c) Gas shielded semiautomatic arc welding (MIG/MAG)

5. Indicator of the operating condition of the welding unit, do not light normally (blinks when

machine is overheating)

6. Button “WIRE INSTALLATION” When the button is pressed, only the wire feed is switched

on.

7. Digital display showing the wire feed speed and feeder functions,

8. Button for adjusting the wire feed speed and parameters of the feeder function

9. Button “GAS TEST” When the button is pressed, only the gas supply valve is switched on

10. Button for adjusting the function of wire feeder.

9 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

11. Euro connector socked for connecting the MIG/MAG holder

12. Polarization change cable

13. 4A and 2A fuses

14. Socket for supplying protective gas to the welding torch

15. Wire feeder inlet connector

16. Connector for supplying power to the electrode wire feeding unit from the welding unit from an

external power source

17. Push-button switch for switching on and off the welding unit

18. Power socket for 36 V gas pre-heater.

A (+) The bayonet connector socket for connecting:

a) The electrode cable (or the grounding cable in some cases when special electrodes are used

for welding) for the manual arc welding process (MMA)

b) Only the grounding cable for the argon arc welding process (TIG)

c) For welding with the "MIG/MAG" method with a solid wire - the polarization change

wire (12) is connected and the ground wire is connected to the "-" current socket.

B (-) The bayonet connector socket for connecting:

a) The grounding cable (or the electrode cable in some cases when special electrodes are used

for welding) for the manual arc welding process (MMA)

b) Only the argon gas torch for the argon arc welding process (TIG)

c) For welding with the "MIG/MAG" method with self-shield wire - the polarization change

wire is connected (12) and the ground wire is connected to the "+" current socket.

2. SETTING THE WELDING UNIT INTO OPERATION

ATTENTION!Read Section 16, "Safety instructions", before setting the

welding unit into operation.

2.1. PROPER USE

The welding unit is designed for manual covered-electrode arc welding, argon arc welding, and gas-

shielded semiautomatic arc welding. Any other use of the welding unit is considered as improper. The

manufacturer of the welding unit is not responsible for damages caused by any improper use of the

unit.

The use of the welding unit is proper if all the requirements of this Operation Manual are satisfied.

ATTENTION!Do not use the welding unit to unfreeze pipes.

10 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

2.2. REQUIREMENTS FOR INSTALLATION

The welding unit is protected against ingress of foreign particles more than 2.5 mm in size.

The welding unit is allowed for outdoor operation. The internal electrical and electronic elements of

the welding unit are protected against moisture but are not protected against atmospheric condensate

drops.

ATTENTION!After completing welding works in hot weather, or

completing intensive welding works in any weather, switch off the welding

unit only after at least 5 minutes of time required for the electronic elements of

the unit to be cooled.

ATTENTION!When operating the welding unit in cold season, after the unit

was switched off and cooled, condensate can be formed inside of the unit, so

switch on the welding unit only 3 … 4 hours after the switching off.

For this reason, do not switch off the welding unit if it is anticipated that the

unit is to be switched on not later than 4 hours after the switching off.

Install the welding unit so as not to block or cover the ventilation slots on the front and rear panels of

the unit. Prevent ingress of metallic particles (for example, when grinding the weld) sucked into the

welding unit by the unit ventilator.

ATTENTION!After fall from a height, the welding unit might be a source of

electrical shock. Install the unit on a firm stable surface.

2.3. CONNECTION TO A POWER SUPPLY SYSTEM

The commercial welding unit is rated for an input power supply voltage of 3x400 V (±15%)

ATTENTION!If the input power supply voltage of the welding unit exceeds

450 V, the warranty of the manufacturer of the welding unit will be invalid. Such

a condition is possible at large unbalance of phase voltages in the standard power

supply system or if the welding unit is connected to the power supply system

improperly. Do not use the supply system neutral wire for this purpose!!!

The power supply connector, power cable cross-section area, and supply-line fuses should be selected

with consideration for the technical characteristics of the welding unit.

2.4. REQUIREMENTS FOR AN ELECTRICAL OUTLET

ATTENTION!The parameters of an electrical outlet for the power supply of

the welding unit must correspond to the power supply voltage and consumption

current of the welding unit (see Section 1.1, "Technical characteristics"). Connect

the welding unit to an electrical outlet that is rated for a three-wire plug with a

grounding conductor.

11 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

3. MANUAL COVERED-ELECTRODE ARC WELDING PROCESS (MMA)

3.1. PREPARING THE WELDING UNIT FOR OPERATION

Preparation the welding unit for MMA operation:

1. Insert the plug of the electrode cable into socket A (+) of the welding unit.

2. Insert the plug of the grounding cable into socket B (-) of the welding unit.

3. Connect the grounding cable to the workpiece.

4. Connect the power cable of the welding unit to the outlet of the power supply system.

5. Set switch (17) on the rear panel of the welding unit to position I (switching on).

6. Switch the button (4) to the MMA welding position, if the desired welding method has been

skipped, press the button (4) again - the methods are switched over and over again

7. Holding the button (3) for about 5 seconds, we gain access to the locked functions of the

welder;

8. Using the buttons (1) set the current basic parameter - welding current or parameter of the

selected function;

9. The device is ready for use. Enjoy Your work.

If required, perform the additional functions specified for the manual arc welding process (see Section 6.1).

ATTENTION!In the manual arc welding process, after switching on the

welding unit by switch (17), the welding electrode is under voltage. Do not

allow the electrode to contact current-conducting or grounded parts, such as the

casing of the welding unit, because such a contact will cause the start of

welding.

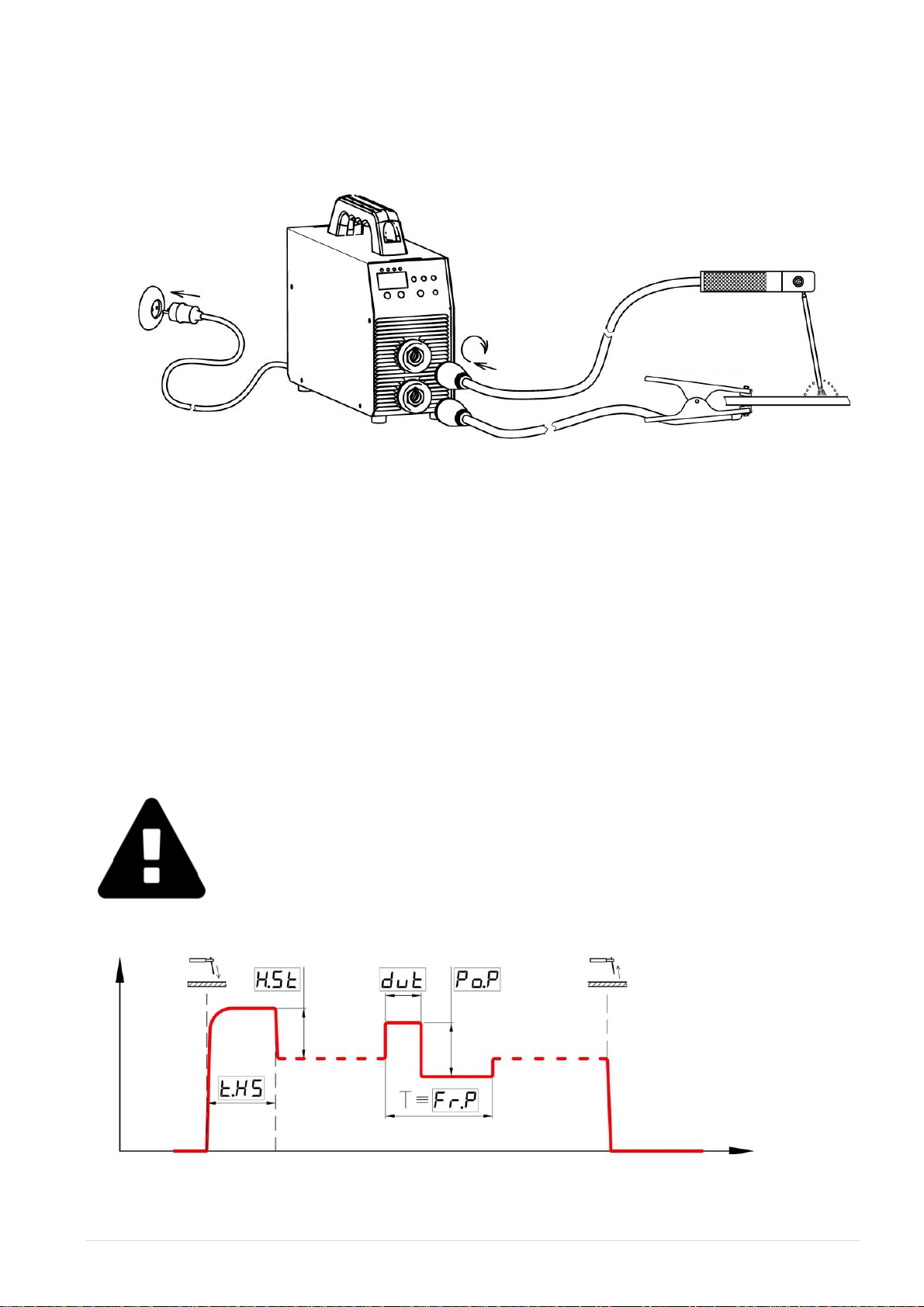

3.2. OPERATIONAL CYCLE OF THE MANUAL ARC WELDING PROCESS

The procedure for changing the values of the operational parameters of the welding unit is described in Section 6.1.

I (A)

~400 V

WORKPIECE

t (s)

ELECTRODE HOLDER

GROUNDING CLAMP

12 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

3.3. INCREASED –CURRENT ARC STARTING

The advantages ensured by the increased-current arc starting function are the following:

1. Improved arc starting even when low-quality electrodes are used

2. Better joint penetration during arc starting period and, as a result, the lower number of defects

associated with incomplete joint penetration.

3. Prevention of slag inclusions

Manual adjustment operations: allow the minimum arc starting current to be set in order to decrease

power consumption at the stage of arc starting. As a result, the welding arc can be started at the

minimum power supply voltage, but in this case, the arc quality characteristics at the stage of arc

starting are deteriorated, as the welding unit functions as an arc-welding transformer. Nevertheless, in

some conditions, this method of arc starting is the only possible one. The welding current may be

increased in order to improve the conditions for arc starting (when the welding unit is connected to a

reliable power supply system), but the increased current can cause burn-out when welding thin parts.

Therefore, it is recommended to set the minimum arc starting current.

What is achieved by:

During the short time interval of arc starting, the welding current increases by 40% of the welding

current set by default.

Example: Electrode diameter is 3 mm. Set welding current is 90 A. The current at the increased-

current arc starting stage is 90 + 40%= 126 A

The additional adjustment operations allow both the arc starting current [POWER HOT START] and

the arc staring period [TIME HOT START] to be varied. Do not set the increased values of these

parameters if such increased values are not required, because the operation of the welding unit and

reliable arc starting in these conditions are possible only if the welding unit is connected to a high-

power system.

The procedure for changing the values of the operational parameters of the welding unit for the current

welding process is described in Section 6.1.

3.4. REDUCED –VOLTAGE WELDING MODE

The advantages ensured by the reduced-voltage welding function are the following:

1. Improved arc stability in short arc welding mode

2. Improved transfer of molten metal drops into the welding pool

3. Improved arc starting

4. Reduced probability of electrode sticking (see Section 3.5)

Manual adjustment operations allow the minimum welding voltage to be set in order to decrease

power consumption and heat input to the weld when welding thin parts. As a result, the probability of

burn-out is decreased, but the stability of arc in short arc welding mode is also decreased, as the

welding unit functions as an arc-welding transformer. It is possible to increase the voltage reduction

percentage to the maximum value in order to improve the stability of arc in short arc welding mode

(when the welding unit is connected to a reliable power supply system), but the increased current in

this mode can cause burn-out when welding thin parts. Therefore, it is recommended to set the

minimum voltage reduction percentage.

13 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

How it is achieved:

When the arc voltage drop is lower than the minimum voltage required for stable arcing, the welding

current increases by 40% relative to the set current.

The additional adjustment operations allow both the welding voltage reduction percentage [POWER

ARC FORCE] and the voltage reduction period [TRESHHOLD ARC FORCE] to be set. Do not set the

increased values of these parameters if such increased values are not required, because in the operation

of the welding unit in this condition, specifically in welding with electrodes less than 3.2 mm in

diameter, electrode sticking is possible (see Section 3.5).

The procedure for changing the values of the operational parameters of the welding unit for the current

welding process is described in Section 6.1.

3.5. PROTECTION AGAINST ELECTRODE STICKING

At the stage of arc starting, the electrode can stick to the workpiece and, as a result, the electrode can

be damaged due to overheating.

If the electrode has stuck to the workpiece, the welding current decreases within 0.6 … 0.8 s after the

sticking. The temporary reduction in the welding current makes it easier for the welder to peel off the

stuck electrode. After separating the electrode from the product, the welding process can be resumed

without any problems.

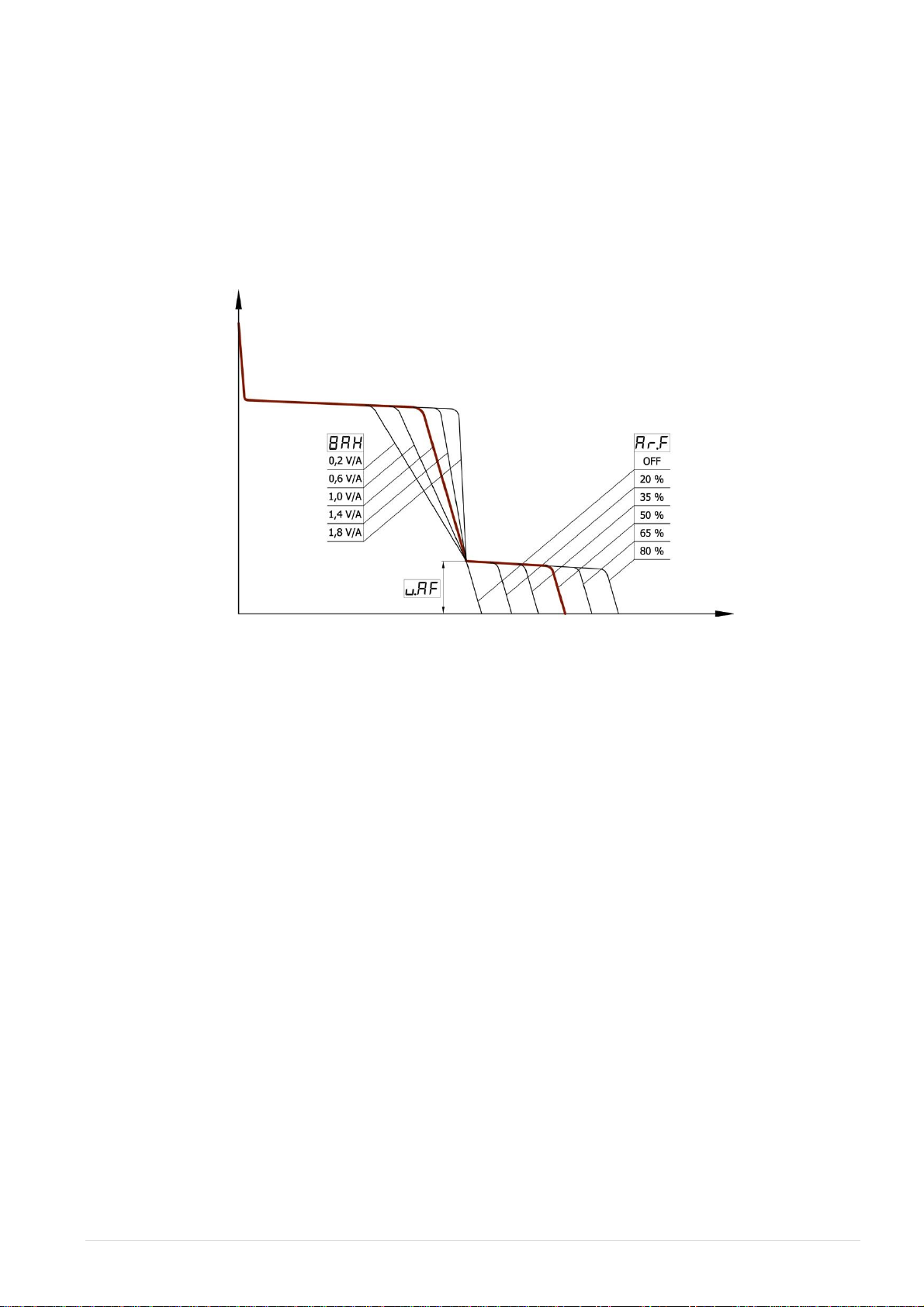

3.6 SETTING THE SLOPE OF THE VOLT-AMPERE CHARACTERISTICK OF

THE WELDING UNIT

This function is designed to facilitate welding with electrodes with diverse coatings. By default,

the slope of the volt-ampere characteristic [VOLT-AMPER CHARAKTERISTIC] of the welding unit is

1.4 V/A. This value is optimal for the most common electrodes with rutile coating. In order to facilitate

welding with electrodes with standard coating, it is recommended to set the slope of the volt-ampere

characteristic equal to 1.0 V/A. If electrodes with cellulose coating are used, the slope of the volt-

ampere characteristic should be 0.2 … 0.6 V/A. In this case, it is sometimes required to increase the

threshold value [TRESHHOLD ARC FORCE] for the reduced-voltage welding function to 18 V.

The procedure for changing the values of the operational parameters of the welding unit for the current

welding process is described in Section 6.1.

I (A)

U (V)

14 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

3.7. SHORT ARC WELDING MODE

The short arc welding mode should be used in overhead position welding, when it is required to

prevent arc stretching. For this purpose, activate (ON) the short arc welding function [SHORT ARC

MODE] of the welding unit. By default, the function is deactivated (OFF).

The procedure for changing the values of the operational parameters of the welding unit for the current

welding process is described in Section 6.1.

3.8. REDUCTION OF OPEN –CIRCUIT VOLTAGE

When welding works with the manual arc welding process are being performed on vessels, tanks, or

other objects with higher requirements for electrical safety, it is reasonable to use the reduction of

open-circuit voltage function [VOLT REDUCTION DEVICE].

When this function is activated, the output voltage of the welding unit is reduced to the safe value of

12 V within 0.1 s after the detachment of the electrode from the workpiece.

The welding unit model is equipped with this function, it requires an open-circuit voltage reduce unit

[BSn] but, by default, this function is deactivated (OFF), as the reduction of open-circuit voltage

impairs arc starting

The procedure for changing the values of the operational parameters of the welding unit for the current

welding process is described in Section 6.1.

3.9. WELDING AT PULSE WELDING CURRENT

This function is designed to simplify the control of a welding process in various spatial welding

positions, excluding a flat welding position. This function is also used in welding nonferrous metals.

When this function is activated, the application of pulse welding current improves the mixing of

molten metals in the weld area and causes forced action on the transfer of molten metal drops into the

welding pool, therefore the stability of the weld formation and the stability of the welding process are

improved. The pulse welding current in the manual arc welding process affects the weld parameters

similar to the movement of the operator hand in manual arc welding process, specifically at hard-to-

reach places. The proper adjustment of the welding process parameters in the welding at pulse

welding current has a direct effect on the weld quality, specifically reduces weld metal porosity and

decreases the graininess of the weld metal. As a result of the improved weld quality, the weld strength

increases.

To activate this function, it is necessary to set the following three operational parameters of the

welding process: current pulse amplitude [POWER OF PULSE],current pulse frequency [FREQUENCY

OF PULSE],and duty cycle [DUTY CYCLE OF PULSE]. By default, the current pulse amplitude is 0

[OFF], that is, the function is switched off, the current pulse frequency is 50 Hz, and the duty cycle is

50%. To activate the function, set the current pulse amplitude [POWER OF PULSE] higher than 0. The

current pulse amplitude should be set in percentage of the welding current specified for the welding

process.

Example: Welding is to be performed with electrode wire 3.0 mm in diameter. The set welding

current is 90 A. The current pulse amplitude is 40%. The current pulse frequency is 50

Hz (default value). The duty cycle is 50% (default value).

Result: The result is the following: the welding current pulse amplitude will be in the range of

54 … 126 A, the current pulse frequency will be 50 Hz, and the current pulse length

will be equal to the length of an interval between pulses. If the duty cycle is not equal to

50%, the current pulses will be nonsymmetrical relative to the intervals between pulses,

but the average welding current value will be equal to the set welding current value of

90 A. As a result, the average heat input to the weld will not change.

15 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

Default

[DUTY CYCLE OF PULSE]

50%

[DUTY CYCLE OF PULSE]

20%

[DUTY CYCLE OF PULSE]

70%

If it is required to reduce heat input to the weld, as in welding thin parts, the welding current should be

decreased by performing the standard setting operations. In this case, current pulse parameters will be

adjusted automatically according to the set welding current, and the operator can control the reduction

of the heat input, as compared with the heat input at the initial welding current, by simultaneously

varying the current pulse amplitude and duty cycle.

The aforementioned parameters should be set differently for different welding processes, depending on

the requirements of the operator.

Operations required to set these parameters for the current welding process are described in Section 6.1.

4. ARGON ARC WELDING PROCESS (TIG)

4.1. PREPARING THE WELDING UNIT FOR OPERATION TIG –LIFT

ATTENTION!As a protective gas in argon arc welding, such inert gas as

argon (Ar), sometimes helium (He), or a gas mixture, such as 40% Ar + 60%

He, is used. Do not use combustive gases. The use of other gases is allowed

only by agreement with the manufacturer of the welding unit.

t, s

t, s

WYRÓB

t, s

ARGON

WELDING

TORCH

GROUNDING CLAMP

WORKPIECE

ARGON

~ 400 V

16 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

Preparation the welding unit for TIG operation:

1. Connect the TIG torch into socket B (–)of the welding unit;

2. Connect the grounding cable into socket A (+) of the welding unit;

3. Connect the grounding cable to the workpiece;

4. Connect the power cable of the welding unit to the outlet of the power supply system;

5. Set gas reducer on gas bottle;

6. Open the shut-off valve of the gas cylinder. Check the tightness of the connection with the gas

cylinder;

7. Connect the power cable of welding unit to the outlet of the power supply system;

8. Set switch (17) on the rear panel of the welding unit to position I (switching on);

9. Switch the button (4) to the TIG welding position, if the desired welding method has been

skipped, press the button (4) again - the methods are switched over and over again;

10. Holding the button (3) for about 5 seconds, we gain access to the locked functions of the

device;

11. Press button (3) and hold it until [BUTTON OF TORCH] indication is displayed for selecting the

TIG-LIFT contact arc starting function of the button on the welding torch. When button (3) is

released, after 1 s, the display will show the value of the current function. Set value [LFT] by

buttons (1). If the TIG-LIFT contact arc starting function has been missed during the selection,

press button (3) again the methods are switched over and over again;

12. Using the buttons (1)set the current basic parameter - welding current or parameter of the

selected function;

13. The device is ready for use. Enjoy Your work.

If required, perform the additional functions specified for the argon arc welding process (see Section 6.1).

ATTENTION!Do not sharpen the electrode tip to a needle-like shape, as

such a shape can cause deviation of a welding arc from side to side. The

properly sharpened electrode tip should have a slightly blunted end with a

diameter corresponding to the specified welding current. In welding with a

large welding current, the high-sharpened electrode easily melts due to

insufficient heat dissipation. The sharpening marks should be arranged along

the electrode centerline.

ATTENTION!Use a gated welding torch with a Ф13mm bayonet connector.

Select the maximum current of the welding torch according to the

specifications.

17 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

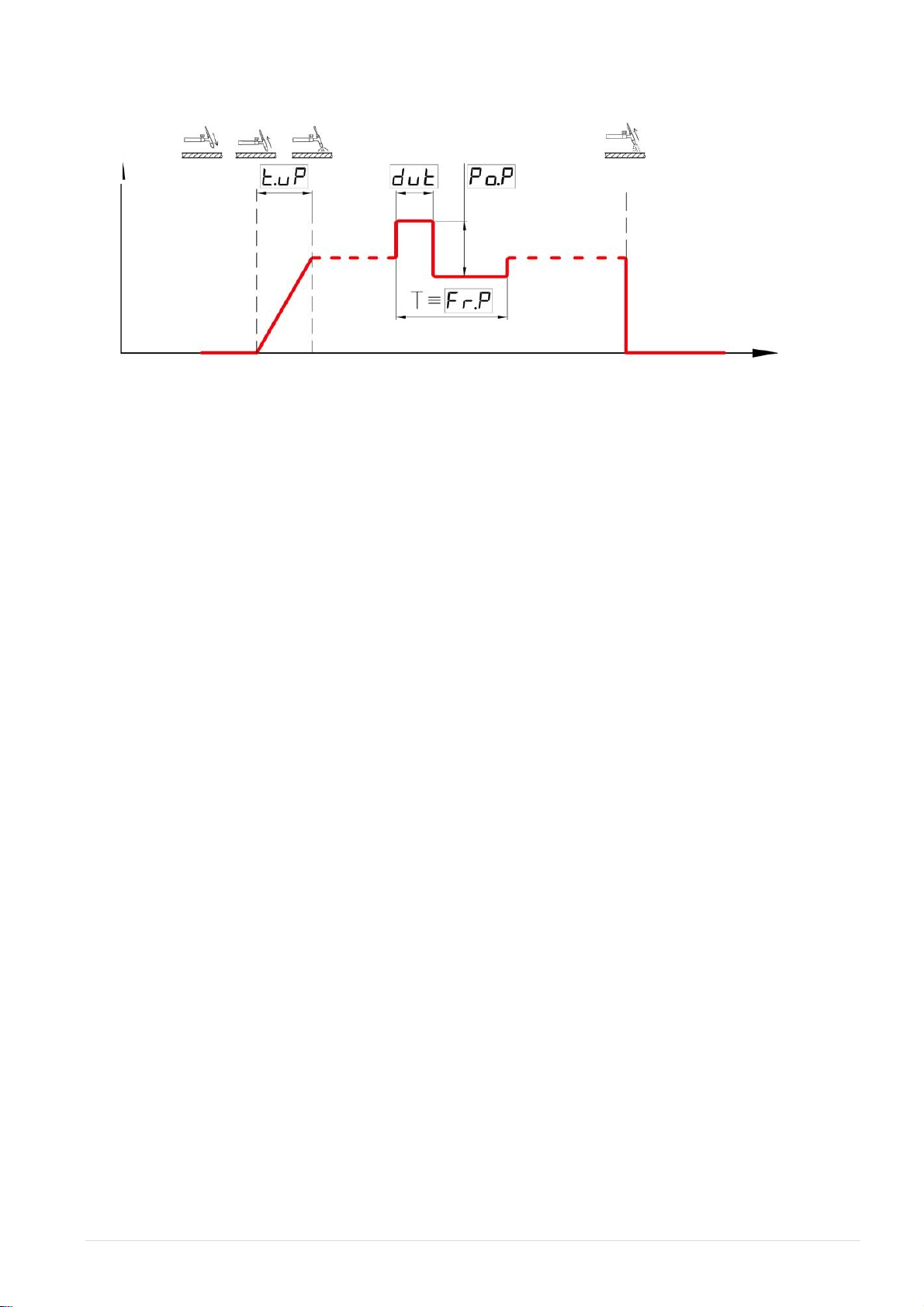

4.2. OPERATIONAL CYCLE OF THE WELDING PROCESS TIG –LIFT

The procedure for changing the values of the operational parameters of the welding unit is described in

Section 6.1.

4.2.1. TIG-LIFT CONTACT ARC-STARTING FUNCTION

This function of the control button on the welding torch is set by default and is designed for welding

torches with contact arc starting, without using oscillators and other like devices. In contrast to

conventional methods of arc starting, the contact arc starting prevents the formation of current surge at

the instant of the arc starting. As a result, disintegration of the no consumable tungsten electrode and

ingress of the electrode particles into the weld can be prevented.

When this function has been activated, contact the electrode with the workpiece. It is allowed to hold

the electrode in this position for an unlimited length of time. When the operator is ready to welding

(for example, when the operator has lowered the protective shield and purged the weld area with gas),

it is necessary to lift the electrode tip slowly from the workpiece. The welding unit will sense this

action as a signal to start welding, and the welding current will be linearly increased to the set value.

To prevent surface melting of the electrode tip, the rate of lifting the electrode should correspond to the

set welding current value. The period [TIME UP ARC] of linear current rise is discussed in Section 4.5.

t (s)

I (A)

18 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

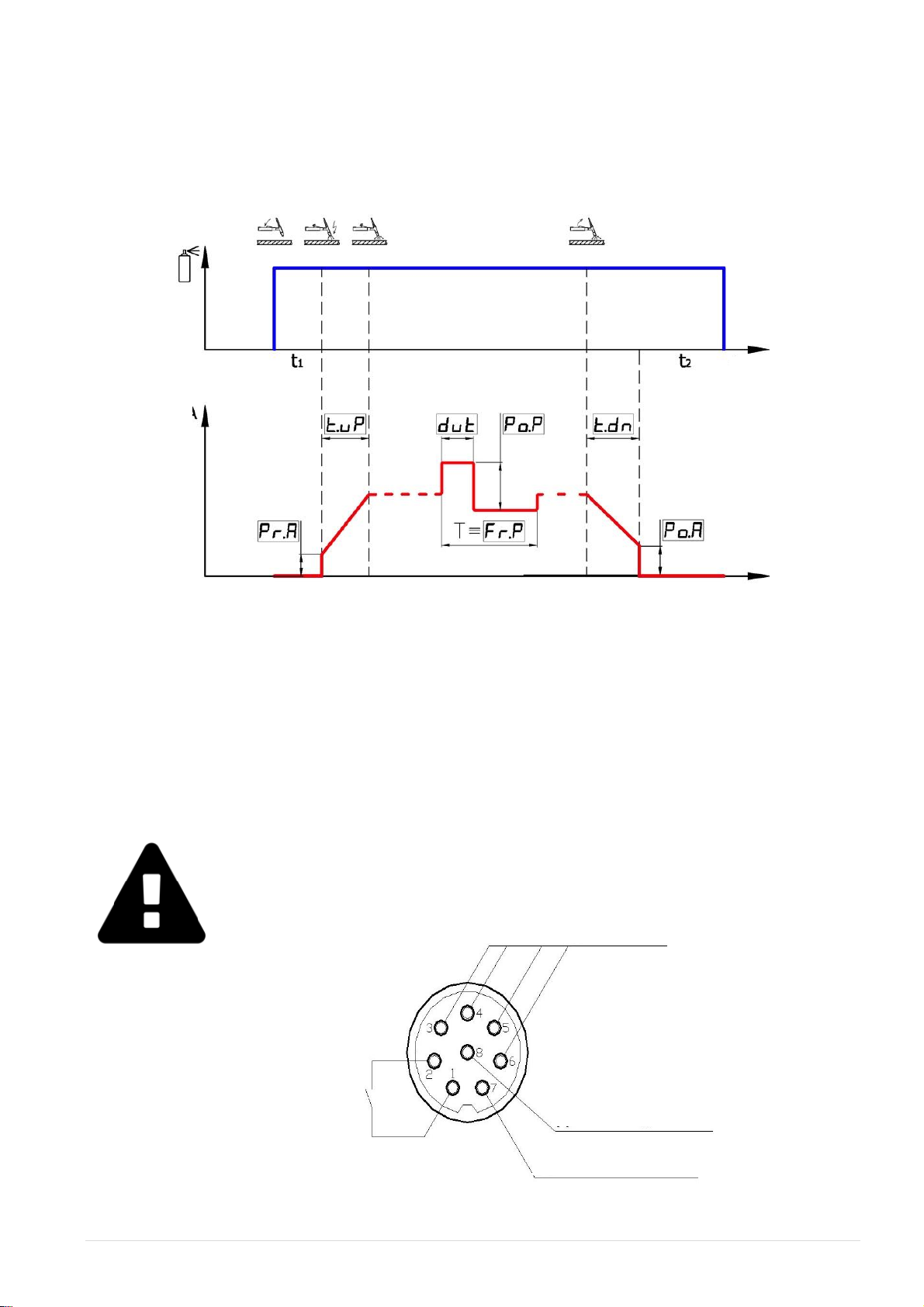

4.3. PREPARING THE WELDING UNIT FOR OPERATION TIG –2T

4.3.1 OPERATIONAL CYCLE OF THE WELDING PROCESS WITH TIG-2T

FUNCTION

The procedure for changing the values of the operational parameters of the welding unit is described in

Section 6.1.

The procedure for preparing the welding unit for operation with an external oscillator is an individual

one and should be described in the oscillator operation manual. The connector for remote switching on

and off the welding unit is located on the rear panel of the welding unit. Use only contacts 1 and 2 of

the connector. Do not confuse contacts 1 and 2 with contacts 3 and 4, as these contacts are designed

for powering the electrode wire feeding unit. When contacts 3 and 4 are cross-circuited, the electrode

wire feeding unit will be damaged.

ATTENTION!If this connector is not used, cover it in order to prevent

contamination.

Digital connection

(-) motor power

supply

(+) motor power

supply

I (A)

t (s)

t (s)

19 | Pag e PATON®PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

1. Switch on the oscillator for contactless arc starting.

2. Set switch (17) on the rear panel of the welding unit to position I (switching on).

3. Press button (4) to select the argon arc welding process (TIG). The display of the welding unit

will blink, warning the operator that the unit is ready to switch to the next welding process. If

the argon arc welding process has been missed during the selection, press button (4) again the

methods are switched over and over again;

4. Holding the button (3) for about 5 seconds, you gain access to the locked functions of the

welder;

5. Select the functions of the TIG-2T torch button. To do this, press the button (3) until the

[BUTTON OF TORCH] function appears on the display, after releasing the button for 1 second,

the device will display the current position of the function, use the (1)buttons to set [2T]. If

you do not do anything for a long time, the device will exit this function, you can go back the

same way, if the desired mode has been skipped, press the button (3) again, the functions will

switch over and over again;

6. Set the specified welding current by buttons (1).

If required, perform the additional functions specified for the argon arc welding process (see Section 6.1).

ATTENTION!Use a gated welding torch with a Ф13mm bayonet connector.

Select the maximum current of the welding torch according to the

specifications.

4.3.2 TIG-2T CONTACTLESS ARC STARTING FUNCTION

This function of the control button on the welding torch is used if the welding unit is connected to an

external module for contactless arc starting (an oscillator) with an integrated gas supply valve.

The control button on the welding torch is connected directly to the oscillator. When the control button

is pressed, the control signal is generated and transmitted to the oscillator. On this control signal

(moment of time t1), the gas supply valve will be opened for purging the weld area with gas before

welding, the welding unit will be switched on, with delay, and a high-voltage pulse for the contactless

arc starting will be generated. After these operations, all other functions, specified with consideration

for the operational cycle of this welding process, will be performed (see the sections presented below).

When the button is released, the welding current will decrease linearly, the welding unit will be

switched off (instant of time t2), and the weld area will be purged with gas. After these operations, the

gas supply valve will be closed.

ATTENTION!The oscillator must contain a device for protecting the output

of the welding unit against electric breakdown caused by a high-voltage

discharge generated at the instant of time of arc starting. Before the operation,

activate the protective device.

This manual suits for next models

1

Table of contents

Other Paton Inverter manuals