Polar Bear East/West 10 Degree Installation Manual

9910022 Rev A

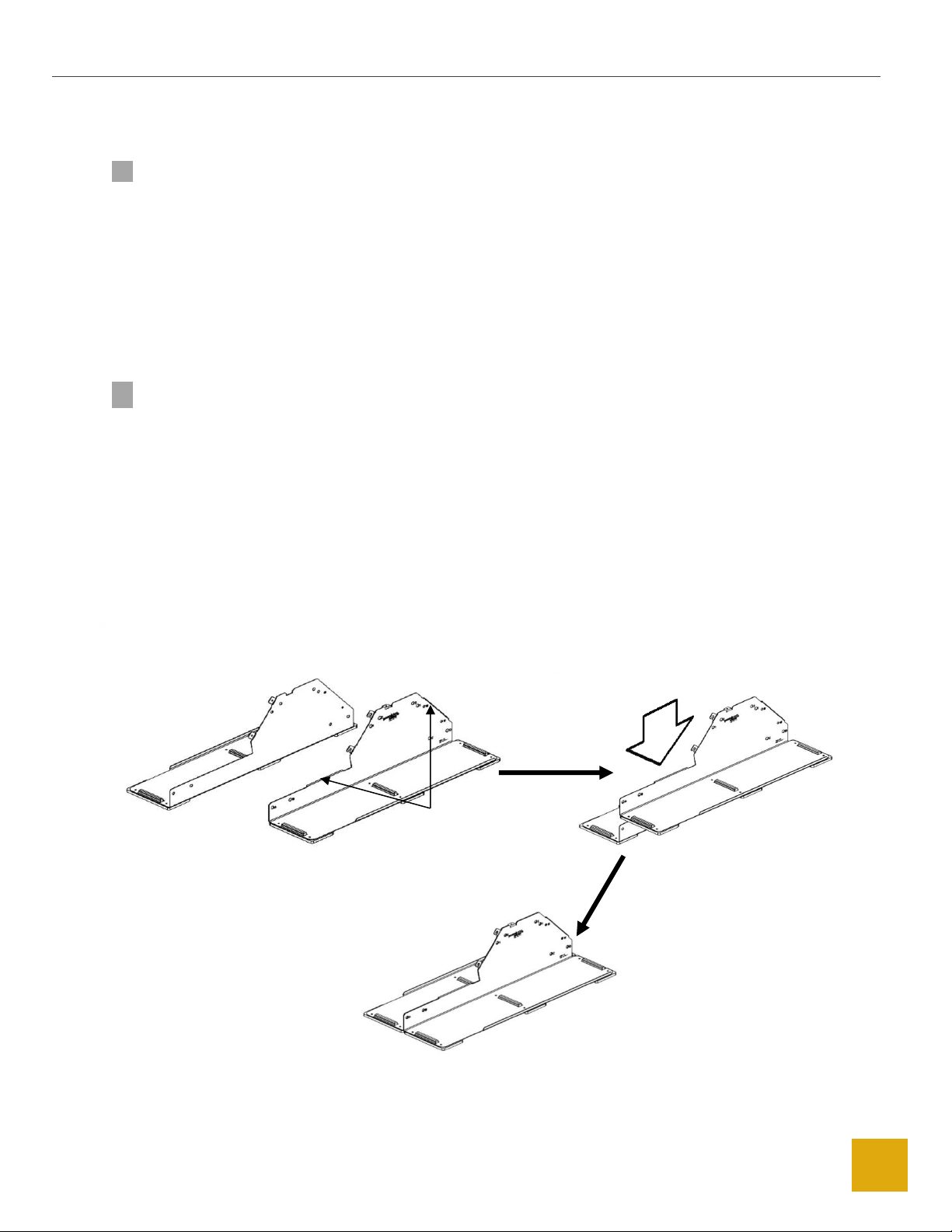

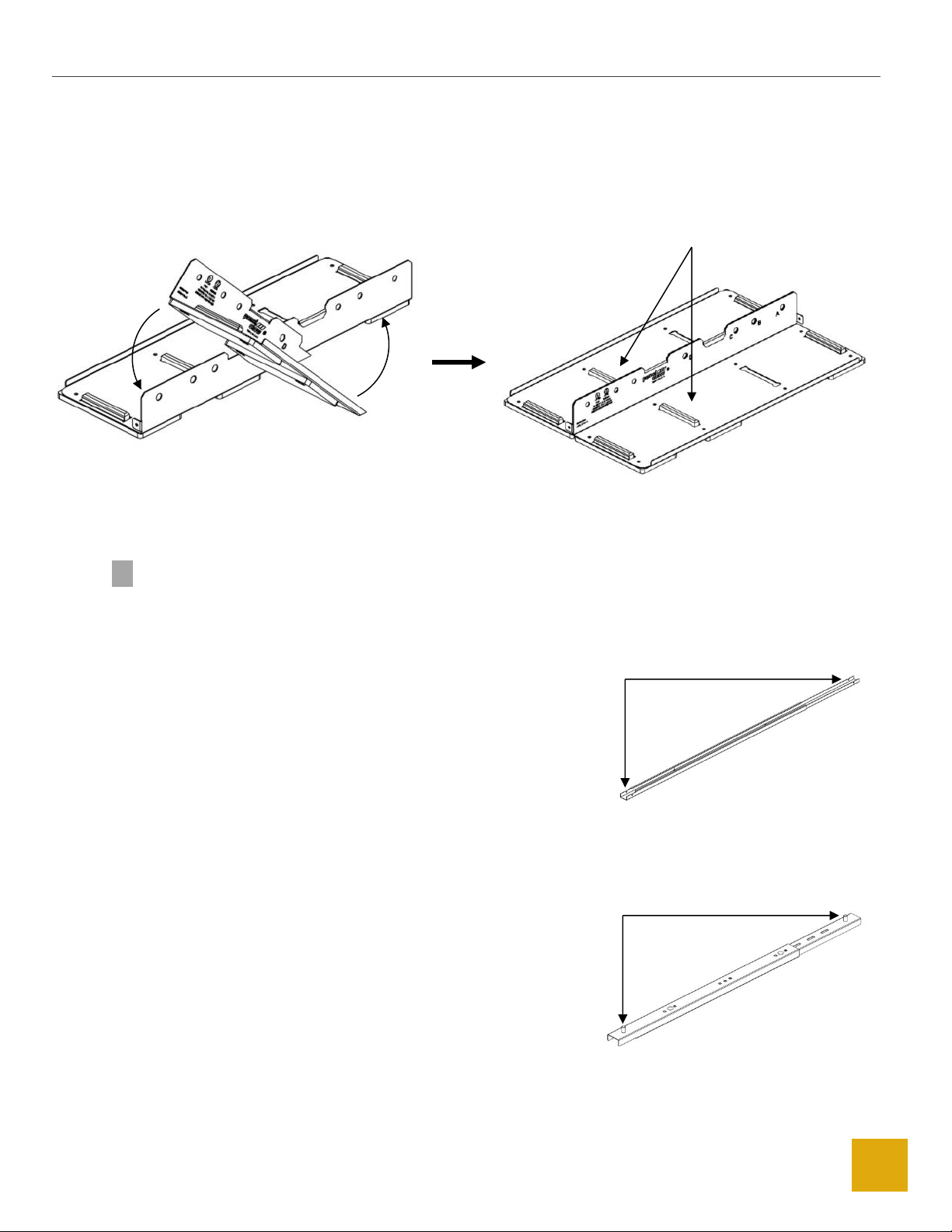

6. Pick a starting corner on the North West end of the array and place Supports as shown below in

Figure 3. The first East West support should be laid out with the high end to the West and the

low end to the East

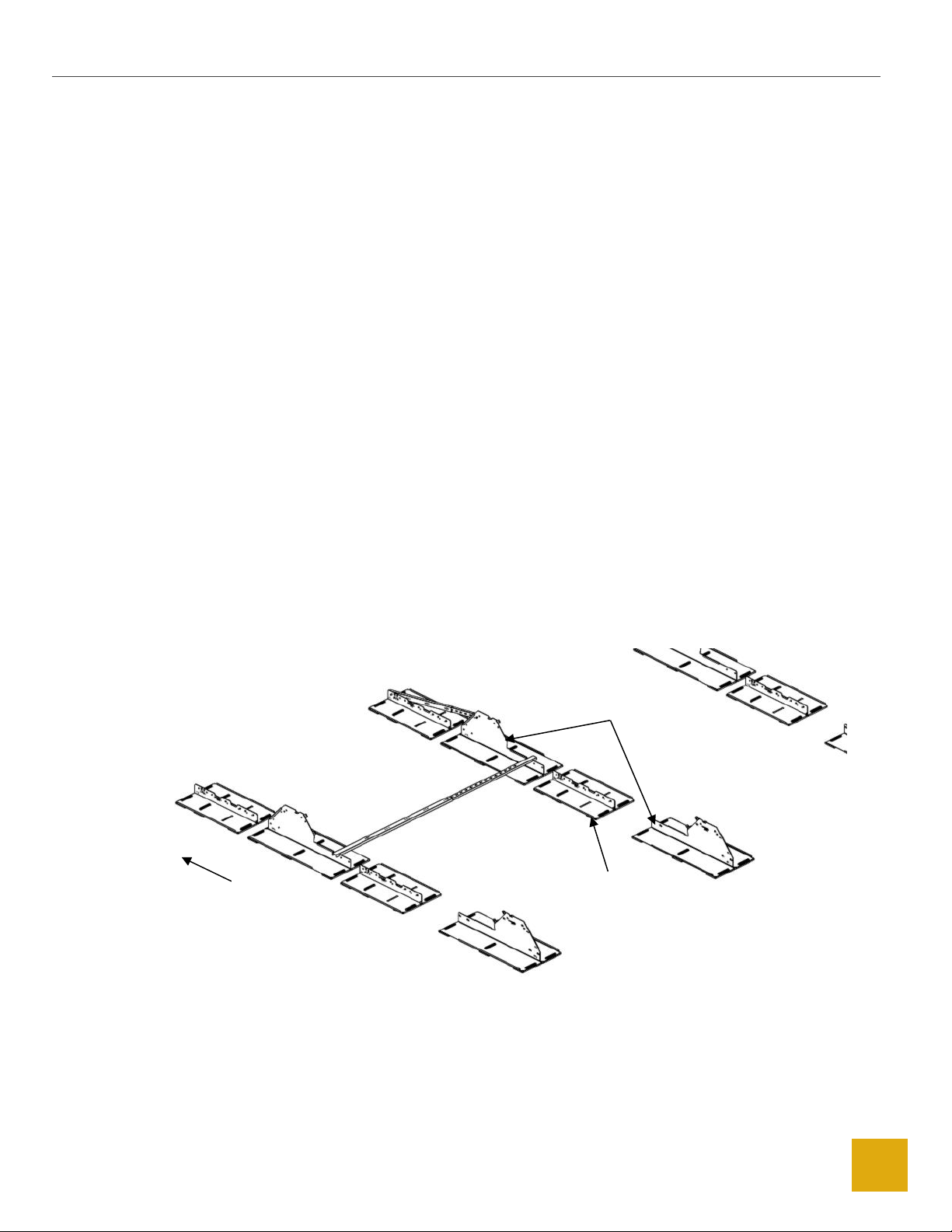

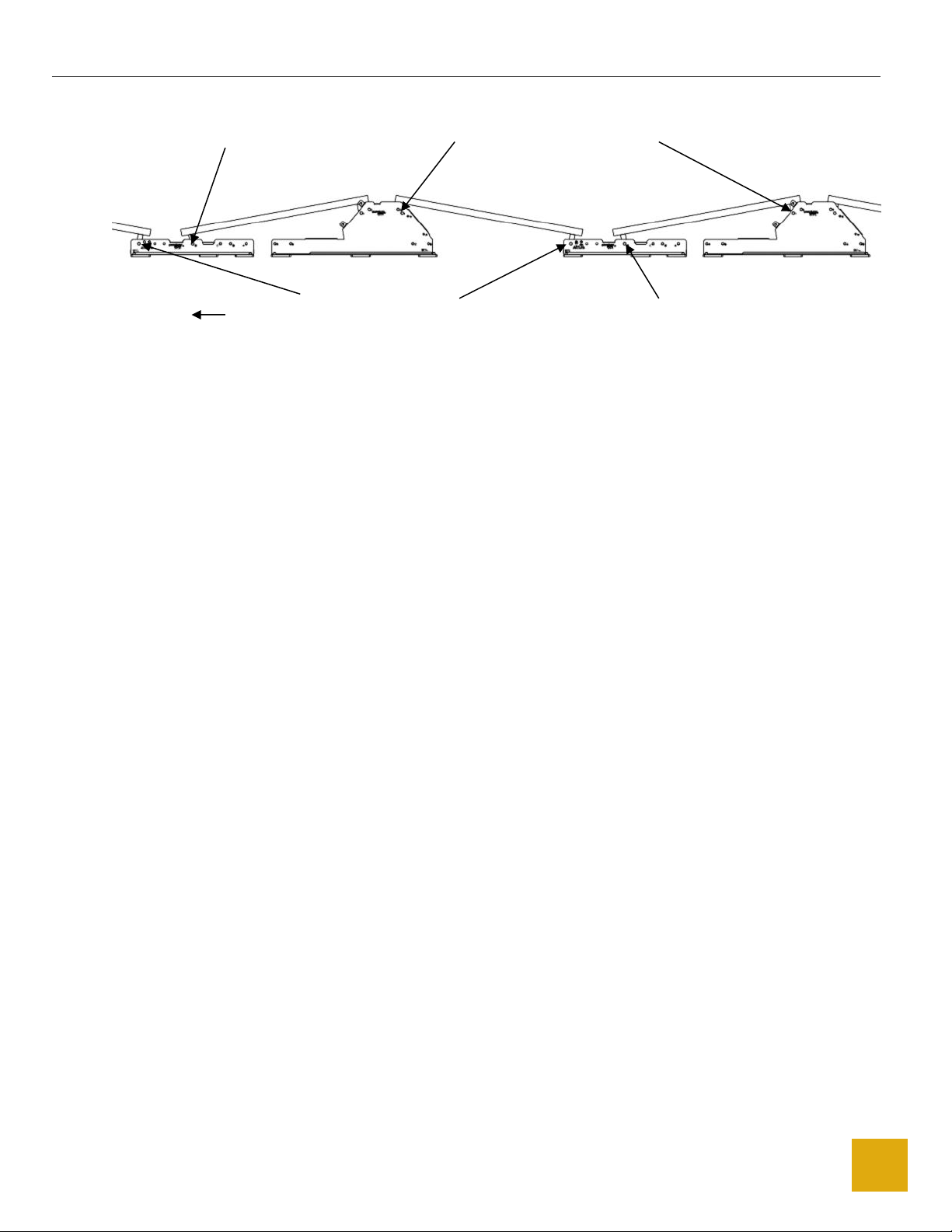

7. Each additional East West Supports will be laid out with the low end to the West and high end to

the East (Figure 4, Figure 5). PanelClaw recommends starting the array in a corner with low

complexity and moving outwards in a direction that best suits the individual array you are

building (e.g. rows and columns with the least number of interruptions/breaks).

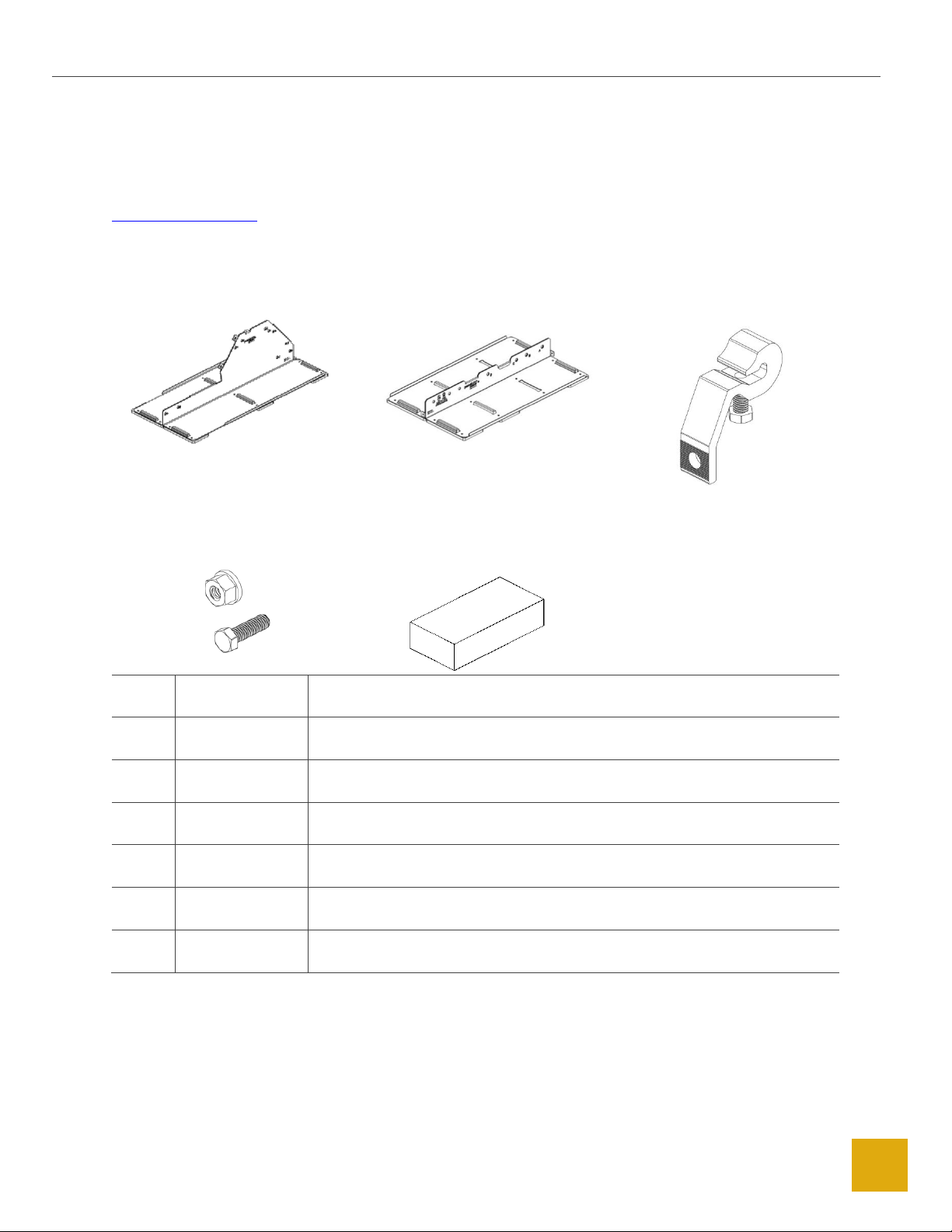

Note: Supports without the optional integrated roof protection pad ensure that a proper roof

protection pad is installed. Center the pad under the Support such that the roof protection pad

extends beyond the edge of the Support by an equal amount on all sides (E-W and N-S).

8. Use the properly configured Spacer Stick - A (the longer stick) to position the Supports

apart in the North South direction. Place the notch in the Spacer Stick - A, over the low

end of the Support at the edge of the array and position the Support directly to the

North or South (depending on build direction) so that the notch at the other end of the

spacer stick fits over the low end of the adjacent Support.

9. The distance between Supports in the East/West direction is set using the Spacer Stick - F. The

3/8” studs in the Spacer Stick are placed in the proper Claw mounting hole of a Low Support and

an East West support to properly space out supports. This process can be continued to lay out

the remainder of the array. To determine the proper holes to use with the Spacer Stick on the

high and low end of the Support for this array, please refer to the Ballast Drawing

(typical examples shown in Figure 4,Figure 5 and Figure 6).

Figure 3 Support Positioning West Side