4

CAUTION

• The product must be used by a person certified to perform dentistry, such as a Dental Technician or Dentist, in a

dental clinic, hospital or other dental institution.

• When using the product, for health and safety purposes, wear eye protectors, use a grindbox and a vacuum

system, etc.

• Read this Operation Manual before use to fully understand the product functions.

• Do not subject the product to strong shocks (such as by dropping it). Doing so may lead to electric shock or

malfunction.

• Clean the Motor Handpiece on a timely basis. For information on cleaning, refer to “8 Post-use Maintenance” in

this Operation Manual.

• Do not place the product next to a heat source such as a heater. Doing so may lead to discoloration or

deformation.

• Do not lubricate the Motor Handpiece. Doing so might cause it to generate heat or malfunction.

• Do not clean, soak, or wipe the product with electrolyzed oxidizing water (acidic water or strongly acidic water),

strongly acidic or alkaline agents, solutions including chlorine, or solvents such as benzine or thinner.

• Do not use the product in locations where static electricity is emitted, as this may damage its protective

mechanisms.

• Do not expose to water or liquids.

• Use the Control Unit in an environment between 0 and 40 °C and with no condensation. Condensation may lead

to electric shock due to a short circuit.

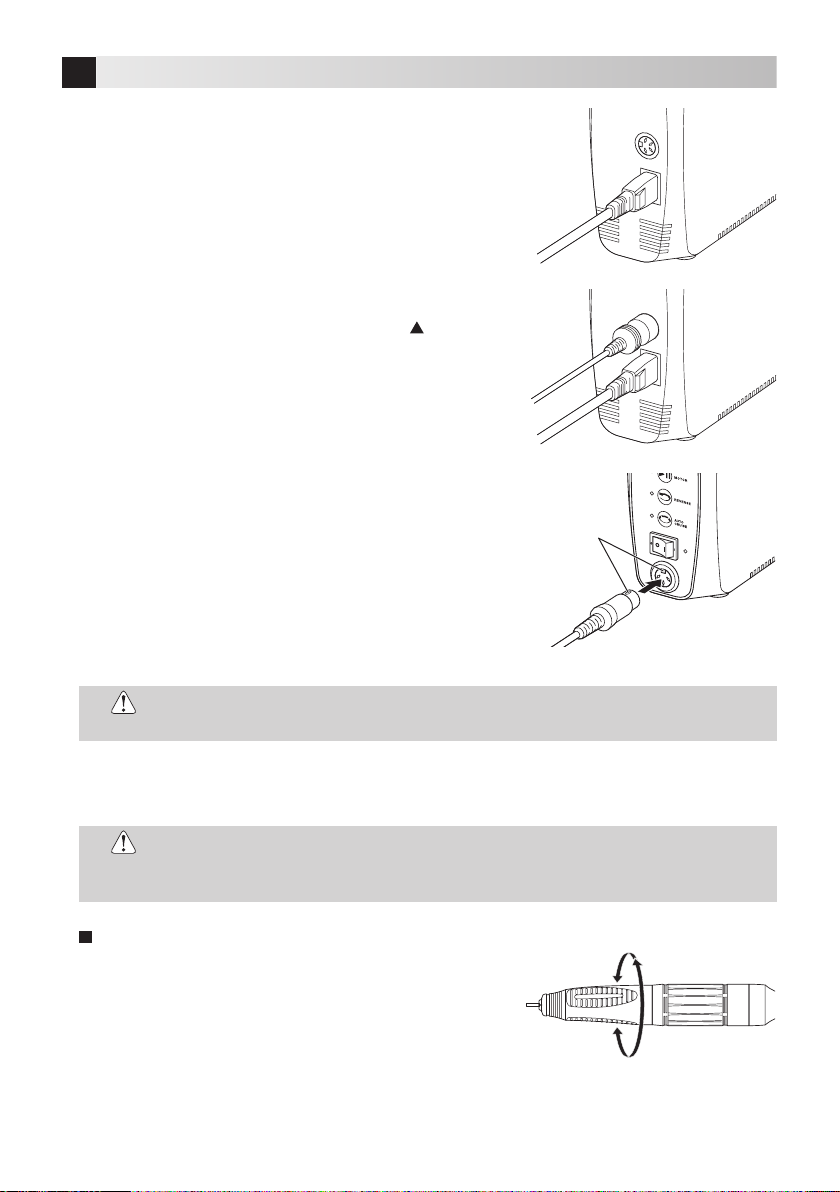

• When a bur is rotating, do not turn the bur lock ring in the OPEN direction. Doing so will cause the Motor

Handpiece to break. Replace a bur only after rotation has completely stopped.

• When using a bur with a large cutting blade (4 mm or larger in diameter), use it at as low a rotation speed as

possible.

• Avoid using the product with loads that will cause the protection circuit to operate where possible. Failure to do

so may cause motor heat generation, bur damage and early wear in the Motor Handpiece.

• If disinfectant, water, or saline, etc. becomes attached to the Control Unit or Motor Handpiece, turn the power

OFF, wipe them clean with a damp cloth, and then wipe them well with a dry cloth.

• Do not cover the air vents on the rear of the product.

• Make sure to perform periodic inspections of the product and its parts.

• It is recommended that you prepare a spare product just in case it breaks during use, etc.

• Portable and mobile RF communication devices may affect the operation of this product.

• If accessories or cables other than those sold as replacement parts by the manufacturer are used, the EMC

performance of the product may be reduced (emissions may increase or immunity may decrease).

• Turn the Power OFF after use. When not using the product for an extended period of time, disconnect the Power

Cord from the outlet.

• Install the product so that the Power Cord can be disconnected from the outlet immediately if a problem occurs,

to cut it off from the commercial power supply. Do not place any objects within 15 cm of the Power Cord.

• When disconnecting the Power Cord, hold the cord by its plug and pull the plug out. Holding and pulling the cord

may snap the wiring in the cord.

• When attaching a bur, confirm that there is no debris or foreign material on the shank. If foreign material, etc.

enters the chuck, the bur may break or the chuck may weaken.

• Users are responsible for the operational control, maintenance and continual inspection of the product.

• When the product has not been used for a long time, perform an operational check for abnormalities such as

rattling, vibrations, abnormal sounds, and generation of heat.