1 2

TABLE OF CONTENTS

SECTION PAGE

1.0 Warranty Information.............................................................2

1.1 Radio and TV Interference

1.2 CE Notice

1.3 Service Information

2.0 General Information...............................................................4

2.1 Features

2.2 Description

3.0 Scope......................................................................................5

3.1 Definition of Service Personnel

4.0 Safety Precautions and Operating Instructions.....................6

5.0 Installation .............................................................................7

5.1 The 1001RP16P Rack Chassis

5.2 Installing the Power Supply Modules

5.3 Configuring the Rear Power Entry Card Alarm Operation

5.4 Installing the Rear Power Entry Cards

5.5 Installing the Front Power Cards (Initial Installation)

5.6 Making the Alarm Relay Connections

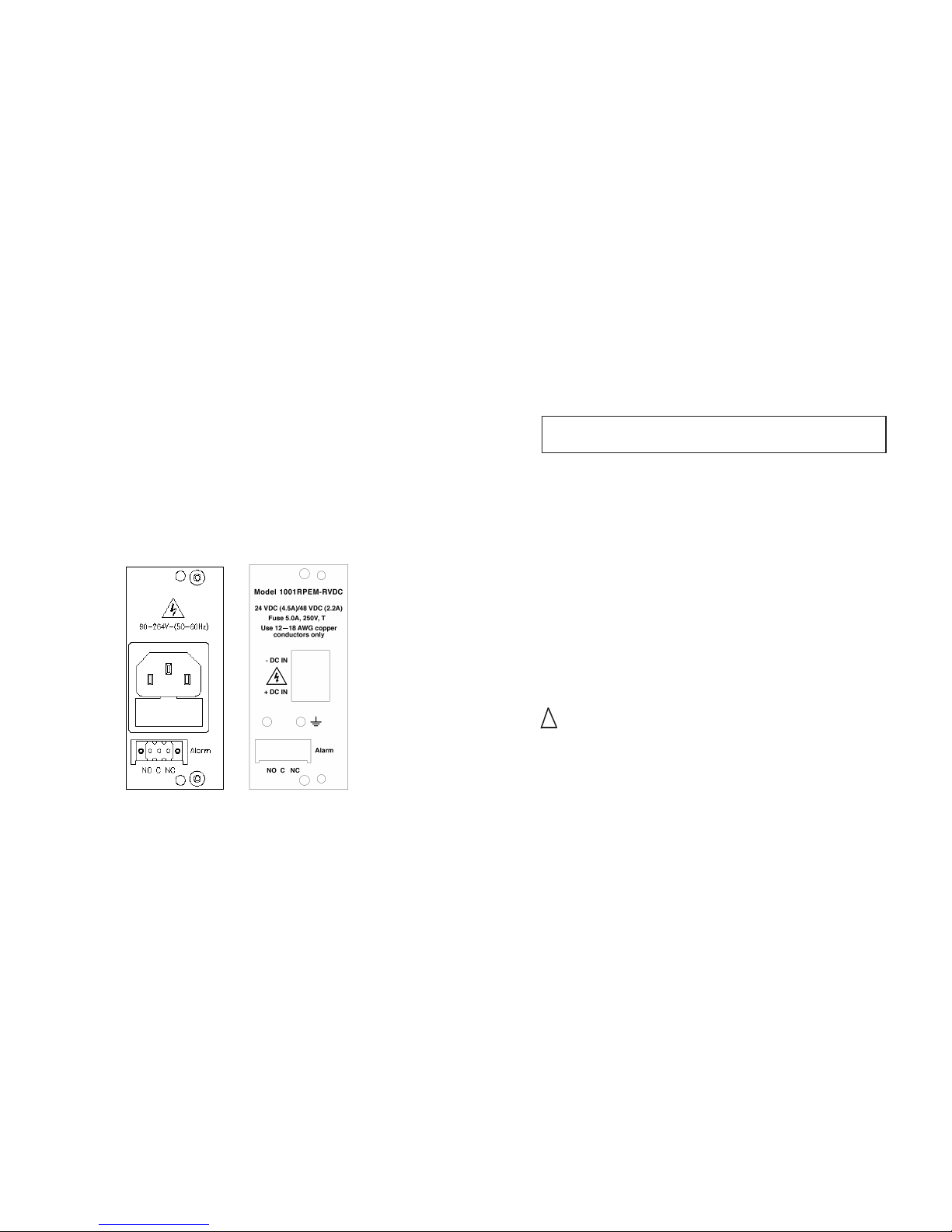

5.7 Connecting a 1001RPEM-RAC Entry Card to the AC

Voltage Source (90-264 VAC, 50-60 Hz)

5.8 Connecting a 1001RPEM-RVDC Entry Card to the 48 VDC

Source (42-62 VDC)

5.9 Service Procedure - Replacing a 1001RPSM-RUI Front Card

5.10Service Procedure - Replacing a 1001RPSM-R48V Front

Card

6.0 Operation.............................................................................15

6.1 LED Status Monitors

Appendix A - 48VDC Power Supply Specifications....................16

Appendix B - Universal AC Input Power Supply Specifications..19

Appendix C - Replacement Parts and Accessories ...................22

Appendix D - Safety Agency.......................................................23

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 1001RP Series components to

be free from defects, and will—at our option—repair or replace the

products should they fail within one year from the first date of ship-

ment. This warranty is limited to defects in workmanship or materials,

and does not cover customer damage, abuse or unauthorized modifi-

cation. If these products fail or do not perform as warranted, your sole

recourse shall be repair or replacement as described above. Under no

condition shall Patton Electronics be liable for any damages incurred

by the use of these products. These damages include, but are not lim-

ited to, the following: lost profits, lost savings and incidental or conse-

quential damages arising from the use of or inability to use this prod-

uct. Patton Electronics specifically disclaims all other warranties,

expressed or implied, and the installation or use of this product shall be

deemed an acceptance of these terms by the user.

1.1 RADIO AND TV INTERFERENCE

The Model 1001RP Series units generate and use radio frequency

energy, and if not installed and used properly—that is, in strict accor-

dance with the manufacturer's instructions—may cause interference to

radio and television reception. They have been tested and found to

comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection from such interference in a

commercial installation. However, there is no guarantee that interfer-

ence will not occur in a particular installation. If these products do

cause interference to radio or television reception, which can be deter-

mined by turning off the unit, the user is encouraged to try to correct

the interference by one or more of the following measures: moving the

computing equipment away from the receiver, re-orienting the receiving

antenna and/or plugging the receiving equipment into a different AC

outlet (such that the computing equipment and receiver are on different

branches).

1.2 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates

that it is in compliance with the Electromagnetic Compatibility (EMC)

directive and the Low Voltage Directive (LVD) of the European Union.

A Certificate of Compliance is available by contacting Technical

Support.