Pavone Systems MC 315 Series User manual

Pavone Sistemi

pesatura elettronica industriale

Pavone Sistemi

pesatura elettronica industriale

PAVONESYSTEMS

TECHNICAL MANUAL

MC 315 Weight Indicator wit serial outputs, fiber optics, IN/OUT

Software version PATX02

Page II

Rel ID 20190201 SW 0.5

Page 1

TABLE OF CONTENTS

PRECAUTIONS.............................................................................................. P. 2

INTRODUCTION ........................................................................................... P. 3

TECHNICAL CHARACTERISTICS ..................................................................... P. 5

INSTALLATION ............................................................................................. P. 6

FRONT PANEL OF THE UNIT………. .............................................................. P. 14

USE OF THE KEYBOARD ................................................................................ P. 15

DISPLAY INFO .............................................................................................. P. 18

OPERATING FUNCTIONS ............................................................................. P. 19

CONFIGURATION......................................................................................... P. 23

SET-UP MENU DIAGRAM ............................................................................... P. 27

CONFIGURATION PARAMETERS .................................................................... P. 28

CALIBRATION ............................................................................................... P. 28

SERIAL OUTPUT PARAMETERS ........................................................................ P. 35

INPUT/OUTPUT PARAMETERS......................................................................... P. 44

WEIGHING PARAMETERS ............................................................................. P. 48

FILTER PARAMETERS ....................................................................................... P. 50

SET-UP OF FUNCTIONAL FEATURES ............................................................... P. 52

DATE AND TIME ADJUSTMENT ...................................................................... P. 55

UPLOAD/DOWNLOAD FUNCTION ................................................................ P. 56

ACCESS DISPLAY .......................................................................................... P. 57

ALIBI MEMORY CONSULTATION..................................................................... P. 58

SERIAL COMMUNICATION PROTOCOLS ........................................................ P. 59

TROUBLESHOOTING .................................................................................... P. 84

Page 2

PRECAUTIONS

READ this manual BEFORE using or maintaining the unit.

FOLLOW these instructions carefully.

STORE this manual for future reference.

WARNING

This manual uses words and explanatory images to help the operator understand the pre-

scriptions and fundamental criteria for the installation and appropriate use of the unit.

Installation, maintenance, and repairs should only be performed by specialized operators

after reading and understanding this manual. “Specialized operators” means the staff that,

having the necessary professional training and expertise, were expressly authorized by the

plant’s safety Manager to perform installation.

Power the unit within the voltage limits specified in the characteristics.

The user is responsible to ensure that installation complies with the applicable rules in force.

Any attempt to dismantle or modify the unit shall make the relevant guarantee null and void

and release Pavone Sistemi from any and all liabilities, except where expressly authorized.

The installation and maintenance of this unit should only be performed by qualified staff.

Utmost care should be taken when performing checks, tests, and adjustments with the unit

switched on.

Power connections should only be performed when the unit is switched off.

Any failure to comply with the above precautions may imply risks.

DO NOT ALLOW untrained staff to operate, clean, inspect, repair, or tamper with this unit.

The unit bears the following ATEX mark:

II2(1) G Ex ia [ia IIC Ga] IIC T4 Ga (Ta: -10°C ÷ +40°C)

II2(1) D Ex ia [ia IIC Da] IIC T135°C Db X (Ta: -10°C ÷ +40°C)

The unit was approved for specific usage locations: do not install or use the unit in locations

other than the specified ones.

The safety of the weighing system is only ensured if installed and used according to the

provisions contained herein.

Do not open the unit when switched on, do not disconnect the cables when switched on,

do not open in explosive atmospheres.

Do not cover the unit with materials subject to potential electrostatic charge.

Clean the unit with moist cloths and anti-static products.

All peripheral devices connected with the unit, if installed and operated in the same location,

should be marked at least II 1 GD.

Do not connect the unit with modules that are not provided for by the certification; this af-

fects the intrinsic safety of the unit (with subsequent loss of the Ex approval). Please refer to

Pavone Sistemi srl for additional information.

Page 3

INTRODUCTION

The MC 315 is a weighing unit designed and manufactured in accordance with directive 2014/34/

EU, fit for use in locations with potentially explosive atmospheres in compliance with norms EN 60079-

0:2018, EN 60079-11:2012, and EN 60079-26:2015.

Operation is allowed in zones 1, 21, and 2, 22 (1, 2 for gases, 21, 22 for powders) as per Directive

ATEX 2014/34/EU.

Operation in zones subject to the risk of explosion is safe because the indicator uses low energy, which

is not sufficient to trigger explosions either with power sparkles or with excess temperatures (class T4).

The weighing terminal features a centralized CPU, a LED display, a membrane keyboard, and a se-

parate power pack, which should be located in a safe zone or placed in a separately ATEX-certified

enclosure when installed in a dangerous zone; such power pack is made up of a dedicated AL-AX

power unit or an AL-BX battery pack.

The unit can be placed on a table or hung on the wall by means of an optional bracket.

The display ensures easy reading of weight, unit status, configuration parameters, and errors.

The multi-function 21-key keyboard ensures smooth performance of the following functions: ZERO,

TARE, GROSS/NET switching, weight set point set-up, configuration, and calibration, both theoretical

and actual.

The optical fiber connection allows to convey to a safe zone the information required to calculate, via

the S3xx interface, the analogue voltage or current output, IN-OUT, RS232, and RS485, without using

any Zener barriers.

Two RS485 serial ports with ASCII or MODBUS protocol allow remote connection for a maximum of

32 addressable devices, both in a safe and in a dangerous zone, using specific Zener barriers.

Two optoinsulated inputs are also available and can be connected with devices both in a dangerous and

in a safe zone, as well as 6 photorelay outputs that can be connected with devices in a dangerous zone.

Available versions:

• MC315:weightindicatorwithopticalfiberoutput,2RS485serialports.Supportsthe

ASCII and Modbus RTU continuous protocols. Two inputs and 6 outputs.

• MC315/X:versionwithXXXXX.

• MC315/XXX:XXXXXXXXXXXXX.

PAVONE SISTEMI

Page 4

NAMEPLATE OF THE UNIT

It is important to communicate this information when inquiring about the unit, alongside the number of

the software application and version stated on the cover of the manual and displayed when the unit

is switched on.

WARNING

The procedures described below should be performed by specialized staff.

All connections should be performed when the unit is switched off.

Page 5

TECHNICAL CHARACTERISTICS

Power 100 ÷ 250 VAC with AL-AX certified power unit or 6V

battery via AL-BX barrier (in safe zones)

Max absorption 2 W

Insulation Class III

Operating temperature -10°C ÷ +50°C (max. steam-free humidity 85%)

Storage temperature -20°C ÷ +60°C

Weight display Red 6-digit 7-segment LEDs (h 20 mm)

LEDs 8 LED indicators 5mm

Keyboard membrane, 20 keys + ON/OFF

Dimensions 237 mm x 169 mm x 113 mm (l x h x d)

Mounting Table-top, wall-mount, or column (with bracket)

Enclosure material Stainless steel

Connections Removable terminal pads with pitch 3.81 screws

Load cell power supply Max 4 350Ω cells in parallel, protected from short

circuits

Input sensitivity 0.02 µV min.

Linearity < 0.01% of full scale

Thermal drift < 0.002% of full scale / C°

Internal resolution 24 bits

Weight display resolution Up to 999.999 divisions of maximum capacity

Measurement field –3,9 mV/V to +3,9 mV/V

Weight acquisition frequency 50 Hz

Digital filter Can be selected on 10 level

Number of weight decimals 0 to 4 decimals

Zero point and full scale calibration Automated (theoretical) or executable from keyboard

Logical outputs 6 photorelays max 24 Vdc / 100 mA each

Logical inputs 2 optoinsulated at 12÷24 Vdc PNP (external supply)

Serial port (No. 2) RS485

Max. cable length 200m

Serial protocols ASCII, Modbus RTU

Full duplex fiber optic port Data transmission to S318 circuit board in safe zones

Max. cable length 50m

Cable type Duplex cable with 1 mm Plastic Fiber optics (e.g. COP-

1002-HD)

Microcontroller: ARM Cortex M0+ 32 bit, 256KB Flash resettable on-

board from USB.

Data storage 256 Kbytes expandable to 1024 Kbytes

Compliance with norms EN61000-6-2, EN61000-6-3, EN61010-1

EN60079-0, EN60079-11, EN60079-26

175

99

30

177

97

35

55

202

230

DIS1DIS2DIS3DIS4DIS5DIS6

LED1LED2LED3LED4L E D5LED6

ED8

SX 1 1

DX

UP 1 2

14 15

17 18

1CLR 10

3

6

9

PRG

SHF ON

ZERO

1 2

4 5

7 8

CLR 0

3

6

9

PRG

TARE

SHFFUN ON

MC 315

Page 6

INSTALLATION

OVERVIEW

The MC 315 is a multifunction unit contained in a stainless steel enclosure, fit for use in zones subject

to the risk of explosion as per Directive ATEX 2014-34-EU, in accordance with norms EN 60079-0 and

EN 60079-11 Ex-I (Intrinsic Safety).

The MC 315 should not be soaked in water, splashed with water, and cleaned or washed

with solvents.

Do not expose the unit to high temperatures or direct sun light.

Do not install the unit near power equipment (engines, inverters, contactors, etc.) or equipment that

does not comply with EC norms for electromagnetic compatibility.

Follow the guidelines in the unit safety manual and the reference ATEX norms.

DIMENSIONS

POWER INSTALLATION

Cables are fed into the enclosure through six separately “II2G Ex e”-certified cable glands

arranged across the back wall.

The eligible models are selected by Pavone Sistemi: in case of damage and decay, they should

be replaced by Pavone Sistemi.

Unused cable glands should always be closed with the appropriate supplied separable plug, which

restores protection degree IP66.

Cables used with cable glands should be selected in accordance with EN60079-14 and should be

round, compact, full extruded, and non-hygroscopic.

The internal power connection of the MC 315 indicator is performed with removable terminal pads

with pitch 3.81 screws.

L N

- +

Power Supply

AL-AX

Dangerous zone

Safe zone

Output

5Vdc 0.2A

Input

115/230 Vac

115/230 Vac

Power Supply

+5 Vdc

0 Vdc

N

L

EXC-

EXC+

SENSE+

SENSE-

SIG-

SIG+

SHIELD +

-+5 Vdc

0 Vdc

AL-AX

Power Supply

Page 7

POWER SUPPLY OF THE UNIT

The circuit board is powered via an AL-AX certified power unit

(100 ÷250 VAC / 5VDC) or a 6V battery via AL-BX barrier. Both

the power unit and the battery should be located in a safe zone

or, if located in a Dangerous Zone, should be contained within a

separately certified ATEX enclosure.

The unit is powered through terminals 1 and 2 of connector J1. The

power cable should be fed separately from other cables.

Ensure that appropriate grounding is available.

Power supply voltage: 5 VCC ±15%, max 2W

LOAD CELL CONNECTION

The cells’ cable should not be fed together with other cables, but

should follow its own separate path.

Up to 4 350-ohm cells can be connected in parallel with the unit.

The cells’ power supply voltage is 3.3 VCC, with protection from

temporary short circuits.

The measurement field of the unit provides for using load cells with

maximum 3.9 mV/V sensitivity.

The load cells’ cable should be connected with terminals 1 to 6 of

connector J11. In case of 4-conductor cell cable, bridge terminal 1

with 4 and terminal 2 with 3.

Connect the cells’ cable shield with terminal 1 of connector J11.

If two or more load cells are used, use specific junction boxes

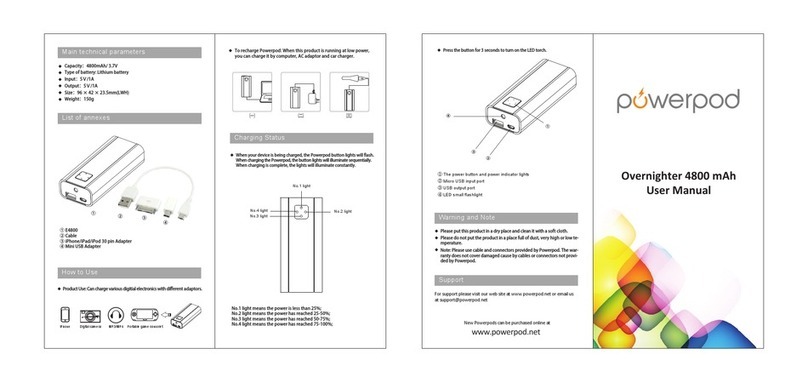

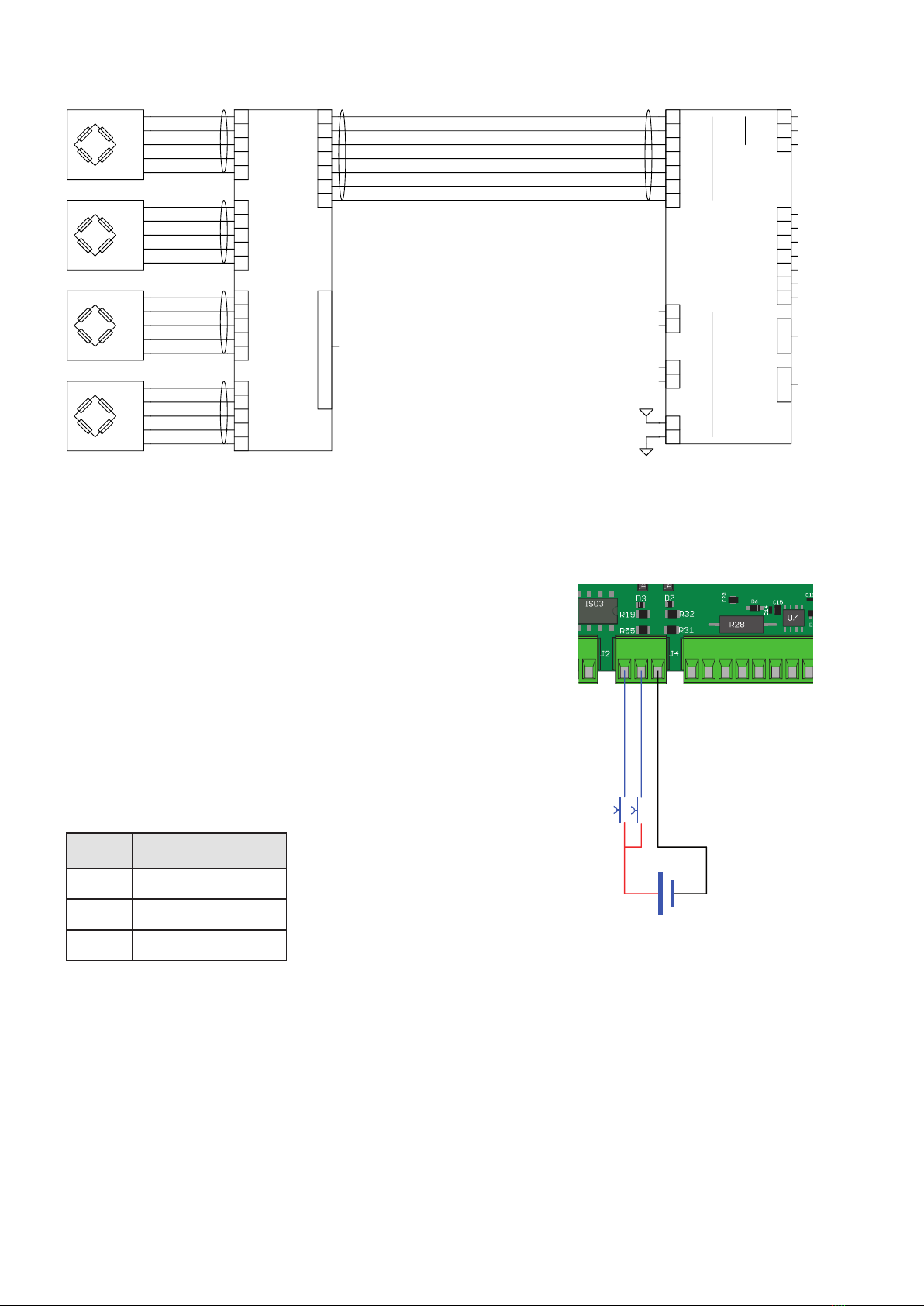

(CEM4/E ATEX or CSG4/C ATEX), connected as shown below.

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

25 PIN CONNECTOR

+SGN

-ALM

+ALM

-SGN

+SNS

-SNS

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

SCH

SCH

SCH

SCH

SCH

2

3

6

1

5

4

7

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

J-BOX CGS4C ATEX

XR2

MC 315

TX+/RX+

TX-/RX-

-SENSE

+SENSE

SHIELD

TX+/RX+

TX-/RX-

-SIG1

+SIG1

COM OU

COM IN

OUT2

-EXC

+EXC

OUT1

OUT3

OUT4

OUT5

OUT6

IN2

IN15

6

1

4

3

2

1

2

00

7

3

4

5

6

3

4

5

6

2

1

2

+Vin

GND

1

3

+5V

XT1

J1

COM1

COM2

J11

J4J2

OPTICAL FIBER

+

-

INPUT 2

INPUT 1

24 Vdc

100 mA Max

COM. INPUT

Page 8

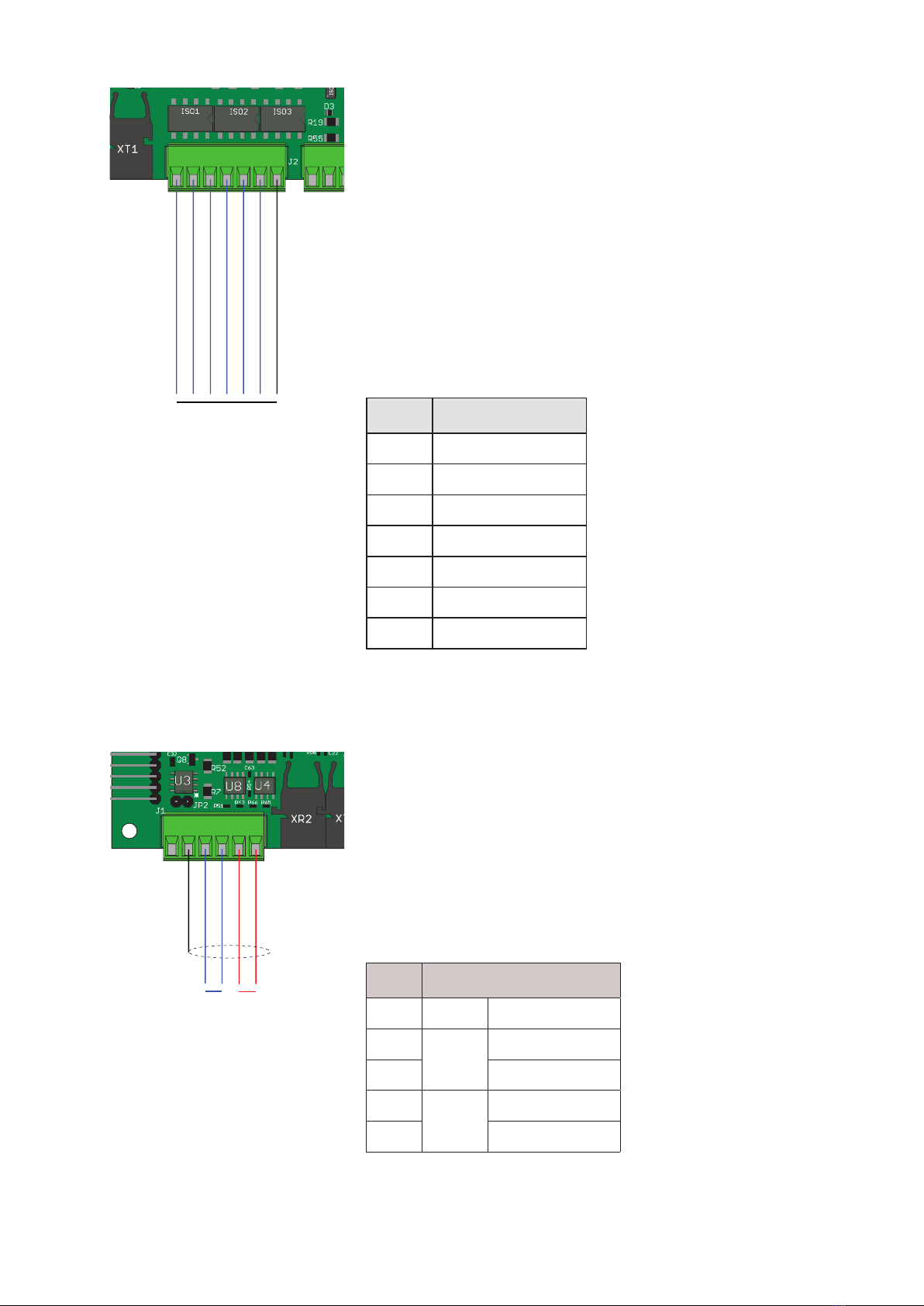

LOGICAL INPUT CONNECTION

Logical inputs are insulated from the unit by means of optoinsulators

with minimum inner distance of 0.5 mm. This allows to connect inputs

located both in a safe and in a dangerous zone.

• The connection cables of the logical inputs should not be fed

together with power or supply cables.

• The connection cable should be as short as possible.

Logical input enabling requires a 7 to 24 VDC voltage. The com-

mon inputs should be connected with the negative having the same

voltage.

NUM. Terminal Board J4

1 Input 1

2 Input 2

3 Common Input

OUTPUTS

30 Vdc

100 mA Max

OUTPUT 2

OUTPUT 1

COM. OUTPUT

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

COM1

RS485 TX-/RX-

TX+/RX+

COM2

RS485 TX-/RX-

TX+/RX+

SHIELD

Page 9

LOGICAL OUTPUT CONNECTION

The 6 logical outputs are based on a Photorelay (clean contact) with

a common. The capacity of each contact is 100 mA / 30VDC. When

the output is enabled, the contact closes (contact NA).

• The location that hosts to the unit can be normally subject to strong

magnetic fields and electrical noises caused by other appliances.

Therefore ordinary measures should be taken to prevent any

impact thereof on the typical signals of a high-precision electro-

nic device (filters on contactors, diodes on 24 Vdc relays, etc.).

The outputs are designed to drive devices through a dangerous zone.

For use with devices in a safe zone, an optical fiber connection or

a specific barrier can be used.

Output connection is shown below:

NUM. Terminal board J2

1 Output 1

2 Output 2

3 Output 3

4 Output 4

5 Output 5

6 Output 6

7 Common Output

SERIAL COMMUNICATION

RS485

Serial connections for distances up to 200m can be performed via the

RS485 serial interface. The RS485 serial connection is of the 2-thread

type and allows to connect up to 32 devices with one MASTER unit

(personal computer, PLC, etc.) via one twisted and shielded cable.

The cable shield should be connected with terminal 2 of connector J1.

The cable should not be fed together with power cables.

A RS485 barrier must be used to connect the MC 315 (in a dange-

rous zone) with a PC or other devices in a safe zone. Several models

are available on sale, including the D1061S by GM International.

NUM. Morsettiera J1

2 SHIELD

3COM1 TX+/RX+

4 TX-/RX-

5COM2 TX+/RX+

6 TX-/RX-

USB+

Fiber Optic Interface

Fiber Optic

RX TX

Options:

Fiber Optic

A Gnd

TX

RX

Out An

V Out +

I Out +

S Gnd

RxD

TxD

RS485 -

RS485 +

GND

+ Vdc

+

-

GND

7÷30 Vdc

V+ (10 kΩ min)

mA+ (300 Ω max)

RS485

TX-/RX-

TX+/RX+

ANALOG

OUTPUT RS232

RXD

TXD

SGND

A Gnd

Page 10

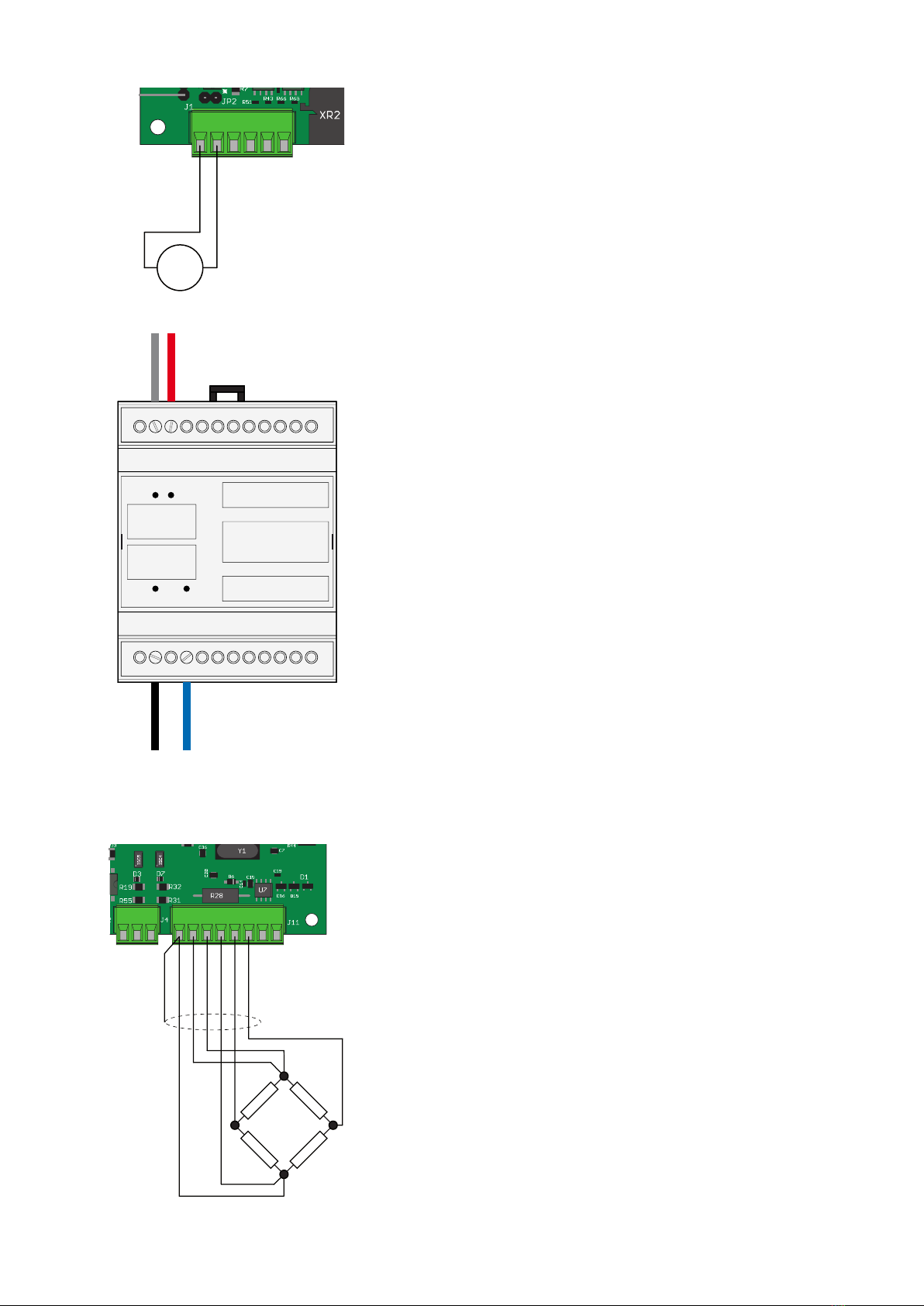

OPTICAL FIBER CONNECTION

The use of optical fiber communication systems in dangerous zones

offers some advantages in terms of galvanic isolation and use of

low energy.

Galvanic isolation makes it unnecessary to use a barrier, which would

be anyway required between the dangerous and the safe zone in

case of, for example, RS232 or RS485 communication or analogical

output, even if the signals come from an intrinsically safe unit.

The use of diffused-light LEDs, as for the interfaces on this unit, com-

plies with the ATEX norms and, specifically, with norm EN 60079-28.

Two-way optical fiber communication allows to send and receive

data in a safe zone to/from the S318 circuit board; such data is

then switched to Fieldbus, RS485, RS232, analogical outputs, in-out.

The requested cable is a Duplex cable with two fibres inside the

same sheath, with 1mm Plastic Optical Fiber (e.g. COP-1002-HD).

The fiber terminal should be designed according to document

“AV02-0460EN _DS_HFBR-

453xZ_2015-06-18.PDF”

by AVAGO/BROADCOM, and

using connectors of the HFBR-

453xZ series.

The use of two different colours

for the TX and RX, is recommen-

ded, e.g. HFBR-4531Z (black)

for the TX and HFBR-4533Z

(blue, see photo on the right) for

the RX.

The optical fiber could reach a

maximum length of 100m (as from the characteristics) with a very

accurate finish, as specified in the above-mentioned document.

If the finish is not ascertained, a maximum length of 50m is recom-

mended.

The fibers can also be cut with an appropriate cutter (see figure).

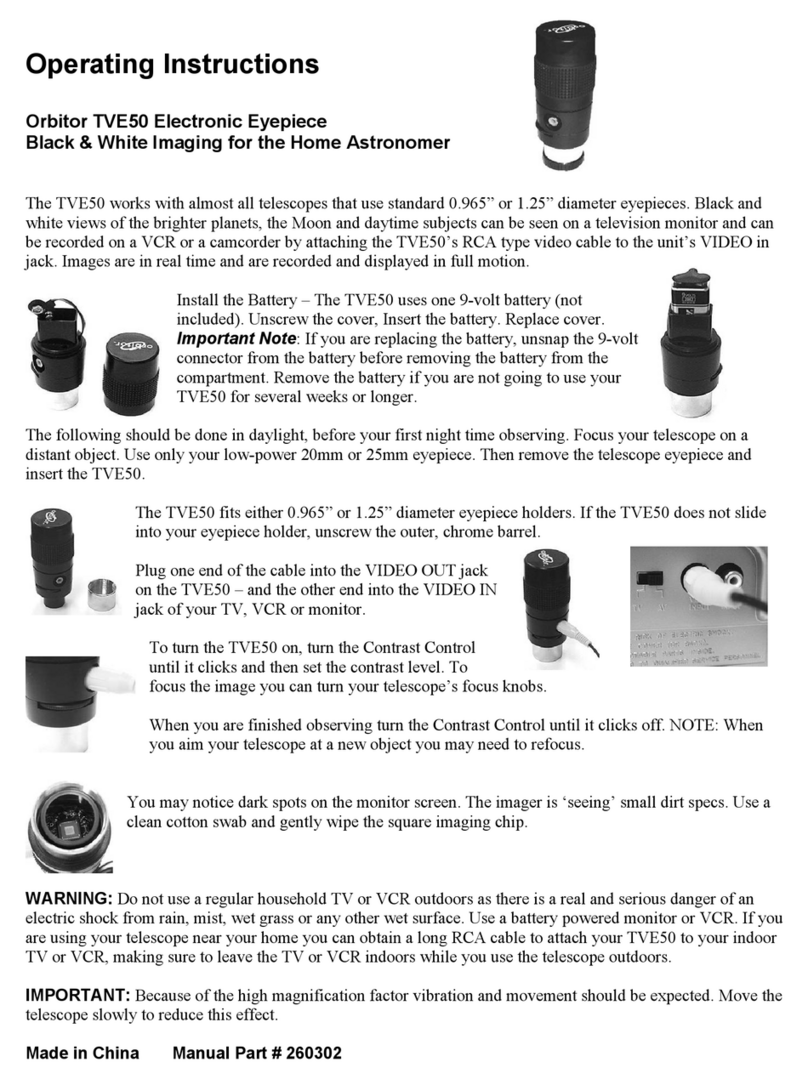

S318 CIRCUIT BOARD

The Optical Fiber interface board is contained in a plastic enclosure

with DIN 35mm guide. Its size is 70x90x58mm (LxHxD). While the

board should be powered at the typical voltage rate of 24 VDC,

voltage values between 7 and 30 VDC are also accepted.

The base version of the board features a RS232 serial port and a

RS485 serial port. It is also available with analogical voltage or

current output as an option.

As an alternative to the RS485 serial port, any of the following

FIELDBUS options can be used: Profibus DP, Profinet, Ethercat, or

Ethernet IP.

The configuration of the serial ports, of the analogical output and

of the Fieldbus (if any) is performed directly by the MC 315 unit.

MC 315

Kg

T

RO

1

ZE

2

4 5

7 8

CLR 0

3

6

9

PRG

ARE

SHFFUN ON

Page 11

FRONT PANEL OF THE UNIT

The MC 315 has a bright 6-digit display, 8 status LEDs, and 21 keys for easy operation. In the operating

mode, the display shows the weight, and the LEDs indicate the weight and set point status.

The set-up parameters are easy to access and adjust using the front keys to select, change, and confirm

the new values.

DISPLAY

The 6-digit display usually shows the scale weight. Based on the different set-up processes, the display

is used to set up the parameters to be saved, i.e. messages about the current operation mode, and

therefore ensure smooth user operation and set-up of the unit.

LEDS

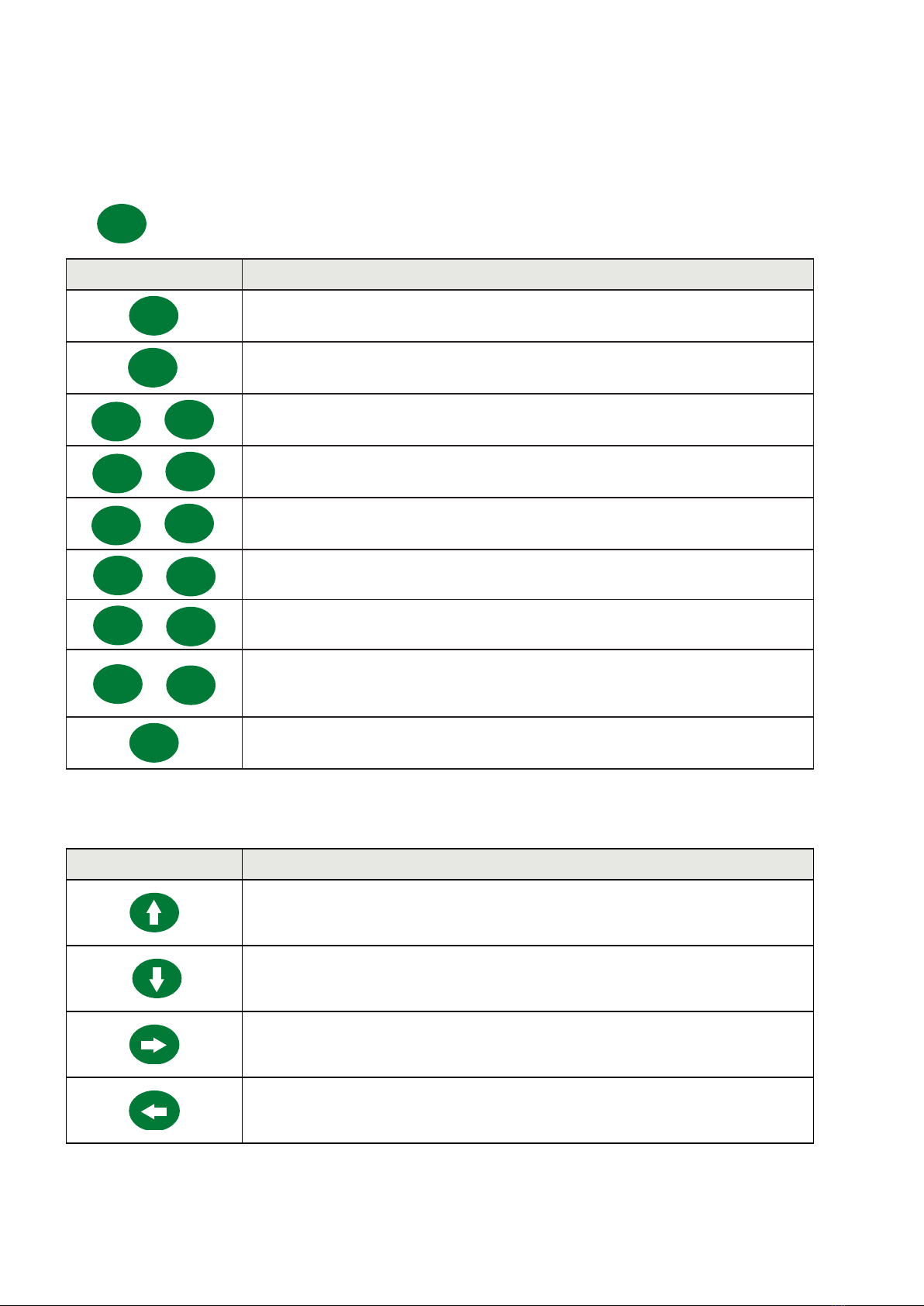

The 6 status LEDs above the display have the following functions:

BAT Battery operation / battery low (flashing)

FUN Function key enabled

NET Net weight display (entered tare)

MIN Gross weight below the set zero band

>0< Zero point (gross weight < 0,25 e)

Stable weight

There are 2 LEDs on the left side of the display:

1 Multirange field 1

2 Multirange field 2. ( 1 + 2 ) = Multirange field 3.

Page 12

USE OF THE KEYBOARD

The unit is set up and controlled via the 21-key keyboard. Set-up menus are usually managed by pressing

the arrow keys to scroll the items and the PRG key to access the relevant sub-menu or programmable

parameter.

The ON key allows to switch the unit on and off.

KEY FUNCTIONS DURING WEIGHT DISPLAY

ZERO Displayed value zeroing (gross weight).

TARE Automated Tare function

FUN + TARE Manual Tare function; this function is only accessible when no automated

tare is entered (*).

FUN + CLR Tare clear. (*)

FUN + SHF Switch displayed weight (net/gross). (*)

FUN + 1Access to set-point value set-up menu (*)

FUN + 2Cell channel switching. (*)

FUN + 3

Serial weight transmission via On Demand protocol. In case of metric ope-

ration, weight is saved in the alibi memory; weight and the weighing ID

code are transmitted via the On Demand protocol. (*)

PRG (Hold) Access to set-up menu.

*) Certain operating functions are performed by pressing the FUN key and an operating key in sequence

(e.g. the TARE key for manual tare set-up) The sequence should be completed within 2 seconds from

pressing the FUN key; during this time, the FUN status LED remains on.

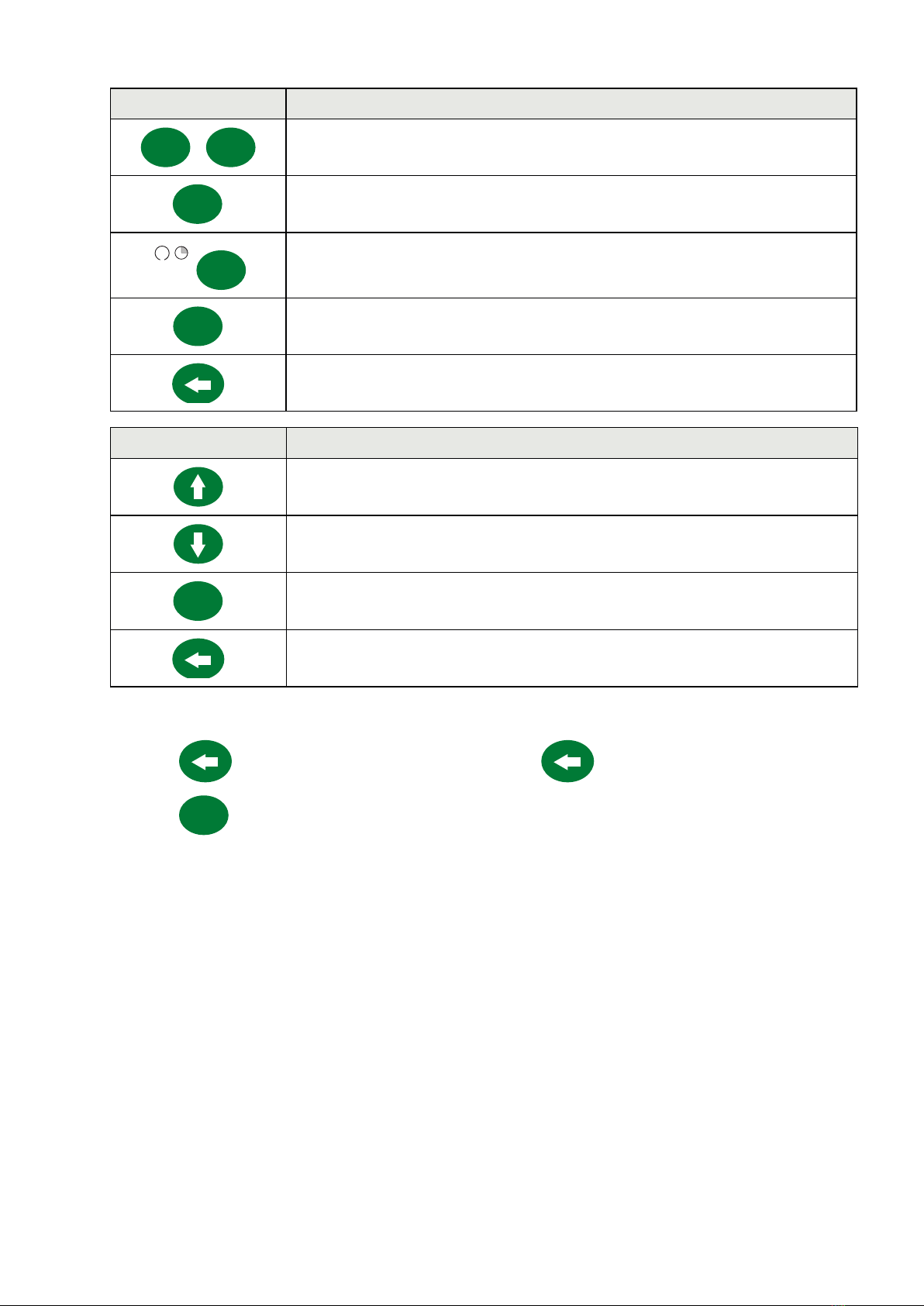

KEY FUNCTION WHEN BROWSING THROUGH THE SET-UP MENU

Selects the next menu.

Selects the previous menu.

Accesses the relevant sub-menu or set-up or confirms the selected parameter.

Exits from the set-up menu or returns to the higher level.

Page 13

KEY FUNCTION WHEN SETTING UP NUMERIC VALUES

0... 9Writes the selected value (a digit is added on the right).

CLR Delete last digit.

J

CLR (Holds) Resets set-up.

PRG Ends entry and saves the value

Exits without saving changes

KEY FUNCTION WHEN SETTING UP PROPOSED VALUES

Selects the higher value.

Selects the lower value.

PRG Confirms and saves the displayed value.

Exits without saving changes.

EXITING THE SET-UP MENU

Press the key to return to the main menu. Press the key again. “StorE?” is displayed.

Press the PRG key to save the entries and return to weight display.

Page 14

DISPLAY INFO

PAtH02

rEV. 04

When the unit is switched on, a display test is performed; the software ID and the

relevant version are then displayed. Such codes should be communicated in case of

support request.

When the set-up procedure is not under way, the display shows the measured weight in kg. The following

messages appear in certain conditions:

ERROR REPORTING

The following error codes may appear on the display in the operating mode.

Fixed message

O-L No load cell signal, or signal falls outside the mV/V measurement field.

- - - -

- -

Overload. The weight applied to the load cells exceeds the maximum capacity of the

weighing system by over 9 divisions.

- - - - - -Underload. This message appears when the measured weight is negative below the

displayable value.

Flashing message, alternating with the measured weight

no-CAL Weight calibration not performed, flashing message (alternating with the measured

weight).

Low.Uin Power supply too low in case of operation with power unit, flashing message (alternating

with the measured weight).

E.FibEr

Communication error with the S318 optical fiber interface board. This error is only

displayed in case of communication timeout and when the interface is enabled (ana-

logical output option enabled, COM3 protocol enabled, or COM4 protocol enabled).

No CoN Fieldbus network disconnected.

E-F.buS Fieldbus interface connection error.

Page 15

OPERATING FUNCTIONS

After calibration, the display shows the current weight when switched on next.

The possible operations that can be performed from the keyboard when weight is displayed are de-

scribed below.

KEY FUNCTIONS DURING WEIGHT DISPLAY

ZERO Display value zeroing (gross weight).

TARE Automated Tare function.

FUN + TARE Manual Tare function; this function is only accessible if no automated tare is

entered (*).

FUN + CLR Tare clear. (*)

FUN + SHF Switch displayed weight (net/gross). (*)

FUN + 1Access to set point value set-up menu (*)

FUN + 2Cell channel switching. (*)

FUN + 3

Serial weight transmission via On Demand Protocol. In case of metric opera-

tion, weight is saved in the alibi memory; weight and the weighing ID code

are transmitted via the On Demand protocol. (*)

PRG (Hold) Access to set-up menu.

(*) Some operating functions are performed by pressing the FUN key and an operation key in

sequence (for example, the TARE key to perform manual tare programming). The sequence must be com-

pleted within 2 seconds after pressing the FUN key, during this period the FUN status LED remains on.

ZEROING

The gross weight reset command is used to correct minor zero shifts of the weighing system during

regular operation. These zero shifts are usually due to thermal drifts or material residues accumulating

on the weighing system in time.

The gross weight reset command is not executed if any of the following conditions occurs:

• Unstable weight (with weight stability control enabled). In this case the reset command is only effec-

tive if weight is stabilized within 3 seconds, or if the weight stability control is disabled (“MOTION”

parameter = zero)

• Gross weight exceeding (in positive or negative terms) the number of divisions set in the “0 BAND”

parameter, when the self-zero set point is not set.

After the unit is switched off, the zero value acquired by zeroing gross weight is saved, in case of FREE

operating mode selected and AUTO ZERO function deactivated.

While gross weight can be zeroed multiple times, the number of divisions zeroed each time is summed

up. Therefore when the total exceeds the limit set in the “0 BAND” parameter, no zeroing can be per-

formed. In this case, Zero point calibration should be performed.

Page 16

Setting up the automated zero parameter upon switch-on (AUTO 0) reduces (or annuls, in case of

“AUTO 0” > “0 BAND”) the scope of action of the zero command.

AUTO-TARE

Autotare is not performed under the following conditions:

Unstable weight (the weight does not stabilize within 3 seconds of the reset command).

Gross weight equal to or greater than the maximum capacity of the weighing system.

After the unit is switched off, the AUTO TARE value is saved, only in case of FREE operating mode

selected and AUTO ZERO function deactivated.

ON-DEMAND TRANSMISSION

Serial transmission via the on-demand protocol is performed if the following conditions are in place:

• Stable weight (within 3 seconds from command).

• Weight changed by about 20 divisions since the last transmission performed (weight delta).

• Gross weight below maximum capacity.

• Only in case of METRIC operation, gross weight should be equal or lower than minimum weighing

(20 divisions).

• Only in case of METRIC operation, net and gross weight should be positive and not null.

WEIGHING SAVING

Weighing is saved in the alibi memory if the following conditions are in place:

• METRIC operation.

• Alibi memory option available in the unit.

• Stable weight (within 3 seconds from command).

• Weight changed by about 20 divisions since the last weighing performed (weight delta).

• Gross weight is equal to or lower than minimum weighing (20 divisions) and lower than maximum

capacity.

• Net and gross weight are positive and not null.

WEIGHT SET POINT SET-UP

The set-up value SET POINTs are compared against weight to drive the relevant logical output. The

comparator is selected in the logical input/output set-up procedure (see the corresponding section).

Press the FUN key to access Set point set-up; the FUN LED turns on; press key 1 within 2 seconds during

weight display.

Page 17

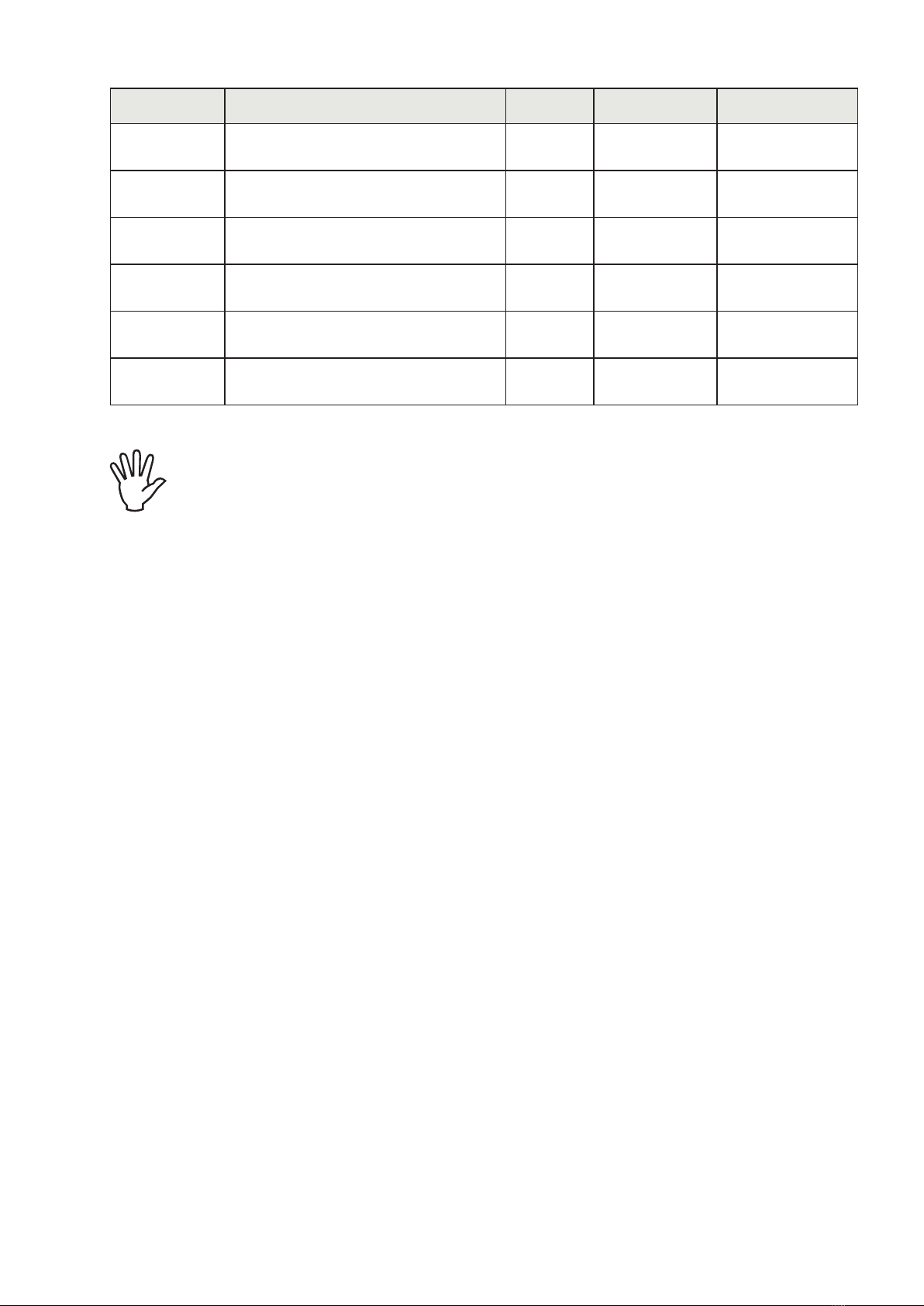

MESSAGGE DESCRIPTION DEFAULT RANGE FIELDBUS ADDR.

SEtP. 1 Sets the value of Setpoint 1 0 0÷Capacity 201(MSB)

202(LSB)

SEtP. 2 Sets the value of Setpoint 2 0 0÷Capacity 203 (MSB)

204 (LSB)

SEtP. 3 Sets the value of Setpoint 3 0 0÷Capacity 205 (MSB)

206 (LSB)

SEtP. 4 Sets the value of Setpoint 4 0 0÷Capacity 207 (MSB)

208 (LSB)

SEtP. 5 Sets the value of Setpoint 5 0 0÷Capacity 209 (MSB)

210 (LSB)

SEtP. 6 Sets the value of Setpoint 6 0 0÷Capacity 211 (MSB)

212 (LSB)

The set-up value set points are compared against weight to drive the relevant logical output.

The comparator is selected in the set point set-up procedure.

When weight cannot be measured or is out of scale, all the outputs are disabled (open or

closed contact according to MODE set-up, see the corresponding section).

In the set point set-up phase, both outputs are disabled. If the saved value set point is 0, the

relevant output is never enabled, whatever the selected set point set-up.

Page 18

CONFIGURATION

OVERVIEW

All the functions of the MC 315 can be enabled and adjusted by accessing a simple set-up menu, shown

on the following page. All the functions selected or enabled are saved even if the unit is switched off.

The MC 315 is pre-configured with default parameters. The “Default” values of each parameter are

shown on the following pages.

After first field installation, certain parameters need to be adjusted in order to ensure appropriate weight

display (theoretical calibration).

This feature can be requested upon purchasing the MC 315.

The values in the set-up menu can be adjusted using the front keys.

KEY FUNCTION WHILE SETTING UP THE MAIN MENU

Selects the next menu.

Selects the previous menu.

Accesses the relevant sub-menu or the set-up or confirmation of the selected

parameter.

Exits the set-up menu or returns to the higher level.

KEY FUNCTION WHILE SETTING UP PROPOSED VALUES

Selects the higher value.

Selects the lower value.

PRG Confirms and saves the displayed value.

Exits without saving changes.

KEY FUNCTION WHILE SETTING UP NUMERIC VALUES

0... 9Writes the selected value (a digit is added on the right).

CLR Delete the last digit.

J

CLR (Hold) Resets set-up.

PRG Ends entry and saves the value.

Exits without saving changes.

Table of contents

Other Pavone Systems Accessories manuals