Pavone Systems MCT 1302 User manual

PAVONESYSTEMS

TECHNICAL MANUAL

MCT 1302 Touch screen batching version with RS232 serial, analog and Fieldbus

output Software version PW1507

Page II

Rel ID 19230101 SW 1.1

Page 1

TABLE OF CONTENTS

PRECAUTIONS.............................................................................................. Page 2

INTRODUCTION ........................................................................................... Page 3

TECHNICAL FEATURES................................................................................... Page 5

INSTALLATION .............................................................................................. Page 5

FRONT PANEL OF THE INSTRUMENT .............................................................. Page 16

MAIN SCREEN.............................................................................................. Page 17

INFO DISPLAY ............................................................................................... Page 19

OPERATING FUNCTIONS .............................................................................. Page 20

BATCHING RECIPES SELECTION ..................................................................... Page 22

MENU STRUCTURE ........................................................................................ Page 26

USER MENU ................................................................................................. Page 27

BATCHING PARAMETERS MENU..................................................................... Page 35

HARDWARE TEST MENU................................................................................ Page 39

INPUT/OUTPUT MENU .................................................................................. Page 40

ACCESSING THE SETUP................................................................................. Page 41

CALIBRATION................................................................................................ Page 42

ANALOG OUTPUT PARAMETERS..................................................................... Page 47

SERIAL OUTPUT PARAMETERS......................................................................... Page 48

WEIGHING PARAMETERS .............................................................................. Page 56

FILTER PARAMETERS ....................................................................................... Page 57

WORKING MODE PARAMETERS..................................................................... Page 59

TIME AND DATE MENU, DISPLAY CONTRAST MENU........................................ Page 62

UPLOAD/DOWNLOAD FUNCTION ................................................................ Page 63

SERIAL COMMUNICATION PROTOCOLS ........................................................ Page 64

FIELDBUS PROTOCOLS .................................................................................. Page 75

TROUBLESHOOTING ..................................................................................... Page 80

Page 2

PRECAUTIONS

READ THIS MANUAL BEFORE using or servicing the instrument.

FOLLOW these instructions carefully.

KEEP this manual for future use.

CAUTION

The purpose of this manual is to make the operator aware of the

texts and explanatory figures, the basic requirements and criteria

for the installation and correct use of the instrument.

Installation, maintenance and repair must carried be out only by

specialized personnel who must have read and understood this ma-

nual. “Specialized personnel” means personnel who, due to training

and professional experience, have been expressly authorized by the

System Safety Manager to perform the installation.

Supply the instrument with voltage whose value is within the limits

specified in the specifications.

It is the user’s responsibility to ensure that the installation complies

with the applicable regulations.

Any attempt to disassemble or modify the instrument not expressly

authorized will invalidate the warranty and relieve Pavone Sistemi

of any responsibility.

The installation and maintenance of this instrument should only be

permitted by qualified personnel.

Pay attention when checking, testing, and adjusting with the instru-

ment turned on.

Make the electrical connections in the absence of the power supply

voltage.

Failure to observe these precautions may result in danger.

DO NOT ALLOW untrained personnel to work, clean, inspect, repair

or tamper with this instrument.

Page 3

INTRODUCTION

The MCT 1302 is a touch screen weight indicator and batcher to be combined with load cells to meet

the industrial applications.

The instrument is installed in a frame in a slot having a drilling template of 138 x 53 mm and is secured

by means of the 2 tensioning screws supplied.

The MCT 1302 uses the RS232 serial port with ASCII protocols, to be connected to the PC, PLC and re-

mote units with a maximum distance of 15m beyond which it is necessary to use the RS422/RS485 serial

output that allows the connection also with MODBUS RTU protocol up to 32 addressable instruments.

The availability of the most popular field buses, as an alternative to the RS485 port, also allows inter-

facing the instrument with any supervision device currently offered by the market.

A USB 2.0 port is also available and facilitates interfacing with PCs using AN Utility Software available

in the kit.

6 digital inputs and 6 digital outputs configurable by Set-up are always available.

It is also possible to have the analog output in voltage or current even in the presence of the FIELDBUS.

Available versions:

• MCT 1302: weight indicator with RS232 serial output, USB, RS485. The supported protocols are

continuous Modbus RTU.

• MCT 1302/A: version with analog output.

• MCT 1302/PROFINET: weight indicator with RS232, USB and PROFINET serial output.

• MCT 1302/ETHERNET IP: weight indicator with RS232, USB and ETHERNET IP serial output.

• MCT 1302/ETHERCAT: weight indicator with RS232, USB and ETHERCAT serial output.

• MCT 1302/PROFIBUS: weight indicator with RS232, USB and PROFIBUS serial output.

The analog output can also be present with the FIELDBUS option

PAVONE SISTEMI

Page 4

IDENTIFICATION PLATE OF THE INSTRUMENT

It is important to communicate this data, in case of request for information or indications concerning

the instrument, together with the program and version number, shown on the cover of the manual and

displayed when the instrument is switched on.

WARNINGS

The procedures listed below must be performed by specialized personnel.

All connections must be made when the instrument is switched off.

Page 5

TECHNICAL FEATURES

Power supply 18÷30 Vdc

Max. absorption 5 W

Isolation Class II

Installation category Cat. II

Working temperature -10°C ÷ +50°C (Max. humidity 85% without

condensation)

Storage temperature -20°C ÷ +70°C

Display Graphic 240x128 pixel LCD

Keyboard 4 wire resistive touch screen

Overall dimensions 150 x 95 x 26 mm (l x h x w) including terminal

blocks

150 x 95 x 56 mm (l x h x w) with FIELDBUS option

Drilling template: 138 x 82 mm

Assembly Panel Mount

Case material Aluminum

Connections Removable screw terminal blocks, 3.81 pitch.

Load cell power supply 5 Vdc/120 mA (max. 8 cells of 350 in parallel)

protected against short circuit

Input sensitivity 0.02 µV min.

Linearity < 0.01% of the full scale

Temperature drift < 0.001% of the full scale / C°

Internal resolution 24 bits

Displayed weight resolution Up to 999,999 divisions on the payload

Measuring range From -3.9 mV/V to +3.9 mV/V

Weight acquisition frequency 12 Hz - 1000 Hz

Digital filter Selectable 0,1 ÷ 250 Hz

Weight decimal number from 0 to 4 decimal places

Zero and Full Scale Calibration Automatic (theoretical) or executable from the

keyboard.

Logic outputs 6 opto-insulated (dry contact) max 24 Vdc / 100 mA

each

Logic inputs 6 opto-insulated at 24 Vdc PNP (external power

supply)

Serial port (#2) RS232C and RS422/485

Maximum cable length 15 m (RS232C) and 1000 m (RS422 and RS485)

Serial protocols ASCII, Modbus RTU

Baud rate 1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200 selectable

USB port: compliant with USB 2.0; speed up to 12 Mbps

Analog output (optional) 16-bit opto-insulated

Voltage: 0 ÷ 5/10 V (R min 10 KOhm),

Current: 0/4 ÷ 20 mA (R max 300 Ohm)

Analog output calibration From the keyboard

Linearity <0.02% FS

Thermal drift 0.001% FS/°C

Microcontroller: ARM Cortex M0 + 32 bit, 256 KB Flash

reprogrammable on-board from USB.

Data memory 64 Kbytes expandable up to 1024 Kbytes

Fieldbus (as an alternative to RS485) PROFINET, ETHERNET IP, ETHERCAT, PROFIBUS

Compliance with Standards EN61000-6-2, EN61000-6-3, EN61010-1,

EN45501

Rmax 2

82±1

138±1

94

149

80

136

52

5.0

20

30

149

94

MCT 1302

Page 6

INSTALLATION

GENERAL INFORMATION

The MCT 1302 is a compact panel mounting instrument made of aluminum.

The instrument is installed in a panel in a slot with a drilling template of 138 x 82 mm and is secured

by means of the 2 tensioning screws supplied.

The MCT 1302 must not be immersed in water, subjected to jets of water and cleaned or washed with

solvents.

Do not expose to heat or direct sunlight.

Do not install the instrument near power equipment (motors, inverters, contactors, etc.) or near devices

that do not comply with CE regulations for electromagnetic compatibility.

The connection cable for the load cells must have a maximum length of 140 m/mm².

The RS232 serial line must have a maximum length of 15 meters (EIA RS-232-C standards).

The warnings given on the connection of the individual peripheral devices must be observed.

OVERALL DIMENSIONS

237

146

202

32

169

20

68

37

M4

113

62

Page 7

MCT S 1302 DIMENSIONS

+

-

10÷30 Vdc

GND

123456789

1 2 3 4 5 6 7 8 9 15 16 17 18 19 20 21 22 2310 11 12 13 14 24 25 26

1 2 3 4 5 6 7 8 9 10 11 12 13 14

In 1

In 2

In 3

In 4

In 5

In 6

I Com

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

O Com

-Sig2

+Sig2

+Sig1

-Sig1

-Sense

+Sense

+Exc

-Exc

Shield

123456789

N.6 INPUTS N.6 OUTPUTS

LOAD CELL 1LC2

&

2008/ 9 5/ EC

USB

Device

17 18 19 20 21 22 23 24 25 26

TXD

RXD

SGND

S I/O +

S I/O -

AGND

Vout+

Iout+

+Vdc

GND

SERIAL Power

Supply

AN.

+

-

EXC-

EXC+

SENSE+

SENSE-

SIG-

SIG+

SHIELD

OUTPUTS

30 Vdc

100 mA Max

OUTPUT 2

OUTPUT 1

COM. OUTPUT

V+ (10 kΩ min)

Ana-

mA+ (300 Ω max)

RS485

INPUT 2

INPUT 3

INPUT 4

INPUT 5

INPUT 6

COM. INPUT

INPUT 1

OUTPUT 3

OUTPUT 4

OUTPUT 5

OUTPUT 6

TX-/RX-

TX+/RX+

ANALOG

OUTPUT

24 Vdc

100 mA Max

RS232

RXD

TXD

SGND

OPTIONAL

OUTPUT

OPTIONAL ETHERNET

FIELDBUS

+

-

25 +Vdc

Power Supply

24 Vdc

26 GND

Screw

Page 8

ELECTRICAL INSTALLATION

The MCT 1302 instrument uses for the electrical connection of the 3.81 mm removable screw terminal

blocks. The load cell cable must be shielded and channeled away from power cables to avoid elec-

tromagnetic interference.

The field wiring of the instrument must be suitable for the environment in which it will be used

and must comply with all national regulations.

A switch or disconnector must be included in the electrical system.

The switch must be close to the instrument and easily reachable by the operator.

The switch must be marked as a device to stop the machine.

The switch or circuit breaker used as a disconnecting device must comply with the applicable require-

ments of IEC 60947-1 and IEC 60947-3.

WARNING

Disconnect the power supply to the instrument before making electrical connections.

POWER SUPPLY OF THE INSTRUMENT

The instrument is powered through terminals 25 and 26. The power cable must be routed separately

from other cables.

The electric zero (terminal 26) is connected to the metal case. Connect

the terminal 26, in addition to the GND of the power supply, also

on the ground using the screw near the power terminals.

Supply voltage: 18÷30 Vdc, max 5W

3 +Signal

4 -Signal

5 -Sense

6 +Sense

7 +Exc.

8 -Exc

9 Shield

JBOX

+Exc-Exc

+Sig

-Sig

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

+EXC

-EXC

+SGN

-SGN

SHD

25 PIN CONNECTOR

+SGN

-ALM

+ALM

-SGN

+SNS

-SNS

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

+ALM

-ALM

+SGN

-SGN

SCH

SCH

SCH

SCH

SCH

2

3

6

1

5

4

7

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

J-BOX CGS4

FIELDBUS

MCT 1302

TX+/RX+

TX-/RX-

-SENSE

+SENSE

SHIELD

S I/O+

S I/O-

-SIG1

+SIG1

O COM

S.GND

Iout+

Vout+

I COM

AGND

OUT2

-EXC

+EXC

OUT1

OUT3

OUT4

OUT5

OUT6

IN3

IN4

IN5

IN2

IN1

RXD

TXD

24V

IN6

04

03

08

05

06

07

19

18

17

25

26

09

24

23

22

14

10

11

12

13

15

16

20

21

9

1

2

7

+

-

8

3

4

5

6

+24V

Page 9

LOAD CELL CONNECTION

The load cell cable must not be routed with other cables, but must follow its own path.

Any cable extension connections must be carefully shielded, respecting the color code and using the

cable of the type supplied by the manufacturer. The extension connections must be made by welding,

or through support terminal blocks or through the junction box supplied separately.

Up to a maximum of 8 350 ohm load cells in parallel can be connected to the instrument. The supply

voltage of the load cells is 5 Vdc and is protected by a temporary short circuit.

The measuring range of the instrument involves the use of load cells with sensitivity up to 3.9 mV/V.

The load cell cable must be connected to terminals 3 to 9. In the case of a 4-wire cell cable, jumper

the terminals 5 to 8 and 6 to 7.

Connect the load cell cable shield to terminal 9.

In case of use of two or more load cells, use appropriate junction boxes (CEM4/C or CSG4/C) of

which the connection is shown below.

1 In1

2 In2

3 In3

4 In4

5 In5.

6 In6

7 I Comm

+

-

24 Vdc

8 Out 1

9 Out 2

10 Out 3

11 Out 4

12 Out 5.

13 Out 6

14 O Comm

+

-

24 Vdc

Page 10

LOGIC INPUTS

The logic inputs are insulated from the instrument through optocouplers.

The connection cables of the logic inputs must not be channeled with power cables.

Use a shorter connection cable as possible.

To activate a logic input, it must be brought to the positive of a 24Vdc power supply while

the common item must be connected to its negative. The function of the inputs is established

in the relevant Setup menu.

LOGIC OUTPUTS

The 6 logic outputs are of the Photorelay (dry contact) type with a common item. The capacity of each

contact is 100 mA / 30Vdc. By enabling the output, the contact closes (NA contact).

The environment where the equipment is installed can normally be subject to strong magnetic

fields and electrical noise caused by the machinery present, so it is advisable to implement

the usual precautions in order to avoid that these affect the typical signals of a precision

electronic equipment. (filters on contactor, diodes on 24 Vdc relays, etc.)

The connection of the outputs is shown below

17 TX

18 RX

RS232

INTERFACE

RX

TX

19 GNDGND

MCT 1302

20 S I/O+

21 S I/O-

External

I/O Board

19

20

MCT 1302

Page 11

CONNECTION WITH ADDITIONAL INPUTS/OUTPUTS BOARD

In applications where additional inputs/outputs are required, optional I/O boards can be connected

using the dedicated serial connection.

To make the connection, use a shielded cable, taking care to connect the screen to ground at only one

of the two ends. If the cable has more conductors than those used, connect the free wires to the screen.

SERIAL RS232

COMMUNICATION

The serial connection cable must have a maximum length of 15 meters (EIA RS-232-C standards), beyond

which it is necessary to adopt the RS485 interface with which the instrument is equipped.

The cable must not be channeled with other cables (i.e. outputs connected to contactors or

power cables), but must possibly follow its own path.

The PC used for the connection must comply with the EN 60950 standard.

The RS232 serial port is normally used for PC, printer and repeater connections.

To make the serial connection, use a suitable shielded cable, taking care to connect the screen to ground

at only one of the two ends.

The serial connection cable must have a maximum length of 100 meters. The cable must

not be channeled with other cables, but must possibly follow its own path

15 TX+/RX+

16 TX-/RX-

USER

RS485

INTERFACE

TX+/RX+

TX-/RX-

MCT 1302

24 +mA

23 +Volt

ANALOG

INTERFECE

CURRENT

VOLTAGE

22 GNDGND

MCT 1302

Page 12

RS485

Through serial RS485 interface, it is possible to make serial connections for long distances (up to 1000 m).

The RS485 serial connection is of the 2-wire type, and allows to connect up to 32 instruments to a

single MASTER unit (personal computer, PLC, etc.) using a twisted and shielded cable, taking care to

connect the screen to the ground at only one of the two ends.

The cable must not be channeled with other cables (i.e. outputs connected to contactors or power ca-

bles), but must possibly follow its own path.

The PC used for the connection must comply with the EN 60950 standard.

NOTE: If there is a fieldbus, the RS485 is not available.

ANALOG OUTPUT (OPTIONAL)

The instrument provides an opto-insulated analog output in current and/or voltage.

Features:

• Analog voltage output: range from 0 to 10 Volt or from 0 to 5 Volt, minimum load 10K

• Analog current output: range from 0 to 20 mA or from 4 to 20 mA. The maximum load is 300.

To make the connection, use a shielded cable, taking care to connect the screen to ground at only one

of the two ends.

The analog sending can be sensitive to electromagnetic disturbances, it is therefore recommended that

the cables are as short as possible and that they follow their own path.

Warning: do not connect the analog output to active devices.

Page 13

USB DEVICE (SPECIFICATION 2.0 COMPLIANT, FULL-SPEED 12 MBPS)

Use this communication port to directly interface a PC via a USB port.

Use a standard USB cable for the connection.

To connect the instrument via the USB device port, the appropriate driver for the operating system used

must be installed on the PC. For the installation, follow the specific instructions.

FIELDBUS CONNECTIONS

As an alternative to the RS485 serial port, some of the most popular fieldbuses are available. Only

one fieldbus can be used, which must be specified when ordering.

ETHERNET CONNECTION

In the lower left part of the instrument there is an RJ45 connector for Ethernet network.

Features:

10 Mbps transmission speed

Network compatible with 10/100/1000 Base-T networks

Ethernet TCP, Modbus / TCP, UDP, IP, ICMP, ARP protocols

TCP server communication mode

Indicator LEDs (2) Ethernet line presence and communication/diagnostics

Buffer size 256 bytes

Connection Timeout Min. 30 seconds - Max. 90 seconds

Link Timeout (cable disconnected) 30 seconds

PIN DESCRIPTION

1 TX+

2 TX-

3 RX+

4

5

6 RX-

7

8

To connect to the MASTER, use an Ethernet twisted pair cable with the relevant RJ45 connector.

• The RJ45 Ethernet connection cable has a variable maximum length depending on the type of cable.

A common shielded Cat5 cable can have a maximum length of about 180 m.

• It is possible to connect the ethernet communication port directly to the PC, without switching from

other network devices (routers, switches, hubs, lan-bridges or other), but special RJ45 cables, called

“crossovers”, must be used.

• Usually the cables are “direct”, and allow the connection to network devices such as routers or hubs,

but not to directly connect two PCs (although currently there are network cards with auto-sensing

technology, which recognize the type of cable and the type of connection, allowing direct PC-PC

connections even using non-crossover cables).

• The following page shows the diagrams of the two types of cables mentioned above and the related

connection diagram.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

TX+

RX+

RX-

TX-

TX+

RX+

RX-

TX-

1TX+

2TX-

3RX+

6RX-

1 RX+

2 RX-

3 TX+

6 TX-

DIRECT ETHERNET CABLE

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

TX+

RX+

RX-

TX-

RX+

TX+

TX-

RX-

1TX+

2TX-

3RX+

6RX-

1 TX+

2 TX-

3 RX+

6 RX-

CROSSOVER ETHERNET CABLE

Page 14

ETHERNET/IP CONNECTION

Ethernet/IP is a real-time industrial protocol based on the Ethernet network.

There are 2 RJ45 connectors to allow the connection of several instruments under the same network.

Refer to the description above for connection notes and warnings.

Features:

10 and 100 Mbit operations, Full and Half Duplex

Modbus-TCP server

Up to 128 bytes of fieldbus I/O in every direction.

PROFINET CONNECTION

There are 2 RJ45 connectors to allow the connection of several instruments under the same network.

Refer to the previous page for connection notes and warnings.

Features:

PROFINET IO Real Time (RT) communications

Modbus-TCP server

Up to 128 bytes of fieldbus I/O in every direction.

ETHERCAT CONNECTION

EtherCAT is a real-time industrial protocol based on the Ethernet network.

The EtherCAT protocol requires that the RJ45 connectors have the function of IN and OUT.

By putting several MCT 1302 instruments in series, the MASTER will be connected to the IN connector

of the first MCT 1302 whose OUT connector will connect to the IN connector of the next, etc.

Refer to the previous page for connection notes and warnings.

3

8

15

9 6

B_LINE

A_LINE

Page 15

MAC ADDRESS IN THE INSTRUMENTS WITH ETHERNET INDUSTRIAL FIELDBUS.

The instruments that mount Hilscher modules with Industrial Ethernet protocol (Profinet, EthernetIP, Ether-

cat, etc.) have a label under the connectors, as shown below.

This label shows the MAC Address of the module (red box), an identification number of the module

(blue box) and a QR code that contains the MAC Address. The latter can be read with a smartphone

using a QR reading app i.e., on the Google Play Store, “QR Code Reader”).

PROFIBUS CONNECTION

Pin Signal Description

3 B line +RxD/+TxD, level RS485

4RTS Request to send

5 GND Ground (insulated)

6 + 5V Bus Output +5V end (insulated)

8 A line -RxD/-TxD, level RS485

Housing Cable shield

Internally connected to the protective

ground according to Profibus

specifications

To connect to the Profibus MASTER, use a standard Profibus cable. The typical impedance of the cable

should be between 100 and 130 Ohm (f > 100 kHz). The cable capacity (measured between conductor

and conductor) should be less than 60 pF/meter and the minimum conductor cross-section should not

be less than 0.22 mm2.

In a Profibus-DP network, both type A and type B cables can be used, depending on the required per-

formance. The following table summarizes the characteristics of the cable to be used:

Feature Type A cable Type B cable

Impedance 135 to 165 ohm (f = 3÷20 MHz) 100 to 300 ohm (f >100 kHz)

Capacity < 30 pF/m < 60 pF/m

Resistor < 110 ohm/km -

Conductor section > 0.34 mm2> 0.22 mm2

The following table shows the maximum length of the line with type A cable and with type B cable

according to the different communication speeds required:

Baudrate (kbit/s) 9.6 19.2 187.5 500 1500 3000 6000 12000

Length (m) of the type A cable 1200 1200 1000 400 200 100 100 100

Length (m) of the type B cable 1200 1200 600 200 - - - -

For reliable operation of the fieldbus, a line terminator should be used at both ends.

In case of multiple MCT 1302 instruments, use the line end only on an instrument.

For the setup of the board, the GSD file (hms_1810.gsd) is available and must be installed in the master.

149

94

MCT 1302

MCT 1302 - DOSAGGIO

PW1507 Rev. 0.9

Page 16

FRONT PANEL OF THE INSTRUMENT

The MCT 1302 is a touch screen instrument dedicated to batching applications.

The main operating characteristics are:

• Programmable recipes, standard - 100 recipes of 20 steps. With Alibi memory option - 1000

recipes with 20 steps.

• 50 programmable activities.

• Management of 38 configurable outputs (6 internal outputs to the instrument plus 8 outputs for each

connected I/O module; maximum 4 modules that can be connected to the instrument). Depending

on the type of activity, up to 2 outputs can be selected.

• Coarse and Fine batching control, tolerance control of the dosed weight and lack of product.

• Automatic repetition of the batching cycles.

• Management of the batched totals by activity and recipe.

The setup parameters are easily accessible and modifiable through the use of the function keys that

from time to time appear on the display used to select, edit, confirm and save the new settings.

DISPLAY

In the operating mode the display shows all the information necessary for a complete control of the

system. According to the various programming procedures, the display is used for programming the

parameters to be entered in the memory, i.e. messages indicating the type of operation being carried

out and therefore helping the operator in the management and programming of the instrument.

POWER UP OF THE INSTRUMENT

When switched on, the display temporarily shows an introductory mask, which shows the firmware

code and the version number. After a few seconds, the main screen is displayed, from which all the

instrument operations can be accessed.

Page 17

MAIN SCREEN

From this screen it is possible to access all the operational and programming functions of the instrument,

following the indicated commands.

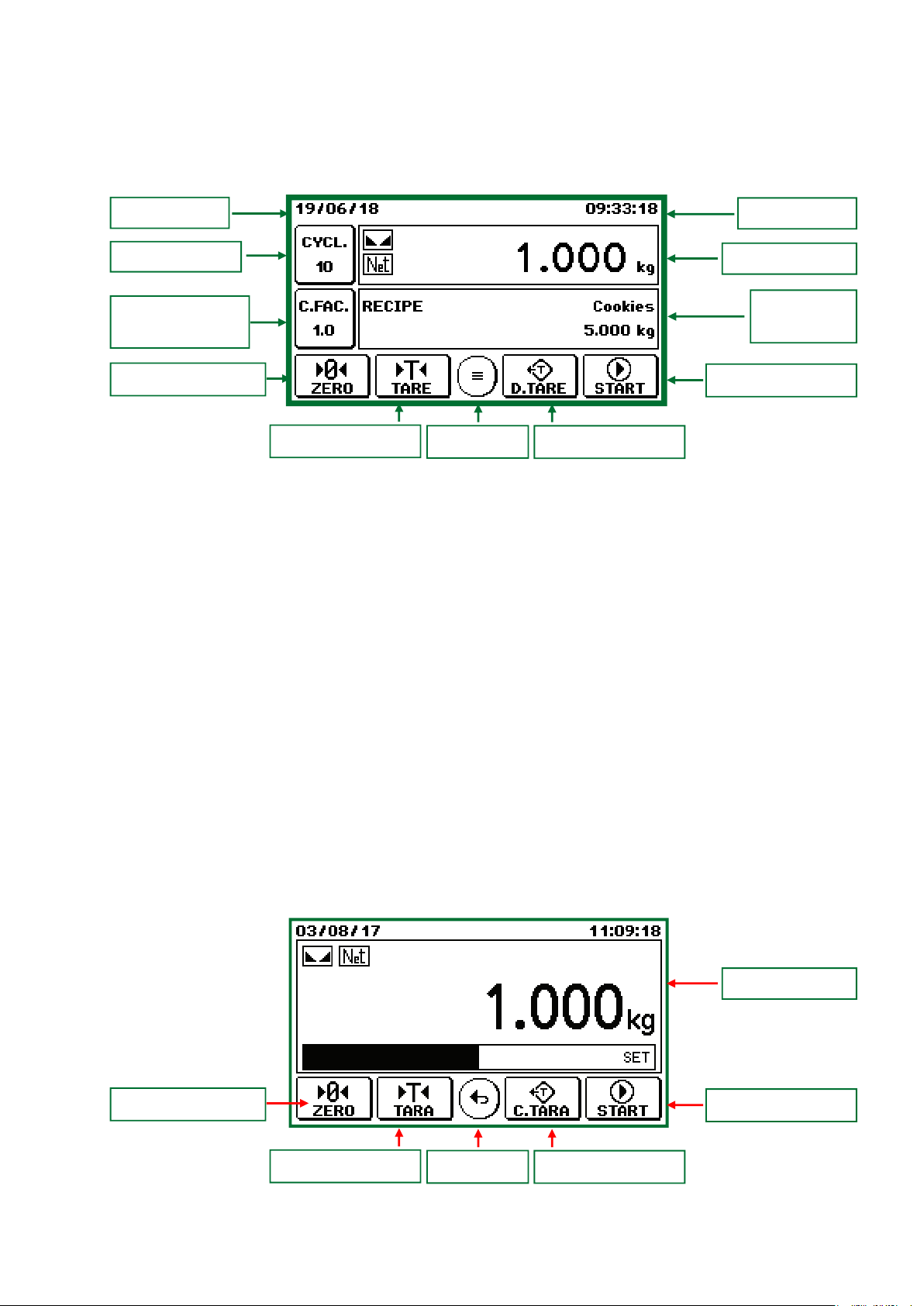

Date

The display mode of the main screen can be selected using the appropriate parameter in the “Opera-

ting Mode” menu:

• “Standard” main screen, in which all the quadrants are displayed (weight, recipe selection, cycle

setting, set correction factor setting, batching information).

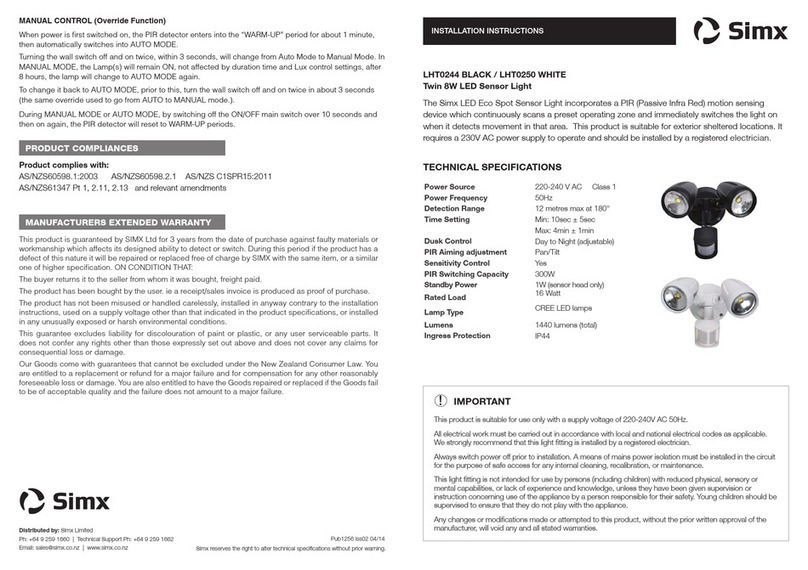

• Main screen “weight only”, in which only the weight dial is displayed. In this case the weight value

is displayed with a larger size than the standard display. Moreover, in case of batch in progress,

a bargraph is displayed, which represents the net weight batched in relation to the set value.

The “weight only” main screen is activated under the following conditions:

• After 5 seconds from switching on the instrument.

• After 5 seconds from the start of the batch.

To temporarily restore the “standard” main screen, press on the weight value. After 5 seconds the

“weight only” main screen appears again.

The functions of the operation keys (F1, F2, F3 and F4) can be programmed using the appropriate

parameters in the “Operating Mode” menu.

All the keys on the main screen can be locked using the appropriate parameters in the “Operating

Mode” menu.

Time

Batching cycles Weight quadrant

Recipe

quadrant

Recipe correction

factor

F1 Operation key

F2 Operation key F3 Operation key

F4 Operation key

Menu key

Weight quadrant

F1 Operation key

F2 Operation key F3 Operation key

F4 Operation key

Menu key

Page 18

OPERATION KEYS

Access to the parameter programming menu.

Press in the weight display dial to switch the weight display (net, gross).

Access to the recipe selection screen.

Press in the setting screen for the number of batching cycles.

Access to the recipe correction factor setting screen. The correction value

change creates the printout of the recipe with the recalculated batching

set point. The value is expressed in percentage or weight (Parameter

"CORRECTION MODE" - page 22)

Semi-automatic Zero Command.

Tare Command.

Deleting Tare Command.

Start batching command.

Weight Print Command

Table of contents

Other Pavone Systems Accessories manuals

Popular Accessories manuals by other brands

SImx

SImx LHT0244 installation instructions

Chef's Choice

Chef's Choice Trizor XV 15 instructions

URBAN VITAMIN

URBAN VITAMIN PASADENA PD user manual

Schüco

Schüco FWS 114 Technical manual

XLT Ovens

XLT Ovens XLT TS3-S Standard Series Installation & operation manual

URBAN VITAMIN

URBAN VITAMIN ALAMEDA user manual