XD-9010-TS3-S Rev A 04/2009

Installation & Operation Manual

1

WARNING & SAFETY INFORMATION

•Post in a prominent location instructions to be followed in the event you smell gas. This information

can be obtained by consulting your local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

liquids or vapors in the vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury, or death. Read the installation, operating and maintenance instructions

thoroughly before installing, using, or servicing this equipment.

•In the event a gas odor is detected, shut off the gas at the main shutoff valve immediately. Contact

your local Gas Company or supplier.

•Do not restrict the flow of combustion and/or ventilation air to the unit. Provide adequate clearance

for operating, cleaning, and maintaining the unit and adequate clearance for operating the gas shutoff

valve when the unit is in the installed position.

•Keep the area free and clear of combustible material.

•Ovens are certified for installation on combustible floors.

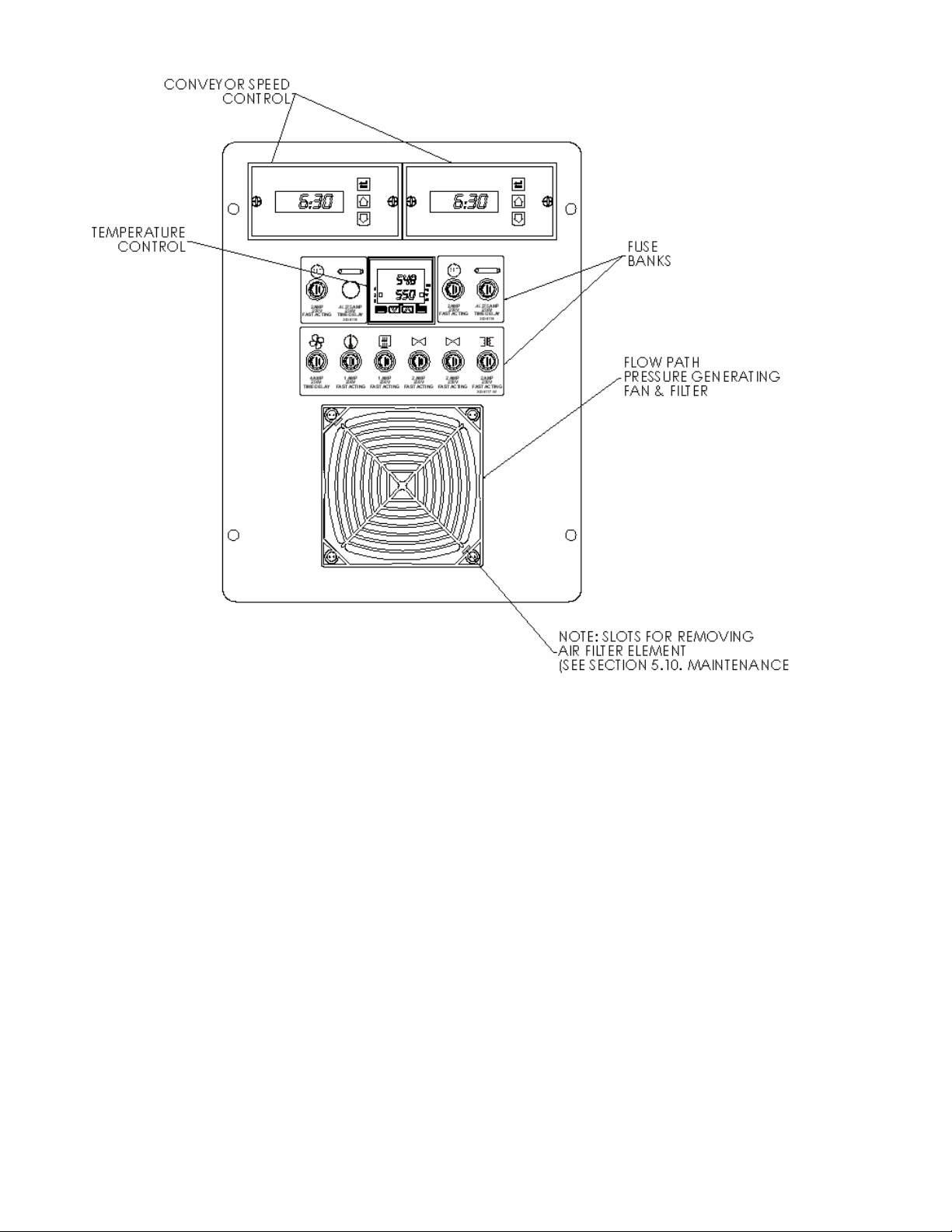

An electrical schematic is located inside the control box of the oven and on pages 31-33

of this manual. Disconnect input power to the unit before performing any maintenance.

•This unit requires a type II ventilation hood, which has make-up and exhaust air to ensure adequate air

supply. The installation should conform to local codes and the National Fire Protection Association

Code, ANSI/NFPA 70, and the National Electrical Code.

•This unit may be operated with either natural gas or propane fuel as designated on the nameplate label

located on the back of the unit.

•This unit must be operated by the same voltage, phase, and frequency of electrical power as

designated on the nameplate label located on the back of the unit.

•Minimum clearances must be maintained from combustible and noncombustible construction

materials. See Physical Location & Spacing Requirements on page 19.

•Follow all local codes when installing this unit. In the absence of local codes, the installation must

conform to the National Fuel Gas Code, ANSI Z223.1, latest version, Natural Gas Installation Code,

CAN/CGA-B149.1, or the Propane Installation Code, CAN/CGA-B149.2, as applicable.

•Follow all local codes to electrically ground the unit. The installation must conform to the National

Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable.

•PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.