1General Information

2020/03 9936073x-mub-en – V03 3

1General Information

Carefully read these instructions before installation and commissioning.

Save these instructions in the vicinity of the installation for future reference.

1.1 Scope of these instructions

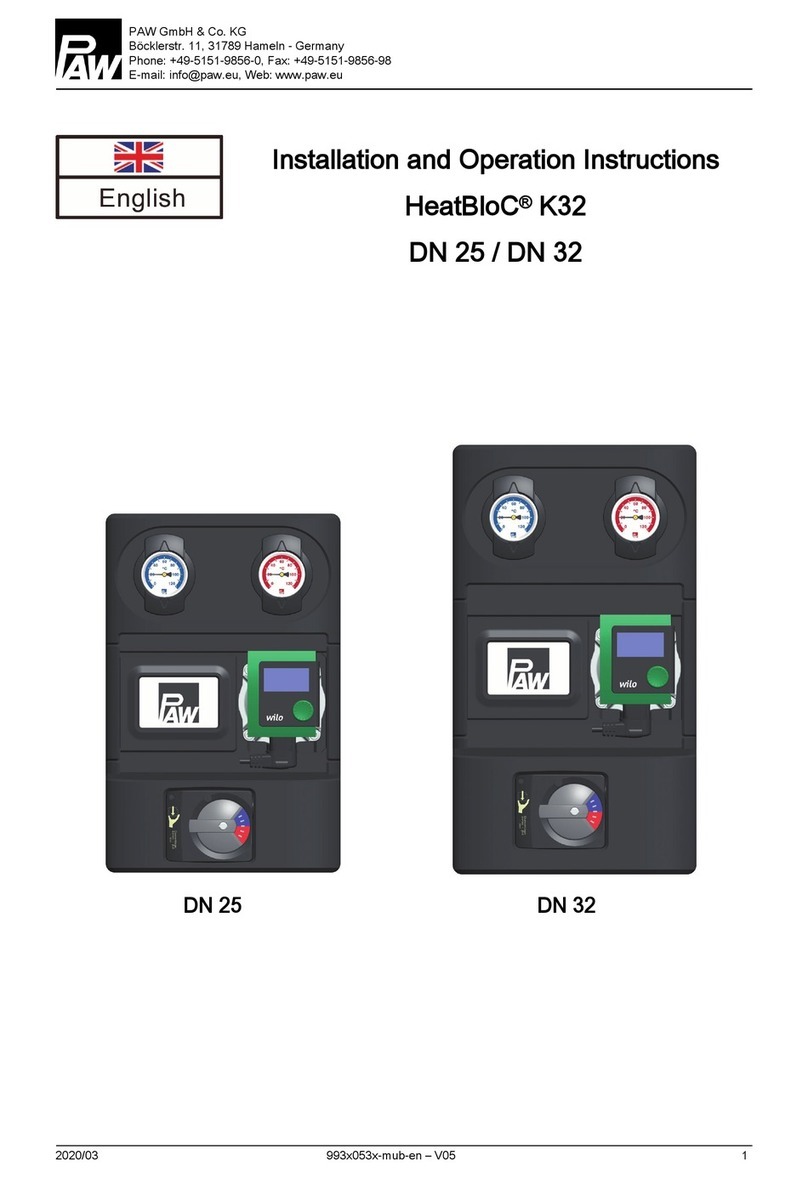

These instructions describe the installation, commissioning, function and the operation of

the mixed HeatBloC®K33 DN 25.

For other components of the installation, such as the pump, the controller or the modular

distribution manifold, please observe the instructions of the corresponding manufacturer.

The chapters called [specialist] are intended for specialists only.

1.2 Designated use

The HeatBloC®may only be used in heating circuits taking into consideration the technical

limit values indicated in these instructions.

The HeatBloC®must not be used in drinking water applications.

Improper usage of the HeatBloC®excludes any liability claims.

This product complies with the relevant directives and is therefore labelled with the CE mark.

The Declaration of Conformity is available upon request. Please contact the manufacturer.

Only use PAW accessories with the HeatBloC®.

The wrapping materials are made of recyclable materials and can be disposed of

with recyclable materials.

1.3 Disposal

Possibilities to return waste electrical and electronic equipment

Waste electrical and electronic equipment deriving from private households

can be disposed at collection points of the public waste management

authorities or at disposal points set up by manufacturers or distributors

according to the ElektroG (Electrical and Electronic Equipment Act).

You find an online directory of all collection and disposal points here:

https://www.ear-system.de/ear-verzeichnis/sammel-und-

ruecknahmestellen.jsf