PCB EX1503M42 User manual

Model EX1503M42

PRESSURE TRANSMITTER (500 PSI) CSA, ATEX, IECEx, ETL approved

Installation and Operating Manual

For assistance with the operation of this product,

contact the PCB Piezotronics, Inc.

Toll-free: 716-684-0001

24-hour SensorLine: 716-684-0001

Fax: 716-684-0987

E-mail: [email protected]

Web: www.pcb.com

Manual 21354 Rev E

ECN 50523

Repair and Maintenance

PCB guarantees Total Customer Satisfaction through its

“Lifetime Warranty Plus” on all Platinum Stock Products

sold by PCB and through its limited warranties on all other

PCB Stock, Standard and Special products. Due to the

sophisticated nature of our sensors and associated

instrumentation, field servicing and repair is not

recommended and, if attempted, will void the factory

warranty.

Beyond routine calibration and battery replacements

where applicable, our products require no user

maintenance. Clean electrical connectors, housings, and

mounting surfaces with solutions and techniques that will

not harm the material of construction. Observe caution

when using liquids near devices that are not hermetically

sealed. Such devices should only be wiped with a

dampened cloth—never saturated or submerged.

In the event that equipment becomes damaged or ceases

to operate, our Application Engineers are here to support

your troubleshooting efforts 24 hours a day, 7 days a

week. Call or email with model and serial number as well

as a brief description of the problem.

Calibration

Routine calibration of sensors and associated

instrumentation is necessary to maintain measurement

accuracy. We recommend calibrating on an annual basis,

after exposure to any extreme environmental influence,

or prior to any critical test.

PCB Piezotronics is an ISO-9001 certified company whose

calibration services are accredited by A2LA to ISO/IEC

17025, with full traceability to SI through N.I.S.T. In

addition to our standard calibration services, we also offer

specialized tests, including: sensitivity at elevated or

cryogenic temperatures, phase response, extended high

or low frequency response, extended range, leak testing,

hydrostatic pressure testing, and others. For more

information, contact your local PCB Piezotronics

distributor, sales representative, or factory customer

service representative.

Returning Equipment

If factory repair is required, our representatives will

provide you with a Return Material Authorization (RMA)

number, which we use to reference any information you

have already provided and expedite the repair process.

This number should be clearly marked on the outside of

all returned package(s) and on any packing list(s)

accompanying the shipment.

Contact Information

PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY14043 USA

Toll-free: (800) 828-8840

24-hour SensorLine: (716) 684-0001

Repair inquiries: rma@pcb.com

For a complete list of distributors, global offices and sales

representatives, visit our website, www.pcb.com.

Safety Considerations

This product is intended for use by qualified personnel

who recognize shock hazards and are familiar with the

precautions required to avoid injury. While our equipment

is designed with user safety in mind, the protection

provided by the equipment may be impaired if equipment

is used in a manner not specified by this manual.

Discontinue use and contact our 24-Hour Sensorline if:

Assistance is needed to safely operate equipment

Damage is visible or suspected

Equipment fails or malfunctions

For complete equipment ratings, refer to the enclosed

specification sheet for your product.

Definition of Terms and Symbols

The following symbols may be used in this manual:

DANGER

Indicates an immediate hazardous

situation, which, if not avoided, may

result in death or serious injury.

Manual 21354 Rev E

ECN 50523

CAUTION

Refers to hazards that could damage

the instrument.

NOTE

Indicates tips, recommendations and

important information. The notes

simplify processes and contain

additional information on particular

operating steps.

The following symbols may be found on the equipment

described in this manual:

This symbol on the unit indicates that

high voltage may be present. Use

standard safety precautions to avoid

personal contact with this voltage.

This symbol on the unit indicates that

the user should refer to the operating

instructions located in the manual.

This symbol indicates safety, earth

ground.

Manual 21354 Rev E

ECN 50523

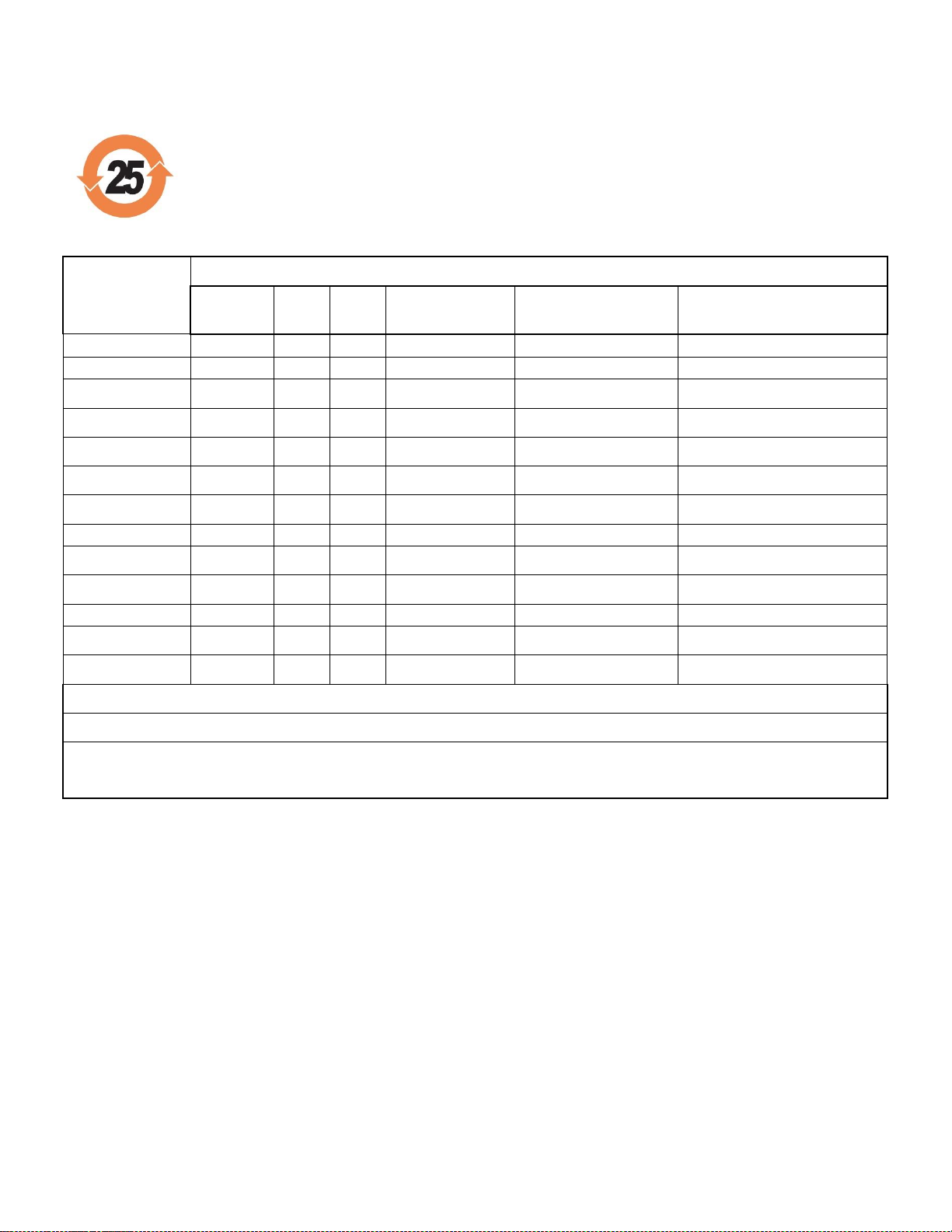

PCB工业监视和测量设备 - 中国RoHS2公布表

PCB Industrial Monitoring and Measuring Equipment - China RoHS 2 Disclosure Table

部件名称

有害物质

铅(Pb)

汞

(Hg)

镉

(Cd)

六价铬(Cr(VI))

多溴联苯 (PBB)

多溴二苯醚(PBDE)

住房

O

O

O

O

O

O

PCB板

X

O

O

O

O

O

电气连接器

O

O

O

O

O

O

压电晶体

X

O

O

O

O

O

环氧

O

O

O

O

O

O

铁氟龙

O

O

O

O

O

O

电子

O

O

O

O

O

O

厚膜基板

O

O

X

O

O

O

电线

O

O

O

O

O

O

电缆

X

O

O

O

O

O

塑料

O

O

O

O

O

O

焊接

X

O

O

O

O

O

铜合金/黄铜

X

O

O

O

O

O

本表格依据 SJ/T 11364 的规定编制。

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

铅是欧洲RoHS指令2011/65/ EU附件三和附件四目前由于允许的豁免。

CHINA RoHS COMPLIANCE

Manual 21354 Rev E

ECN 50523

Component Name

Hazardous Substances

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Chromium VI

Compounds

(Cr(VI))

Polybrominated

Biphenyls (PBB)

Polybrominated

Diphenyl Ethers

(PBDE)

Housing

O

O

O

O

O

O

PCB Board

X

O

O

O

O

O

Electrical Connectors

O

O

O

O

O

O

Piezoelectric Crystals

X

O

O

O

O

O

Epoxy

O

O

O

O

O

O

Teflon

O

O

O

O

O

O

Electronics

O

O

O

O

O

O

Thick Film Substrate

O

O

X

O

O

O

Wires

O

O

O

O

O

O

Cables

X

O

O

O

O

O

Plastic

O

O

O

O

O

O

Solder

X

O

O

O

O

O

Copper Alloy/Brass

X

O

O

O

O

O

This table is prepared in accordance with the provisions of SJ/T 11364.

O: Indicates that said hazardous substance contained in all of the homogeneous materials for this part is below the limit

requirement of GB/T 26572.

X: Indicates that said hazardous substance contained in at least one of the homogeneous materials for this part is above the limit

requirement of GB/T 26572.

Lead is present due to allowed exemption in Annex III or Annex IV of the European RoHS Directive 2011/65/EU.

Model Number

EX1503M 42 PRESSURE TRANSMITTER Revision: NR

ECN #: 53014

Performance ENGLISH SI

Measurement Range 500 psig 3,447 kPa

Output 4-20 mA 4-20 mA [1]

Accuracy ≤ .35 % FS ≤ .35 % FS [2]

Linearity ≤ .25 % FS ≤ .25 % FS

Hysteresis ≤ 0.2 % FS ≤ 0.2 % FS

Repeatability ≤ 0.1 % FS ≤ 0.1 % FS [3]

Zero Output Tolerance ± 0.3 % FS ± 0.3 % FS [1]

Span Tolerance ± 0.3 % FS ± 0.3 % FS [1]

Resolution ≤ 150 mpsi ≤ 1.03 kPa [3]

Resonant Frequency > 2 kHz > 2 kHz

Environ mental

Proof Pressure 2 x FS 2 x FS

Burst Pressure 3 x FS 3 x FS

Temperature Range(Operating) -65 to +300 °F -55 to +149 °C

Temperature Range(Compensated) -40 to +250 °F -40 to +121 °C

Thermal Error(Span) ± 2 % FS ± 2 % FS [4]

Thermal Error(Zero Shift) ± 2 % FS ± 2 % FS [4]

Acceleration Sensitivity(Maximum)(any

direction)

≤ 0.005 %FS/g ≤ 0.05 % FS / (m/s²)

Maximum Shock 1,000 g pk 9,800 m/s² pk

Vibration Survivability 50 g pk 495 m/s² pk

Hazardous Area Approval See Manual See Manual

Electrical

Supply Voltage 15 to 28 VDC 15 to 28 VDC

Electrical Isolation(at 50 VDC) > 100 MOhm > 100 MOhm

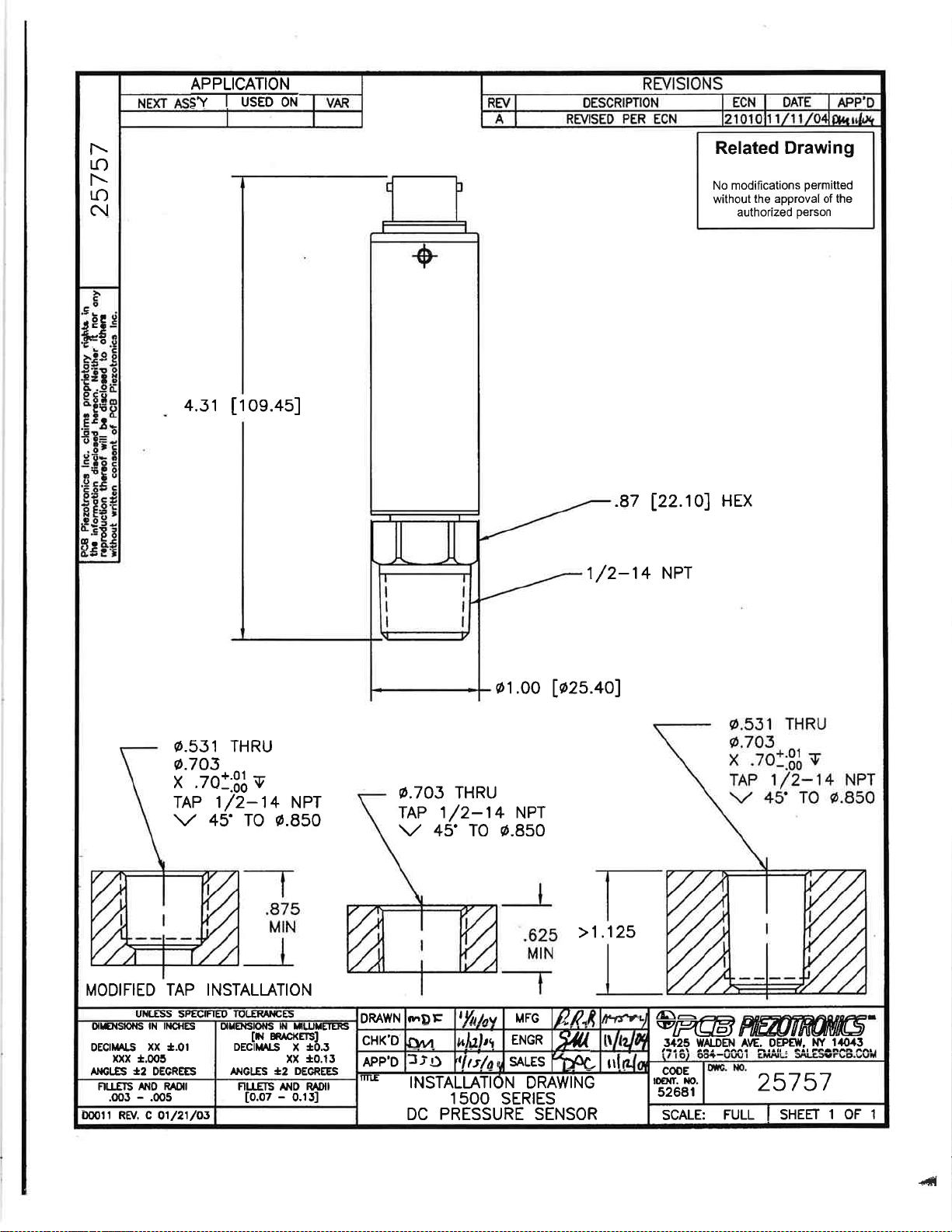

Physical

Sensing Element Foil Strain Gage (Full Bridge) Foil Strain Gage (Full Bridge)

Pressure Port 1/2-14 NPT 1/2-14 NPT

Thread External External

Dead Volume 0.3 in³ 4,900 mm³ [3]

Wetted Parts Material 17-4 PH Stainless Steel 17-4 PH Stainless Steel

Housing Material 304/304L Stainless Steel 304/304L Stainless Steel

Electrical Connector 6-Pin Bayonet Jack 6-Pin Bayonet Jack

Electrical Connections(Pin A) Pos (+) Power/Signal Pos (+) Power/Signal

Electrical Connections(Pin D) Neg (-) Power/Signal Neg (-) Power/Signal

Weight(without cable) 5.36 oz 152 gm

[5]

[6]

All specifications are at room temperature unless otherwise specified.

In the interest of constant product improvement, we reserve the right to change specifications without notice.

ICP® is a registered trademark of PCB Piezotronics, Inc.

OPTION AL VERSION S

Optional versions have identical specifications and accessories as listed for the standard model except

where noted below. More than one option may be used.

NOTES:

[1]Adjustable.

[2]Combined least squares linearity, hysteresis and repeatability.

[3]Typical.

[4]Over compensated temperature range.

[5]See PCB Declaration of Conformance PS231 for details

[6]See Model's “Instructions For Use” (IFU) for North American Conformity and Certification

Statements.

Date: 07/12/2022 Date: 07/12/2022 Date: 07/12/2022 Date: 07/12/2022 76573

Entered: ND Engineer: RPF Sales: DPC Approved: RPF Spec Number:

Phone: 716-684-0001

Fax: 716-684-0987

E-Mail: info@pcb.com

3425 Walden Avenue, Depew, NY 14043

1

1

2

2

3

3

4

4

A A

B B

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

69269

CODE

IDENT. NO.

52681

DWG. NO.

SCALE: SHEET

DRAWN CHECKED ENGINEER

TITLE

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

DECIMALS X ` .05

XX ` .01

XXX ` .005

ANGLES ± 2 DEGREES

FILLETS AND RADII .003 - .005

HEX DIMENSIONS ARE:

≤ .5 + .000 / - .003

> .5 + .000 / - .005

REMOVE ALL BURRS

SHARP = R.000 - R.003

INTERNAL THREAD DEPTH MIN.

3425 WALDEN AVE. DEPEW, NY 14043

(716) 684-0002 E-MAIL: [email protected]

XXXX ` .0005

APPROVAL

INTERCONNECTION 69269

1 OF 2NONE

JJF 3/25/22 JJF 3/25/22 RF 3/25/22

REVISIONS

REV DESCRIPTION DIN

NR RELEASED TO DRAFTING 52686

CAUTION

ELECTROSTATIC

DISCHARGE SENSITIVE

SCHEDULE DRAWING

NO MODIFICATIONS PERMITTED

WITHOUT REFERENCE TO THE

NOTIFIED BODY

1

1

2

2

3

3

4

4

A A

B B

PCB Piezotronics Inc. claims proprietary rights in

the information disclosed hereon. Neither it nor any

reproduction thereof will be disclosed to others

without the written consent of PCB Piezotronics Inc.

69269

REVISIONS

REV DESCRIPTION DIN

- SEE SHEET 1 -

CODE

IDENT. NO.

52681

DWG. NO.

SCALE: SHEET

DRAWN CHECKED ENGINEER

TITLE

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

DECIMALS X ` .05

XX ` .01

XXX ` .005

ANGLES ± 2 DEGREES

FILLETS AND RADII .003 - .005

HEX DIMENSIONS ARE:

≤ .5 + .000 / - .003

> .5 + .000 / - .005

REMOVE ALL BURRS

SHARP = R.000 - R.003

INTERNAL THREAD DEPTH MIN.

3425 WALDEN AVE. DEPEW, NY 14043

(716) 684-0002 E-MAIL: [email protected]

XXXX ` .0005

APPROVAL

INTERCONNECTION 69269

2 OF 2NONE

JJF 3/25/22 JJF 3/25/22 RF 3/25/22

CAUTION

ELECTROSTATIC

DISCHARGE SENSITIVE

SCHEDULE DRAWING

NO MODIFICATIONS PERMITTED

WITHOUT REFERENCE TO THE

NOTIFIED BODY

IECEx Certificate

of Conformity

INTERNATIONAL ELECTROTECHNICAL COMMISSION

IEC Certification System for Explosive Atmospheres

for rules and details of the IECEx Scheme visit www.iecex.com

Certificate No.: IECEx ETL 20.0037X

Status: Current

Date of Issue: 2021-02-24

Applicant: PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY 14043

United States of America

Equipment: EX1503 Series Pressure Sensor

Optional accessory:

Type of Protection: Intrinsic Safety "ia", Non arcing 'nA"

Marking:

Page 1 of 4

Issue No: 0

Certificate history:

Ex ia IIC T4 Ga

Ex nA IIC T4 Gc

-40°C ≤ Tamb ≤ +121°C

IECEx ETL 20.0037X

1.

2.

3.

Approved for issue on behalf of the IECEx

Certification Body:

Position:

Signature:

(for printed version)

Date:

This certificate and schedule may only be reproduced in full.

This certificate is not transferable and remains the property of the issuing body.

The Status and authenticity of this certificate may be verified by visiting www.iecex.com or use of this QR Code.

Certificate issued by:

Intertek

3933 US Route 11 South

Cortland NY 13045-2995

United States of America

Kevin J. Wolf

Certification Officer

2021-02-24

IECEx Certificate

of Conformity

Certificate No.: IECEx ETL 20.0037X

Date of issue: 2021-02-24

Page 2 of 4

Issue No: 0

Manufacturer: PCB Piezotronics, Inc.

3425 Walden Ave.

Depew, NY 14043

United States of America

Additional

manufacturing

locations:

This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the

IEC Standard list below and that the manufacturer's quality system, relating to the Ex products covered by this certificate, was assessed and

found to comply with the IECEx Quality system requirements.This certificate is granted subject to the conditions as set out in IECEx Scheme

Rules, IECEx 02 and Operational Documents as amended

STANDARDS :

The equipment and any acceptable variations to it specified in the schedule of this certificate and the identified documents, was found

to comply with the following standards

IEC 60079-0:2017

Edition:7.0

Explosive atmospheres - Part 0: Equipment - General requirements

IEC 60079-11:2011

Edition:6.0

Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i"

IEC 60079-15:2010

Edition:4

Explosive atmospheres - Part 15: Equipment protection by type of protection "n"

This Certificate does not indicate compliance with safety and performance requirements

other than those expressly included in the Standards listed above.

TEST & ASSESSMENT REPORTS:

A sample(s) of the equipment listed has successfully met the examination and test requirements as recorded in:

Test Reports:

Quality Assessment Report:

US/ETL/ExTR20.0043/00 US/ETL/ExTR20.0044/00

NL/DEK/QAR14.0004/04

IECEx Certificate

of Conformity

Certificate No.: IECEx ETL 20.0037X

Date of issue: 2021-02-24

Page 3 of 4

Issue No: 0

EQUIPMENT:

Equipment and systems covered by this Certificate are as follows:

SPECIFIC CONDITIONS OF USE: YES as shown below:

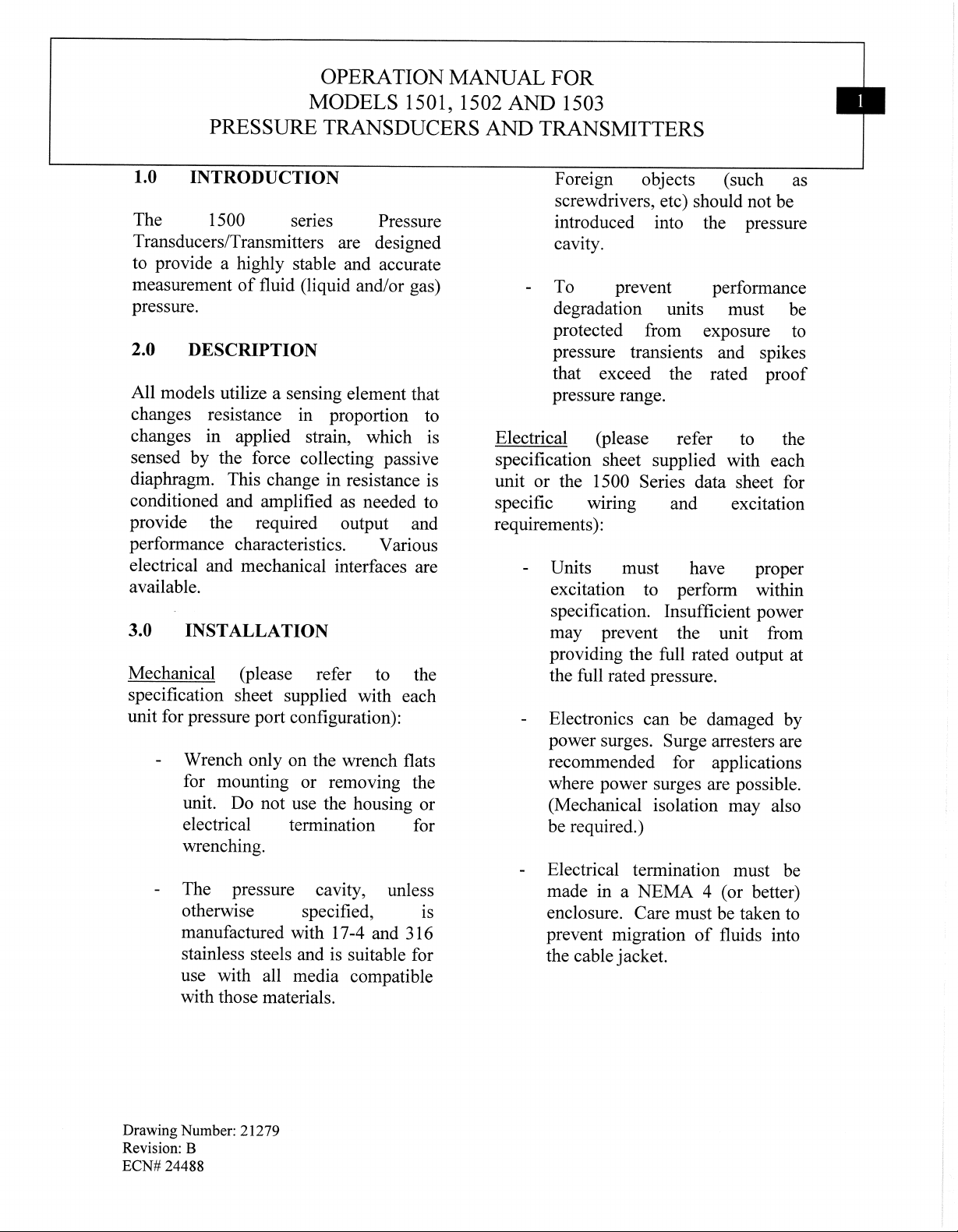

The equipment covered by this certificate are PCB Pressure Sensors with strain gage sensing elements and built-in electronics. The

equipment provides a 4-20mA current output when subjected to mechanical motion (pressure). These sensors are designed to be energy

limited. The equipment rating is 28 VDC. The equipment entity parameter ratings for 'ia' are Ui = 28V, Ii = 100mA, Pi = 0.65W, Ci = 0F, Li =

2.4μH.

•

•

•

The specific conditions for protection method “ia” is that a protected apparatus must only be connected to certified associated intrinsically

safe equipment and this combination must be compatible regarding intrinsic safety rules.

The specific conditions for protection method “nA” is connected cable and the connector must provide a minimum ingress protection of

IP54, when assessed according to IEC 60079-0 and IEC 60079-15. Unused connector must be fitted with an appropriately rated blanking

cover.

The end user is to use and Ex certified IP 54 minimum plug with the socket.

IECEx Certificate

of Conformity

Certificate No.: IECEx ETL 20.0037X

Date of issue: 2021-02-24

Page 4 of 4

Issue No: 0

Equipment (continued):

Annex:

103974085CRT-001 - Annex for IECEx Certificate.pdf

EX1503xyyy Series Pressure Sensors where:

x = A through Z Family Code

yyy = 01 through 999 indicating variations in sensitivity, mounting thread or adaptor.

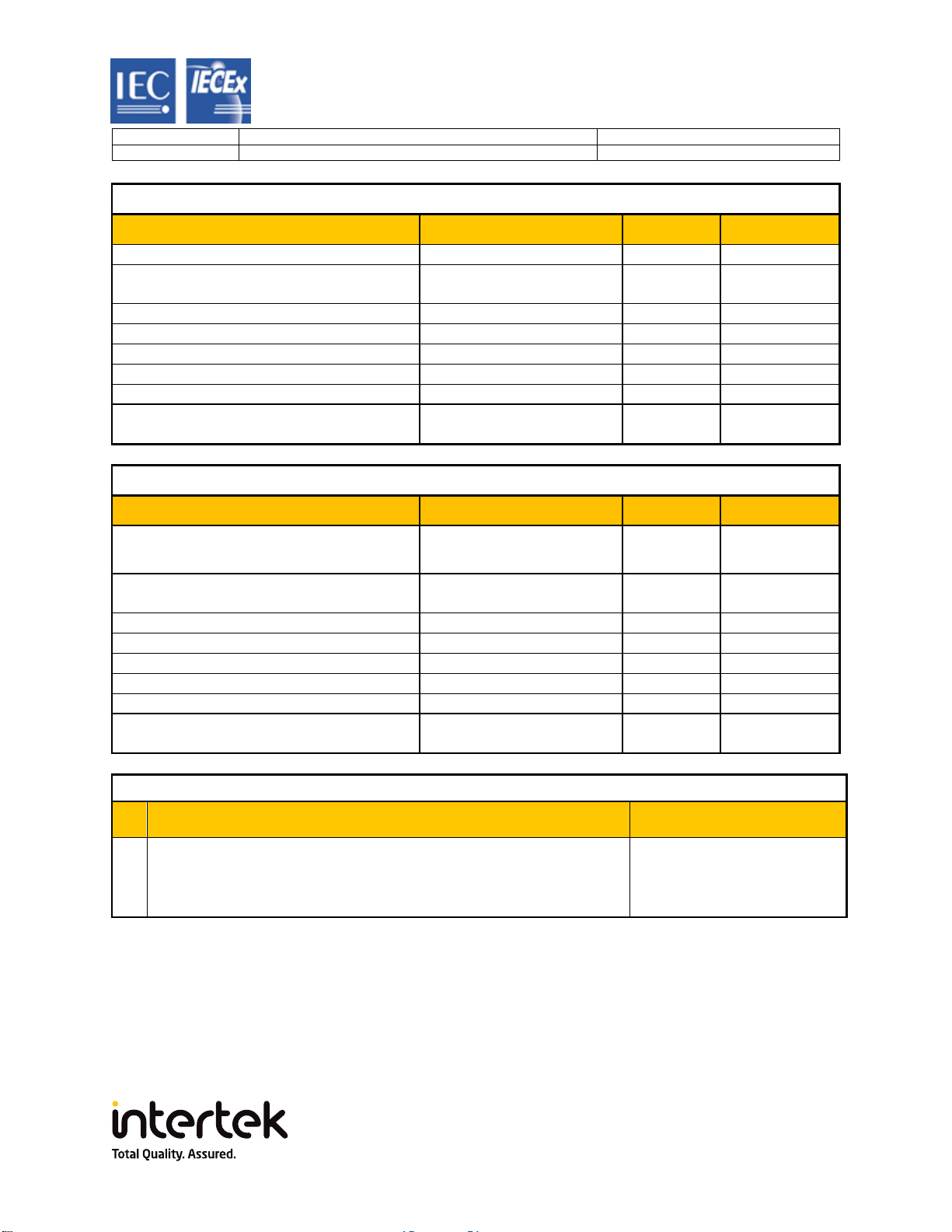

Annex to IECEx Certificate of Conformity

Certificate No:

IECEx ETL 20.0037X

Issue No. 0

Annex No. 1

Certificate issued by:

Intertek Testing Services NA

3933 Us Route 11, Cortland, NY

13045 USA

Page 1 of 1

SFT-IECEx-OP-19f (26 October 2018)

Technical Documents ‘nA’

Title:

Drawing No.:

Rev. Level:

Date:

IECEx Technical File Non-Arcing (Sheets: 2)

69279

NR

April 9, 2018

Descriptive Notice For The Certification Of PCB

Pressure Sensors

69277

NR

April 9, 2018

Approval Board Assembly

74229

NR

-

Etching Drawing

69272

NR

-

Approval Schematic & BOM (Sheets: 2)

69297

NR

1/4/2021

Approval Assembly Model EX1503 Series

74226

NR

1/4/2021

Approval Interconnection (Sheets: 2)

69269

NR

1/4/2021

Instructions For Use –EX1503 Series Pressure

Sensors (Sheets: 2)

69307

NR

-

Technical Documents ‘ia’

Title:

Drawing No.:

Rev. Level:

Date:

IECEx Technical File

Intrinsic Safety (Sheets: 2)

69278

NR

April 9, 2018

Descriptive Notice For The Certification Of PCB

Pressure Sensors

69276

NR

April 9, 2018

Approval Board Assembly

74229

NR

-

Etching Drawing

69272

NR

1/4/2021

Approval Schematic & BOM (Sheets: 2)

69297

NR

1/4/2021

Approval Assembly Model EX1503 Series

74226

NR

1/4/2021

Approval Interconnection (Sheets: 2)

69269

NR

1/4/2021

Instructions For Use –EX1503 Series Pressure

Sensors (Sheets: 2)

69307

NR

-

Required Manufacturer Routine Testing

Test

Title/Description of Test

Standard and Clause

1

Dielectric Strength Test

•A routine dielectric strength test shall be carried out in accordance with

Clause 23.2.1. Alternatively, a test shall be carried out at 1.2 times the

test voltage but maintained for at least 100ms.

IEC 60079-15 Clause 23.2.1

TYPE-EXAMINATION CERTIFICATE

This Certificate is for the exclusive useofIntertek's client and isprovidedpursuant tothe agreement between Intertekand its Client. Intertek's

responsibilityand liability are limitedto the terms and conditions of the agreement. Intertek assumes no liability to any party, other than to the Client in

accordance with the agreement, for any loss, expense or damage occasioned by the use of this Certificate.Only the Client is authorized to permit copying

or distribution of this Certificate and then only in itsentirety. Anyuse of the Intertek name or one of its marks forthe sale or advertisement of the tested

material, product or service must first be approved in writing by Intertek.

Intertek Italia S.p.A. Via Miglioli, 2/A - 20063 Cernuscosul Naviglio, Milano - Italy

LFT-EMEA-IT-ATEX-OP -23p (29 August2019) Page 1 of 3

Certificate issue date

Todd L. Relyea

Certification Officer

Intertek Italia S.p.A.

31 March 2021

1. Type-examination Certificate (Module A)

2. Equipment or Protective System intended for use in potentially explosive atmospheres (Directive

2014/34/EU)

3. Type examination certificate Nr

ITS-I21ATEX28703X R.0

4. Product:

EX1503 Series Pressure Sensors

5. Manufacturer:

PCB Piezotronics, Inc.

Applicant:

PCB Piezotronics, Inc.

6. Address:

3425 Walden Ave

Depew, NY 14043

USA

Address:

3425 Walden Ave

Depew, NY 14043

USA

7. This product and any acceptable variation thereto are specified in the schedule to this certificate and therein referred to.

8. INTERTEK ITALIA S.p.A., certifies that the equipment or protective system has been found to comply with the essential

Health and Safety Requirements relating to the design and construction of equipment and protective system intended for

use in potentially explosive atmosphere, given in Annex II of the Directive.

The examination and tests results are recorded in confidential technical evaluation Intertek Report Nr. 103974085CRT-

004b.

9. Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN IEC 60079-0:2018

and EN 60079-15:2010…except in respect of those requirements referred to at item 16 of the Schedule

10. If the sign X is placed after the certificate number, it indicates that the product is subject to Special Conditions for Safe

Use specified in the schedule to this certificate.

11. This Type Examination Certificate relates only to the design and construction of the specified product. Further

requirements of the Directive apply to the manufacturing process and supply of this product. These are not covered by

this certificate.

12. The marking of the product shall include the following:

II 3 G

Ex nA IIC T4 Gc

Tamb: -40°C to +121°C

SCHEDULE

TYPE EXAMINATION CERTIFICATE NUMBER: ITS-I21ATEX28703X R.0

LFT-EMEA-IT-ATEX-OP -23p (29 August2019) Page 2 of 3

13. DESCRIPTION OF THE EQUIPMENT OR PROTECTIVE SYSTEM

The equipment covered by this certificate are PCB Pressure Sensors withstrain gage sensingelements and built-

in electronics. The equipment provides a 4-20mA current output when subjected to mechanicalmotion

(pressure). Thesesensorsare designed tobe energy limited. The equipment ratings are Ui = 28V, Ii = 100mA, Pi

= 0.65W, Ci = 0F, Li = 2.4μH.

EX1503xyyy Series Pressure Sensors where:

x = A through Z Family Code

yyy = 01 through 999 indicating variations in sensitivity, mounting thread or adaptor.

14. DRAWINGS AND DOCUMENTS

TITLE

DOCUMENT Nr

LEVEL

DATE

ATEX Technical File Non-Arcing (Sheets: 2)

34627

NR

April 9, 2018

Descriptive Notice For The Certification Of PCB Pressure

Sensors

34628

NR

April 9, 2018

ApprovalBoard Assembly

74229

NR

-

Etching Drawing

69272

NR

-

ApprovalSchematic & BOM (Sheets: 2)

69297

NR

1/4/2021

ApprovalAssembly ModelEX1503 Series

74226

NR

1/4/2021

ApprovalInterconnection (Sheets: 2)

69269

NR

1/4/2021

Instructions For Use –EX1503 Series Pressure Sensors

(Sheets: 2)

69307

NR

-

Copies of the above listed documents are kept at Intertek Italia S.p.A. archive.

15. SPECIAL CONDITIONS FOR SAFE USE

The apparatus must be onlyconnected to an equipment whose electricalparameters are compatible with the

electrical parameters. The apparatus shall be connected according to drawing 69269 (page 2/2). The connected

cable and the connectormust provide a minimum ingress protection of IP54, when assessed according to EN

60079-0 and EN60079-15. Unused connectormust be fitted with an appropriately rated blanking cover.

16. ESSENTIAL HEALTH AND SAFETY REQUIREMENTS

The relevant essentialHealth and Safety Requirements have been identified and assessed in Intertek Report Nr.

103974085CRT-004b Revision 0 dated 103974085CRT-004b

SCHEDULE

TYPE EXAMINATION CERTIFICATE NUMBER: ITS-I21ATEX28703X R.0

LFT-EMEA-IT-ATEX-OP -23p (29 August2019) Page 3 of 3

17. ROUTINE (FACTORY) TESTS

Dielectric Strength Test

•A routine dielectric strength testshall be carried out in accordance with Clause 23.2.1. Alternatively, a

test shall be carried out at 1.2 times the test voltage but maintained for at least100ms.

Table of contents

Popular Transmitter manuals by other brands

NIVELCO

NIVELCO AnaCONT LE-100 Installation and programming manual

BWI Eagle

BWI Eagle AIR-EAGLE SR PLUS manual

Williams Sound

Williams Sound PPA T46 Instructions for use and care

Dwyer Instruments

Dwyer Instruments Magnesense MS Series Installation and operating instructions

SY Electronics

SY Electronics MFT-31C user manual

Crestron

Crestron DigitalMedia DM-TX-300N Operation guide

JUMO

JUMO dTRANS p02 DELTA operating manual

Lectrosonics

Lectrosonics UM400AV instruction manual

Emerson

Emerson Rosemount MultiVariable 3051SMV quick start guide

Pyle view

Pyle view PLVWGM3 supplementary guide

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA PH 200 - REV 4 instruction manual

KMC Controls

KMC Controls THE-1102 installation guide