pcl TE3 Instruction manual

76442 Issue 2 www.pclairtechnology.com

TE3 Digital test unit - Quick Start Manual

Safety Guidelines

This manual contains information that is very important to know

and understand. This information is provided for safety and to

prevent equipment problems. To help recognise this information,

observe the following symbols.

Danger indicates an imminently hazardous

situation which if not avoided WILL result

in death or serious injury.

Warning indicates a potentially hazardous

situation which if not avoided, COULD

result in death or serious injury.

Caution indicates a potentially minor or

moderate injury.

Notice indicates important information,

that if not followed, may cause damage to

equipment.

Unpacking

After unpacking the unit, inspect carefully for any damage that

may have occurred during transit.

Do not operate unit if damaged during

shipping, handling or use.

General Safety Information

The operator of this product must take the necessary precautions

to prevent the level of danger indicated by these symbols. The

operator is required to read and understand this instruction

manual and all safety warnings, labels etc.

Any employer allowing the use of this product in their field of work

must distribute this instruction manual to all users. The employer

must also ensure all users read, understand and follow the

instructions as described in the manual, safety warnings, labels,

etc.

Read and understand all safety warnings

and instructions before operating this

product. Failure to read and follow all

safety warnings may result in serious

personal injury or death.

Property damage and/or product damage

may also occur if all warnings are not

followed.

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

1. Do not expose the product to flammable gases,

vapours or fumes

2. Do not store flammable gases in or near this product

3. Never use flammable or toxic solvents to clean the

product or any of the unit's parts

4. Never remove or alter any safety warning labels, tags,

etc. located or provided with product.

5. Follow all directions for maintenance.

The use of other than genuine PCL replacement parts may

result in reduced equipment performance. Repairs must be

performed by authorised repair personnel, otherwise the

warranty will be void.

PART NUMBER TE3

SERIAL NUMBER

PCL TE3 Digital Test Unit

www.pclairtechnology.com

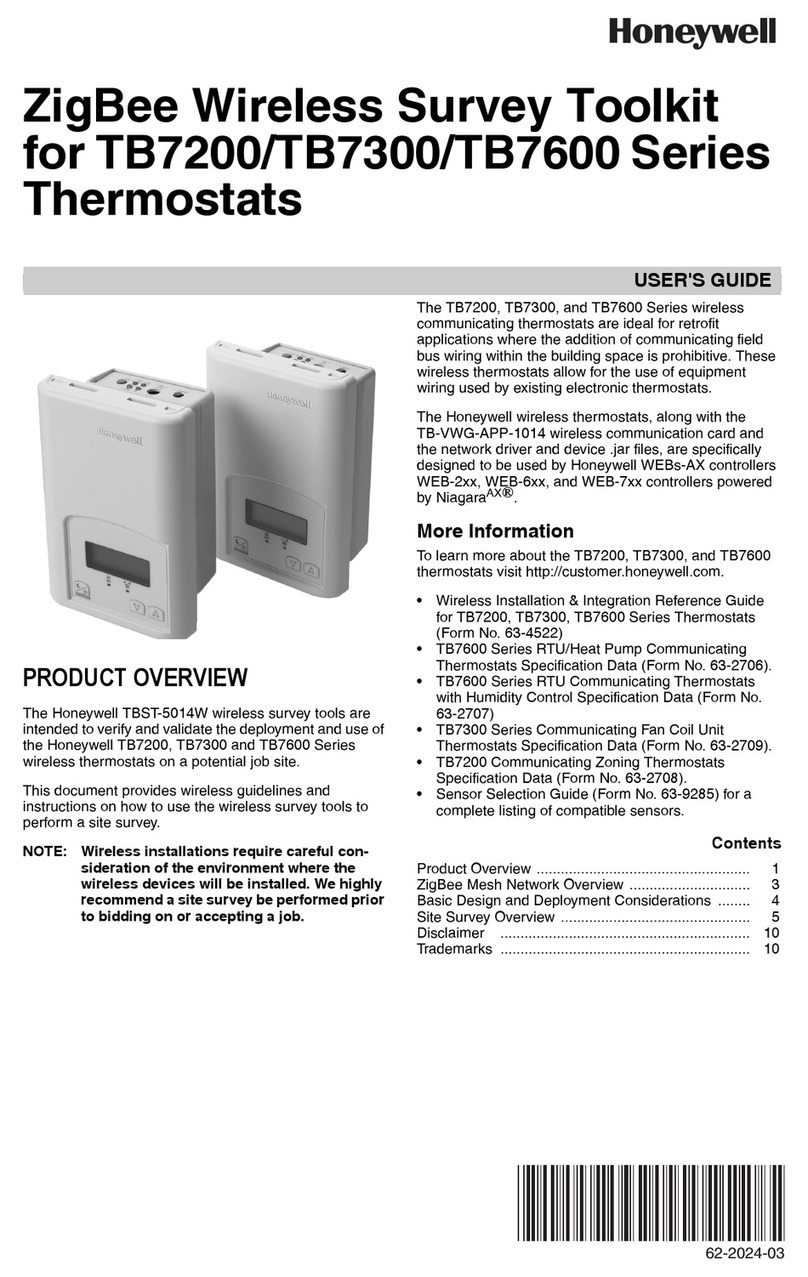

Control Panel

Ensure the battery is fully charged with the

appropriate mains plug, UK,EU or US.

Connect the charger jack to the front of the

case (Fig. 1.2).

Upon connection of charger observe the LED light condition in the

box

Note: During charging the buttons are

disabled but the display and pressure

measurement is fully operative.

Start-up

1. Turn on power supply

2. Display will show all LCD digits check

3. Display will show the current Firmware version number e.g.

'.1.0.1”

4. Display will show Program model variant '379'

5. Display will show the application, 'Std'

6. After 10 seconds the display will show '‘- - -’

7. The unit will then display the pressure gauge reading.

Do not allow the Test Unit to be started with any pressure

in the tank otherwise Error E5 will show. If this occurs turn

ball valve to ‘EMPTY’ and restart.

Standard Operation

Pressure Check

1. Switch on the power switch, the red LED will light up next

to charger point. (Fig. 1.1 & Fig. 1.2)

2. Ensure tank is empty (Ball valve turned to ‘EMPTY’—Press

Button ‘0’ to reset Zero point (only required periodically).

3. Set desired pressure unit by touching either ‘bar’ ,’psi’ or

‘kpa’ buttons

The Set unit is saved for the next power cycle.

4. Set ball valve to fill (Fig. 2.0)

5. Connect to the 8V1 Valve Product requiring testing observe

comparison readings.

6. Empty tank after use.

General Specifications

Max gauge reading: 175 psi / 12.2 bar / 1220 kPa

Units of measurement: psi / bar / kPa

Display resolution: 0.1 PSI/ 0.01 bar / 1 kPa

Battery type: 12V 2.5Ah Nickel Metal Hydride

Rechargeable

Hours running time: 50 hours continuous before recharge

Pressure vessel volume 3.8 Litres

Maximum pressure allowable 13 bar <50barlitres

An Internal Safety relief valve is fitted.

Installation

Before use fully charge the Test Unit with the supplied Battery

Charger. The Charger includes UK/EU and US plug adaptor

Ensure the compressor producing the air has the necessary

water and dirt filtration to minimise accumulation of debris inside

the pressure vessel.

Outdoor use

Ensure the unit is protected from rain and water ingress

Calibration & Accuracy

The accuracy of our digital units when released from our factory is

• Accuracy according to EN12645 Inflation tolerance

1/4 of EN12645

+/- 0.02 bar from 0—to and including 4 bar

+/- 0.03 bar above 4 bar to and including 10 bar

+/- 0.05 bar above 10 bar

Accuracy levels above 4 bar exceed EN12645 standards

Each unit, before release, is checked and calibrated on test

equipment that has accuracy traceable to a UKAS Laboratory No.

0221 referenced to certificate 0029346.

LED MODE

YELLOW Battery not connected

YELLOW Battery initialisation and

analysis

ORANGE Fast charge

Green with intermittent

yellow flash

Top-off Charge

GREEN Trickle Charge

Alternating ORANGE—

GREEN

Error

PCL TE3 Digital Test Unit

www.pclairtechnology.com

test point

ball valve pressure unit

buttons

power switch

charging port

LED power

indicator

Fig. 1.1

Fig. 1.2

Fig. 2

ball valve to fill

PCL TE3 Digital Test Unit

www.pclairtechnology.com

Service/Maintenance

There is no requirement to service the following items:

1. Pressure Transducer

2. Electric Control Board

If these are faulty they can only be

replaced by a competent person.

Please refer to an Authorised

Dealer.

Periodically

• Clean the unit with a damp cloth, do not use chemicals or

solvents

• Check the 8V1 test valve

• Periodically check the charger and lead is not damaged

• Periodically unscrew the drain valve as observed in Fig. 3

Working safety instructions

Since the unit is not explosion-proof, the device should not be

installed in areas where explosions are possible. Consideration

must be given to the requirements relative to Hazardous Area

Standards for your region or country.

The unit is designed and built to the

relevant basic health and safety

requirements of the EC.

This product can be dangerous if used improperly. Children should

not be allowed to use this equipment, as incorrect setting can

allow tyres to be over inflated and a subsequent tyre burst/

explosion can occur!

Each person who is involved with installation, start-up,

maintenance and the operation of the unit must read and

understand the complete operating manual.

This unit is designed to measure other

inflation products.

Each use which doesn't follow this purpose as well as

modifications to the product will be deemed to be improper

use. The manufacturer is not liable for damages caused by

improper use, the risk lies solely with the user.

High Pressure air is stored within the

system.

Do not exceed the maximum contents of

12.3 bar

To avoid the risk of personal injury,

especially to the eyes, face or skin DO

NOT direct the air/N2 stream at any

person.

Fig. 3

drain valve

PCL TE3 Digital Test Unit

www.pclairtechnology.com

Problem Possible Cause Solution

No display No power connected

Battery flat

Switch power on

Charge battery

Connector will not seal to the

tyre stems

Worn 8V1 Test port Replace 8V1 Test port.

Display shows ‘- - -’Pressure contents is above maximum pressure

reading

Reduce pressure in tank

E2 Faulty Pressure Sensor Refer to authorised repairer

E5 Attempted to rest Zero under with pressure tank

inflated with residue pressure

Empty tank fully, open ball valve before attempting a

Re-Zero

E6 Pressure sensor drift out New sensor required - Refer to authorised repairer

E8 Pressure sensor disconnected from PCB or faulty New sensor required - Refer to authorised repairer

E9 Pressure sensor failure - high New sensor required - Refer to authorised repairer

E10 Under voltage Check power supply

E11 Over voltage Check power supply - Refer to authorised repairer

E12 Checksum corrupted New PCB required - Refer to authorised repairer

E13 Lost or corrupted calibration settings New PCB required - Refer to authorised repairer

E17 Through to E28 Microprocessor fault Recalibrate unit - Refer to authorised repairer

Trouble Shooting Guide/Error Messages

PCL TE3 Digital Test Unit

www.pclairtechnology.com

This page is intentionally left blank

PCL TE3 Digital Test Unit

www.pclairtechnology.com

PCL LIMITED WARRANTY

PCL warrants the components of each unit to which this Limited Warranty applies against defects in materials and workmanship for

a period of twelve (12) months from date of sale (as evidenced by bill of sale or equivalent) or for a period of eighteen (18) months

from date of shipment from PCL manufacturing facility (identifiable by the serial number and noted on original bill of lading from

the manufacturing facility), whichever period is shorter. During this warranty period and subject to the conditions set forth in this

statement, PCL will, at its option, repair or replace component parts that were defective at the time of shipment from PCL

manufacturing facility, subject, however, to the following specific EXCLUSIONS: hoses and connections.

Repair or replacement will not extend the warranty period.

Customer must give PCL timely notice of any warranty claim by contacting an authorized PCL service centre. Claims must be

accompanied by (1) evidence, by a bill of sale or equivalent, which clearly establishes date of purchase of the unit and (2) the

serial number, found on the unit. Customers must properly pack parts in their original or equivalent packaging, prepay shipping

charges, and insure the shipment or accept the risk for loss or damage in shipment. Return shipment to customer will be freight

collect unless otherwise agreed. For service at a customers location, customer will be charged the then prevailing service rates .

The Limited Warranty applies to PCL manufactured units only. Items listed in the applicable operators manual under routine

maintenance are not covered by this or any other warranty. Failure to complete maintenance as stated in any applicable

maintenance schedule will void the Limited Warranty. The Limited Warranty is expressly conditioned upon proper and normal use

and service of the unit and upon strict compliance by customer with all of PCL instructions and recommendations for installation,

operation and maintenance. The Limited Warranty does not apply to the unit or parts that are damaged or become defective due to

improper handling, maintenance, storage, use, or operation, and does not cover ordinary wear and tear, corrosion, or erosion.

THE LIMITED WARRANTY SET FORTH IN THIS STATEMENT CONSTITUTES PCL'S SOLE WARRANTY FOR THE UNIT AND

THE REMEDIES SET FORTH HEREIN CONSTITUTE CUSTOMERS SOLE REMEDIES FOR BREACH OF WARRANTY. THIS

LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, IN FACT OR BY LAW,

INCLUDING WITHOUT LIMITING THE GENERALITY OF THE FOREGOING, ANY WARRANTY OR MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Determination of the suitability of the unit for the use contemplated by the customer is the sole responsibility of the customer. PCL

shall not, under any circumstances, be liable in contract, tort or otherwise (including negligence and strict liability) for indirect,

special, incidental, or consequential damages, and PCL's total liability shall not exceed the net purchase price for the unit. PCL shall

be excused for delay or inability to perform obligations due to events beyond its reasonable control.

CUT HERE

Mail

Warranty Department

PCL

Holbrook Rise

Holbrook Industrial Estate

Sheffield

S20 3GE

United Kingdom

Warranty Registration

Please complete and mail this form to activate warranty

Or visit us at www.pclairtechnology.com

Name ________________________________________ Title __________

Company Name _______________________________________________

Type of Business ______________________________________________

Address _____________________________________________________

City ______________ County _______________ Post Code __________

Telephone ___________________________________________________

Part Number ___________________ Serial No _____________________

Purchased From _______________________________________________

Purchase Date __________________________

Table of contents

Popular Test Equipment manuals by other brands

Carimali

Carimali Macco M Installation and use manual

Mark-10

Mark-10 CT Series user guide

Keysight Technologies

Keysight Technologies U3022AM42 User's and service guide

BGS technic

BGS technic 63503 instruction manual

Elcometer

Elcometer 224 operating instructions

IDEAL Networks

IDEAL Networks SignalTEK NT manual