PCM Erwin XL User manual

Other PCM Toy manuals

PCM

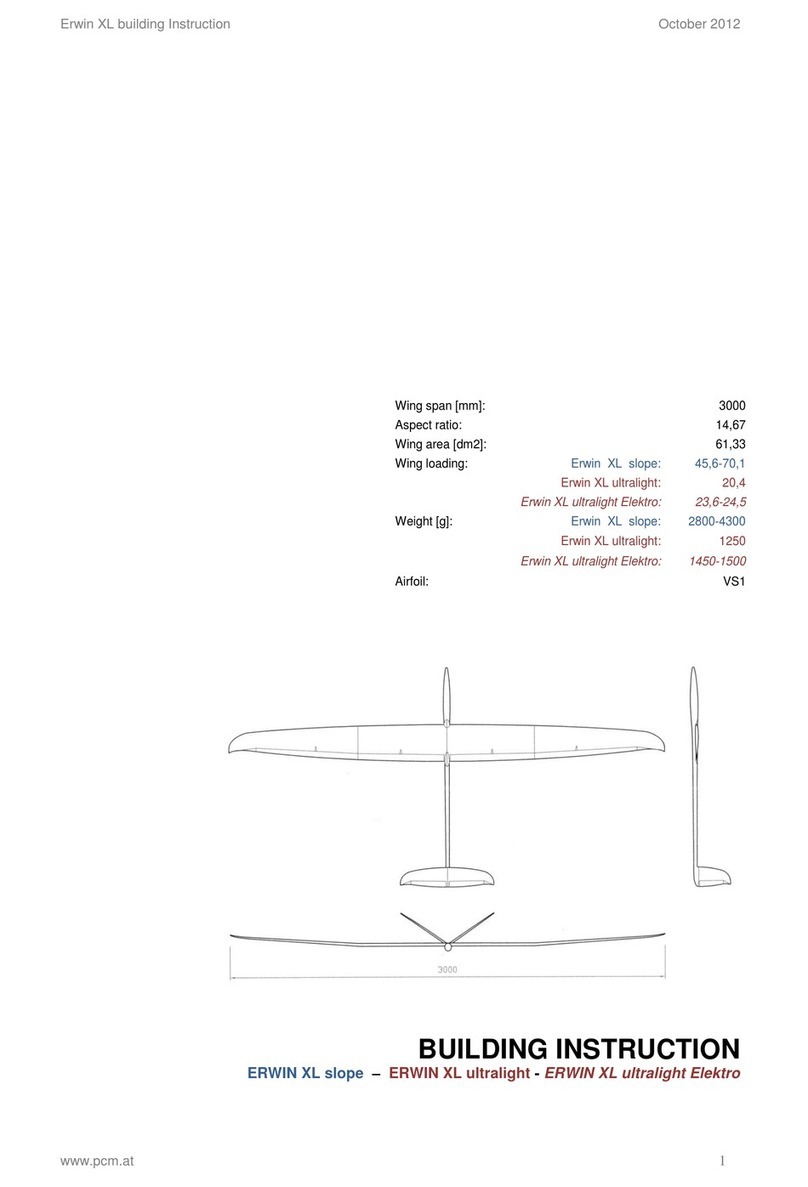

PCM ERWIN XL slope User manual

PCM

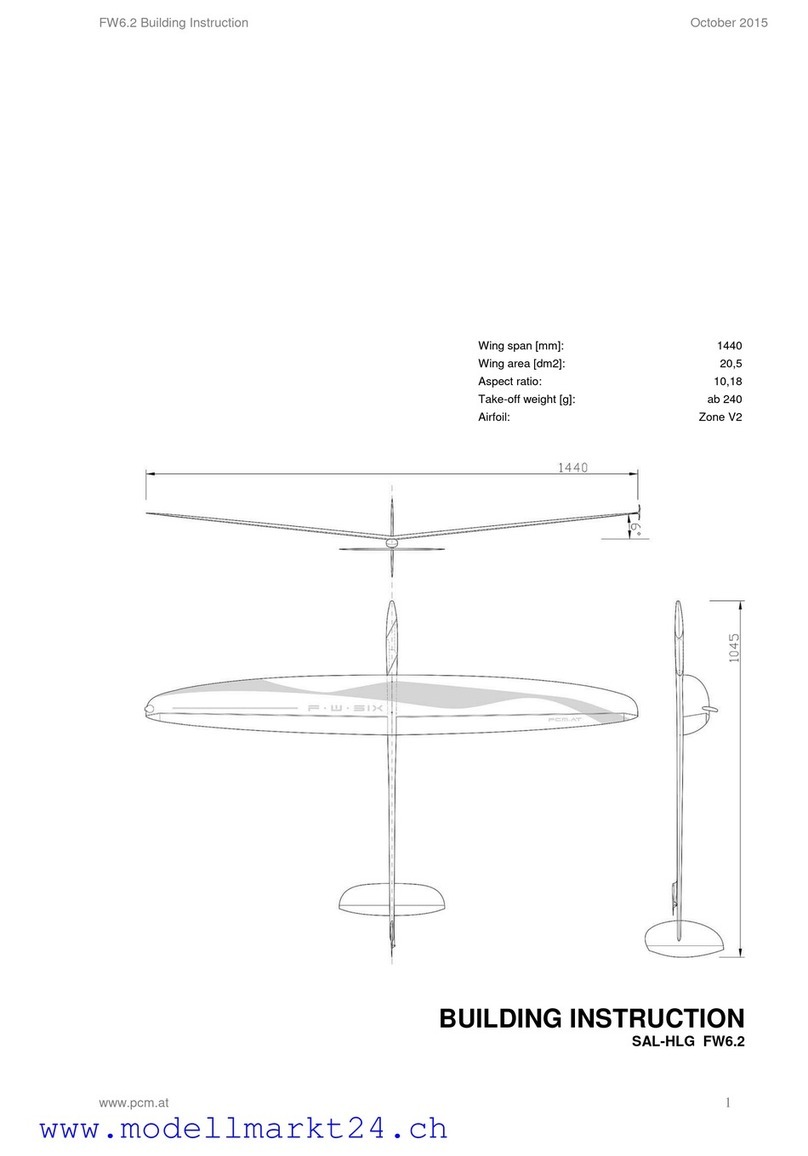

PCM FW6 Instruction Manual

PCM

PCM ERWIN XL slope User manual

PCM

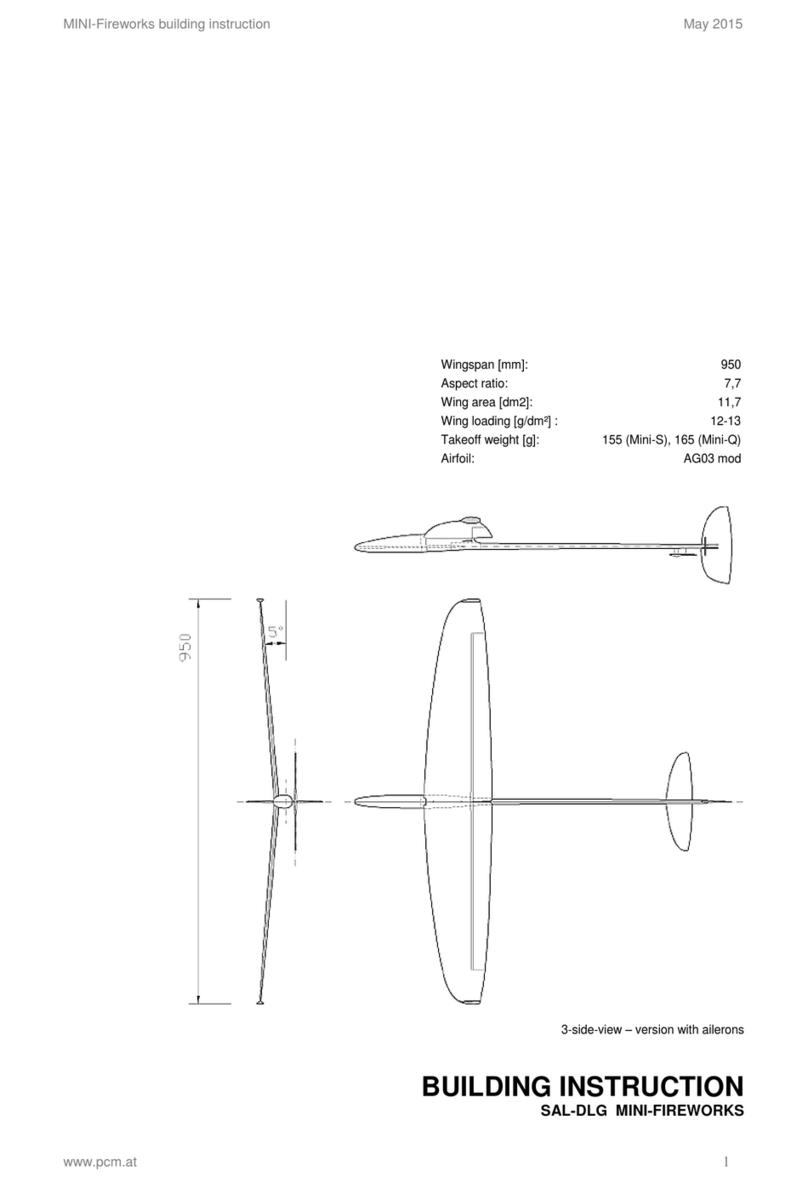

PCM GLIDER MINI-RACE User manual

PCM

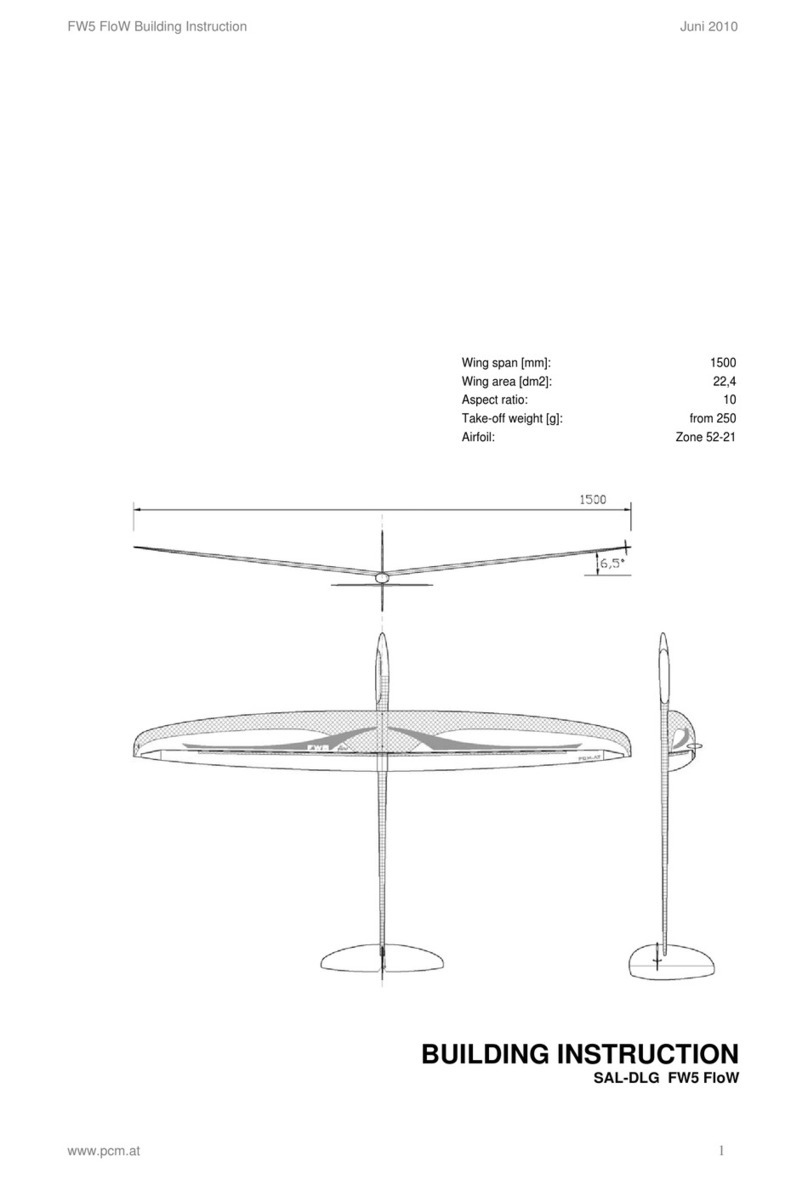

PCM FW5 FloW Instruction Manual

PCM

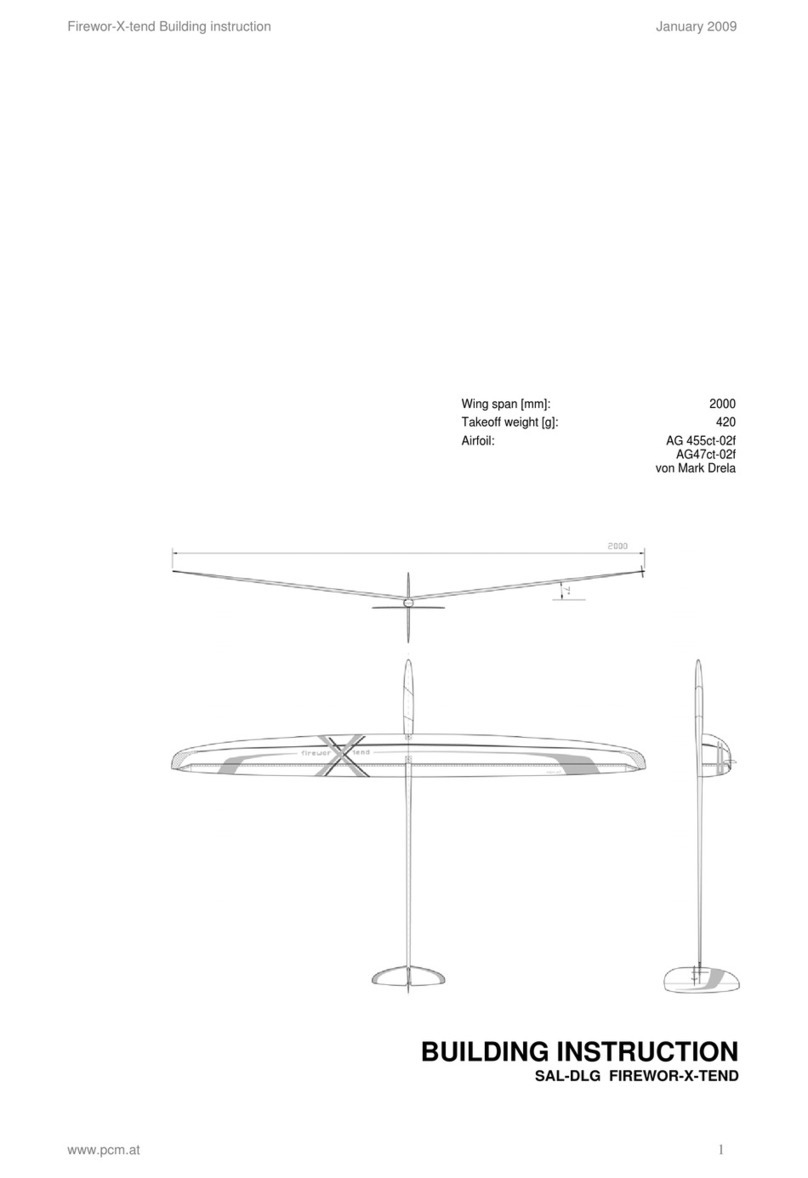

PCM SAL-DLG FIREWOR-X-TEND Instruction Manual

PCM

PCM DV8R Technical specifications

PCM

PCM ELVIRA User manual

PCM

PCM Erwin XL Ultralight Electro User manual

PCM

PCM FW6.2 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions