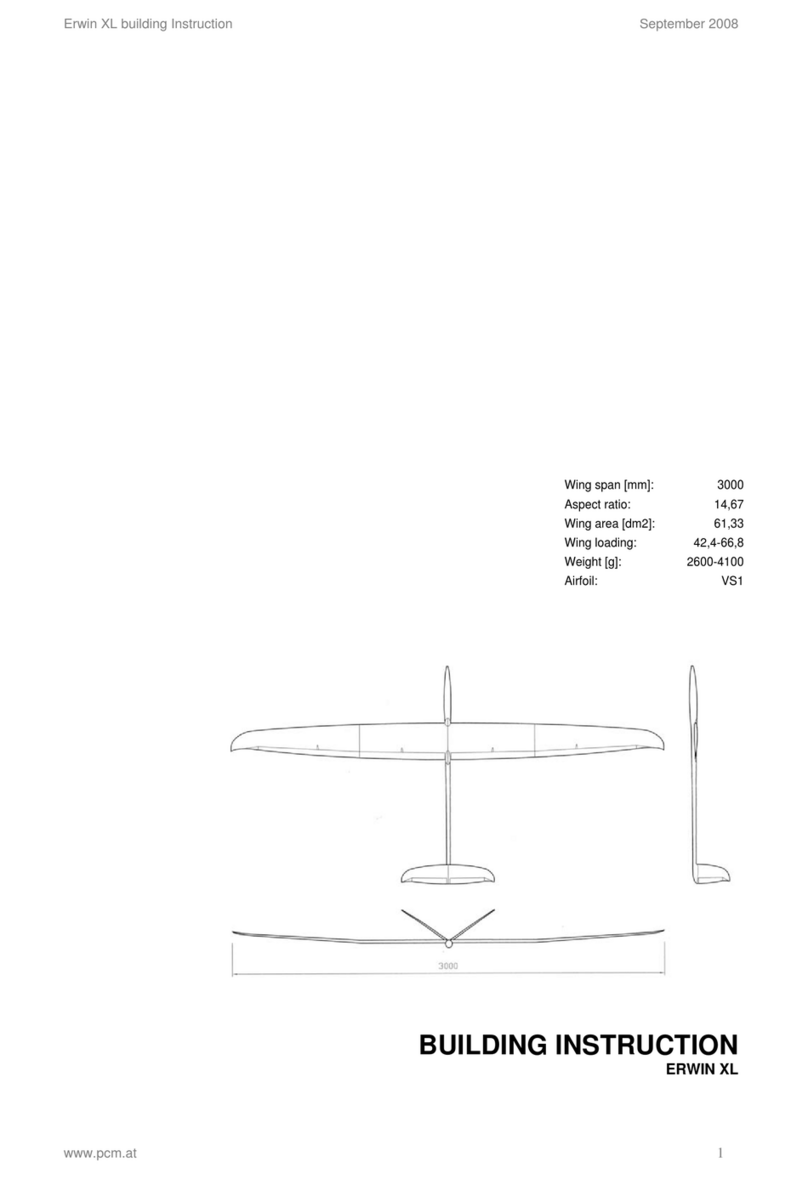

Fuselage, in two parts, incl. canopy and cover for end of fuselage, 1 piece

Wing, in two parts

V-Tail

Steel-connector, 3 pieces (1x long, 2x short) (XL slope)

Carbon connector (bar), 2 pieces (XL slope)

Carbon connector (pipe), 1 piece (XL ultralight + elektro)

Covers for servos on wing, 4 pieces

Levers for rudders, 4 pieces

Servo board (XL slope, XL ultralight)

Assembly board for hook for winch start (XL slope, XL ultralight)

Installation frame for engine (XL ultralight Elektro)

Fuselage board with 2 sideboards (XL ultralight Elektro)

Ball connectors for the elevator, 2 pieces (XL slope, XL ultralight)

Brass pipes for the elevator, 2 pieces (XL slope, XL ultralight)

Pipes and push rod, 2 pieces each (XL slope, XL ultralight)

Cover for opening for receiver (XL ultralight Elektro)

Tube for 2,4 GHz-antennas (XL ultralight Elektro)

Plugs and frames for connection of wing and fuselage, 4 pieces each

Screws, 2 pieces, for fixing the V-tail

Covers for servos on V-tail (XL ultralight Elektro)

Plug for V-tail, 1 piece (XL ultralight Elektro)

Levers, 2 pieces (XL ultralight Elektro)

Template for cutting nose of fuselage (XL ultralight Elektro)

Template for cutting opening for receiver (XL ultralight Elektro)

Building instruction (please download from our homepage)

Controls of the wing:

Connectors for push rods, M2,5mm, 8 pieces

Welding rod, d=2mm

Hook for winch start and nut

On-off switch / socket for loading

Cables (electricity)

Cable for antenna, possibly steel wire for extension of

antenna

Plugs

Epoxy-glue (for example UHU 300 endfest or Stabilit, no

fast hardening epoxy resin)

Cotton flocks to thicken glue