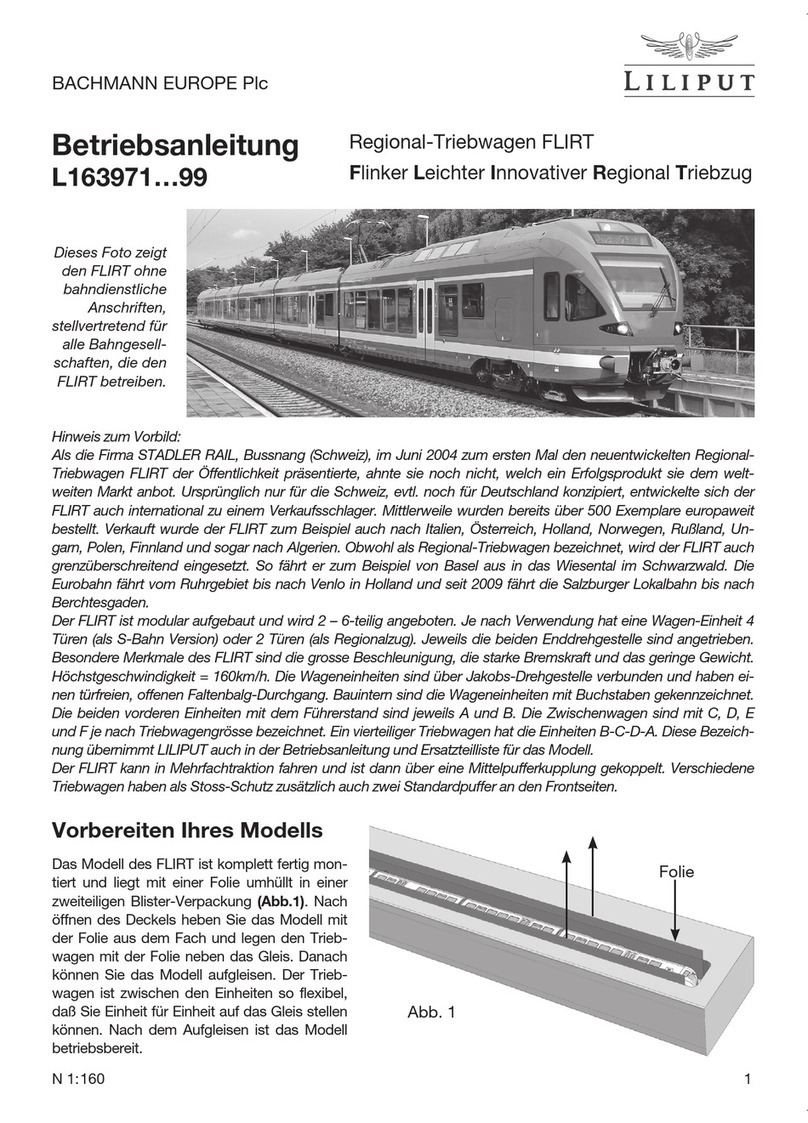

PCM GLIDER MINI-RACE User manual

MINI-Race building instruction January 2014

www.pcm.at 1

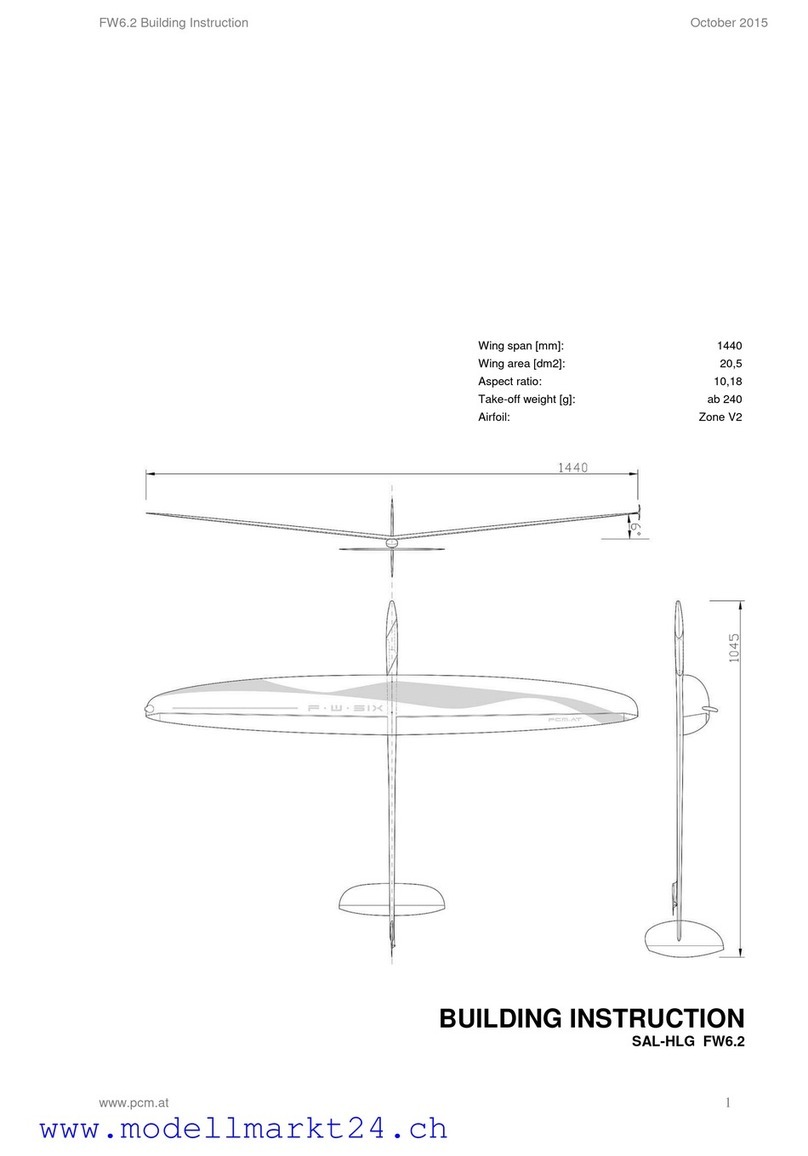

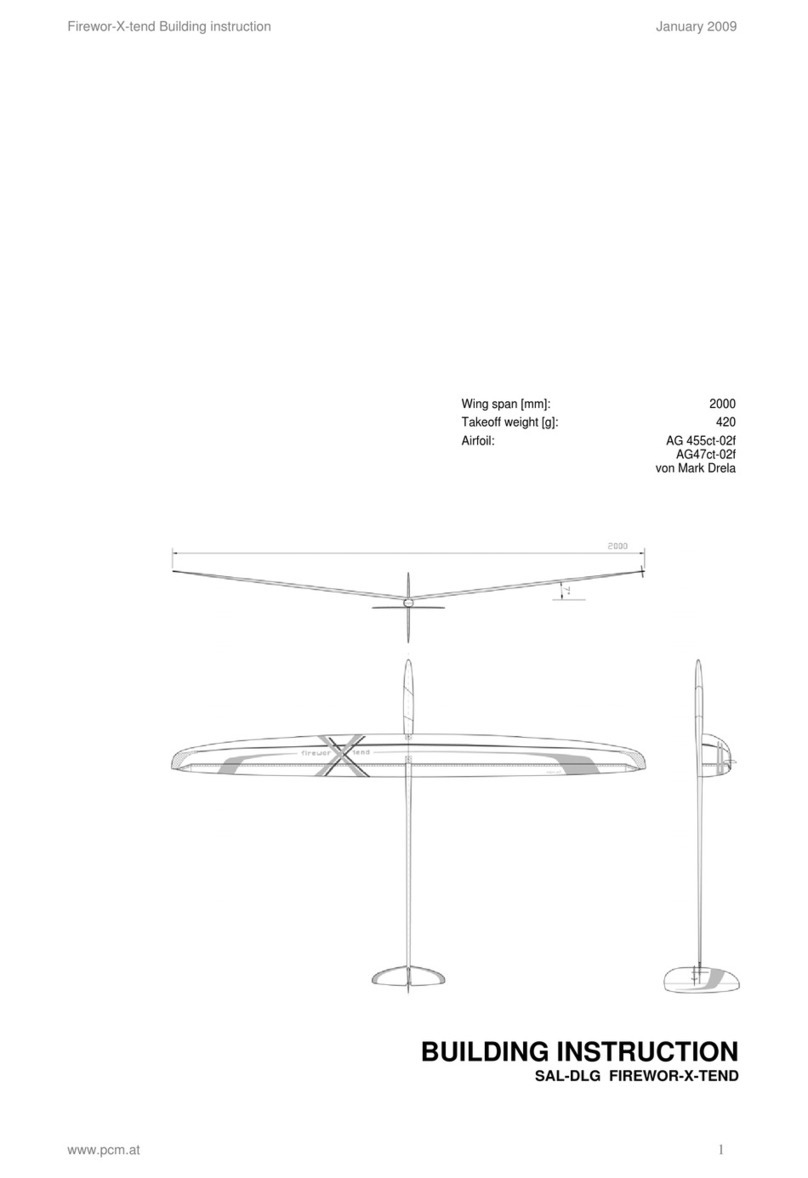

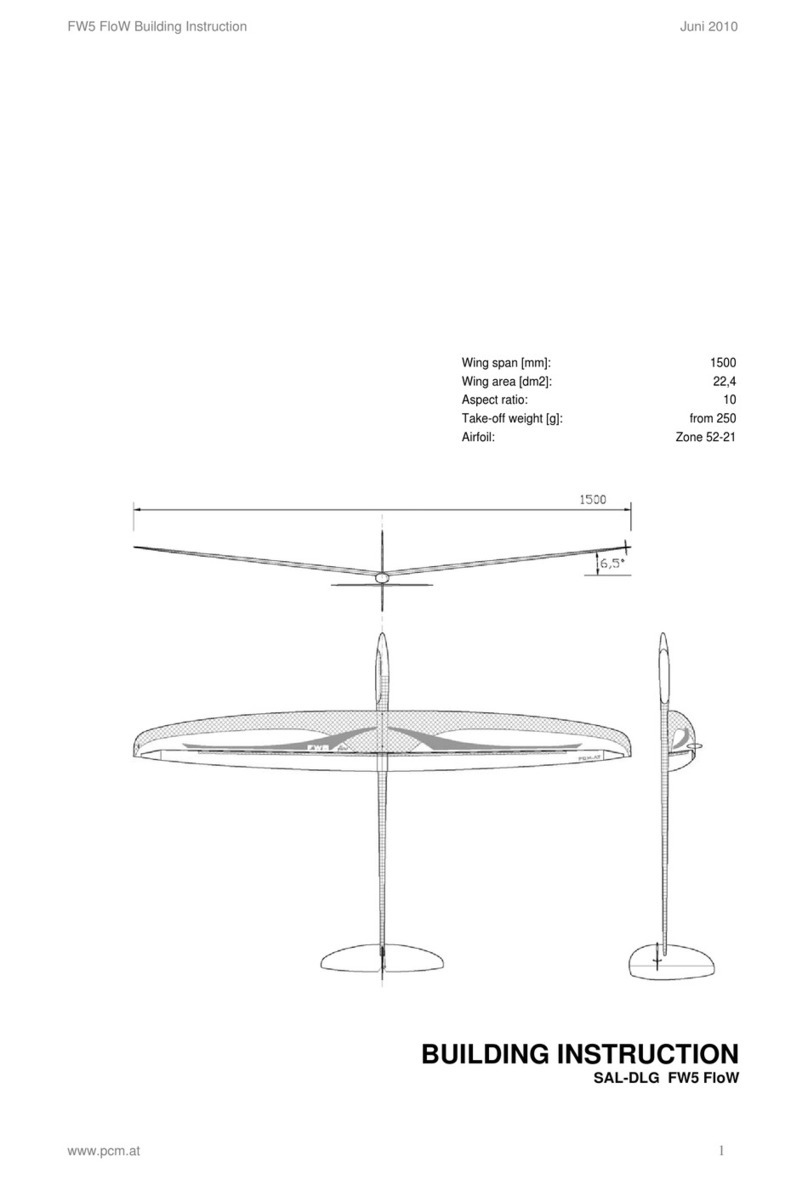

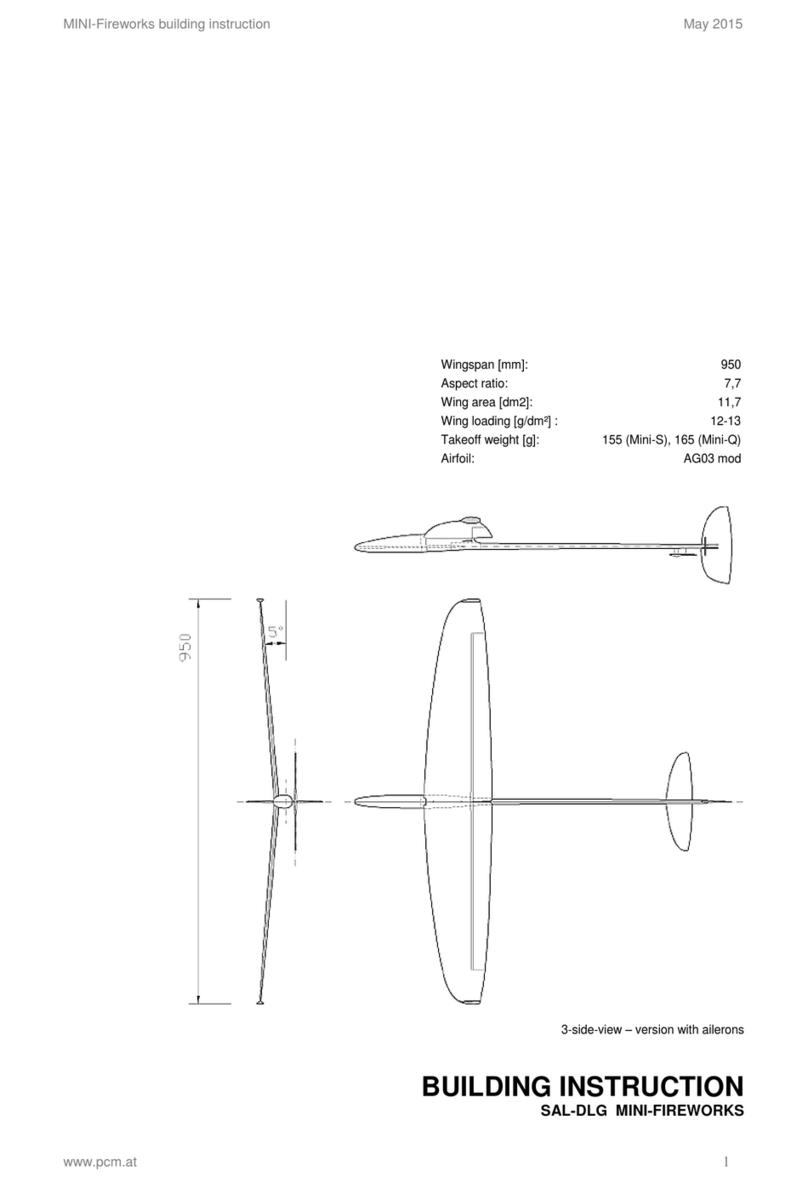

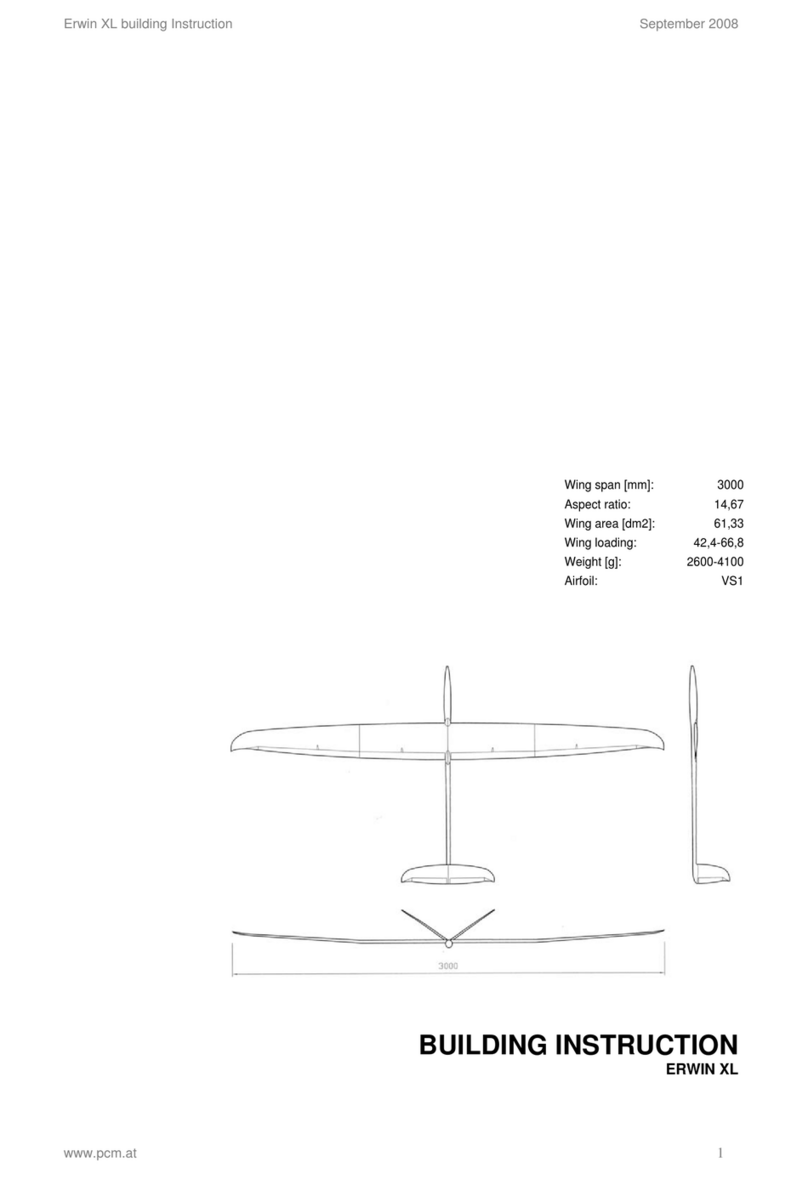

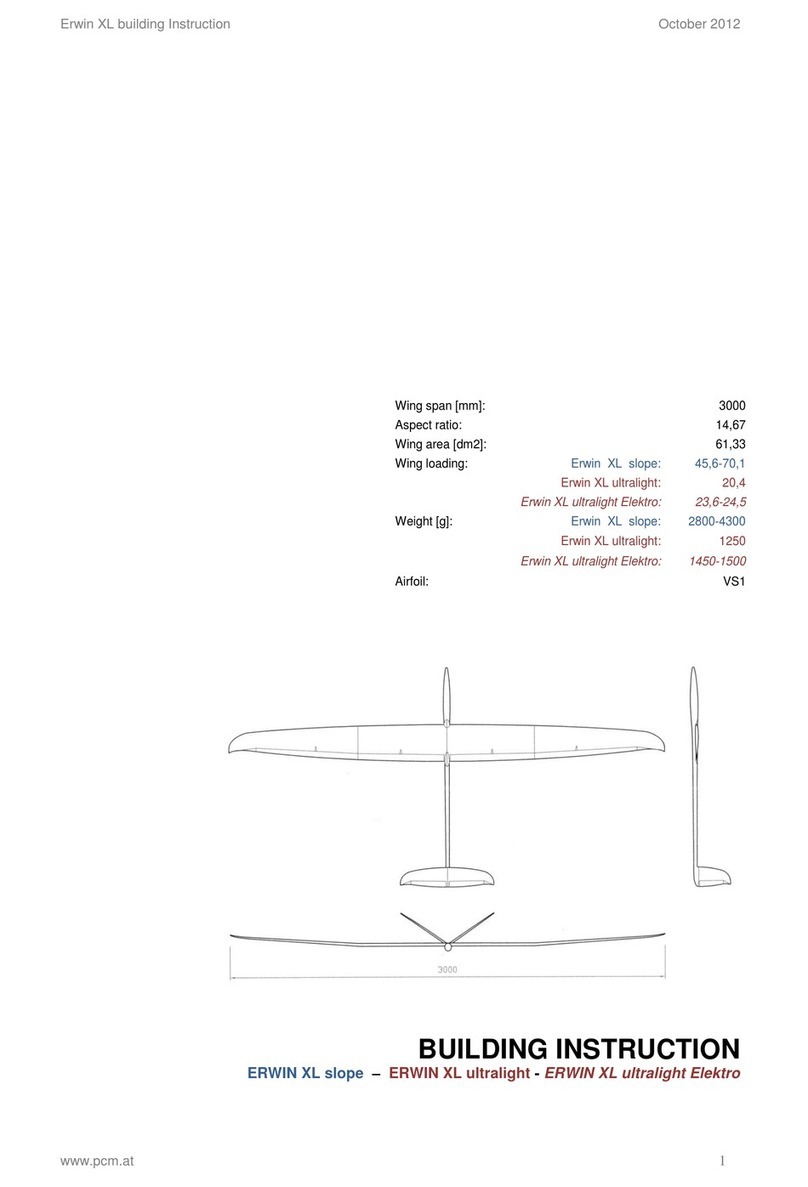

Wingspan [mm]:

950

Aspect ratio:

7,7

Wing area [dm2]:

11,7

Wing loading [g/dm²] :

16

Takeoff weight [g]:

190

Airfoil:

AG03 mod

BUIDLING INSTRUCTION

GLIDER MINI-RACE

MINI-Race building instruction January 2014

www.pcm.at 2

CONTENTS

DATA

1. Kit –contents

2. What else do you need?

3. Electronic equipment

4. Settings for the first flight

ASSEMBLING THE MODEL

5. General information on DLG-models

6. Fuselage - structure

7. V-tail

8. Fuselage - installation of electronic components

9. Controlling of the ailerons

10. Installation of antenna

OTHER

11. Check list before starting

3

3

3

4

5

5

7

9

10

11

12

MINI-Race building instruction January 2014

www.pcm.at 3

DATA

1. Kit –contents

Fuselage (canopy, middle part, boom)

Wing

V-tail

Radioboard

Carbon lever for controlling elevator, 2 pieces

Carbon levers for controlling ailerons, 2 pieces

Carbon push rods for controlling ailerons, 2 pieces

Kevlar wire for controlling elevator

Steel wire for torsion springs, 2 pieces

Screws for fixing wing, 2 pieces

Carbon roving

Building instruction (please download from website)

2. What else do you need:

Epoxy-glue (for example UHU 300 endfest or Pattex Stabilit)

Super glue, thin

Maybe cotton flocks (to thicken epoxy-glue)

Electrical equipment (On/Off-switch, cables, plug, ...)

Electronic equipment

Steel wire, shrinking tube...

3. Electronic equipment

Servos

elevator/rudder/aileron

- Dymond D-47

Similar:

- Futaba FS31

- Modell Expert X31

Accumulators:

- GP NiMH accu 35AAAH, weight/cell 6g

(1,2 Volt 0,35 Ah 1/2AAA)

Receiver:

- MZK Sexta Mini

- Jeti Rex 540MPD

MINI-Race building instruction January 2014

www.pcm.at 4

4. Settings for the first flight

Centre of gravity: 62mm

(measure from the leading edge of the wing to the back)

Deflection of controls

Flaps negative (speed)

Flaps positive (thermal)

Landing position

Snap Flap

MINI-Race building instruction January 2014

www.pcm.at 5

ASSEMBLING THE MODEL

5. General information on DLG-models

DLG-models - such as MINI-Fireworks - are constructed strong enough to withstand the demands

of flying and landing and at the same time light enough to achieve the least possible flying weight.

Each part is dimensioned to its possible minimum and produced using lightest and fewest

material.

In order to continue this concept, please account the following when you assemble the model:

- Always use glue sparingly. Grind all gluing spots thoroughly, before you apply the glue.

- Electronic components should be placed as far as possible to the front, as you normally

need additional lead in the nose of the fuselage to achieve the necessary centre of gravity.

- If you don’t have any experience in working with resin or if you prefer an easier method, you

can combine the carbon rovings and glass fibre with super glue: Put some drops of super

glue on the rovings or the fibre, spread and press it with a (rustling) plastic bag. You will also

save one or the other gram with this method..

6. Fuselage - structure

Cut holes as shown

into the fuselage for

the pushrods of the

ailerons.

Push the boom into the middle part of the fuselage, until

the boom stands out 400mm. If the boom can’t be

pushed out far enough, you can sand off some material

inside the middle part of the fuselage.

Before you glue the boom, check that the servoboard can

be fixed to the boom inside the fuselage later according

to the picture. The flat side of the boom should be on the

upper side, the round one on the downside.

MINI-Race building instruction January 2014

www.pcm.at 6

Further, you must check, that the distance between the

end of the boom and both wingtips is the same.

If all alignments are correct, glue the boom with epoxy-

glue to the middle part of the fuselage.

In addition, the boom must be glued to the bottom of the

fuselage (see picture above).

Before you fix the servoboard inside the fuselage,

strengthen the board with a carbon roving.

You can glue the roving with super glue or epoxy glue.

We recommend to install all electronical components

provisionally before (see chapter 8) you glue the board

and try to mount the canopy. So you will be sure, that

everything fits inside.

In order to gain full strength, it is absolutely necessary to

fix the servoboard in the fuselage!

Strengthen the edges of the servo board with super

glue.

Glue the board with epoxy-glue to the boom (see picture

above) and to the sides of the fuselage.

If you have a hard landing, always check if the

servoboard is still fully glued before you make the next

start!

MINI-Race building instruction January 2014

www.pcm.at 7

7. V-tail

(The description is partly based on the model "Taser" as

the V-tails are almost identical.)

The V-tail is controlled by only one servo. The levers are

connected with a V-shaped wire.

First of all, glue the levers on the lower ends of the control

surfaces. The holes of the levers should be above the

hinge line.

Now, place the V-tail on the boom. Before you glue it,

Check the alignment of the V-tail regarding the axis of

the fuselage and the EWD, so that it is fixed correctly.

To do this, mount V-tail and wing on the fuselage. Fix the

V-tail with adhesive tape. Put another little piece of tape

in the middle of the sticky side of the adhesive tape. By

this, you will still be able to move the V-tail, as the

adhesive tape will not stick to the boom.

First method:

Look at the model from the front and slowly lower the tail,

until the ends of the elevator disappear behind the wing.

If both ends of the elevator disappear at the same time,

the V-tail is aligned symmetrically.

Second method:

Place the model upside down on a flat table. If both

wingtips and both tips of the elevator lie on the table,

the V-tail is aligned symmetrically.

MINI-Race building instruction January 2014

www.pcm.at 8

Make sure you have grinded the gluing spots on

fuselage and V-tail thoroughly, before you glue.

If the V-tail is aligned correctly, let super glue run into

the gluing spot from both sides.

Torsion springs

Bend the wires according to the drawing on the right. Tip

back the control surface of the rudder completely. (180°)

Stick the spring into the wood.

Then harden these spots with super glue.

Connection of the wire

First, the kevlar wires should be attached to the servos.

The servos should be brought into the zero position by

using a servo tester.

Then, you can hook in the kevlar wire into the lever.

Make a loop, twist the end and put the end of the wire into

a shrinking tube. Shrink it and fix it with a drop of super

glue.

Drill a small hole in the boom to lead the wire inside the

fuselage to the servo.

To keep the carbon from chafing at the wire, use a plastic

tube to lead the wire through the hole.

Note, that the wire keeps free movable without problems.

MINI-Race building instruction January 2014

www.pcm.at 9

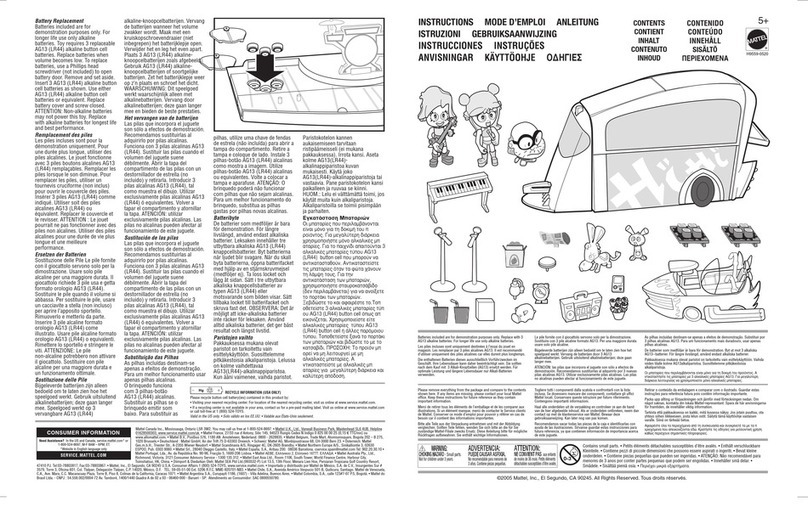

8. Fuselage –installation of electronic components

Suggestion for

arrangement:

View from above:

Mini-S

(elevator/rudder):

green accus,

right side

Mini-Q

(elevator/aileron):

red accus,

left side

View from the

bottom

Mini-S

(elevator/rudder):

green accus,

top

Mini-Q

(elevator/aileron):

red accus, bottom

(servo for elevator is

on downside of

radio board)

MINI-Race building instruction January 2014

www.pcm.at 10

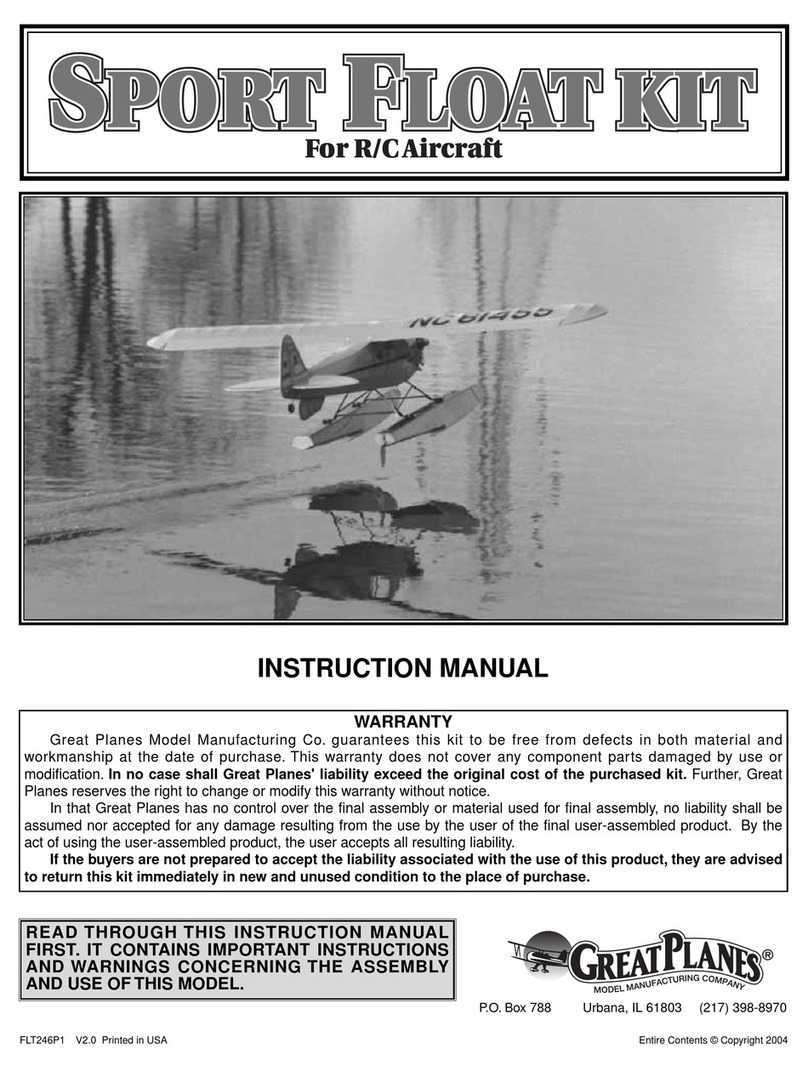

9. Controlling of the ailerons

To avoid

unintentional

demounting glue

little steel hooks to

the ends of the

carbon pushrods

Connection to the

servos in the

fuselage

Connection to the

levers on the wing

MINI-Race building instruction January 2014

www.pcm.at 11

10. Installation of antenna

In order to have an undisturbed reception a part of the

antenna must be situated outside the model.

An easy solution is to fix the antenna to the end of the

elevator. Lead the antenna inside the fuse behind the wing

and then leave the fuselage.

Another possibility is to lay the antenna inside the gap of

the aileron. For improving reception you can solder the

antenna to a steel wire, d=0,3mm, which you fix at the end

of the wing and let stand out to the back about 10-15cm.

Always TEST THE RECEPTION on ground before you

fly!

MINI-Race building instruction January 2014

www.pcm.at 12

OTHER

11. Check list before starting:

1. Check centre of gravity

2. Check control surfaces:

Do control surfaces move in the correct direction?

Check the greatest swings

3. Check reception:

Leave the antenna inside the radio control and go

away from the glider up to a distance of about

60m. The control surfaces should not tremble.

Table of contents

Other PCM Toy manuals

PCM

PCM ELVIRA User manual

PCM

PCM Erwin XL Ultralight Electro User manual

PCM

PCM FW6.2 User manual

PCM

PCM ERWIN XL slope User manual

PCM

PCM SAL-DLG FIREWOR-X-TEND Instruction Manual

PCM

PCM FW5 FloW Instruction Manual

PCM

PCM MINI-S Instruction Manual

PCM

PCM Erwin XL User manual

PCM

PCM FW6 Instruction Manual

PCM

PCM ERWIN XL slope User manual