PDK PDPG-H User manual

PDPG-H

PDPG-H

Dead-Weight Tester

User Manual

PDPG-H Manual

Page 2

Table of Contents

1 Introduction ......................................................................................................... 3

1.1 Product Overview ....................................................................................................... 3

1.2 Specifications ............................................................................................................ 3

1.3 Product Figures ........................................................................................................ 4

2 Installation & Operation ............................................................................ 6

2.1 Unpacking And Inspection .......................................................................................... 6

2.2 Product Requirement ................................................................................................ 7

2.3 Setup .......................................................................................................................... 8

2.4 General Operation ..................................................................................................... 9

2.5 Defined Pressure Calculations ................................................................................. 12

2.6 Storage ....................................................................................................................... 13

3 Troubleshooting ................................................................................................ 14

3.1 Overview .................................................................................................................... 14

3.2 PDPG Troubleshooting Checklist ............................................................................. 14

PDPG-H Manual

Page 3

Maximum Pressure

Oil - up to 200 MPa

Measurement uncertainty

0.008 % of reading

Piston cylinder material

Tungsten carbide

Mass material

Stainless Steel

Mass set

Oil - 50 kg set / up to 100 kg available

Test port

Oil - 9/16" UNF Cone & Thread (AE F250C, HIP HF4)

Weight

12 kg

Power Requirements

220 VAC, 50/60 Hz

Media

Hydraulic - Oil (Sebacate Oil recommended)

P/C and pressure range

Mass

Piston

Piston 0.1 kg

Piston+Bell 0.5 kg

50 kg

100 kg

0.2 MPa / kg

0.02 MPa

0.1 MPa

10 MPa

20 MPa

0.5 MPa / kg

0.05 MPa

0.25 MPa

25 MPa

50 MPa

1 MPa / kg

0.1 MPa

0.5 MPa

50 MPa

100 MPa

2 MPa / kg

0.2 MPa

1 MPa

100 MPa

200 MPa

1. Introduction

1.1 Product Overview

Dead-Weight Tester is used as a generator of an accurately known pressure. It

measures pressure as force per unit area. Therefore, Dead-Weight Tester is the most

accurate pressure calibrator.

M (Mass) x g (Acceleration Of Gravity)

P (Pressure) = -------------------------------------------------------------

Ae (Effective Area)

A typical PDPG Dead-Weight Tester system includes PDPG main platform body,

Piston-Cylinder Module, Mass and Pressure Controller that user can be selected

depending on user's system configuration.

1.2 Specifications

PDPG-H Manual

Page 4

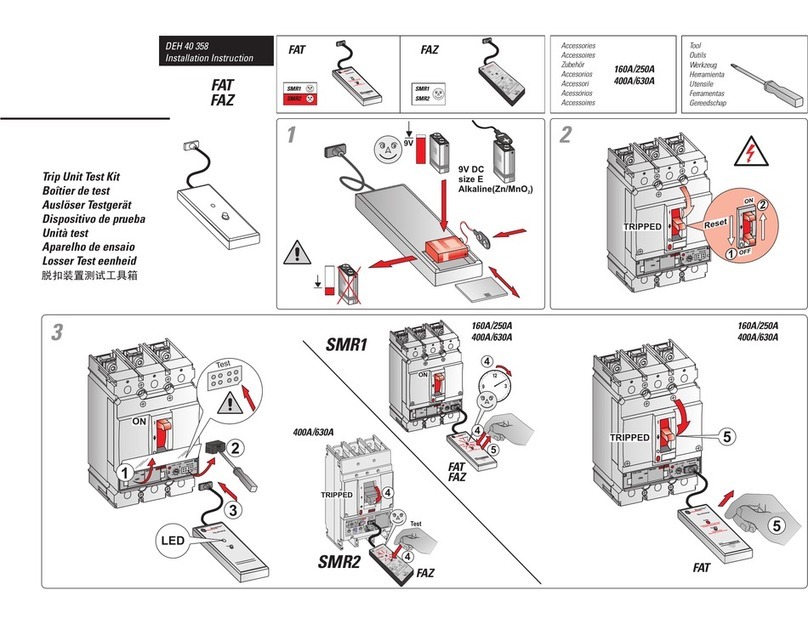

1.3. Product Figures

1.3.1 Front Panel

Figure 1. Front Panel

1.3.2 Product Dimension

Figure 1 Front And Side Appearance & Dimension [W:39 cm, D:30 cm , H:33 cm]

PDPG-H Manual

Page 5

1.3.3 Appearance Of System

Figure 2. Appearance Of System

No.

Parts

No.

Parts

①

Piston - Cylinder Module

⑥

Height Adjustment Knob

②

Bell

⑦

Manual Piston Rotation button

③

Mass

⑧

Automatic Piston Rotation Button

④

Instrument Platform Handle

⑨

Piston Position Indicator

⑤

Platform

Table 1. Description of [Figure 2. Appearance Of System]

PDPG-H Manual

Page 6

2. Installation

2.1. Unpacking and Inspection

2.1.1 Unpacking

PDPG Dead-Weight Tester delivered via PDK or shipped and packed with wooden

case that included basic accessories.

2.1.2 Inspection

Checking all of the parts from PDPG system. Refer to Table2 when its unpacking.

PARTS

PART #

PDPG-H System

Included Accessaries:

Pressure Controller ( OPS - J )

1

Piston-Cylinder Module

1

Mass set

1

Mass Tray

1

Fitting and Adaptor Set

1

SUS Tube

1

Power Cable

1

Sebacate Oil ( 1 Liter )

1

User Manual

1

KOLAS Certificated Calibration Report

1

☞ Parts on above equipped directly to the product can be shipped.

Table 2 . P D P G P arts List

PDPG-H Manual

Page 7

2.2. Product Requirement

PDPG is composed of separate with pressure generator. To use the equipment, it

required to install a pressure controller. Basically PDPG system includes pressure

controller OPS-J.

Before PDPG system installing, the following points should be noted.

▶ The stability of the table :

PDPG weight is approximately 12 kg. 35 kg of Mass set can be raised. The table

should selected with no change horizontally when mass set raised to the maximum

weight.

▶ The location of the platform other than the equipment and components :

It required sufficient space to install the Multi-test port, pressure controller and etc.

External pressure connection tubing and fitting MUST use same as

PDPG maximum pressure or more.

PDPG-H Manual

Page 8

2.3. Install

2.3.1 Setup

▶ Front panel of PDPG and pressure controller facing you, it shall be placed on the

table.

▶ After placed PDPG system, using height adjustment knob and see the level for

adjusting horizontal.

▶ User can choose the placement of the platform and pressure controller. but here is

recommended placement is as follows.

ex) From left side

Mass Set → PDPG Platform → Pressure Controller → Multi-Test port

2.3.2 Pressure Tubing Connection

General information for connection

▶ Connect the PDPG platform with pressure controller that using PDK supplied

connection kit.

▶ Using tubing line(PDK Supplied) to connect rear test port of PDPG platform and

side port of pressure controller.

PDPG-H Manual

Page 9

2.4. General Operation

2.4.1. The selection of Piston-Cylinder module and Mass combination

PDPG be able to use many different ranges by replacing each range of Piston

Cylinder module.

▶ Piston Cylinder Module : 1 MPa/kg

▶ Composition Of Mass

1) Piston Cylinder : 1 bar

2) Bell : 4 bar

3) 1 bar

4) 2 bar - 1

5) 2 bar - 2

6) 5 bar

7) 10 bar

8) 20 bar - 1

9) 20 bar - 2

10) Make-Up 45 bar

11) 50 bar - 1

12) 50 bar - 2

13) 50 bar - 3

14) 50 bar - 4

15) 50 bar - 5

16) 50 bar - 6

17) 50 bar - 7

18) 50 bar - 8

19) 50 bar - 9

20) 50 bar - 10

21) 50 bar - 11

22) 50 bar - 12

PDPG-H Manual

Page 10

2.4.2. Purging Air

▶ Purging Air on Pressure Generator/Controller before connect PDPG base.

① Open the Vent Valve then operate lever type hand pump for 4 - 5 times.

② It can see the Air bubble on left hole in oil reserver during step ①.

③ After finished step ②, turn Volume Controller to end of CW direction then

operate lever type hand pump for 4 - 5 times to see bubble coming out.

④ If there is no bubble, turn back to CCW direction, do step ① again.

2.4.3 Calibration/Adjustment

Verified that the default setting of the PDPG system has been complete before started.

▶ Connect UUT(Unit Under Test) to Pressure generator or test port.

▶ Loading mass on mass loading bell as much as user wants to measure the

pressure.

① Close Vent Valve then using lever type hand pump to generate initial pressure

generating.

② After initial pressure generated using Volume Adjust to increasing the pressure

slowly. (Volume Adjust : CW - Pressurize, CCW - Reduce Pressure)

③ Pressurize with checking the Piston location during Step ②. measure when LED

indicates "Green color".

④ 9 of LED indicator located on front panel for measuring piston position.

Approximately 1 mm height difference on each LED.

PDPG-H Manual

Page 11

○ Red : Out of measuring area (Piston is fully floating or in the bottom)

○ Yellow : Instability area (Piston is a little float or down)

○ Green : Measurable area

⑤ In order to reduce the friction of the piston and the cylinder, rotate the piston.

1) Red Button Only :

When this button is pressed, motor works then piston rotates always. If

piston is fully float or in the bottom, piston does not rotate and motor rotates

only. Even piston is in out of measuring area, motor always works therefore

we recommend between measurable area.

2) Red+Green Button : When these buttons are pressed, motor works and

piston rotates when piston is in measurable area. Automatically stop the

piston and motor rotation when piston is in out of measuring area.

PDPG-H Manual

Page 12

gh

TTPA

Cmg

Paf

rcpno

m

a

)(

)])((1)[1(

cos1

rr

aal

gq

r

r

-+

-+++

+

÷

÷

ø

ö

ç

ç

è

æ-

=å

⑥ Record the reference pressure value and UUT pressure value.

- At this point reference pressure means pressure value that total mass loaded.

- After finished measuring, if next measuring point is UP(pressurized), make a

piston position a bit lower then stop the piston rotates, repeat step ②.

- If pressure is Down point, make a piston a bit higher then stop the piston

rotates, repeat step ②.

2.5. Reference Pressure Calculation

▶ Basic Calculation : Add Bell+Piston Cylinder's pressure value with loaded masses

that pressure value marked on masses.

Ex) Basically Bell + Piston : 5 bar

If masses are as following, 45 bar 1ea, 50 bar 3 ea

Total pressure value is 5+45+50+50+50 = 200 bar

▶ Precision Reference Pressure Calculation

m = T otal m asses load ed on p iston

g = Local g ravity

ρa = A ir density

ρm = M ass d ensity

γ= S urface tension coefficient of O il (D oes n ot applied p neum atic)

C = C ircum ference of piston (D oes n ot applied p neum atic)

Ao = P iston effective a rea at stan d ard tem perature

λ= P iston-C ylind er pressure coeffic ie nt

Pn = N om inal pres sure

αp = P iston linear therm al e xpan sion coefficient

αc = C ylinder linear therm al e xpansion coefficient

T = P iston-C ylind er tem perature

Tr = R eference pressure

(ρf-ρa)gh = H ead correctio n

PDPG-H Manual

Page 13

2.6. Storage

2.6.1. Short Term Storage

When the equipment is not use for a short term

▶ Unload all of masses.

▶ Vent Open Vent valve to vent the pressure.

▶ Close the Inlet valve.

2.6.2. Long Term Storage And Moving

When the equipment is not use for a long term or moving PDPG system for

calibration

▶ Turn Piston-Cylinder module CCW to remove from PDPG platform then store in

Piston-Cylinder module case.

▶ Store all of masses in mass set case.

▶ Remove the tubing from test port on rear PDPG platform then plugged.

▶ Packing well the PDPG platform in carrying case to prevent shaken. When it need

to move, do not shake or turn the PDPG platform carrying case.

PDPG-H Manual

Page 14

SYMPTOM

PROBABLE CAUSE

SOLUTION

Piston suddenly floating or

descend.

Piston and Cylinder

contaminated.

Disassemble P/C module to

cleaning.

Piston does not rotate.

1. Piston position is fully

floating or in the bottom.

2. Motor trouble or

disconnected belt.

1. Pressurized or reduce pressure

to make correct piston position.

2. Replace motor or belt.

Piston dropped very

quickly.

Internal or external leaks.

Find the leaks point then tighten

or change the fitting to remove

the leaks.

Piston does not float.

Damaged Pressure

generator/controller O-ring.

Replace Pressure

generator/controller O-ring.

3. Trouble Shooting

3.1. Overview

PDPG has precision machining technology and high electronic engineering technology

therefore, it need to handle carefully.

Parts of the defect and the damage can lead to unexpected and dangerous results.

User needs to get training from who is well-acquainted with operation of PDPG

system.

3.2. Troubleshooting Checklist

PDPG-H Manual

Page 15

PDK AUTHORIZED SERVICE CENTER

COMPANY

ADDRESS

TEL.

FAX.

e-mail

PDK Co., Ltd.

10-6, EXPO-RO 339 BEON-GIL, YUSEONG-GU,

DAEJEON, KOREA ZIP 34122

Solution for Pressure

Measurement & Calibration

Table of contents

Other PDK Test Equipment manuals

Popular Test Equipment manuals by other brands

Multi-Amp

Multi-Amp CB-832 instruction manual

Sonel

Sonel P-4 user manual

Gossen MetraWatt

Gossen MetraWatt METRISO PRIME 10 operating instructions

OfiTE

OfiTE 171-193-6K instruction manual

Horotec

Horotec VIBRATO MSA 19.709 operating manual

Keysight Technologies

Keysight Technologies InfiniiVision 1000 X Series user guide