1.1 Properties at a Glance

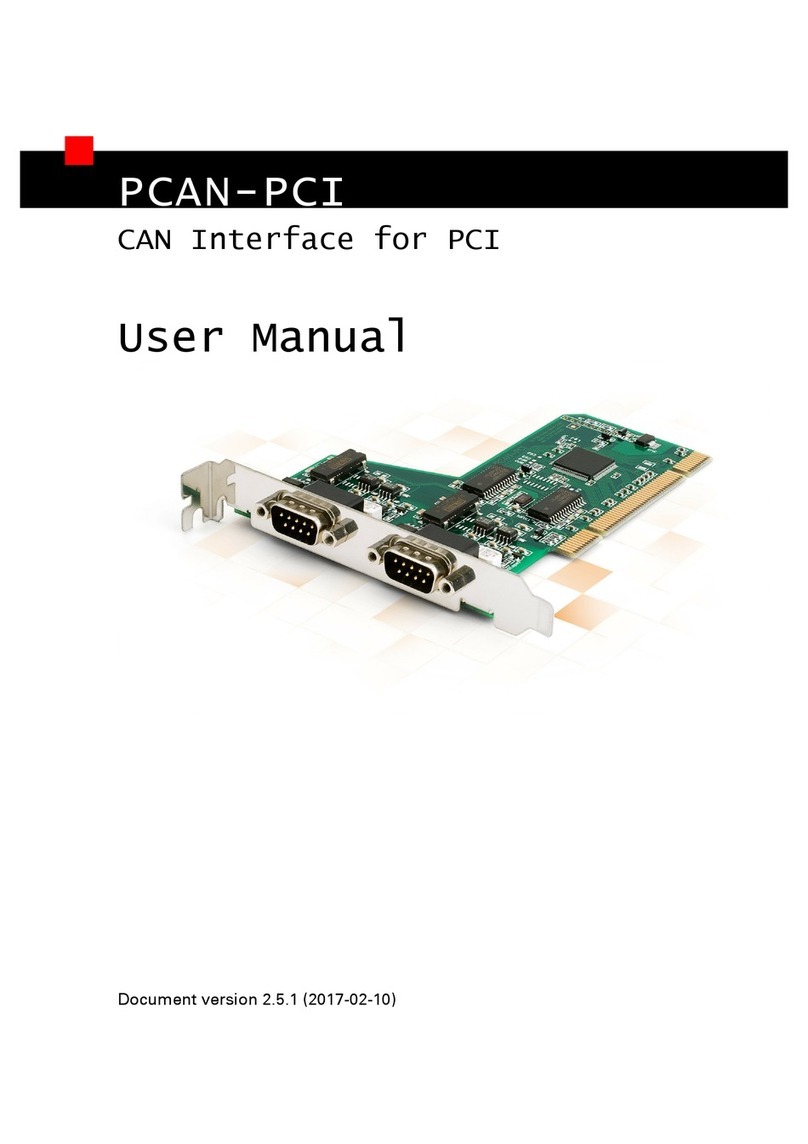

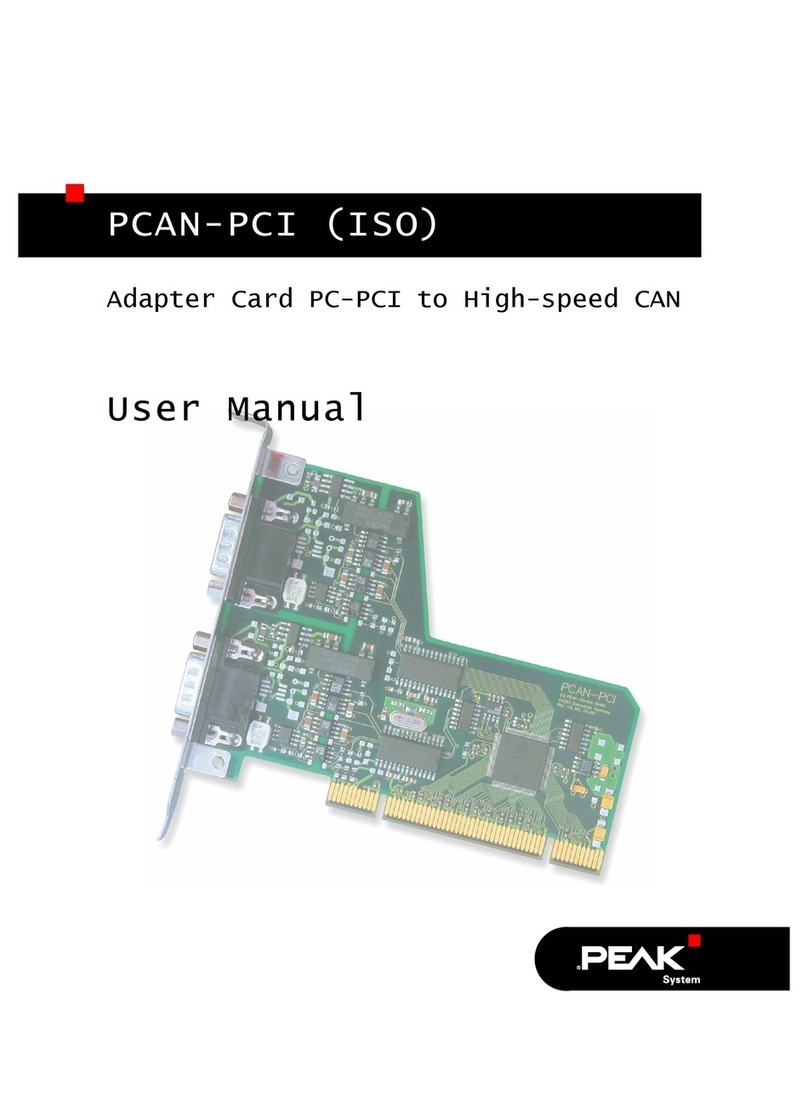

■PC plug-in card (PCIe x1) for PCI Express slots

■1, 2, or 4 High-speed CAN channels (ISO 11898-2)

■Complies with CAN specifications 2.0 and FD

■CAN FD support for ISO and Non-ISO standards switchable

■CAN FD bit rates for the data field (64 bytes max.) from 25 kbit/s up to 12 Mbit/s

■CAN nominal bit rates from 25 kbit/s up to 1 Mbit/s

■CAN bus connection via D-Sub, 9-pin (in accordance with CiA® 303-1)

■FPGA implementation of the CAN FD controller

■NXP TJA1044GT CAN transceiver

■Galvanic isolation up to 500 V per CAN connection

■CAN termination can be activated through a solder jumper, separately for each

CAN channel

■PCIe data transfer via bus master DMA

■DMA memory access operations with 32- and 64-bit addresses

■Measurement of bus load including error frames and overload frames on the

physical bus

■Induced error generation for incoming and outgoing CAN messages

■Power supply for external devices via CAN connection can be connected through a

solder jumper

■Extended operating temperature range from -40 to +85 °C (-40 to +185 °F)

1 Introduction PCAN-PCI Express FD

User Manual 2.0.0 © 2022 PEAK-System Technik GmbH

5