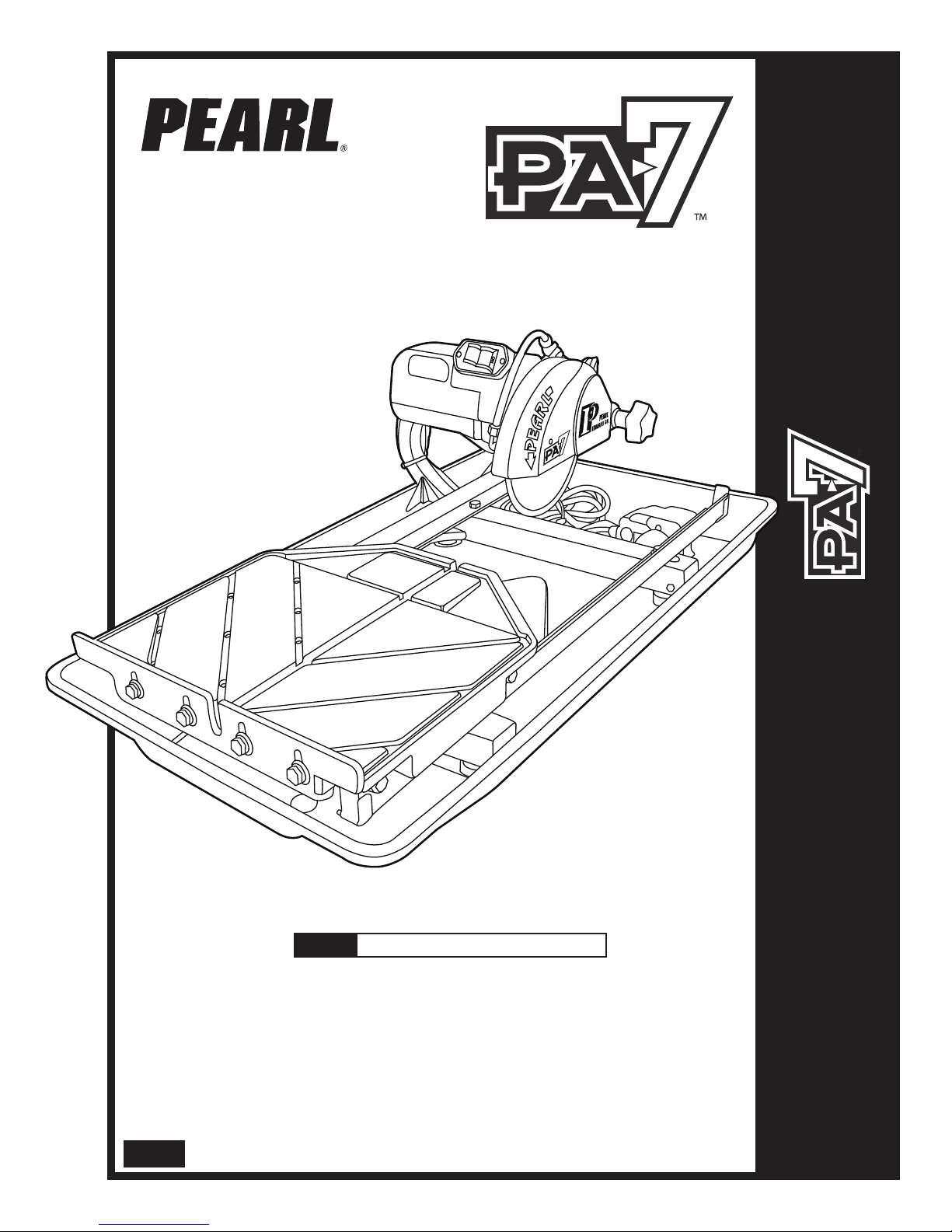

Pearl PA-7 Owner's manual

serial number -

MODEL PA-7™ TILE SAW

Owner’s/OperatOr’s Man al

Caution! Read Safety and General Instructions carefully before using saw for the first ti e.

ou should record the Serial Number of your Tile Saw on this

Owner’s/Operator’s Manual and on the Warranty Card. The Warranty

Card ust be sent back with all the required pertinent infor ation

for the warranty to take effect.

Covered by one or more of the following US Patents:

6,080,041; 6,119,676; 6,272,990; 6,460,533; and D458,282

P e a r l A b r a s i v e C o . 2 . 1 T I L E S A W

REV. 3

TABLE OF CONTENTS

i. general saFetY r les FOr all pOwer tOOls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ii. sYMBOls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

iii. Feat res . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

iv. speCiFiCatiOns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

v. npaCKing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vi. installatiOn and OperatiOn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vii. prOper Blade se . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

viii. saFe Operating praCtiCes FOr tile saw. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ix. Care and MaintenanCe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

x. eleCtriCal MOtOr speCiFiCatiOns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

xi. replaCeMent parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

xii. trO BlesHOOting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

xiii. aCCessOries and parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

xiv. tHe rigHt Blades dOes tHe rigHt JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

xv. HOw tO Order parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

page

– 3–

i. GENERAL SAFETY RULES FOR ALL POWER TOOLS

1. Know your power tool - read owner’s/operator’s manual carefully. Learn its applications and limitations as

well as the specific potential hazards unique to this tool.

2. Keep guards in place - and in working order.

3. Ground all tools - if tools are equipped with three prong plug, it should be plugged into a three-hole electrical

receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter lug must be attached

to a known ground. Never remove the third prong.

4. Remove wrenches - Form a habit of checking to see that adjusting wrenches are removed from tool before

turning it “on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted. Do not use tool in the presence of flammable liquids or gasses.

7. Keep children and visitors away. All children and visitors should be kept at a safe distance from work area.

8. Make workshop childproof with padlocks, master switches or by removing starter keys.

9. Do not force tool. It will do the job better and be safer at the rate for which it was designed.

10. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that may

get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain

long hair.

12. Always use safety glasses. Wear safety glasses (must comply with ANSI Z87.1) at all times. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses. Use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs) during extended periods of operation.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have

repaired by authorized service facility.

15. Disconnect tools. When not in use, before servicing, and when changing accessories, such as blades, bits,

cutters.

16. Avoid accidental starting. Make sure switch is in “off” position before plugging in power cord.

17. Use recommended accessories only. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

contacted.

19. Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and perform it’s intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions

that may affect it’s operation. A guard or part that is damaged should be properly repaired or replaced.

20. Never leave tool running unattended. Turn power “off”. Do not leave tool until it comes to a complete stop.

Read all instructions. As with all machinery there are certain hazards involved with

operation and use of the machine. The following asic safety precautions should e followed at all times to

reduce the risk of fire, electric shock and serious personal injury to you or others. Keep these important

operating instructions with this product.

WARNING!

– 4–

KEEP GUARD IN PLACE

DIAMOND BLADE

BLADE CUTTING DEPT

ELECTRIC SWITC OFF

ELECTRIC SWITC ON

ELECTRICAL AZARD

REMOVE TOOLS

PAY EXTREME

ATTENTION

REPAIRS TO BE DONE

MAC INE AZARD

FLAMMABLE

READ INSTRUCTIONS

CAREFULLY

WARNING

FRAGILE

KEEP DRY

DO NOT STEP ON

WEAR EARING

PROTECTION

WEAR EYE PROTECTION

WEAR BREAT ING

PROTECTION

WEAR ARD AT

WEAR PROTECTIVE

CLOT ING

WEAR SAFETY S OES

WELL VENTILATED

NO NON-WORKING

PERSONNEL

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord, be

sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. Extension cord tables (refer to page 21) show

the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage numbers the heavier the cord.

22. Do not abuse cord. Never carry tool by cord or pull it to disconnect from receptacle, Keep cord from heat,

oil, and sharp edges.

23. Guard against electric shock. Prevent body contact with grounded surfaces. For example, pipes, radiators,

ranges and refrigerator enclosures.

24. Outdoor use extension cords. When tool is used outdoors, use only extension cords intended for use

outdoors and so marked.

25. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

26. Drugs, alcohol, medication. Do not operate tool while under the influence of drugs, alcohol or any

medication.

27. Store idle tool. When not in use, tool should be stored in a dry and locked place, out of reach of children.

ii. SYMBOLS

CALIFORNIA PROPOSITION 65: Sawing and drilling generates dust. Excessive air orne

particles may cause irritation to eyes, skin and respiratory tract. To avoid reathing impairment always employ

dust controls and protection suita le to the material eing saw or drilled in accordance with OSHA (29 CFR Part

1910.1). Diamond lades improperly used are dangerous. Comply with ANSI Safety Code B7.1 and OSHA covering

speed, safety guards, flanges, mounting procedures, general operating rules, handling, storage and general

machine condition.

WARNING!

– 5––

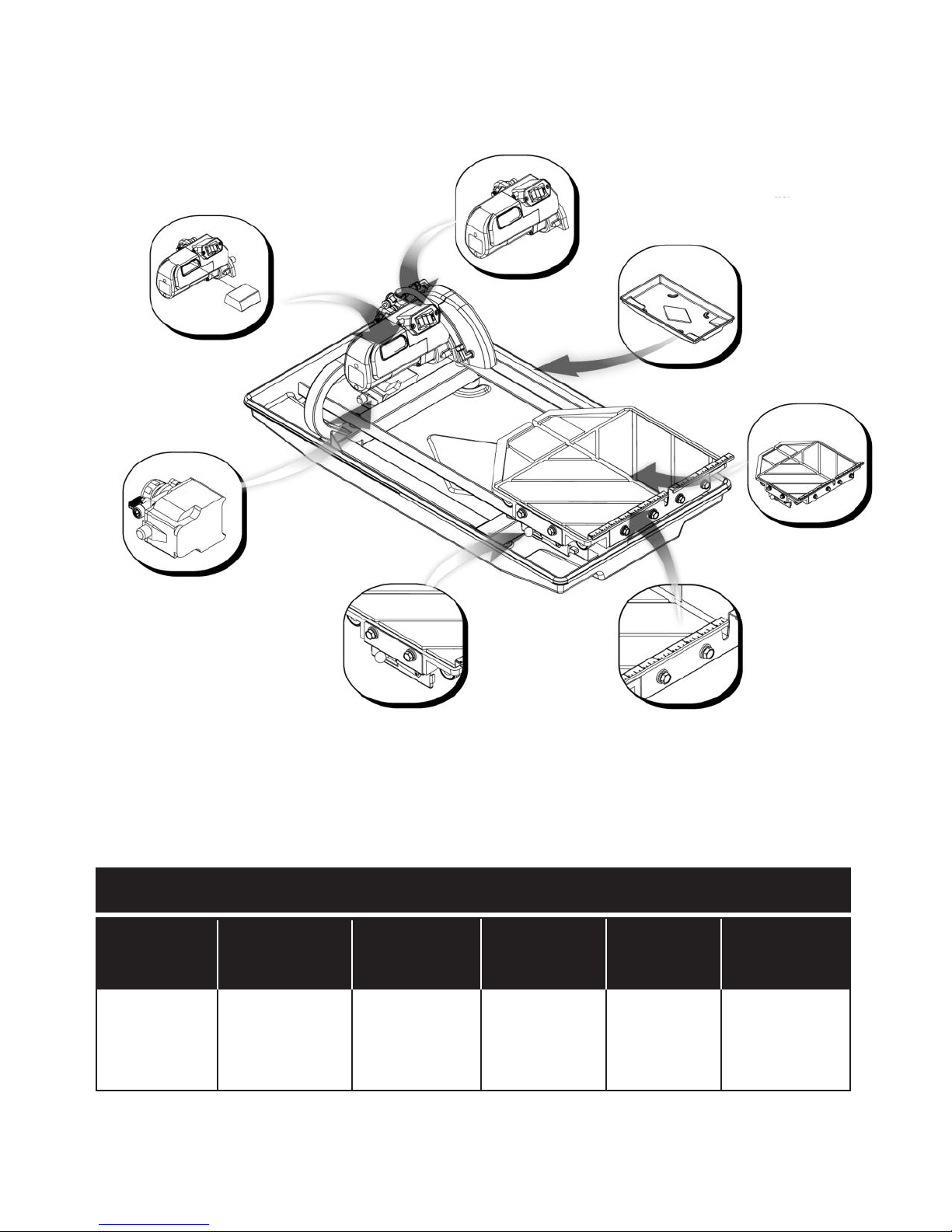

iii. FEATURES

REUSABLE AIR FILTER

Air intake to the motor is filtered

by a fire resistant filter, which

can be cleaned and reused.

3/4 HP BRUSH MOTOR

Generates more torque and is physically

smaller and lighter than similarly rated

induction motors.

STAINLESS STEEL

WATER TRA

igh durability tray

for heavy-duty jobs.

CUTTING TABLE

Provides a durable

work surface while

the ball bearing

wheels and rollers

ensure smooth

effortless

movement.

RULER GUIDE

The guide allows convenient

measurements and promotes

precision cuts.

TABLE RETENTION DEVICE

The device secures the cutting table

when transporting the saw.

WATER PUMP

A high-output water pump

provides sufficient water flow to

cool the blade.

PA-7 TILE SAW

MOTOR MAX. BLADE

CAPACITY

CUTTING

LENGTH

CUTTING

DEPTH WEIGHT

DIMENSIONS

iv. SPECIFICATIONS

7" Blade

5/8" arbor blade

20" rip cut,

14" diagonal cut

1-1/4" 40 lbs. 33.1" L

x 18.7" W

x 12.7"

3/4 P

115 v, 60 z,

6,000 rpm

– 6–

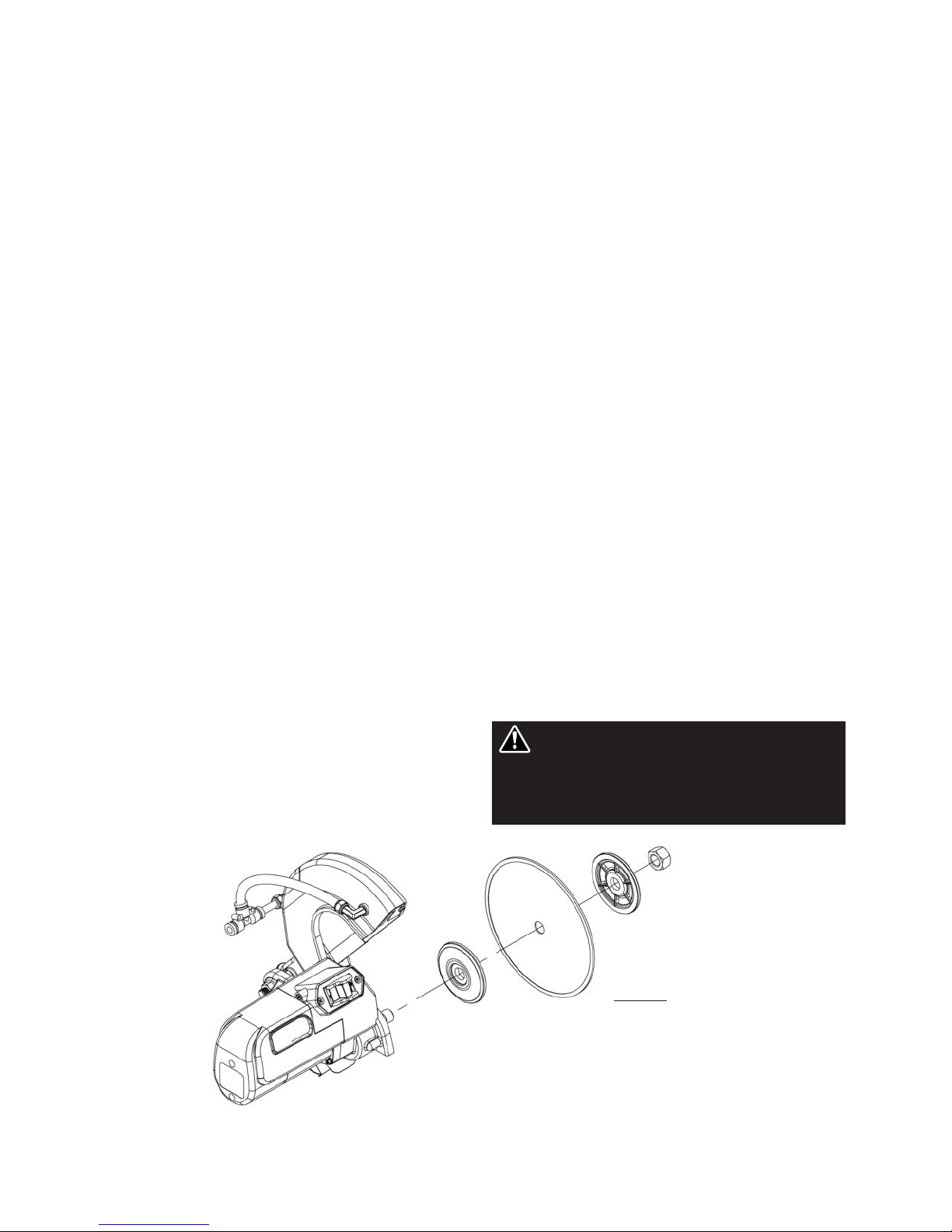

vi. INSTALLATION AND OPERATION

1. Loosen blade guard adjustment knob located at

the rear of the blade guard. Raise the blade

guard to the highest position and retighten the

knob.

2. Remove the blade shaft nut and outer flange.

(see figure 1) If a blade has been mounted,

hold the blade with one hand and use the other

hand to loosen the nut with the universal

wrench. Remove existing blade.

3. Mount new blade, but make certain the arrow

on the blade coincides with the rotation

direction of the shaft.

4. Attach outer flange and blade shaft nut. old

the blade with one hand and use the other hand

to tighten the nut with the universal wrench.

Make certain the flanges are pressed flush

against the blade and that the nut is firmly

tightened, but do not over tighten.

5. Loosen blade guard adjustment knob, lower the

blade guard and retighten the knob.

WARNING: nly use 7" blades on this saw.

Setting a smaller blade may cause the blade

to grab the material being cut, possibly

causing injury to the operator and the saw.

Figure 1

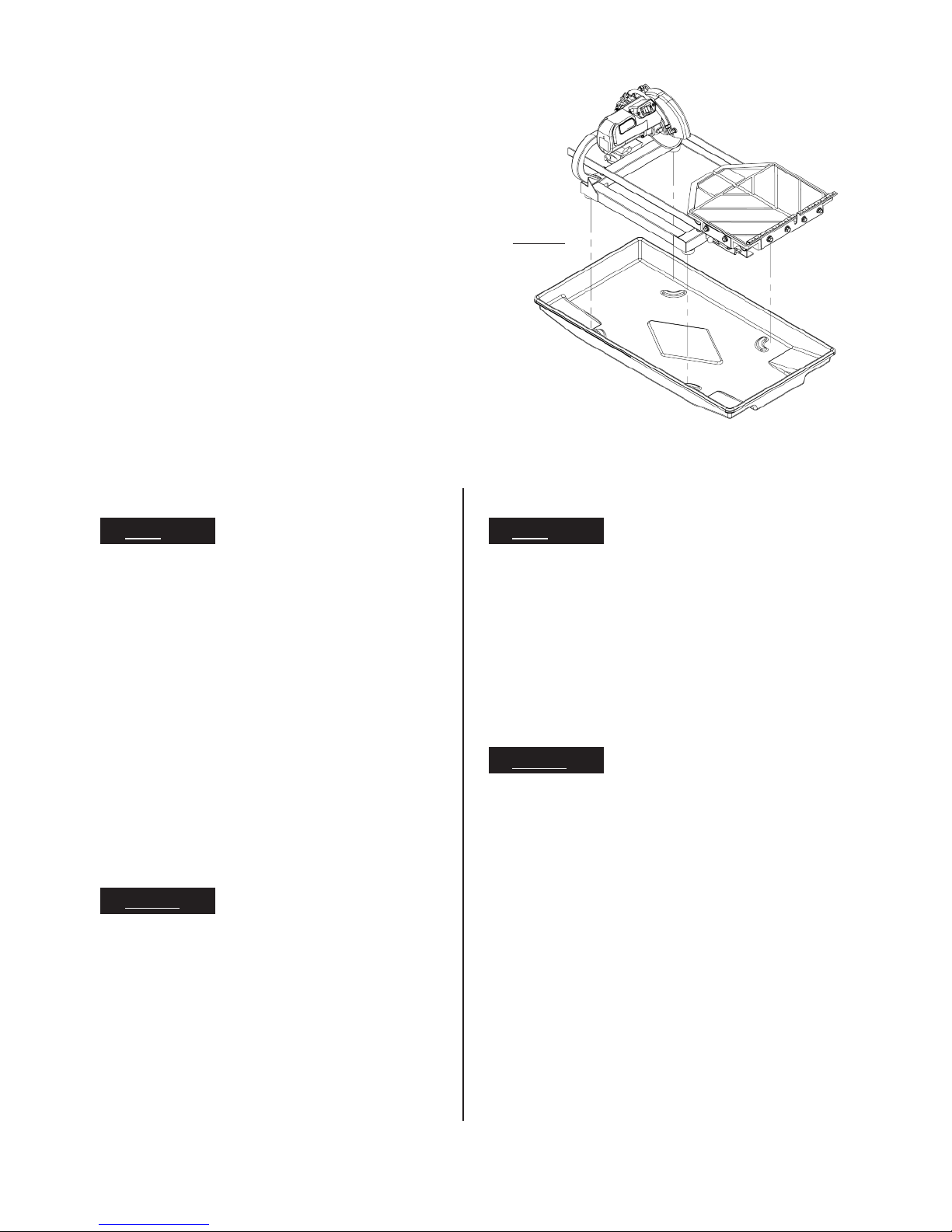

v. UNPACKING

Open the container and carefully lift the saw by the foam packaging and place it on a flat, level

working area. Be sure that you have the following items before you discard the container:

• Saw

• Stainless steel water tray

• 7" saw blade

• 45º/90º rip guide

• Universal wrench

• Water pump

• Owner’s manual

• Drain plug

BLADE INSTALLATION

– 7––

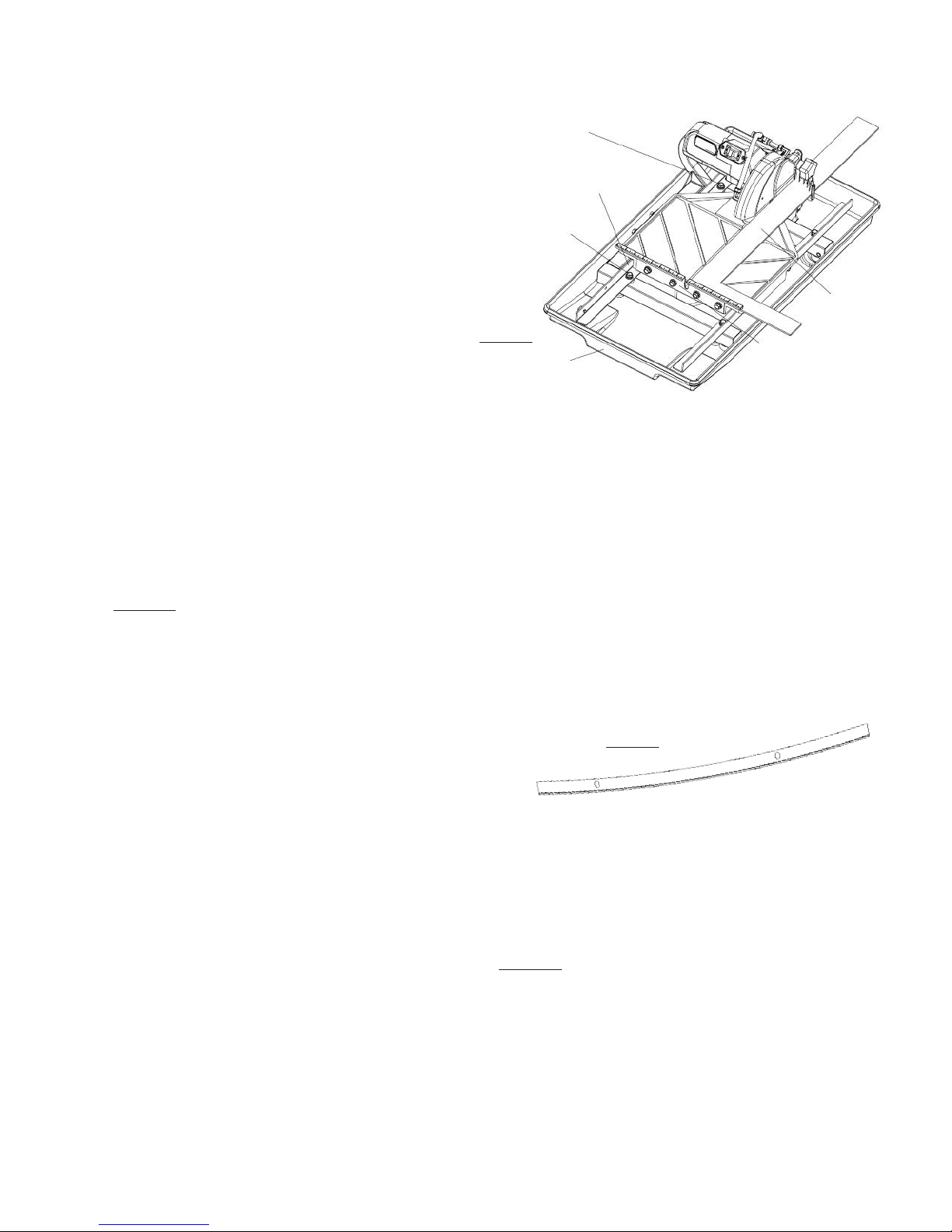

1. Remove the water pump from the box and

check that it is not damaged.

2. Place the pump within the water tray such that

the water outlet is horizontal. (see figure 2)

3. Connect the water hose from the blade guard to

the pump and plug the pump’s power cord into

the female plug that is attached to the post.

4. Fill the water tray so that the water intake is fully

immersed. Proper water level must be

maintained at all times during saw operation.

WARNING: Disconnect the pump before

attempting to handle the pump. Never

operate pump without water in the tray.

1. The ruler guide has inches marked along the top

to allow convenient measurements and to

promote precision cuts. (see figure 3)

2. The cast aluminum cutting table spans an area

of 14-1/2" x 14", which allows it to provide

greater support for handling larger materials.

3. A rip guide should be used together with the

cutting table to ensure precision while making

cuts.

1. Set the rip guide at the desired location on the

ruler guide and tighten the threaded knob.

Make sure that the rip guide is firmly tightened

to avoid slippage. The rip guide can be used for

45º and 90º cuts from both the left and right

side.

2. After the rip guide is positioned for the desired

cut, place material flat against the rip guide and

the ruler guide.

3. Now you are ready to make your cut.

1. Remove threaded knob from the end of the rip

guide with the horizontal groove and insert it

into the other end with the diagonal grooves.

2. Position the rip guide along either of the

diagonal premarked lines that intersect the

ruler guide and the vertical channel of the

cutting table. Tighten threaded knob once in

place.

3. Place one corner of the material being cut in the

vertical slot of the ruler guide and rest the

adjoining edge flat against the rip guide.

4. Now you are ready to make your cut.

To make miter cuts, an optional miter block must

be purchased.

1. Place the lip of the miter block on the ruler

guide with the threaded knob facing you.

2. Position the miter block such that a tile laying

flat against the block may rest its left-most

edge within the vertical channel of the cutting

table. Tighten the threaded knob to secure the

miter block in place.

3. Place material onto miter block and you are

ready to cut.

1. Lift the saw up from inside the water tray.

2. Remove the drain plug and drain any water left

inside the water tray.

Figure 2

Figure 3

WATER PUMP INSTALLATION USING THE RIP GUIDE

PERFORMING DIAGONAL CUTS

PERFORMING MITER CUTS

CLEANING THE WATER TRAY

USING THE CUTTING TABLE

– 8–

3. Flush water into the tray while holding it upright to

remove any sludge buildup.

4. Replace the saw back into the tray. (see figure 4)

5. Reinstall the drain plug into the drain hole before

filling the tray with water.

1. Ensure that the water tray is empty and dry.

2. Unplug the power cord and store it in the

water tray.

3. Secure the cutting table to the front of the saw

using the table retention device.

D ’S

• Inspect blades daily for cracks or uneven wear.

• Always use appropriate blade for material

being cut.

• Inspect arbor shaft for uneven wear before

mounting blade.

• Always use blades with the correct arbor shaft

size.

• Ensure that blade is mounted in the correct

direction.

• Use proper safety equipment when operating

the saw.

• Always have a continuous flow of water on

both sides of blade.

• Secure the blade to the arbor with a wrench.

D NT’S

• Do not operate the saw without safety guards

in position.

• Do not operate the saw with blades larger or

smaller than 7".

• Do not cut dry with blades marked “Use Wet”.

• Do not exceed manufacturer’s recommended

maximum RPM.

• Do not force blade into material. Let blade cut

at its own speed.

D ’S

• In addition to the following, always follow wet

recommendations.

• Use appropriate blade for material being cut.

• Inspect segment blades for segment cracking

or loss.

• Do not use damaged blades.

• Use proper safety equipment when operating

the saw.

D NT’S

• In addition to the following, always follow wet

recommendations.

• Do not make long cuts with dry blades. Allow

them to air cool.

• Do not use the edge or side of blade to cut or

grind.

• Do not attempt to cut a radius or curve.

• Do not cut too deep or too fast into the

material.

• Do not cut any material not recommended by

blade manufacturer.

TRANSPORTING THE SAW

WET CUT BLADES DRY CUT BLADES

Figure 4

vii. PROPER BLADE USE

– 9––

viii. SAFE OPERATING PRACTICES FOR TILE SAW

1. Use safety equipment - wear safety approved

hearing, eye, head and respirator protection.

2. Read and understand the symbol definitions

contained in this manual.

3. Read and understand all warnings and

instructions on the machine.

4. Read all safety materials and instructions that

accompany any blade or accessory used with

this machine.

5. Establish a training program for all operations

of this machine.

6. Always provide a copy of this manual to the

equipment user. If you need extra copies

call our Customer Service Department at

1-800-969-5561.

7. Always select a diamond blade according to

the manufacturers recommendation suitable

for the material to be cut. Never use a blade

having a maximum operating speed lower than

the “No load R.P.M.” marked on the tool

nameplate. Do not operate any saw without

safety guards in place or with a blade diameter

larger than the maximum saw blade capacity.

8. Before mounting a blade on the saw clean and

inspect the arbor shaft, blade flanges and the

diamond blade for uneven wear or damage. If

it appears to be damaged, Do not operate the

tool. ave it serviced by a qualified service

technician.

9. Before each use of the saw, inspect the

diamond blade for hairline fatigue cracks. If

such a crack or flaw is evident, discard the

blade. Using a damaged lade may cause

injury to the operator or others.

10. Be sure that the blade arbor hole matches the

blade adapter flange supplied with the saw.

Use only blade adapter flanges that came on

your saw. Never use damaged or worn blade

adapter flanges.

11. Installing the blade, install the blade with the

arrow pointing the same direction as the

rotation of the arbor shaft or the arrow on the

blade guard. Be sure to tighten the blade shaft

arbor nut with the wrench provided.

Be careful not to over tighten.

12. Check that the blade tracks near the center of

the channel in the main table, and that the table

moves freely from front to back.

13. Sometimes the material being cut is not

abrasive enough to expose new diamonds on

the blade. If the blade is not sharpened, it will

rub against the surface resulting in heat build

up in the core. To prevent this, it is necessary

to dress the blade. To dress the blade simply

cut something that is very abrasive such as a

piece of cement block. Indications that the

blade needs dressing includes:

• The diamond in the matrix appear shiny

because they are worn flat.

• The blade stops cutting or noticeably

slows down.

Blade dressing stones are available from your local Pearl

Warehouse.

14. Before using the saw fill the water tub enough

to submerge the water pump with clean water

only. Replenish as necessary and clean the

water tub frequently. Do not operate a wet

cutting blade without adequate water flow to

both sides of the blade. Never run the pump

dry.

15. When cutting, always hold the material firmly

lying flat, supported by the main table with one

edge resting against the main table backstop.

The dust generated y cutting

of tile, mar le, stone, ricks etc. can e injurious

to your health. Always operate machinery in well

ventilated areas and provide proper dust removal.

Always wear a dust mask approved for respiratory

protection against these types of dusts and mists.

For your own safety and the

safety of others do not attempt to operate this saw

until you have read and understand the general

safety rules for all power tools and the following

additional safety precaution unique to this saw.

WARNING!

WARNING!

Not dressing the lade

frequently or setting the lade too high will cause

it to gra the tile possi ly causing injury to the

operator and the saw. Setting the lade depth too

low will cause it to cut into the main ta le that

may result in injury.

WARNING!

– 10 –

• Do not attempt to cut pieces too small to

safely hold down on the main table.

• Never use the side of the blade to cut or

grind with, only cut in a straight line.

• Keep all parts of your body away from the

blade and all other moving parts.

• Never touch or try to stop a moving blade

with your hand.

16. When cutting dry - always unplug the water

pump first. Never run the pump dry.

• Do not use a wet cutting blade for dry

cutting. Select the proper dry cutting

blade for your application.

• Never make long continuous cuts with dry

cutting blades. To avoid heat build up,

allow the blade to cool, remove the tile

and allow the blade to run freely for a few

minutes.

IMPORTANT - If there is any tendency for the

saw to tip or ove during certain operations,

such as when cutting large heavy tile; the saw

ust be securely fastened to a supporting

table.

17. Make certain all adjusting knobs or locks are

tight and engaged in their detents and that

movable parts not intended to move during

operation are securely locked before making a

cut. Be careful not to over tighten.

18. Before connecting the machine to a power

source check to see that the “On/Off” switch is

in the “off” position.

• Make sure the blade is not contacting

anything before connecting to a power

source and starting the motor.

• Know how to stop the machine quickly in

case of an emergency.

19. Grounding Instructions

• In the event of a malfunction or

breakdown, grounding provides a path of

least resistance for electric current to

reduce the risk of electric shock. This tool

is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug. The plug must be

plugged into a matching outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

• Do not modify the plug provided - if it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

• Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock.

• Check with a qualified electrician or

service personnel if the grounding

instructions are not completely

understood, or if in doubt as to whether

the tool is properly grounded.

• Use only 3 wire extension cords that have

3 prong grounding plugs and 3 pole

receptacles that accept the tool’s plug.

Repair or replace damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

that looks like the one illustrated in Figure 5. The tool has

a grounding plug that looks like the plug illustrated in

Figure 5(A). A temporary adapter, which looks like the

adapter illustrated in Figure 5(B) and 5(C), may be used

to connect this plug to a 2 pole receptacle as shown in

Figure 5(B) if a properly grounded outlet is not available.

The temporary adapter should be used only until a

properly grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, and the like,

extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet

box.

Note: USE OF A TEMPORARY ADAPTER IS NOT

PERMITTED IN CANADA.

Additionally, water pump requires the use of a Ground

Fault Circuit Interrupter. Therefore, when using the water

pump receptacle, this tool must be plugged into a

properly installed Ground Fault Circuit Interrupter outlet.

See Figure 5(D). If a Ground Fault Circuit Interrupter

outlet is not available, Pearl Abrasive Co. has it available

as an accessory item. A plug-in Ground Fault Circuit

Interrupter may be plugged into a properly installed and

grounded 3-pole outlet. Refer to Figure 5(E).

20. Position of the Tile Saw

• To avoid the possibility of the appliance

plug or receptacle getting wet, position

tile saw to one side of a wall mounted

NOTE - Use of a Te porary Adapter is not per itted

in Canada.

– 11 –

receptacle to prevent water from dripping

onto the receptacle or plug. The user

should arrange a “drip loop” in the cord

connecting the saw to a receptacle. The

“drip loop” is that part of the cord below

the level of the receptacle, or the

connector if an extension cord is used, to

prevent water traveling along the cord and

coming in contact with the receptacle. See

Figure 6.

• If the plug or receptacle does get wet,

Do not unplug the cord. Disconnect the

fuse or circuit breaker that supplies power

to the tool. Then unplug and examine for

presence of water in the receptacle.

21. Extension Cords

• Use only extension cords that are

intended for outdoor use. These extension

cords are identified by a marking

“Acceptable for use with outdoor

appliances; store indoors while not in

use.” Use only extension cords having an

electrical rating not less than the rating of

the product. Refer to chart on page 14.

Do not use damaged extension cords.

Examine extension cord before using and

replace if damaged. Do not abuse

extension cords and do not pull on any

cord to disconnect. Keep cord away from

heat and sharp edges. Always disconnect

the extension cord from the receptacle

efore disconnecting the saw from the

extension cord.

* Ground Fault Circuit Interrupter (GFCI)

protection should be provided on the

circuit(s) or outlet(s) to be used for the

tile saw. Receptacles are available having

built-in GFCI protection and may be used

for this measure of safety.

(A) (B)

Figure 5

Grounding Methods

(C) (D) (E)

Grounding pin

Grounding pin

Cover of

grounded

outlet box

Metal

Screw

Grounding

Means

(Lug)

To reduce the risk of electrocution, keep

all connections dry and off the ground.

Do not touch plug with wet hands.

TOOL

Figure 6

Drip Loop

Supporting

Surface

Power Cord

Drip Loop

– 12 –

ix. CARE AND MAINTENANCE

For your safety efore performing any maintenance on the saw turn off the power switch

and unplug the power cord.

WARNING!

GENERAL RULES

• Always clean the machine before performing any

maintenance/ repair.

• Before performing any cleaning/maintenance

/repair, the machine must be switched off with the

main power switch.

Steps to Follow When Cleaning:

• Please do not use aggressive cleaners (i.e.

containing solvents). Do not use high-pressure

water jets, aggressive detergents or solutions and

liquids with a temperature exceeding 86ºF! Use a

fluff-free cloth only.

• Use a cloth which may be lightly moistened only for

removing dust and dirt. ard packed dirt can be

removed with a soft brush.

• For the sake of safety, no water/cleaning

liquid/vapor may penetrate into the electric motor,

connectors/plugs, switches, etc. Therefore cover

all apertures, holes in the housing, connectors or

plugs, etc. or seal them with adhesive tape!

• Use a soft, low-pressure water jet and a brush to

rinse dirt and incrustations away. Be particularly

careful when near hazardous parts of the machine

(e.g. switch, motor). Clean the motor and switches

only by wiping with a moist cloth.

• Do not “rinse” the bearings of the drive elements to

prevent them from running dry. The ball bearings

of the machine are permanently lubricated.

• After cleaning, remove all covers and adhesive

tape! All screws/nuts which you may have

loosened must be tightened again!

• After wet cleaning, try the machine on a power

outlet which is equipped with a power breaker (i.e.

fault current circuit breaker). If the fault current

circuit breaker cuts the power supply, the machine

must be inspected by an authorized dealer prior to

use!

CLEANING

After every use of the machine:

• Remove dirty water from container.

• Remove dirt and mud from the bottom of the

container.

• Rinse the immersion pump with fresh water to

prevent the water pump from clogging with

residual dirt.

After wet cleaning and before using the machine

again:

• Connect the machine to an electric power outlet

equipped with a “GFCI” safety power breaker. If the

safety power breaker cuts off the electrical power

supply, do not try to operate the machine but have

it checked by an authorized dealer first.

PROLONGED PERIOD OF NON-USE

Before not using the machine for a prolonged period

of time:

• Clean and lubricate all movable parts. owever, do

not grease the guide rails.

After not using the machine for a prolonged period of

time:

• Check that the stand is safely fixed.

• Check that all screw joints and nuts are fixed.

• Check that the cutting table is seated properly on

the guide rails and that it moves easily along the

entire length of the rails.

• With the saw blade removed, switch on the motor

for an instant and switch it off again. If the motor

does not run, have the machine inspected by a

qualified electrician.

• Check that the immersion pump works properly.

Turn on the cooling water tap and switch the

machine on. If the pump does not give any water or

only a little, switch the machine off at once. Clean

the pump, or replace if necessary.

EXTREME TEMPERATURE

Ambient temperature below 32° F (Winter):

• To prevent the water in the pump and cooling

system from freezing, remove the water after using

the machine or when there will be a long break.

Make sure that the cooling system is entirely

drained so that there is no water left inside the

pump and water hose!

– 13 –

WATER PUMP MAINTENANCE

When the machine has not been used for a long period of

time, hard packed dirt may begin to build up inside the pump

and block the pump wheel. If the machine is activated with

the immersion pump blocked, the electric motor of the

pump will be damaged within a few minutes! Please follow

the steps listed below to clean the pump before operating

the saw:

1. Remove the immersion pump from the water container.

2. Clean the immersion pump.

3. Loosen the fixing screws of the pump lid.

4. Take the lid off the pump. Be careful not to damage or

lose the gasket underneath.

5. Clean the pump lid.

6. Remove all dirt and incrustations from the pump wheel.

7. Check whether the pump wheel can be easily turned.

8. Then reassemble the immersion pump correctly and

check whether it works properly.

REALIGNMENT

Method 1:

This procedure deals with the most common source of

misalignment that occurs when the guide rails are not

parallel with the blade.

1. Place a straight edge on the cutting table as shown in

figure 7.

2. Loosen the left guide rail by untightening the fasteners

found at the ends of the rail. (see figure 7) Do not loosen

the rail too much to avoid excessive play during

adjustments.

3. Make sure the straight edge is placed flush against the

ruler guide. Adjust the left guide rail so the front and rear

edges of the blade touch the straight edge, although a

tolerance of 0.1mm between the front and rear edges is

allowed. Perform this adjustment along the entire length

of the straight edge.

4. Position the table as close to the user as possible. Place

the straight edge flush against the ruler guide and blade.

While gently holding down the straight edge, move the

table towards the rear of the saw and then back. Apply

just enough force to prevent the straight edge from

moving due to table vibrations, but not enough to prevent

the blade from displacing the straight edge. Observe any

gaps that may appear between the straight edge and

blade or between the straight edge and ruler guide. A gap

exceeding the allowed tolerance means that the table is

not moving parallel to the blade; hence, further

adjustments as outlined in step 3 will be required.

owever if scenario A or B described below occurs, other

adjustments may be required instead.

A. If the straight edge only touches the blade when

the table is positioned midway along the rail or at

the ends of the rail, then the left rail may be

deformed (i.e. bowed). (see figure 8) Typically a

bowing displacement of up to 0.2mm will not affect

cutting accuracy. Perform test cuts to determine if

the rail should be replaced. If a replacement is

required try swapping the left rail with the right rail

and perform the alignment procedure again. If this

does not solve the problem, then replacement rails

will have to be acquired.

B. If the straight edge touches both edges of the blade

intially, but shifts apart as the table travels along

the rail, proceed to method 2 below.

5. Tighten the fasteners at both ends of the left rail. If

alignment has been achieved do not proceed to

method 2.

Method 2:

This procedure corrects another source of misalignment

that occurs when the table’s orientation is not parallel with

the guide rails.

1. Lower the table bracket by loosening the two affixed

bolts. (see figure 9) Remove the table from the rails.

2. If the table shifts to the right as it travels away from the

user, a shim needs to be added to the guide roller furthest

Figure 7

Figure 8

Fastener

Fastener

Front

Straight

Edge

Ruler

Guide

Left Guide Rail

Straight

Edge

– 14 –

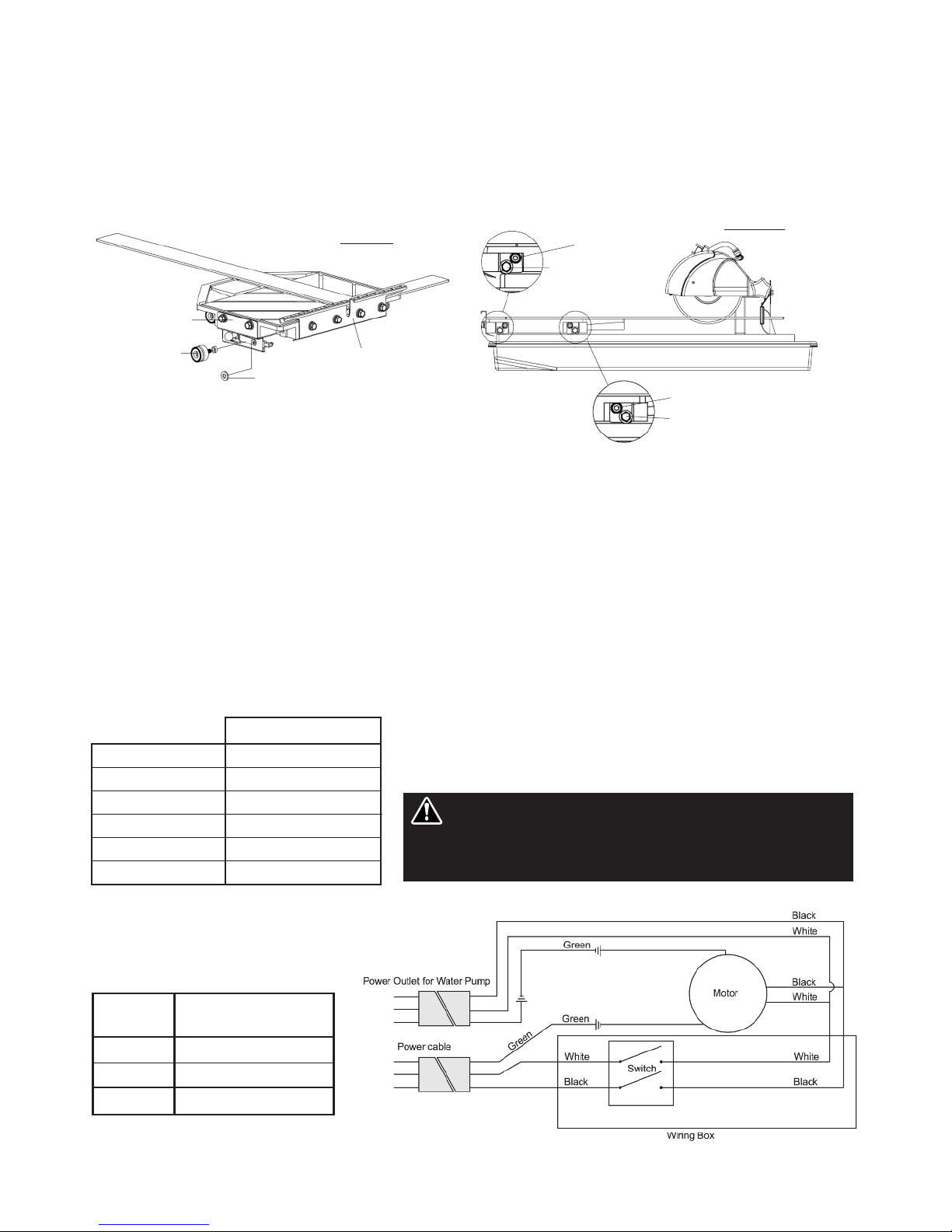

x. ELETRICAL MOTOR SPECIFICATIONS

from the ruler guide. On the other hand, if the table shifts

to the left, a shim needs to be added to the guide roller

closest to the ruler guide. Remove the appropriate guide

roller to insert a shim between the roller and table, then

reattach. (see figure 9) Depending on the severity of the

shift, more than one shim may be required.

3. After adding shim(s), mount the table onto the guide rails

and realign the table to the blade using method 1. Check

to see if any shifting persists. A shift tolerance of 0.2mm

is allowed. A shift in excess of that will require further

adjustment—repeat step 2.

4. Once alignment is successful, restore the table bracket to

its original position and secure it in place by tightening

the affixed bolts.

LEVELING ADJUSTMENT

This procedure levels the table so that it is perpendicular to

the blade and flush against the rails.

1. Loosen the bolt on the flat roller plate so that the roller

can swing freely about the bolt. (see figure 10) Do this for

both flat roller plates.

2. old the table against the rails. The flat rollers should

reposition themselves to maintain contact with the rails.

If the table is not perpendicular to the blade, lift the right

side of the table instead to obtain the proper angle. A

square tool will be required to confirm the angle. Tighten

the bolts. Check the table for play. Repeat step 1 if some

play is still present.

Figure 9 Figure 10

Ruler Guide

Bolt

Bolt

Flat Roller

Flat Roller

Shim

Guide Roller

Table Bracket

Horse Power 3/4 hp

Volts 115 V/ 60hz

Amps 7.5 amps

Motor RPM 6,350 rpm

Cycle 60

Phase 1

PA-7 TILE SAW

WIRE

GAUGE

No. 12

No. 10

No. 8

LENGTH F C RD

25'

50'

75'

Recommendations:

• It is recommended that a 7.5 amp circuit be used while operating this

saw. This will prevent possible power interruption or loss.

• Always plug saw as close as possible to the power source while

operating. This will allow you to receive optimum electricity.

Electrical Wiring Diagram

WARNING: To avoid permanent motor damage you must use

the correct extension cord. Never use more than one extension

cord at a time. Follow the chart for proper size.

– 15 –

xi. REPLACEMENT PARTS LIST

pa-7 C tting taBle asseMBlY

1 20 19

145166152

10718817162021

9

21

20

16

12 4 13 11 3

1 TC02 cutting table PA00001

2 Ruler guide PA00002

3 D12.7 d8.5 x 6L spacer PA00003

4 Type 6 guide ruler PA00004

5 Teflan flat ruler PA00005

6 Roller mounting plate PA00006

7 Table lock bracket PA00007

8 Leaf spring PA00008

9 Ball handle PA00009

10 Pin head PA00010

11 M22 Internal C-clip PA00011

12 M8 x 1.25 x 30L Socket head bolt PA00012

13 608 LLU radial bearing PA00013

14 M8 x 1.25 x 35L ex bolt PA00014

15 M8 x 1.25 nut PA00015

16 M8 narrow washer PA00016

17 M4 x 0.7 x 8L Cross screw PA00017

18 M4 x 0.7 Nylon nut PA00018

19 M8 x 1.25 x 20L socket head hex bolt PA00019

20 M8 Spring washer PA00020

21 M8 x 1.25 x 20L ex bolt PA00021

22 M8 x 1.25 x 25L Socket head hex bolt PA00022

PART NAME PART NUMBER PART NAME PART NUMBER

– 16 –

pa-7 MOtOr asseMBlY

14

68

18

19

20

27

16

32

29

30

12

13

24

33 39 9

42 15

36

35

17

21

7

36

40

28

38

2

39

43

24

41

37

17

21511

34

4

1

23222510

37

36

44

37

21

17

45

46

– 17 –

pa-7 MOtOr asseMBlY pa-7 Main asseMBlY

1 Blade shaft gear PA00023

2 Cutting head housing PA00024

3 Cutting head mounting tube PA00025

4 Blade shaft PA00026

5 Gear cover PA00027

6 Blade guard mounting shaft PA00028

7 Wire anchor plate PA00029

8 Wire separation plate PA00030

9 Wire access plate PA00031

10 Particle filter PA00032

11 D28 d20mm Oil seed PA00033

12 Complete Motor PA17101Z

13 14mm x 6mm Carbon brush PA00035

14 Anchor plate PA00036

15 Rubber Stop 22mm x 8mm x 2.5mm PA00037

16 M10 x 1.5 Nut PA00038

17 M4 Spring washer PA00039

18 M3 Narrow washer PA00040

19 M3 Spring washer PA00041

20 M3 x 8L Cross tapping screw PA00042

21 M4 Narrow washer PA00043

22 M15 External C-clip PA00044

23 5 x 16-Rad. Woodruff key PA00045

24 Dia 5/8'' (15.9mm) Universal flange PA00046

25 D19 d6 Radial bearing 626ZZ PA00047

26 KEDU KJD17B Electromagnetic switch PA00048

27 2 Cable D9 cable boot PA00049

28 Power switch mounting plate PA00050

29 M8 Narrow washer PA00051

30 M8 Spring washer PA00052

31 M8 x 1.25 x 15L socket head hex bolt PA00053

32 M8 Rectangular shim PA00054

33 M8 x 1.25 x 15L flat point set screw PA00055

34 D35 d15 Radial bearing 6202 LLB PA00056

35 M4 x 8L Cross tapping screw PA00057

36 M4 x 5L Countersunk tapping cross screw PA00058

37 M4 x 20L Cross tapping screw PA00059

38 Gasket PA00060

39 M4 x 1.25 Acorn nut. PA00061

40 20A 125V/12A 250V Toggle switch CX38085

41 7'' blade

42 M8 x 1.25 Nut PA00062

43 5/8'' - 11 UNC Nut PA00063

44 Motor fan cover assembly PA00064

45 Water pump receptacle PSV10033R

46 Power cable S710-01

PART NAME PART NUMBER

1 Frame weldment PA00067

2 Left 755L - L-rail PA00068

3 Right 755L - L-rail PA00069

4 Steel water tray assembly PA00070

5 1/2 P Cutting head PA00071

6 TC02 Cutting table PA00072

7 Water pump CX38011

8 Water flow T adapter PSV00005

9 M10 Spring washer PA00073

10 M4 Spring washer PA00074

11 M8 Spring washer PA00075

12 M4 x 0.735L Cross screw PA00076

13 Male M8 x 1.25 x 20L knob PA00077

14 M8 Narrow washer PA00078

15 M8 x 1.25 x 20L ex bolt PA00079

16 M4 x 0.7 Nut PA00080

17 Rubber stop PA00081

18 Rubber splash guard PSV100023

19 M6 Narrow washer PA00082

20 M6 x 1.0 x 10L ex bolt PA00083

21 Blade guard PA00084

22 Water flow L adapter PSV00008

23 Air FIlter PA00085

24 20A 125V 12/250V Toggle Switch CX38085

25 Drain Plug S1000-48

PART NAME PART NUMBER

20

5

6

3

2

15

11

14

16

17

12

20

1

4

19 18 8 9 13

21

22

24

23

7

25

– 18 –

xiii. ACCESSORIES & PARTS

Name (Qty.)

Stainless Steel Water Tray (1)

Drain plug not included

Part Number

PA00072

Name (Qty.)

Optional Universal

Saw Stand (1)

Part Number

V35010-UV

Name (Qty.)

Optional Complete

Miter Block with

Knob (1)

Part Number

S1000-34

Knob Only (1)

V35016

Knob Only (1)

V35016

xii. TROUBLESHOOTING

For your safety and the safety of others, turn the power switch off and always remove the plug from

power source efore trou leshooting. Repairs performed y unauthorized personnel could cause serious hazard. We

recommend that service to this tool e performed y a qualified service technician with original equipment replacement parts.

WARNING!

EXCESSIVE N ISE. Possible blade shaft bearing wear,

motor belt loose or motor fan rubbing on housing. ave

tool serviced.

BLADE WILL N T CUT. Check for worn out diamond edge.

Be sure that the arrow on the blade is rotating the same

direction as the motor arbor and/or arrow on the blade

guard. Make sure the blade is suitable for the material to be

cut. If blade has been used to cut a material that is hard, it

may have become dull, dress the blade by cutting a light

weight abrasive building block to expose fresh diamonds.

Blade dressing stones are available from your local Pearl

Warehouse.

M T R WILL N T START. Check power supply. If the

water pump turns on when the power switch is in the “on”

position, but the motor does not, have the motor serviced.

M T R WILL N T ST P. The contacts in the switch may

have become arched together in the on position, have it

serviced.

M T R SHUTS FF DURING PERATI N. Check to see

that the circuit you are using is not overloaded with lights

or other equipment. The fuse or circuit breaker may not

have sufficient capacity, use 20-amp power. If you are

using an extension cord check the extension cord table to

be sure it is heavy enough to carry the current this product

will draw. See Page 14 for electric cord reference.

EXCESSIVE VIBRATI N Check to see that the blade is

mounted properly according to safe operating practices

section. Blade may be out of balance, try a different blade.

Arbor shaft bearings possibly worn, have tool serviced.

N T CUTTING SQUARE. Check the main table and carriage

adjustment as well as the blade alignment procedure

located in the care and maintenance section.

MAIN TABLE D ES N T M VE FREELY. Inspect the guide

rails and rollers for build up of tile chips or dry slurry

deposits. Clean and check guide roll or adjustments,

according to the procedure in the care and maintenance

section.

N WATER FL W T BLADE. Check the water feed tube for

kinks or obstructions. Check the inlet screen to ensure it is

not clogged. Remove the pump inlet and turn the impeller

to ensure it is not damaged or jammed. Clean the impeller

if necessary and apply a drop of light oil to the shaft - be

sure the impeller spins freely.

P R MACHINE PERF RMANCE WITH LITTLE P WER.

Check cord/extension cable for appropriate length and gage.

Check power network for sufficient power and circuit

breaker capacity.

CENTER H LE IN BLADE VERSIZE R W RN. Saw blade

has slipped on shaft while running. Check shaft for damage

and replace blade.

Name (Qty.)

Complete 45˚/90˚

Rip Guide with

Knob (1)

Name (Qty.)

Complete 45˚/90˚

Rip Guide with

Knob (1)

Part Number

V35000

– 19 –

xv. HOW TO ORDER PARTS

Please have the following information ready before calling:

• Serial Number of your Tile Saw

• Model Number of the Tile Saw

• When purchased and where

• Part Description

All parts listed may be ordered from your Local warehouses. If the part is not stocked locally, call our Corporate

office and ask for our Customer Service Department. For Technical Support call 1-800-969-5561. In Canada call

1-800-387-0008. There is a $25.00 minimum order.

Return Policy: Return goods for credit or exchange on the basis of the following terms: (1) They must be current

products; (2) Items returned for replacement or refund should be in original cartons and must be accompanied

by a packing slip with the following information: Returned Goods Authorization (RGA) number obtainable from

Customer Service Department • List of items returned • Reason(s) for return(s) • Copy of original invoice(s); (3)

Freight charges must be assumed by sender; (4) Returning goods are subject to a 15% handling charge to cover

our cost of repacking and restocking. All Prices are subject to change without notice.

Disclaimer: Pearl Abrasive Co. reserves the right to make changes or improvements on its products without

incurring an additional obligation including any obligation to make corresponding changes or improvements to

products previously manufactured or sold. Pearl reserves the right to discontinue products at any time without

notice.

All illustrations displayed in this manual are the property of Pearl Abrasive Co. and shall not be duplicated or

reproduced without the express written consent of Pearl Abrasive Co.

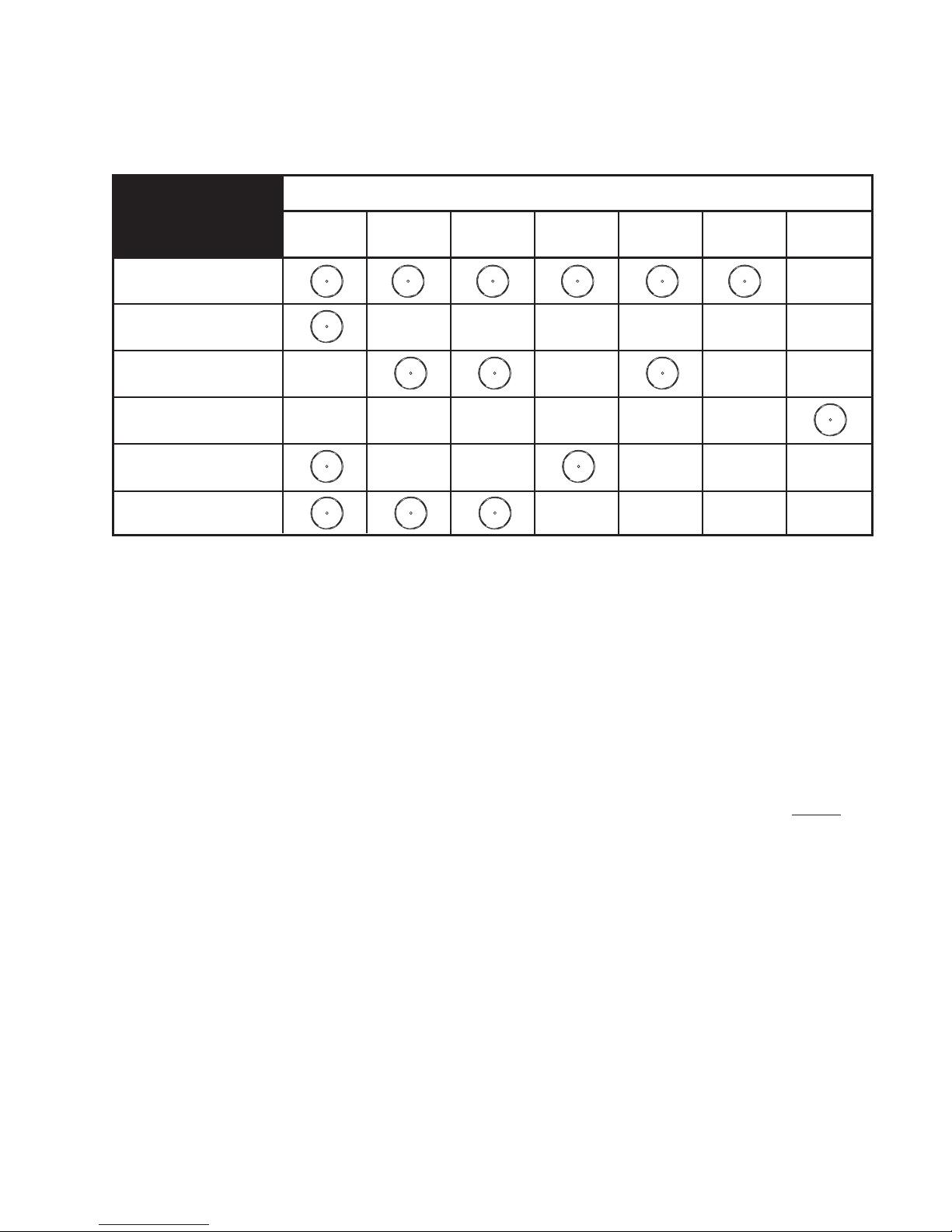

xiv. THE RIGHT BLADE DOES THE RIGHT JOB

For the most effective cutting and blade life always use the recommended Pearl Abrasive Co. blade.

APPLICATION

PEARL BLADE

SERIES

HPXL Series

DTLB19 Series

HP Series

Glass Bla e

SH Series

Pro-V Series

CERAMIC EXTRA HARD PORCELAIN MARBLE GRANITE HARDSTONE GLASS TILE

TILE CERAMIC

Part No. PA7MAN • 04/14

GEORGIA • USA

4963 SOUT ROYAL ATLANTA DRIVE

TUCKER, GEORGIA 30084

ONTARIO • CANADA

375-2 PIDO ROAD

PETERBOROUG , ONTARIO K9J-6X7

C RP RATE FFICE: S . CALIF RNIA • USA

6832 E. SLAUSON AVENUE, COMMERCE, CA 90040-0031

562-927-5561 • FAX 562-928-3857

Toll Free: 800-969-5561

www.pearlabrasive.com

Table of contents

Other Pearl Saw manuals

Pearl

Pearl VX10.2XLPROR Owner's manual

Pearl

Pearl VX141MS User manual

Pearl

Pearl CX10 Owner's manual

Pearl

Pearl VX RSPRO R Owner's manual

Pearl

Pearl VX5WV Owner's manual

Pearl

Pearl PA-10 User manual

Pearl

Pearl PA7TT Owner's manual

Pearl

Pearl VX RSPRO VX1048RSPRO Owner's manual

Pearl

Pearl VX10RSPRO Owner's manual

Pearl

Pearl VX141MS User manual