Pearl VX141MSD Owner's manual

serial number -

MODEL VX141MS™

MASONRY/BRICK SAW

OWNER’S/OPERATOR’S MAN AL

Caution! Read Safety and General Instructions carefully before using saw for the first time.

Y u sh uld rec rd the Serial Number f y ur Saw n this

Owner’s/Operat r’s Manual and n the Warranty Card. The Warranty

Card must be sent back with all the re uired pertinent information

for the warranty to take effect.

Pearl Abrasive Co. 2.1 MASONRY SAW

REV. 3

™

™

TABLE OF CONTENTS

I. GENERAL SAFETY R LES FOR ALL POWER TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

II. SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

III. FEAT RES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IV. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

V. NPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VI. INSTALLATION AND OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VII. PROPER BLADE SE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VIII. CARBON BR SH REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IX. AIR FILTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X. CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

XI. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XII. ACCESSORIES AND PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XIII. ELECTRICAL MOTOR SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

XIV. WATER HOSE KIT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

XV. TRO BLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

XVI. THE RIGHT BLADES DOES THE RIGHT JOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

XVII. HOW TO ORDER PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PAGE

– 3–

i. GENERAL SAFETY RULES FOR ALL POWER TOOLS

1. Know your power tool - read owner’s/operator’s manual carefully. Learn its applications and limitations as

well as the specific potential hazards unique to this tool.

2. Keep guards in place - and in working order.

3. Ground all tools - if tools are equipped with three prong plug, it should be plugged into a three-hole electrical

receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter lug must be attached

to a known ground. Never remove the third prong.

4. Remove wrenches - orm a habit of checking to see that adjusting wrenches are removed from tool before

turning it “on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or expose them

to rain. Keep work area well lighted. Do not use tool in the presence of flammable liquids or gasses.

7. Keep children and visitors away. All children and visitors should be kept at a safe distance from work area.

8. Make workshop childproof with padlocks, master switches or by removing starter keys.

9. Do not force tool. It will do the job better and be safer at the rate for which it was designed.

10. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that

may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain

long hair.

12. Always use safety glasses. Wear safety glasses (must comply with ANSI Z87.1) at all times. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses. Use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs) during extended periods of operation.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance. ollow

instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have

repaired by authorized service facility.

15. Disconnect tools. When not in use, before servicing, and when changing accessories, such as blades, bits,

cutters.

16. Avoid accidental starting. Make sure switch is in “off” position before plugging in power cord.

17. Use recommended accessories only. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

contacted.

19. Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and perform it’s intended function. Check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions

that may affect it’s operation. A guard or part that is damaged should be properly repaired or replaced.

20. Never leave tool running unattended. Turn power “off”. Do not leave tool until it comes to a complete stop.

Read all instru tions. As with all ma hinery there are ertain hazards involved with

operation and use of the ma hine. The following basi safety pre autions should be followed at all times to

redu e the risk of fire, ele tri sho k and serious personal injury to you or others. Keep these important

operating instru tions with this produ t.

WARNING!

– 4–

KEEP GUARD IN PLACE

DIAMOND BLADE

BLADE CUTTING DEPTH

ELECTRIC SWITCH O

ELECTRIC SWITCH ON

ELECTRICAL HAZARD

REMOVE TOOLS

PAY EXTREME

ATTENTION

REPAIRS TO BE DONE

MACHINE HAZARD

LAMMABLE

READ INSTRUCTIONS

CARE ULLY

WARNING

RAGILE

KEEP DRY

DO NOT STEP ON

WEAR HEARING

PROTECTION

WEAR EYE PROTECTION

WEAR BREATHING

PROTECTION

WEAR HARD HAT

WEAR PROTECTIVE

CLOTHING

WEAR SA ETY SHOES

WELL VENTILATED

NO NON-WORKING

PERSONNEL

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. Extension cord tables (refer t page 12)

show the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge numbers the heavier the cord.

22. Do not abuse cord. Never carry tool by cord or pull it to disconnect from receptacle, Keep cord from

heat, oil, and sharp edges.

23. Guard against electric shock. Prevent body contact with grounded surfaces. or example, pipes,

radiators, ranges and refrigerator enclosures.

24.Outdoor use extension cords. When tool is used outdoors, use only extension cords intended for use

outdoors and so marked.

25. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

26. Drugs, alcohol, medication. Do not operate tool while under the influence of drugs, alcohol or any

medication.

27. Store idle tool. When not in use, tool should be stored in a dry and locked place, out of reach of children.

ii. SYMBOLS

CALIFORNIA PROPOSITION 65: Sawing and drilling generates dust. Ex essive airborne

parti les may ause irritation to eyes, skin and respiratory tra t. To avoid breathing impairment always employ

dust ontrols and prote tion suitable to the material being saw or drilled in a ordan e with OSHA (29 CFR Part

1910.1). Diamond blades improperly used are dangerous. Comply with ANSI Safety Code B7.1 and OSHA

overing speed, safety guards, flanges, mounting pro edures, general operating rules, handling, storage and

general ma hine ondition.

WARNING!

– 5––

iii. FEATURES

CLEAR VIEW AIR FILTER

is easily maintained and

protects the motor

providing a longer life

for the motor

STURDY HANDLES

for easy transport

TABLE LOCKING MECHANISM

facilitates the saw’s chopping

operation

OPTIONAL OUTER TRAY

for wet application

POWERFUL 3 HP (AT PEAK)

Carbon Brush motor cuts large

material in a single pass

The VX141MS Masonry saw is designed for the professional contractor in mind. I enhances performance with a

multitude of features facilitating operation.

REINFORCED

RIGID FRAME

contruction

provides steady

precision cutting

VX141MS MASONRY/BRICK SAW

MOTOR MAX. BLADE

CAPACITY

CUTTING

LENGTH

CUTTING

DEPTH WEIGHT SIZE

i . SPECIFICATIONS

14" blade with

1" (25.4mm)

arbor

16"

Max material

size 8 x 8 x16"

5" 75 lbs.

uncrated

31.5 x 18.5

x 19"

3 HP Peak

115 v, 60 Hz,

3,600 rpm

– 6–

i. INSTALLATION AND OPERATION

1. Move the blade shaft cover upwards. To

remove the blade lock nut, open the shaft

space. Figure 1.

2. Place the 14" blade onto the blade shaft.

Make sure that the directional arrow is

pointing in the direction of the shaft

rotation.

3. Lock the blade lock nut with the outer

flange. Use the multiple wrench provided

to fasten the blade tightly.

To install the cutting table to the machine:

1. Set the cutting table on the rails. Figure 2.

2. Install the screws and brackets to the

cutting table.

3. To remove the cutting table, do the reverse

of the above two steps.

. UNPACKING

Open the container. Carefully lift the saw out evenly by the frame. Be certain you have the following

items before you discard the container:

• Saw • Extra air filter

• 14" saw blade • 45º/90º rip guide

• Universal wrench • Owner’s manual

BLADE INSTALLATION CUTTING TABLE ASSEMBLY

Figure 1

Figure 2

– 7––

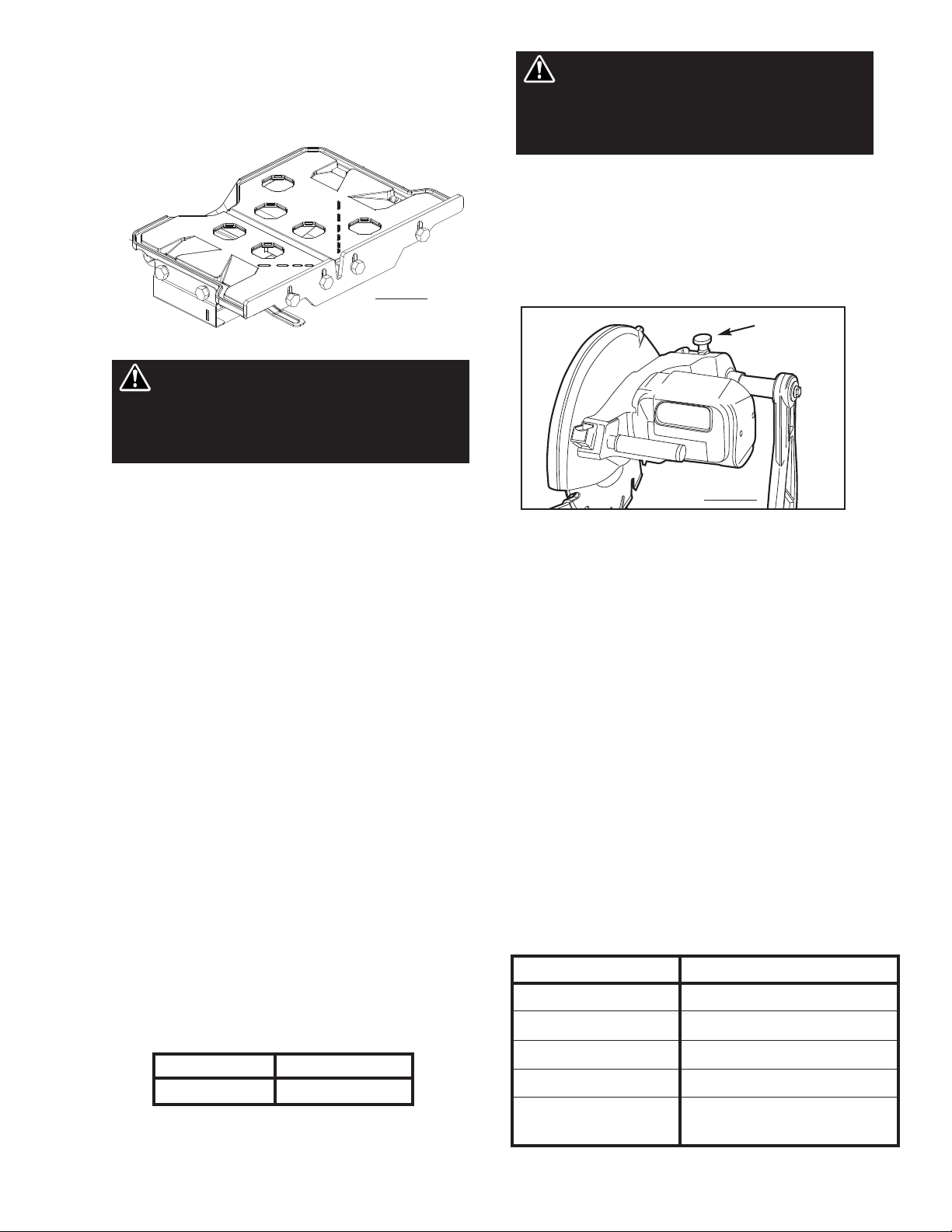

THE CUTTING TABLE

The heavy-duty cutting table provides the durability to

handle large materials. Figure 3.

STEPS TO USE THE 45˚ / 90˚ RIP

GUIDE

1. Set the rip guide by positioning it on the

desired dimension and tighten the threaded

knob. Make sure that the rip guide is firmly

tightened to avoid slippage. The rip guide can

be used 90˚ rip cugts and 45˚ angle cuts from

both the left and right side. (Note: The

straight and 45˚ angled slits on the bottom of

the rip guide.)

2. After the rip guide is positioned for the

desired cut, place material flat against the rip

guide and the measurement rail. or the 45˚

rip cuts, place the corner of material in the

open slot of the measurement rail.

3. Simply line up the material being cut with the

appropriate pre-marked lines on the cutting

table.

4. Now you are ready to make your cut.

CUTTING DEPTH

The recommended cutting depth is 1/4" below the

cutting table surface. When setting the cutting depth,

do a practice pass with the table to make sure the

blade does not cut into it.

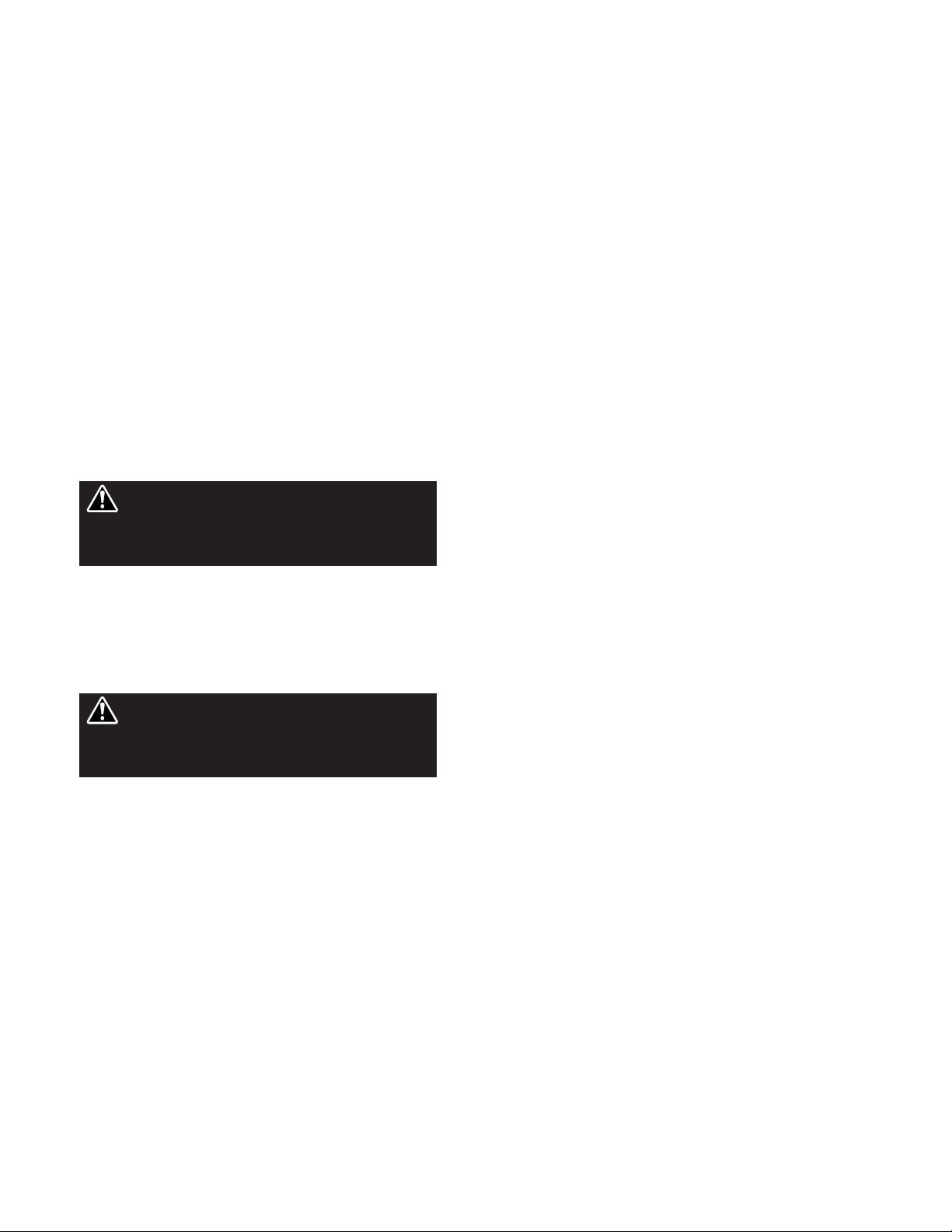

THE SPRING LOCK PIN

The VX141MS Masonry Saw is designed with three

different cutting heights for jam cutting, a moving

head for chop (or plunge cutting), and a moving cart

combined with the moving head for step cutting to

help make any cutting task easier.

1. Before adjusting the cutting depth always

disconnect the electrical power supply.

2. To adjust the saw’s fixed cutting position, pull

up on the Angle Lock Pin, Figure 4, move the

head to the new position, release the Angle

Lock Pin, and rotate the cutting head

up/down until the Angle Lock Pin lokcs into

position (lowest position for cutting thru

bricks). The middle position is for cutting

block and the upper position for blade

replacement.

CHOP / PLUNGE SAW

OPERATION

To operate the VX141MS as a chop or plunge saw:

pull up on the Angle Lock Pin, rotate 90 degrees, and

release. Now the cutting head can be rotated by

pulling up or pushing down on the cutting head

handle. When not in use, always lock the head into

one of the three cutting height positions.

WAR I G: Only use the 14" diameter blade

for this saw. Setting smaller size of diamond blade

may grab the material being cut, causing damage

and possibly injury.

WAR I G: It is recommended to cut all the

way through the material being cut. Failure to do

so can result in the diamond blade grabbing the

material causing damage and possibly injury.

Figure 3

Blade Diameter Cutting Depth

14" 5 inch

HEAD POSITIO APPLICATIO

ixed Lowest Jam cutting bricks

ixed Middle Jam cutting block

ixed Upper Diamond blade replacement

Moving Chop or Plunge Cutting

Moving head with Step cutting

moving table

Figure 4

Angle

Lock Pin

– 8–

ii. PROPER BLADE USE

DO’S

• Inspect blades daily for cracks or uneven wear.

• Always use appropriate blade for material being cut.

• Inspect arbor shaft for uneven wear before mounting blade.

• Always use blades with the correct arbor shaft size.

• Ensure that blade is mounted in the correct direction.

• Use proper safety equipment when operating the saw.

• Secure the blade to the arbor with a wrench.

• Periodically check the blade for cracks or bond fatigue.

• In addition to the following, always follow wet

recommendations.

• Use appropriate blade for material being cut.

• Inspect segment blades for segment cracking or loss.

• Do not use damaged blades.

• Use proper safety equipment when operating the saw.

DON’TS

• Do not operate the saw without safety guards in position.

• Do not operate the saw with blades larger than 14".

• Do not cut dry with blades marked “Use Wet”.

• Do not exceed manufacturer’s recommended maximum RPM.

• Do not force blade into material. Let blade cut at its own

speed.

• In addition to the following, always follow wet

recommendations.

• Do not make long cuts with dry blades. Allow them

to air cool.

• Do not use the edge or side of blade to cut or grind.

• Do not attempt to cut a radius or curve.

• Do not cut too deep or too fast into the material.

• Do not cut any material not recommended by blade

manufacturer.

iii. CARBON BRUSH REPLACEMENT

The VX141MS Masonry Saw uses a high horsepower low

amperage air cooled brush motor. Replace the carbon

brushes when the motor begins to loose power. Brushes

typically need to be replaced during the life of the saw.

Replace the brushes when over 2/3 of their original length is

used (when the overall length of the brush is less than 7/16”

(11.1 mm). It is normal for the brushes to wear down.

To replace the carbon bursh, perform the following steps:

1. Disconnect the electrical supply.

2. Remove the air filter.

3. Remove the four (4) motor air in-take cover mounting

screws. See Figure 5A.

4. Remove the motor air in-take from the motor.

5. Use a coin or wide blade screw driver to remove the

carbon brush cap. Use care not to damage the carbon

brush cap. Inste the cap for damage. If the cap has any

signs of damage, replace. See Figure 5B.

6. Remove the carbon brush.

7. Use the compressed air to blow any access carbon build

up out of the motor.

8. Inspect the inside of the motor by looking into the brush

holder for any excessive wear or carbon build-up.

9. Place the new carbon brush.

10. Replace the carbon brush cap and tighten the cap with a

coin or wide blade screw driver. Only snug the cap down.

Over tigthening the cap can cause damage to the cap.

11. Reinstall the motor air in-take cover and re-attach the

four mounting screws. Do not over tighten.

12. Clean the air filter.

13. Re-install the air filter.

Figure 5B

Figure 5A

– 9––

x. CARE AND MAINTENANCE

ix. AIR FILTER

CLEANING

A TER EVERY USE O THE MACHINE:

• Remove dirty water from container.

• Remove dirt and mud from the bottom of the

container

A TER WET CLEANING AND BE ORE USING THE

MACHINE AGAIN:

• Connect the machine to an electric power

outlet equipped with a G CI safety power

breaker. If the safety power breaker cuts off

the electrical power supply, do not try to

operate the machine but have it checked by an

authorized dealer first.

BE ORE AND A TER A PROLONGED TIME:

• After not using the machine for a prolonged

period of time, clean and lubricate all movable

parts.

• Check that the saw is sitting properly on the

folding stand.

• Check that all the screw joints and nuts are

fixed.

• Check that the roller table is in its guides and

that is easily moves to and from.

• With the saw blade removed, switch on the

motor for an instant and switch it off again. If

the motor does not run, have the machine

inspected by a qualified electrician.

WAR I G: For your saf ty b for p rforming

any maint nanc on th saw turn off th pow r

switch and unplug th pow r cord.

WAR I G: Using th machin with a dirty,

damag d, or missing air filt r will r sult in motor

damag and is not cov r d und r warranty.

The VX141MS Masonry Saw is equipped with a specially designed air filter to help protect the motor from the damage

due to high speed dust intake during operation.

AIR FILTER REPLACEMENT

To replace the air filter, perform the following steps:

1. Carefully removed the old air filter from the

motor air in-take cover opening. Note: Pull the

air filter thru the opening in the front of the

motor air in-take cover.

2. Inspect the new air filter for damage.

3. Place the new air filter into the motor air in-take

cover.

4. The air filter should fill the opening in the front

of the air in-take cover and should completely fill

the filter cavity.

CLEANING THE AIR FILTER

To clean the air filter, perform the following steps:

1. Carefully removed the old air filter.

2. Clean the air filter by patting, and shaking the

dust from the filter. It also be cleaned with

water. After clean dry before replace the air in-

take. Compressed air can be used to blow the

dust out of the filter.

3. Inspect the filter for damage. Any damaged air

filter must be replaced before using the

machine.

4. Replace the filter into the motor air in-take.

5. Check to see if the air filter is installed properly.

The air filter should fill the opening in the front

of the air in-take cover and should completely fill

the filter cavity.

– 10 –

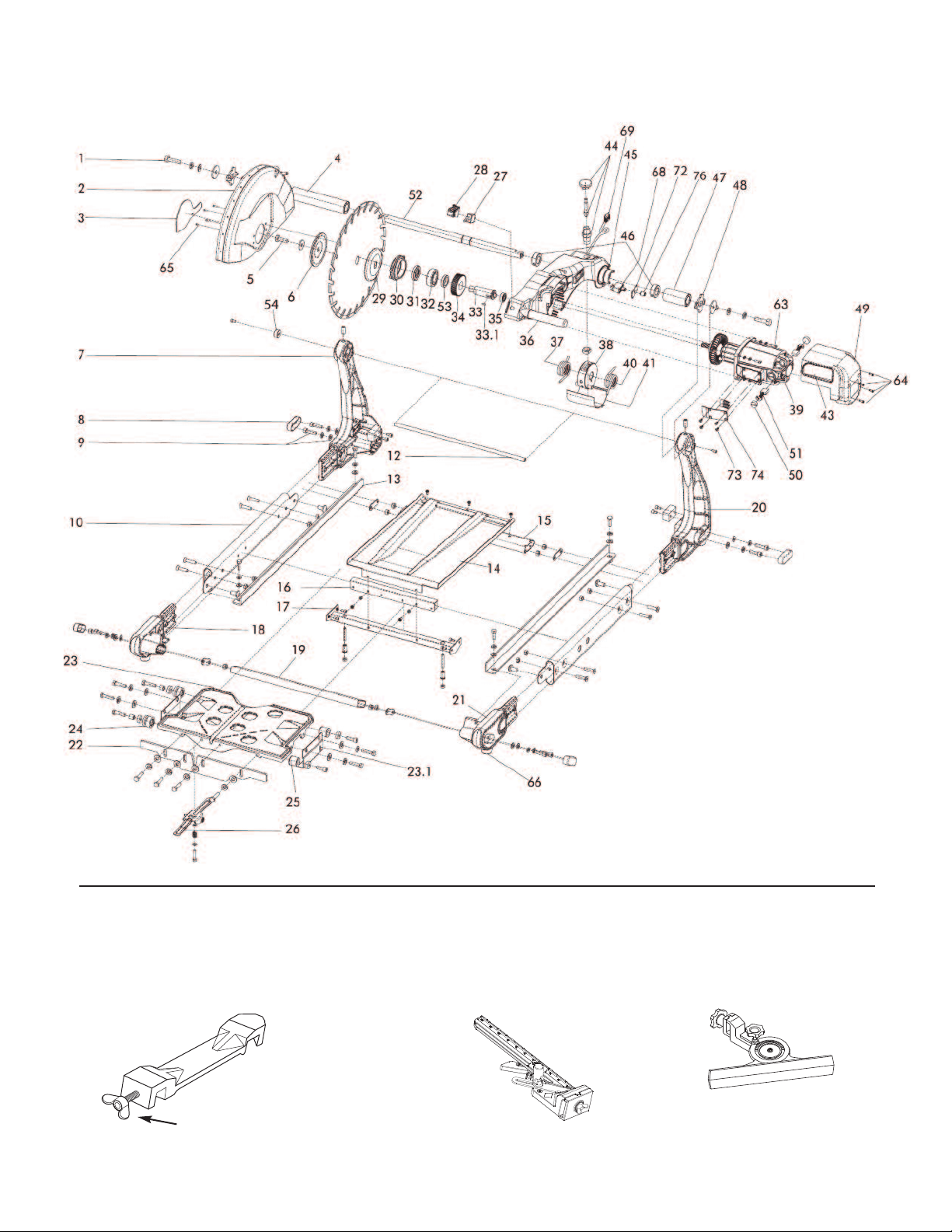

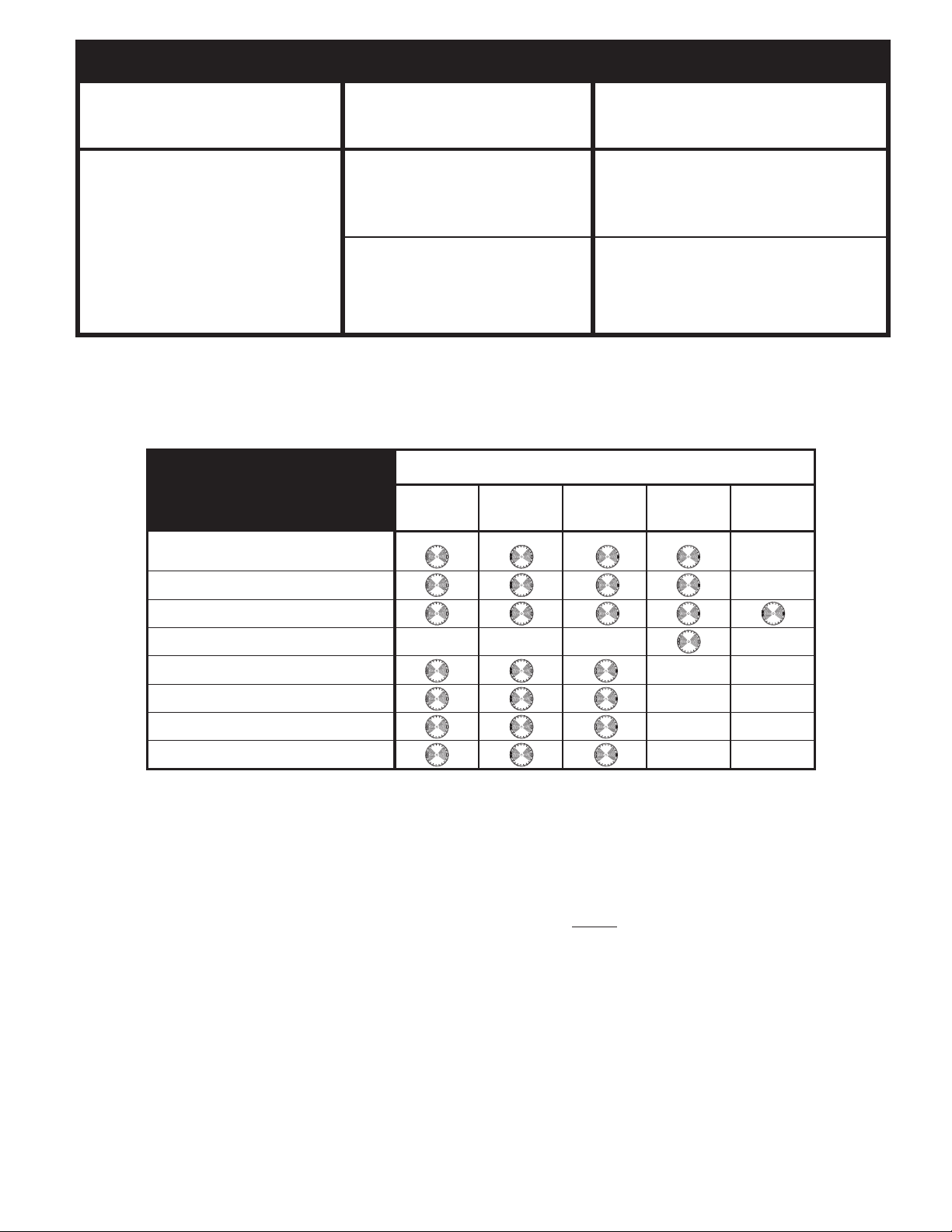

xi. REPLACEMENT PARTS LIST

Knob Only (1)

V35016

ame (Qty.)

Complete 45˚/90˚ Rip Guide with Knob (1)

Part umber

V35000

ame (Qty.)

(Optional) Master Guide (1)

Part umber

V370064

ame (Qty.)

(Optional) Angle Guide (1)

Part umber

V370060

xii. ACCESSORIES & PARTS

– 11 –

1 Screw M10XP1.5X20L V390001

2 Blade Guard V390002

3 Arbor Cover BBM/YBM307 V390003

4 Cross Bar Position Tube (Long) 2 V390004

5 Blade Lock Bolt M10X20 1.25 DIN933 V390005

6 Outer lange V390006

7 Arm rame, Left Side V390007

8 Rubber Cap V390008

9 Bolt & Washer (3 pieces) V390009

10 Side rame (1) V390010

12 Dry Kit Cross Bar V390012

13 Sliding Rail (2) V390013

14 Dust Collecting Pan V390014

15 Cross Tub V390015

16 Metal Pan Bracket V390016

17 Metal Pan rame V390017

18 Left ront Joint V390018

19 Cross Tube V390019

20 Arm rame Right side V390020

21 Right ront Joint V390021

22 Ruler Guide V390022

23 Complete Cutting Table V390023

23.1 Cutting Table Retention Bracket V390023.1

24 U-Shape Roller Wheels (2) V390024

25 Metal Bearing Rollers (2pcs./set) V390025

26 Locking Table Bracket V390026

27 Toggle Switch/ (20A) V390027

28 Toggle Switch Safe Bracket V390028

29 Inner lange V390029

30 Plate Blade Shaft Retaining (qty required=4) V390030

31 Shaft Spacer Outer/ (6305 LLB) V390031

32 Bearing Blade Shaft Outer/ (6305 LLB) V390032

33 Blade Shaft BBM/YMN307 V390033

33.1 Key Woodruf V390033.1

34 Gear Blade shaft V390034

35 Bearing Motor Inner V390035

36 Handle Bar V390036

37 Tension Spring Left Side V390037

38 Cutting Head Angle Main Bracket V390038

39 Complete Motor V390062M

40 Tension Spring Right Side V390040

41 Spring Housing Cover V390041

43 Air ilter V390043

44 Angle Adjustment Lock Pin V390044

45 Cutting Head Casting Only V390045

46 Collar Set Cutting Head V390046

47 Cross Bar Position Tube (Short) 1 V390047

48 Cross Bar Position Bracket V390048

49 Motor Air In-Tank Cover V390049

50 Brush Cap (1) V390050

51 Carbon Brushes (2 pcs./set) V390051

52 Main Cross Bar V390052

53 Shaft Spacer Inner V390053

54 Main Cross Bar Position Stopper V390060

63 Screw M5 x 25L V25155

64 Screw M4 x 16L V25105

65 Screw M5 x 15L V3925058

66 Rubber eet (4) V141029

68 Circuit Breaker V141046

69 Power Cable V141001

72 Circuit Breaker Bracket V141068VX

73 Cable Cover V141126

74 M4 x 8 Countersunk Screw V141127

76 Reset Button Cover VS1000-04.1

PART NAME PART NUMBER PART NAME PART NUMBER

ame

(Optional) Wet Cutting Kit

Includes: Water Tub, Water eed, Drip Tray,

Drain Plug, Water Pump

Part umber

V350MSWKIT

ame (Qty.)

(Optional)

Water Hose Kit (1)

Part umber

V350MSGHKIT

ame (Qty.)

(Optional) Brick Saw Stand (1)

Part umber

V350MS

– 12 –

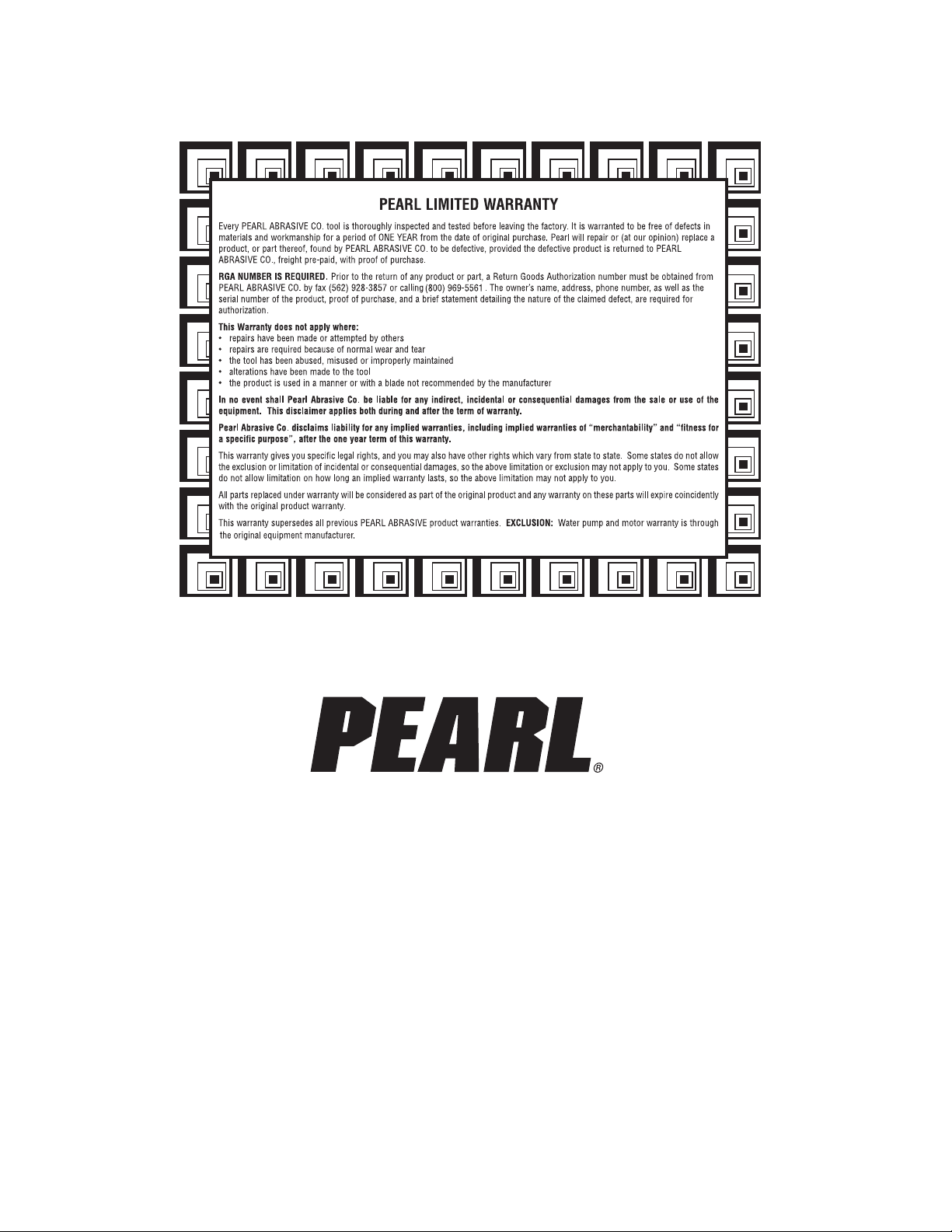

xiii. ELECTRICAL MOTOR SPECIFICATIONS

Horsepower 3 HP

Volts 115V/230V

Amps 15A

Motor RPM 3,600 rpm

Cycle 60 Hz

Watts 2238

Length of Cord

3 HP - 115 V

25'

50'

75'

Recommendations:

• It is recommended that a 15 amp circuit be used while operating this saw.

This will prevent possible power interruption or loss.

• Always plug saw as close as possible to the power source while operating.

This will allow you to receive optimum electricity.

Electrical Wiring Diagram

WAR I G: To avoid

permanent motor damage you

must use the correct extension

cord. ever use more than one

extension cord at a time. Follow

the chart for proper size.

WIRE

GAUGE

No. 10

No. 8

No. 6

xi . WATER HOSE KIT INSTALLATION

1. Orient the water pipes as shown in ig. A. Insert the

shortest pipe from the "Y" adapter into the adjacent

sleeve at the rear of the blade guard. irst, you will need

to remove the black cap covering the hole insert (#1).

The longest pipe, which has a control valve midway,

should be pointed towards the floor. Secure the "Y"

adapter to the rear of the blade guard using the provided

bracket and screws.

2. Insert the second pipe protruding from the top of

the "Y" adapter into the slot located on the side of

the blade guard towards the front of the saw. This

is the hole in the front of the blade guard (#2), do

not remove the black caps on the side. See ig. B.

#1

#2

Black caps

(do not

remove)

Some force will be required to

pinch the mouth of the pipe

when inserting it into the slot.

Fig. A

Fig. B

– 13 –

x . TROUBLESHOOTING

Problem Possible Cause Solutio

Machine does not run when

switched on.

Power cord not properly

fixed/plugged in.

Check that the machine is properly

connected to the power supply.

Motor stops (power cut out). Too much pressure exerted

while cutting.

Exert less pressure when cutting.

Poor machine performance little

power.

Power cord/extension cable too

long or cable still wound up

inside cable drum.

Use a power cord/extension cable of

the rated length, use a cable drum

with a cable fully extended.

Incorrect specification for saw

blade.

Use a saw blade which corresponds

to the material being cut.

Saw has a defective electric

system.

Have the electric system of the saw

checked by a qualified technician.

Power cord defective. Have the power cord checked,

replaced if necessary.

Main power switch defective. Have the main power switch checked

and replaced if necessary by a

qualified electrician.

Loose electrical connection

inside the electric system.

Have the whole electric system of the

machine checked by a qualified

electrician.

Motor defective. Have the motor checked and replaced

if necessary by a qualified technician.

Power network is insufficient. Observe the electric ratings of the

machine and connect it only to a

power network which complies with

these ratings.

Drive motor no longer runs at

rated speed (r.p.m.).

Have the motor checked by a

qualified electrician and have it

replaced if necessary.

For your safety and the safety of others, turn the power swit h off and always remove the

plug from power sour e before troubleshooting. Repairs performed by unauthorized

personnel ould ause serious hazard. We re ommend that servi e to this tool be performed by a qualified servi e

te hni ian with original equipment repla ement parts.

WARNING!

– 14 –

Problem Possible Cause Solutio

Saw blade wobbles when

running.

Saw blade is damaged or bent.

lange of the saw blade is

damaged.

Shaft of the motor is bent.

Have the saw blade aligned/flattened.

Clean the receiving flange.

Solder the diamond segments of the

old blade onto another saw blade or

use a new blade.

Replace the saw blade flange.

Replace the electric motor.

Diamond segment becomes

loose.

Overheating of the saw blade;

cooling water not sufficient.

Have the diamond segment soldered

on the blade again; ensure optimum

flow of cooling water.

Cracks in or near the diamond

segment.

Saw blade too hard.

ixed flange is worn out.

Motor shaft bearing. Replace the bearing of the motor shaft.

Use a softer blade.

Have the fixed flange replaced.

Saw blade is blunt. Saw blade type is unsuitable for

the material being cut.

Saw blade type is unsuitable for

the machine performance.

Saw blade too hard.

Use appropriate type of saw blade.

Appearance of cut is not optimal. Poor tension in the blade

material.

Return the saw blade to the

manufacturer.

Too much load placed on the

saw blade.

Diamond segments are blunt.

Use a suitable saw blade.

Sharpen the saw blade.

The center hole in the saw blade

has become wider due to wear.

The saw blade has slipped on

the motor shaft when running.

The arbor of the saw blade must be

fitted with an appropriate adapter ring.

Check the receiving flange and have it

replaced if necessary.

Diamond segments are blunt. Sharpen the diamond saw blade.

Irregular run of the saw blade. Poor tension in the blade

material.

Return the saw blade to the

manufacturer.

Excessive wear. Wrong type of saw blade.

Shaft of motor causes wobbling.

Overheating.

Use harder saw blades.

Have bearings of the motor of the

motor replaced.

Ensure optimum flow of cooling

water.

– 15 –

Problem Possible Cause Solutio

Saw blades shows blooming

colors.

Lateral friction when cutting. The material feed is too high; proceed

more slowly.

Grinding marks on the saw

blade.

Material is not being fed parallel

to the saw blade.

Poor tension in the blade material.

Ensure that the direction of feed is

absolutely parallel to the saw blade.

Adjust the roller table/have it adjusted.

Too much load on the saw blade. Have the saw blade tensioned.

The material feed is too high, proceed

more slowly.

x i. THE RIGHT BLADES DOES THE RIGHT JOB

APPLICATION

PEARL BLADE

SERIES

Reactor ADM™ Concrete/Masonry

P5™ (BB) Masonry

P5™ ( SP) Hard Materials

P2 PRO-V™ (SDS) Hard Materials

P5™ (CSP) Concrete/Masonry

P4™ (CP) Concrete/Masonry

P2 PRO-V™ Concrete/Masonry

P1 EXV™ Concrete/Masonry

brick block paver hard brick refrac ory

brick

x ii. HOW TO ORDER PARTS

Please have the following information ready before calling:

• Serial Number of your Saw • Model Number of the Saw • When purchased and where • Part Description

All parts listed may be ordered from your Local warehouses. If the part is not stocked locally, call our Corporate office and ask for our

Customer Service Department. or Technical Support call 1-800-969-5561. In Canada call 1-800-387-0008. There is a $25.00

minimum order.

Return Policy: Return goods for credit or exchange on the basis of the following terms: (1) They must be current products; (2) Items

returned for replacement or refund should be in original cartons and must be accompanied by a packing slip with the following

information: Returned Goods Authorization (RGA) number obtainable from Customer Service Department • List of items returned •

Reason(s) for return(s) • Copy of original invoice(s); (3) reight charges must be assumed by sender; (4) Returning goods are subject

to a 15% handling charge to cover our cost of repacking and restocking. All Prices are subject to change without notice.

Disclaimer: Pearl Abrasive Co. reserves the right to make changes or improvements on its products without incurring an additional

obligation including any obligation to make corresponding changes or improvements to products previously manufactured or sold.

Pearl reserves the right to discontinue products at any time without notice.

All illustrations displayed in this manual are the property of Pearl Abrasive Co. and shall not be duplicated or reproduced without the

express written consent of Pearl Abrasive Co.

or the most effective cutting and blade life always use the recommended Pearl Abrasive Co. blade.

Part o. VX141MS • 04/18

GEORGIA • USA

3950 STEVE REYNOLDS BLVD.

NORCROSS, GEORGIA 30093

ONTARIO • CANADA

375-2 PIDO ROAD

PETERBOROUGH, ONTARIO K9J-6X7

CORPORATE OFFICE: SO. CALIFOR IA • USA

4900 ZAMBRANO ST., COMMERCE, CA 90040-0031

562-927-5561 • AX 562-928-3857

Toll Free: 800-969-5561

www.pearlabrasive.com

This manual suits for next models

1

Table of contents

Other Pearl Saw manuals

Pearl

Pearl VX141MS User manual

Pearl

Pearl PA7TTR Owner's manual

Pearl

Pearl VX RSPRO R Owner's manual

Pearl

Pearl PA-7 Owner's manual

Pearl

Pearl PA7TT Owner's manual

Pearl

Pearl VX RSPRO VX1048RSPRO Owner's manual

Pearl

Pearl VX141MS User manual

Pearl

Pearl VX5WV Owner's manual

Pearl

Pearl PA-10 User manual

Pearl

Pearl CX10 Owner's manual