Pearl VX RSPRO R Owner's manual

Caution! Read Safety and General Instructions carefully before using saw for the first time.

Patents Pending

Assembled in U.S.A.

Pearl Abrasive Co. 2.1 RAIL SAW

REV. 3

MODEL VX10RSPROR RAIL SAW

OWNER’S/OPERATOR’S MANUAL

serial number -

You should record the Serial Number of your saw on this

Owner’s/Operator’s Manual and on the Warranty Card.

The Warranty Card must be sent back with all the required

pertinent information for the warranty to take effect.

RENTAL

R

i. TABLE OF CONTENTS

ii. GENERAL SAFETY RULES AND PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

iii. SILICA DUST WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

iv. FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

v. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vi. UNPACKING, ASSEMBLY & SET-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

vii. BLADE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

viii. MOTOR CAPACITOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ix. SIDE TABLE & SPLASH GUARD INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

x. WATER PUMP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xi. OVERFLOW PLUG INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xii. THE ADJUSTABLE ANGLE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

xiii. OPERATING THE SAW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

xiv. GROUNDING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

xv. CHOOSING THE RIGHT BLADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

xvi. ELECTRIC MOTOR SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

xvii. DO’S AND DONT’S FOR BLADES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

xviii. CARE AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

xix. WATER PUMP MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

xx. ALIGNMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

xxi. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

xxii. HOW TO ORDER PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

xxiii. CUSTOMER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

xxiv. REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PAGE

– 3 –

ii. GENERAL SAFETY RULES AND PRECAUTIONS

1. Know your power tool - read owner’s/operator’s manual carefully. Learn its applications and limitations as

well as the specific potential hazards unique to this tool.

2. Keep guards in place - and in working order.

3. Ground all tools - if tools are equipped with three prong plug, it should be plugged into a three-hole electrical

receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter lug must be attached to

a known ground. Never remove the third prong.

4. Remove wrenches - Form a habit of checking to see that adjusting wrenches are removed from tool before

turning it “on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or expose them to

rain. Keep work area well lighted. Do not use tool in the presence of flammable liquids or gasses.

7. Keep children and visitors away. All children and visitors should be kept at a safe distance from work area.

8. Make workshop childproof with padlocks, master switches or by removing starter keys.

9. Do not force tool. It will do the job better and be safer at the rate for which it was designed.

10. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry that

may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to contain

long hair.

12. Always use safety glasses. Wear safety glasses (must comply with ANSI Z87.1) at all times. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses. Use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or muffs) during extended periods of operation.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have

repaired by authorized service facility.

15. Disconnect tools. When not in use, before servicing, and when changing accessories, such as blades, bits,

cutters.

16. Avoid accidental starting. Make sure switch is in “off” position before plugging in power cord.

17. Use recommended accessories only. Consult the owner’s manual for recommended accessories. The use

of improper accessories may cause risk of injury to persons.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

contacted.

19. Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it will operate properly and perform it’s intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

it’s operation. A guard or part that is damaged should be properly repaired or replaced.

20. Never leave tool running unattended. Turn power “off”. Do not leave tool until it comes to a complete stop.

Read all instructions.

As with all machinery there are certain hazards involved with

operation and use of the machine. The following basic safety precautions should be followed at all times to

reduce the risk of fire, electric shock and serious personal injury to you or others.

Keep these important

operating instructions with this product.

WARNING!

– 4 –

KEEP GUARD IN PLACE

DIAMOND BLADE

BLADE CUTTING DEPTH

ELECTRIC SWITCH OFF

ELECTRIC SWITCH ON

ELECTRICAL HAZARD

REMOVE TOOLS

PAY EXTREME

ATTENTION

REPAIRS TO BE DONE

MACHINE HAZARD

FLAMMABLE

READ INSTRUCTIONS

CAREFULLY

WARNING

FRAGILE

KEEP DRY

DO NOT STEP ON

WEAR HEARING

PROTECTION

WEAR EYE PROTECTION

WEAR BREATHING

PROTECTION

WEAR HARD HAT

WEAR PROTECTIVE

CLOTHING

WEAR SAFETY SHOES

WELL VENTILATED

NO NON-WORKING

PERSONNEL

21. Extension cords. Make sure your extension cord is in good condition. When using an extension cord,

be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. If in doubt, use the next heavier gage. The

smaller the gage numbers the heavier the cord.

22. Do not abuse cord. Never carry tool by cord or pull it to disconnect from receptacle, Keep cord from

heat, oil, and sharp edges.

23. Guard against electric shock. Prevent body contact with grounded surfaces. For example, pipes,

radiators, ranges and refrigerator enclosures.

24.Outdoor use extension cords. When tool is used outdoors, use only extension cords intended for use

outdoors and so marked.

25. Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

26. Drugs, alcohol, medication. Do not operate tool while under the influence of drugs, alcohol or any

medication.

27. Store idle tool. When not in use, tool should be stored in a dry and locked place, out of reach of children.

CALIFORNIA PROPOSITION 65: Sawing and drilling generates dust. Excessive airborne

particles may cause irritation to eyes, skin and respiratory tract. To avoid breathing impairment always employ

dust controls and protection suitable to the material being saw or drilled in accordance with OSHA (29 CFR Part

1910.1). Diamond blades improperly used are dangerous. Comply with ANSI Safety Code B7.1 and OSHA covering

speed, safety guards, flanges, mounting procedures, general operating rules, handling, storage and general

machine condition.

WARNING!

– 5 –

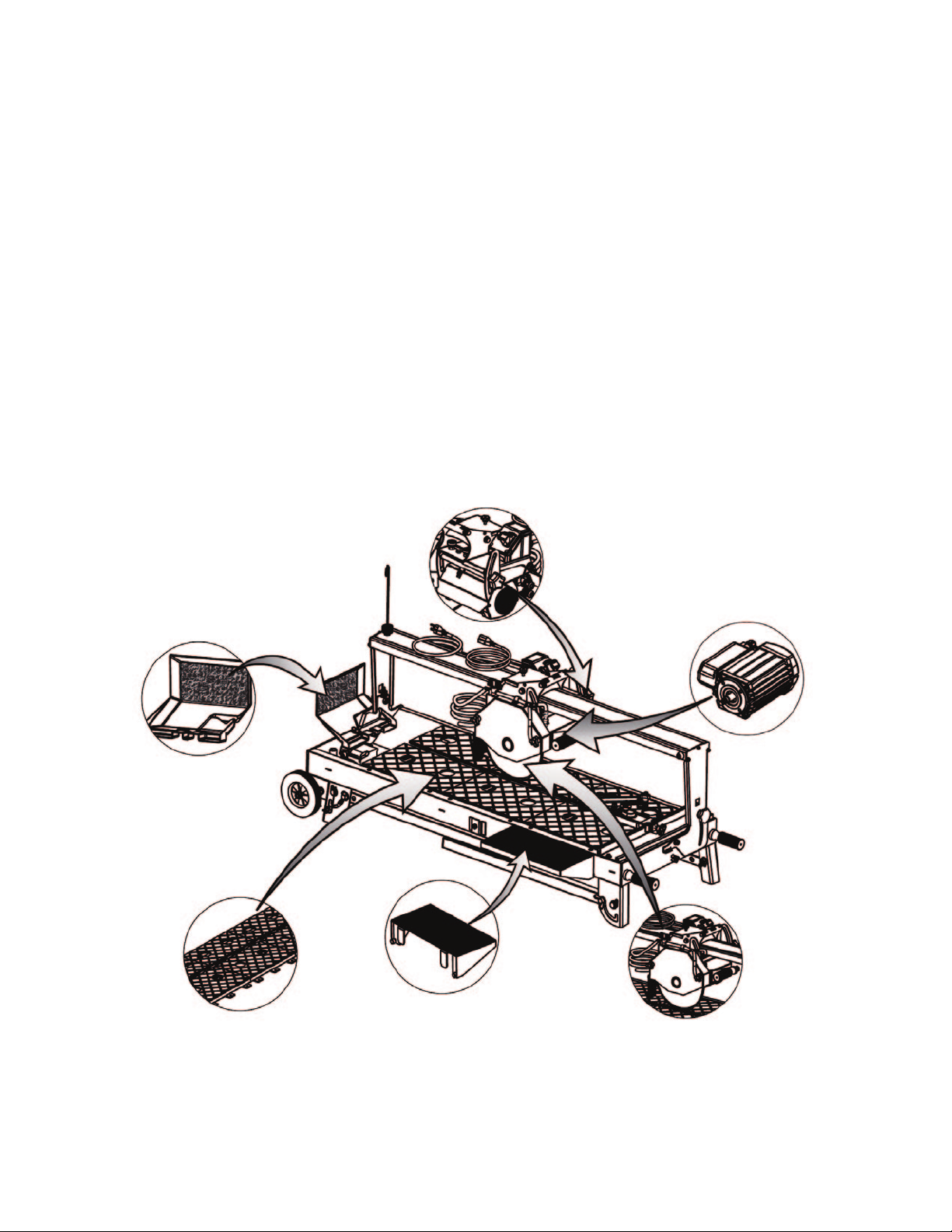

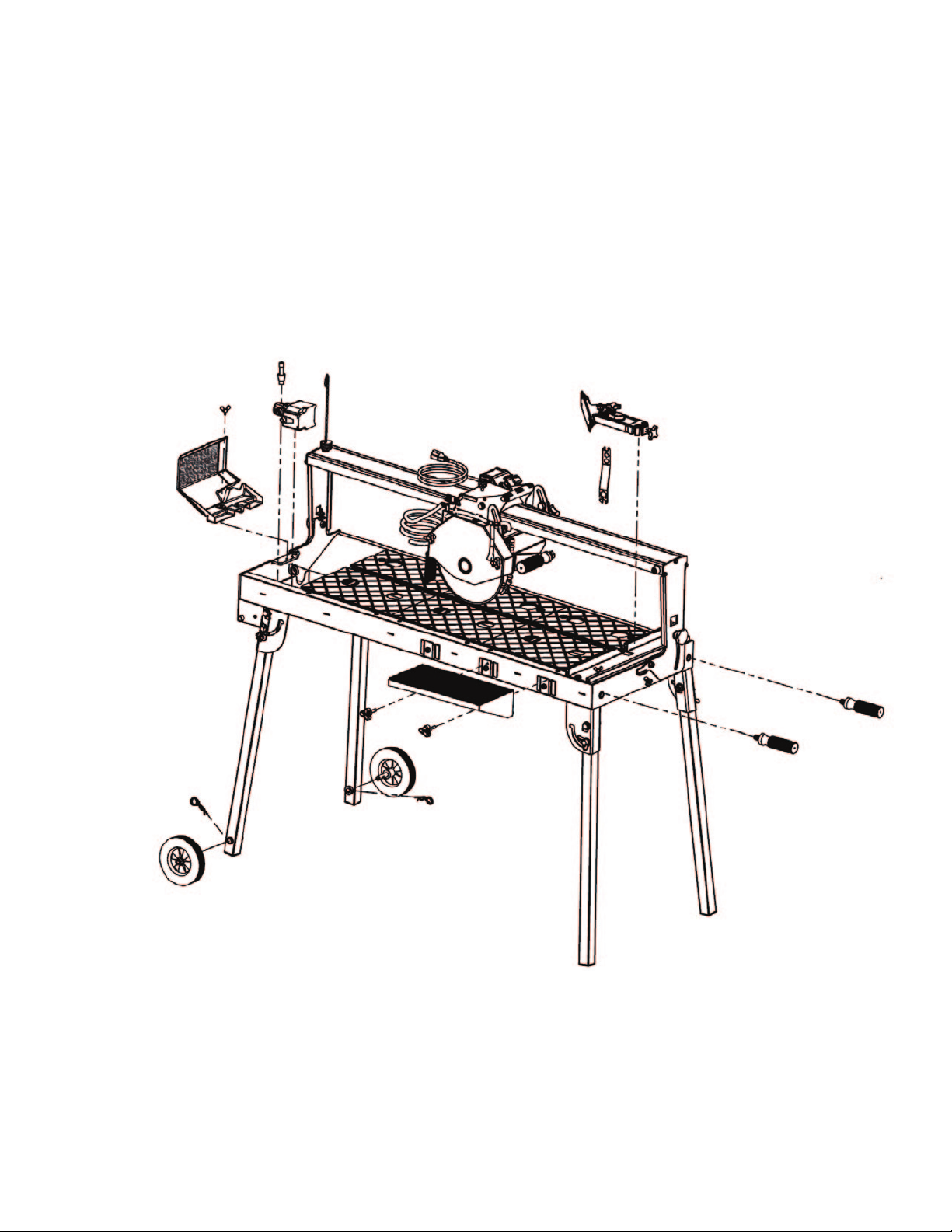

iv. FEATURES

Position lock

cutting head

Powerful 1-1/2HP

Induction motor

allows for large cuts

Blade capacity of 8-10"

enhances cutting capacity

Side Extension Table

Rubber matted

cutting table

Rubber matted

cutting table

Splash guard

reduces water waste

iii. SILICA DUST WARNING

Grinding/cutting/drilling of tile, masonry, concrete, metal and other materials with silica in their composition may give off

dust or mists containing crystalline silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous

other minerals and rocks. Repeated and/or substantial inhalation of airborne crystalline silica can cause serious or fatal

respiratory diseases, including silicosis. In addition, California and some other authorities have listed respirable

crystalline silica as a substance known to cause cancer. When cutting such materials, always follow respiratory

precautions.

Use appropriate NIOSH-approved respiratory protection where dust hazard may occur. Paper masks or surgical masks

without NIOSH approval number are not recommended because they do little to protect the worker. For more information

about respirator programs, including what respirators have received NIOSH approval as safe and effective, please visit the

NIOSH website at http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C.F.R.§1910.134).

Visit http://www.osha.gov for more information.

The Pearl VX10RSPRO is a professional saw for cutting tiles, paving stones, large-sized natural

stones, and similar materials.

– 6 –

UNPACKING

Open the carton box cover by lifting the top portion. Locate the accessory box and check its content for the

following items before discarding any packaging:

• Saw • Pin (2)

• Universal Wrench • Water Pump

• Wheel Assemblies (2) • Owner’s Manual

• Drain Plug • Rear Splash Guard

• Wing Screw • Extension Table

• Knobs (2) • Lifting handles (2)

• Angle guide

Proceed to the following section to complete assembly of the saw.

vi. UNPACKING,ASSEMBLY & SET-UP

v. SPECIFICATIONS

VX10RSPRO RAIL SAW

MOTOR BLADE

CAPACITY

CUTTING

LENGTH

CUTTING

DEPTH WEIGHT

DIMENSIONS*

(legs folded)

8"-10" Blade

5/8" arbor blade

46" rip cut,

32" diagonal

with plunge cut

8": 1-1/2"

10": 2-5/8"

172 lbs. L: 60"

W: 25"

H: 24"

1-1/2 HP

115 v, 60 Hz,

3,450 rpm

Induction motor

*Dimensions do not include extension tables and drip trays.

– 7 –

ASSEMBLY & SET-UP

1. Remove the carton box cover by lifting the upper

cover.

2. Locate the accessory box and open it. Obtain the two

lifting handles and install one on each end of the

saw. Install it in the side furthest from the post.

3. Loosen the lock knob on top of the cutting head.

4. Deploy the stand legs by following the “folded leg

assembly” section.

5. Install the side extension table, side splash guard

and back splash guard.

6. Install the spring holder on top of the sliding rail to

hold the power cable and the water hose.

7. Fill the tray with water before operating the saw.

– 8 –

SAW STAND ASSEMBLY

FOLDING STAND

1. It is recommended that adjusting the

folding leg be done by at least two people.

2. Remove the detachable wheel assembly

and stow it on the frame.

3. Shift the cutting head away from the end

of the frame where the leg is being

adjusted. Tighten the cutting head

carriage knob to hold the head in place.

4. Loosen the knob that is locking the leg in

place.

5. Lift the saw slightly to give the leg room to

rotate into stow/deployed postion.

6. Slide the leg in place and tighten the knob.

7. Repeat steps 2-4 as required to the

remaining legs.

EASY TRANSPORT

1. It is recommended that adjusting the

folding leg be done by at least two people.

2. Remove the detachable wheel assembly

and stow it on the frame.

3. Shift the cutting head away from the end

of the frame where the leg is being

adjusted. Tighten the cutting head

carriage knob to hold the head in place.

4. Loosen the knob that is locking the leg in

place.

5. Lift the saw slightly to give the leg room to

rotate into stow/ deployed postion.

6. Slide the leg in place and tighten the knob.

7. Insert the detachable wheel assembly in

either the frame/leg position depending

on need.

8. Make sure the head is on the side closest

to the wheels before transporting the saw.

Detachable

wheel

assembly Wing screws

(4) to retract

or deploy the

folding legs

Cutting head

carriage knob

– 9 –

Knurled

Nuts

vii. BLADE INSTALLATION

viii. MOTOR CAPACITOR INSTALLATION

Disconnect

the power plug before installing

the blade onto the blade shaft.

WARNING!

Disconnect the

power plug before servicing the motor.

WARNING!

Setting the

blade too low may damage the

cutting table and if set too high,

the blade may grab the material

being cut, causing damage and

possibly injury.

WARNING!

1. Loosen the knobs securing the blade guard and

remove the guard.

2. Loosen the cutting shaft nut (left-hand thread); while

loosening the nut, block the cutting shaft from

turning.

3. Remove the blade clamping flange. Check that the

contact area between the blade holder assembly and

the diamond saw blade is clean.

4. Install the saw blade on the supporting flange. Ensure

the blade rotation arrow matches the clockwise

rotation of the saw blade shaft.

5. Install the blade clamping flange.

6. Re-tighten the cutting shaft nut. Block the cutting

shaft from turning while tightening the nut.

7. Lightly turn the installed saw blade by hand and check

the blade for true running.

8. Mount the blade guard.

1. Locate the aluminum housing on the side of the

motor body.

2. Using a phillip/cross screw driver to remove the two

screws to open the capacitor housing cover.

3. Pull the capacitor out and remove the two wire caps

to disconnect the wires.

4. Replace the old capacitor with the new capacitor and

reattach the wires using the same wire caps.

5. Close the capacitor cover and make sure the rubber

gasket is properly in place so no water can seep into

the housing.

ix. SIDE TABLE & SPLASH

GUARD INSTALLATION

Install the side table and splash guard as shown in

the illustration to the side. Fasten the knobs/screws

respectively to the saw frame.

1. Place the water pump into the bracket at the left

front corner of the water tray, as shown on right.

2. Position the water outlet of the pump so that it lays

horizontally. Connect the water hose from the blade

guard to the water pump.

3. Plug the power cord into the 3-prong receptacle

coming from the power switch housing.

A tube at the rear end of the saw filters the debris from

the water produced during the cutting operation. Debris

settles in the water tray while the water is allowed to

pass through the tube and into the water bucket, where

fresh and filtered water reside.

1. Remove the water level tube from the plastic bag.

2. Insert the thin end of the tube into the rear hole next

to the water pump, as shown in the illustration.

3. Fill the water tray with water.

The Adjustable Angle Guide is

a two-piece assembly

consisting of a base and an

attachment that rotates. This

guide will support cutting

angles between 0°, 22.5°, 30°,

45° and many more. The

attachment has a casted angle

indicator that show what angle

the Angle Guide is currently

set to support.

xi. OVERFLOW PLUG

INSTALLATION

xii. THE ADJUSTABLE

ANGLE GUIDE

Disconnect the pump

before attempting to handle the pump.

Never operate pump without water in

the tray.

WARNING!

x. WATER PUMP

INSTALLATION

Set

Angle

Indicator

– 10 –

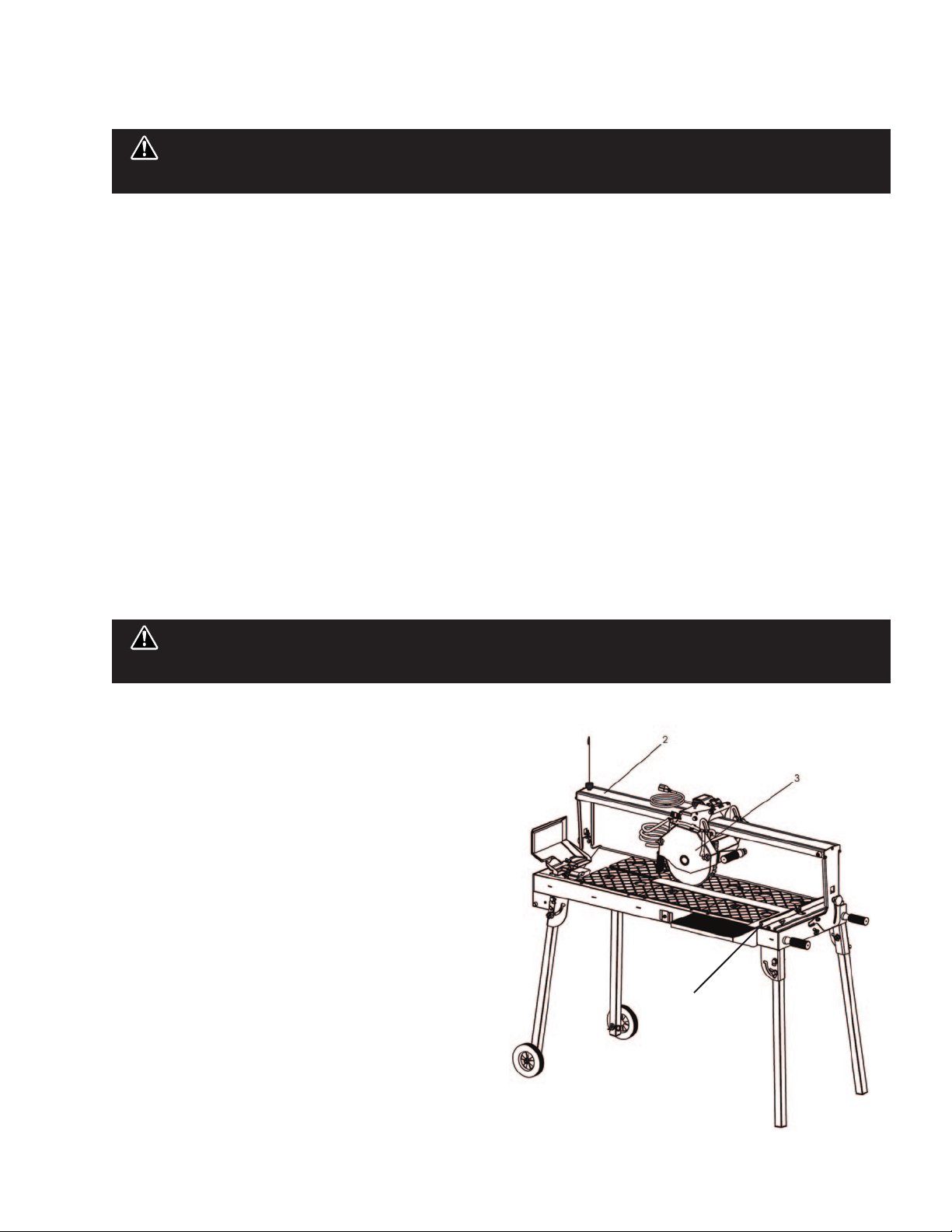

xiii. OPERATING THE SAW

1. After you have made yourself familiar with the

components of your saw, the machine has been

properly set up, the water tray is filled with water,

and the electrical connection is established in

accordance with the relevant safety regulations,

you may now begin with the cutting operation.

2. Before you start operation open the water shut-off

valve.

3. During the operation, the user must stand in front

side of the saw pulling on one of the two handles of

the cutting head when cutting. The workpiece must

rest on the work table and should be pressed

tightly against the cutting fence on the table.

4. Always turn off the saw before you leave the

machine unattended.

5. Prevent accidental restarting of the saw by

unplugging the power cable.

CUTTING AT CONSTANT DEPTH

When cutting at constant depth the cutting head must

be pulled against the work piece. The motor should be

turned off when adjusting the cutting depth.

1. Before starting the cut, hold the current depth by

firmly grasping the plunge handle extending from

the blade guard. Set the cutting head at the desired

cutting depth by first loosening the depth control

knob on the side of the cutting head where the

switch box is located.

2. Adjust the head to the blade depth/clearance

desired. Tighten the depth control knob.

3. Put the workpiece securely on the cutting table.

Have it positioned to achieve the desired cut.

4. Turn on the saw and slowly and uniformly pull the

head along the guide rail and across the workpiece.

5. Slowly return the cutting head to the original

starting position and turn off the motor.

PLUNGE CUTS

The handling of long or partial cuts can be made using

the plunge cutting method. In this case, the cutting

head will not be set to a fixed cutting depth/clearance

while performing a cut. The cutting head is freely

movable during seesaw cutting operations.

1. Before starting the cut, the cutting head must be

fully raised. Be sure to grasp the plunge handle

extending from the blade guard. Loosen the depth

control knob on the side of the cutting head where

the switch box is located.

2. Set the workpiece securely on the cutting table.

Have it positioned to achieve the desired cut.

3. With the head fully raised, move to the desired start

of cut along the path of the blade. Plunge the head

and pull until the desired cut is complete.

4. Slowly return the cutting head to the original

starting position and turn off the motor.

THE CUTTING TABLE

FEATURES:

• The easily removable cutting table is covered with

an anti-skid rubber coating, which allows the

material being cut to sit on the table while the

cutting head is pulled through it.

• Simply line up the material being cut with the

appropriate pre-marked lines on the cutting table.

STEPS TO MAKE MITER CUTS:

1. The bench saw is equipped with a hinged guide rail

that allows the user to make accurate miter cuts.

2. To pivot the guide rail, lightly loosen the knobs at

both ends of the saw.

3. Set the rail to the desired angle by using both hands

to firmly hold the rail and rotating it. While still

holding the rail at the desired angle, tighten each

knob.

Turn off the saw before

pivoting the guide rail. Do not attempt to

pivot the rail mid-cut. The saw blade must be

clear of the material being cut and the saw

must be turned off first!

WARNING!

– 11 –

– 12 –

CUTTING DEPTH

The recommended cutting depth is 1/4" below the

cutting table surface. The cutting clearance has been

fixed from original design.

BLADE DIAMETER CUTTING DEPTH

8 inch 1-1/2 inch

10 inch 2-5/8 inch

Setting the blade too low

may damage the cutting table and if set too high,

the blade may grab the material being cut, causing

damage and possibly injury.

WARNING!

1. Always use the included GFCI plug.

2. In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current, reducing the risk of electric shock.

This tool is equipped with an electric cord which

has an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

3. Do not modify the plug provided – it is intended to

be used with the included GFCI plug and extension

cord. If using an adaptor for a 2-prong outlet,

always attach the adaptor to the GFCI plug, never to

the power cord.

4. Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

5. Check with a qualified electrician or service person

if you do not completely understand the grounding

instructions or are unsure that the tool is properly

grounded.

6. If an additional extension cord is needed, attach it

to the 3-prong GFCI plug. Never use an extension

cord longer than 50 feet.

Always repair or replace a damaged or worn cord

immediately.

7. This saw is intended for use on a circuit that has an

outlet that looks like the one illustrated in

Figure 2

.

The GFCI plug used on the saw has a grounding

plug that looks like the plug illustrated in

Figure

2(A)

. A temporary adaptor, which looks like the

adaptor illustrated in

Figures 2(B)

and

2(C)

, may be

used to connect the GFCI plug to a 2-pole

receptacle, as shown in

Figure 2(B)

, if a properly

grounded outlet is not available. The temporary

adaptor should be used only until a properly

grounded outlet can be installed by a qualified

electrician. The green-colored rigid ear, lug, etc.,

extending from the adaptor must be connected to a

permanent ground, such as a properly grounded

outlet box.

Figure 2

(A) (B) (C)

GFCI

plug

Grounding pin

Cover of

grounded

outlet box

Metal

Screw

Grounding

Means

(Lug)

Grounding pin

xiv. GROUNDING INSTRUCTIONS

NOTE -

Use of a Temporary Adapter is not permitted

in Canada.

– 13 –

8. Position of the Tile Saw.

• To avoid the possibility of the appliance plug

or receptacle getting wet, position the tile saw

to one side of a wall-mounted receptacle to

prevent water from dripping onto the

receptacle or plug. The user should arrange a

“drip loop” in the cord connecting the saw to

a receptacle. The “drip loop” is that part of

the cord below the level of the receptacle, or

the connector (if an extension cord is used); it

prevents water from traveling along the cord

and coming into contact with the receptacle.

See Figure 3

.

• If the plug or receptacle does get wet, do not

unplug the cord. Disconnect the fuse or

circuit breaker that supplies power to the

receptacle. Then unplug and examine for the

presence of water in the receptacle.

• If the receptacle is wet, dry it and make certain

that the GFCI Plug is reset before plugging it

back into the receptacle. Do not reconnect

the fuse or circuit breaker until the receptacle

is dry.

9. Extension Cords

• Always use the extension cord included with the

saw.

• If an additional extension cord is needed, use

only a cord that is intended for outdoor use.

These extension cords are identified by the

marking “Acceptable for use with outdoor

appliances; store indoors while not in use.” Use

only extension cords with an electrical rating

higher than the rating of the tool. Refer to the

chart on page 14. Do not use damaged

extension cords. Examine an extension cord

before use and replace it if it is damaged. Do not

abuse extension cords and do not pull on any

cord to disconnect it. Keep the cord away from

heat and sharp edges. Always disconnect the

extension cord from the receptacle before

disconnecting the saw from the extension cord.

• Never use an additional extension cord that is

longer than 50 feet.

10. Always use the Ground Fault Circuit Interrupter

(GFCI) plug included with the saw.

11. The tile saw cord includes a 15-amp twist lock

plug. Do not modify this plug or use an adaptor

on it. This plug is intended to be used with the

GFCI Plug included with the saw. The GFCI has a

standard 3-prong plug that can be plugged into a

standard 3-prong outlet or extension cord.

To reduce the risk of electrocution, keep

all connections dry and off the ground.

Do not touch plug with wet hands.

TOOL

Figure 3

Drip Loop

Supporting

Surface

Power Cord

Drip Loop

GFCI/Power Cord

Connection

GFCI plug

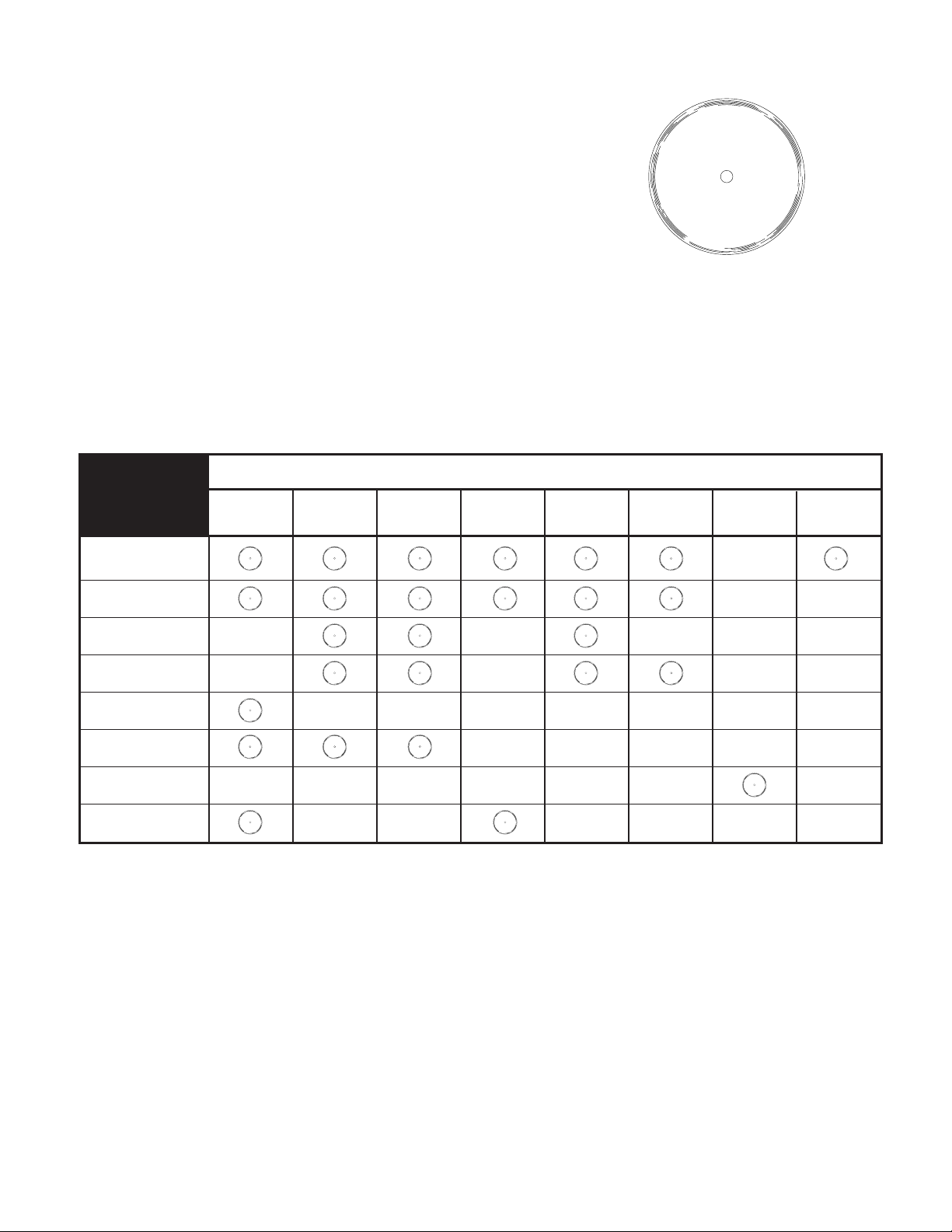

xv. CHOOSING THE RIGHT BLADE

THE RIGHT BLADE DOES THE RIGHT JOB

For the most effective cutting and blade life always use the recommended Pearl Abrasive Co. blade.

APPLICATION

PEARL

BLADE

SERIES

Reactor ADM

HPXL Series

HP Series

Turbo Mesh

DTLB19 Series

Pro-V Series

Glass Blade

SH Series

CERAMIC EXTRA HARD PORCELAIN MARBLE GRANITE HARDSTONE GLASS TILE MOSAIC

TILE CERAMIC METAL TILES

– 14 –

• The blade shaft speed of this saw is exclusively designed for cutting with

diamond saw blades. The saw may only be used for cutting natural and

artificial stone materials, do not cut wood or metal!

• The saw uses diamond saw blades with diameters up to 10". Saw blades

with larger diameters must not be installed on the saw.

• Choose the correct type of saw blade for the material to be cut and the

required cutting depth.

WET CUT BLADES

DO’S

•Inspect blades daily for cracks or uneven wear.

•Always use appropriate blade for material being cut.

•Inspect arbor shaft for uneven wear before mounting

blade.

•Always use blades with the correct arbor shaft size.

•Ensure that blade is mounted in the correct direction.

•Secure the blade to the arbor with a wrench.

•Use proper safety equipment when operating the saw.

•Periodically check the blade for cracks or bond fatigue.

•Always have a continuous flow of water on both sides of blade.

DONT’S

•Do not operate the saw without safety guards in position.

•Do not operate the saw with blades larger than 10".

•Do not cut dry with blades marked "Use Wet".

•Do not exceed manufacturer's recommended maximum RPM.

•Do not force blade into material let blade cut at its own speed.

DRY CUT BLADES

DO’S

•In addition to the following, always follow wet

recommendations.

•Use appropriate blade for material being cut.

•Inspect segment blades for segment cracking or loss.

•Do not use damaged blades.

•Use proper safety equipment when operating the saw.

DONT’S

•In addition to the following, always follow wet

recommendations.

•Do not make long cuts with dry blades--allow them to air cool.

•Do not use the edge or side of blade to cut or grind.

•Do not attempt to cut a radius or curve.

•Do not cut too deep or too fast into the material.

•Do not cut any material not recommended by blade

manufacturer.

xvii. DO’S AND DONT’S FOR BLADES

xvi. ELECTRICAL MOTOR SPECIFICATIONS

Horse Power 1-1/2 hp

Volts 115 V/ 60hz

Amps 15 amps

Motor RPM 3,450 rpm

Cycle 60

Phase 1

WIRE

GAUGE

No. 12

No. 10

No. 8

LENGTH OF CORD

25'

50'

75'

Recommendations:

• It is recommended that a 20 amp circuit be used while operating this saw.

This will prevent possible power interruption or loss.

• Always plug saw as close as possible to the power source while operating.

This will allow you to receive optimum electricity.

Electrical Wiring Diagram

WARNING: To avoid

permanent motor damage you

must use the correct extension

cord. Never use more than one

extension cord at a time. Follow

the chart for proper size.

– 15 –

xviii. CARE AND MAINTENANCE

GENERAL RULES

• Always clean the machine before maintenance/ repair.

• Before cleaning/maintenance/repair, the machine must

be switched off with the main power key.

STEPS TO FOLLOW WHEN CLEANING

1. Please do not use aggressive cleaners (i.e. containing

solvents). Do not use high-pressure water jets,

aggressive detergents or solutions and liquids with a

temperature exceeding 86°F Use a fluff-free cloth only.

2. Use a cloth which may be lightly moistened only for

removing dust and dirt. Hard packed dirt can be

removed with a soft brush.

3. For the sake of safety, no water/cleaning liquid/vapor

may penetrate into the electric motor, connectors

/plugs, switches, etc. Therefore cover all apertures,

holes in the housing, connectors or plugs, etc. or seal

them with adhesive tape.

4. Use a soft, low-pressure water jet and a brush to rinse

dirt and incrustations away. Be particularly careful

when near hazardous parts of the machine (e.g.

switch, motor). Clean the motor and switches only by

wiping with a moist cloth.

5. Do not "rinse" the bearings of the drive elements to

prevent them from running dry. The ball bearings of

the machine are permanently lubricated.

6. After cleaning, remove all covers and adhesive tape All

screws/nuts which you may have loosened must be

tightened again.

7. After wet cleaning, plug the machine to a power outlet

which is equipped with a ground fault current

interrupt. If the device cuts power, the machine must

be inspected by an authorized dealer prior to use!

AFTER EVERY USE OF THE SAW:

• Remove dirty water from container.

• Remove dirt and mud from the bottom of the

container.

• Rinse the immersion pump with fresh water to prevent

water pump clogging from residual dirt.

AFTER WET CLEANING AND BEFORE

USING THE SAW AGAIN:

• Connect the machine to an electric power outlet

equipped with a "GFCI” safety power breaker. If the

safety power breaker cuts off the electrical power

supply, do not try to operate the machine but have it

checked by an authorized dealer first.

BEFORE & AFTER A

PROLONGED TIME

BEFORE NOT USING THE MACHINE FOR A

PROLONGED PERIOD OF TIME:

• Clean and lubricate all movable parts. DO NOT

GREASE THE GUIDE RAILS.

AFTER NOT USING THE MACHINE FOR A

PROLONGED PERIOD OF TIME:

• Check that the legs are safely fixed.

• Check that all screw joints and nuts are fixed.

• Check that the roller table is rolling on the rails and

that it moves securely back and forth. With the saw

blade removed, switch on the motor for an instant and

switch it off again. If the motor does not run, have the

machine inspected by a qualified electrician.

• Check that the immersion pump works properly. Turn

on the valve if applicable and switch the machine on.

If the pump does not give any water or only a little,

switch the machine

TEMPERATURE CHANGES

AMBIENT TEMPERATURE BELOW 37 F (WINTER)

To prevent the water in the pump and cooling system from

freezing, remove the water after using the machine or

when there will be a long break. Make sure that the cooling

system is entirely drained so that there is no water left

inside the pump, the bearing house and the water hose.

For your safety before performing any maintenance on the saw, turn off the power switch and

unplug the power cord.

WARNING!

– 16 –

When the machine has not been used for a long period

of time, hard packed dirt may begin to build up inside

the pump and block the pump wheel. If the machine

is activated with the immersion pump blocked, the

electric motor of the pump will be damaged within a

few minutes. Please follow the steps listed below to

clean the pump before operating the saw.

1. Unscrew the pump filter.

2. Remove the water pump from the water tray/

container.

3. Clean the water pump exterior.

4. Clean the interior where the fan is by removing the

fan cover. If gasket is installed, be careful not to

damage it.

5. The fan can be removed by using pliers to pull it

off. Careful not to damage the fan or the motor

shaft. With it removed, the entire volute can be

cleaned easily.

6. Spin the pump shaft by hand. It should rotate

almost effortlessly. Then press the cleaned fan

back onto the blade. Note to align the shaft

geometry with that of the blade bore before

pressing it back on. Do not press the fan too far

down the shaft or it may not rotate. Spin the fan

blade by hand to confirmit can spin effortlessly.

7. Reassemble the fan cover.

8. Plug the water pump in briefly to check whether it

works properly.

For your safety before performing any maintenance on the saw, turn off the power switch and

unplug the power cord.

WARNING!

For your safety before performing any maintenance on the saw, turn off the power switch and

unplug the power cord.

WARNING!

xix.WATER PUMP MAINTENANCE

REMINDER:

There are 3 methods to adjust the alignment:

1. Cutting fence.

2. Bridge.

3. Cutting head

Note: Usually adjustment method 1 and 2 are the

most common.

METHOD 1: CUTTING FENCE

1. Loosen the bolts that secure the cutting fence.

2. Using a steel square, as shown in Fig. 1, align the

square's long arm with the blade. Both the front

and the rear end of the blade's rim should have

contact.

3. Adjust the cutting fence such that the fence face

sits flush with the steel square's short arm.

4. Now move the cutting head back and forth, along

the bridge, to check for consistent blade contact

with the steel square. Make sure the short arm

does not move during this process. Interference

from the blade may move the steel square away

from the cutting fence.

xx.ALIGNMENT INSTRUCTIONS

Fig.1 3D View

1

– 17 –

METHOD 2: BRIDGE

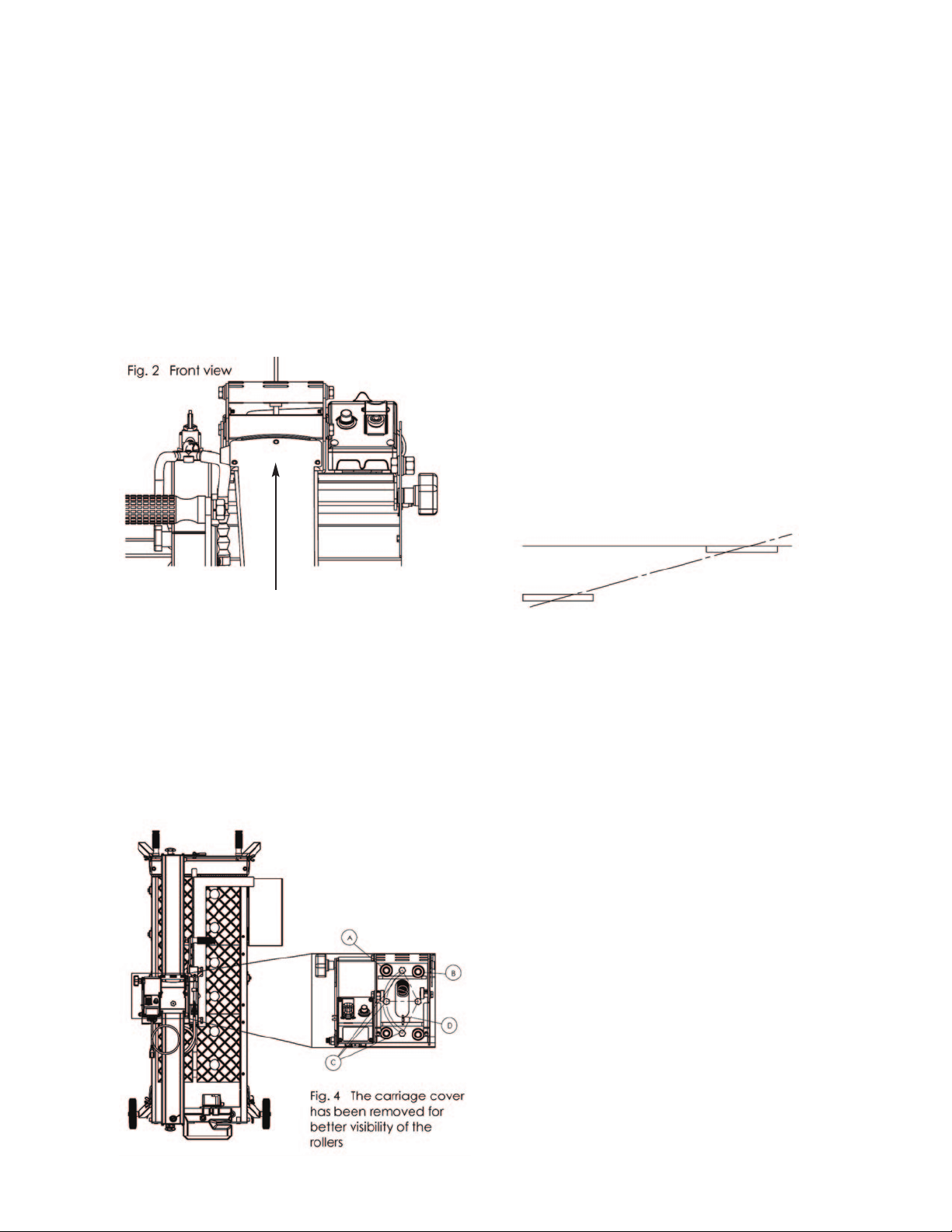

1. Loosen the bolts that secure the bridge (Fig. 2).

DO NOT REMOVE THE BOLTS AS THE BRIDGE

AND CUTTING HEAD WILL FALL.

2. Repeat steps listed in method 1 to align the fence.

3. Now if the cutting fence does not move enough to

align the cutting head, the bridge may be shifted

as shown in the illustration below.

Adjustment range of the bridge/rail

METHOD 3: CUTTING HEAD

1. Underneath the carriage cover is four bolts (size

13 wrench) that hold the head's two sub-

assembly together. The upper assembly is the

carriage and the lower assembly is the actual

cutting head. The three bolts highlighted by the

balloon "C", in the illustration below are the actual

bolts that need to be loosened. Only loosen the

bolts enough that the lower sub-assembly can

move, changing the blade shaft's orientation. The

fourth bolt is the pivoting bolt and does not have

to be loosened.

2. If the blade is constantly shifting left, using Fig. 4

as reference, the cutting head must be rotated

counterclockwise (left).

3. If the blade is constantly shifting right, using Fig.

4 as reference, the cutting head must be rotated

clockwise (right). Note: The cutting head should

glide effortlessly across the bridge. Should the

head be too tight or too loose, adjust the rollers on

the left (A) using a size 17 wrench to rotate it.

Rollers on the right (B) are fixed so they cannot be

adjusted.

Fig. 5 depicts how aligning the blade with the steel

square does not always mean the head is aligned with

the bridge.

1. The solid line represents the steel square.

2. The dotted line represents the bridge and ACTUAL

travel direction of the cutting head.

3. The rectangular box represents the blade/cutting

head orientation. As the user pushes/pulls the

cutting head if the cutting head is not properly

aligned with the bridge, the blade will always

moves away from the steel square.

xx.ALIGNMENT INSTRUCTIONS (cont.)

The post holes allow movement of the bridge

+/- 0.5mm in either the left or right direction.

Fig.3

Top

View

Fig.5 Blade

Shifting

– 18 –

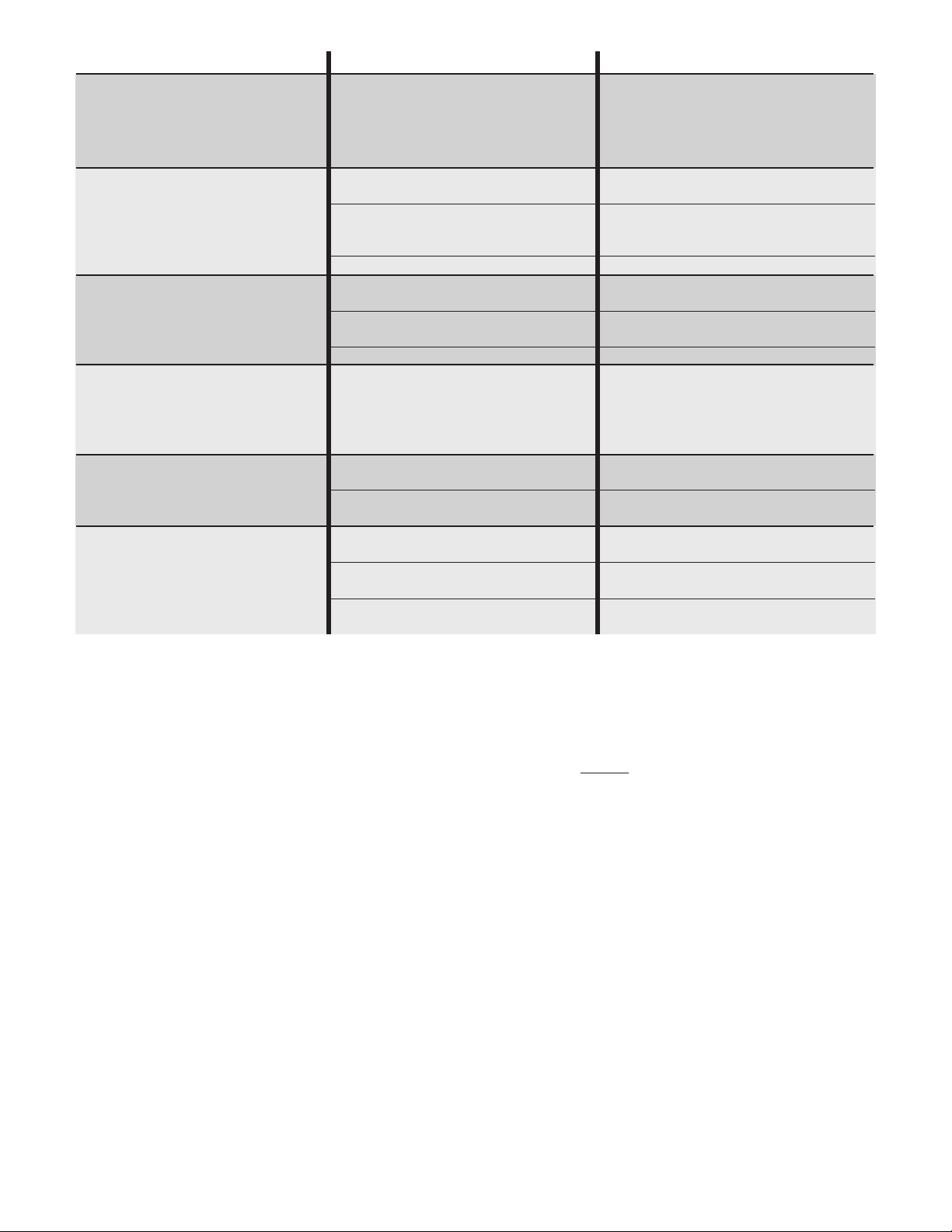

xxi.TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

-Power cord not properly

fixed/plugged in.

-Power cord defective.

-Main power switch

defective.

-Loose electrical connection inside

the electric system.

-Motor defective.

-Too much pressure exerted while

cutting.

-Incorrect specification for saw

blade.

-Saw has a defective electric system.

-Power cord/extension cable too

long or cable still wound up inside

cable drum.

-Power network is insufficient.

-Drive motor no longer runs at rated

speed (r.p.m.).

- The pump draws air.

-Filter clogged.

-Pump wheel of the immersion

pump blocked by dirt.

-Poor tension in the blade material.

-Saw blade is damaged or bent.

-Flange of the saw blade is

damaged. Shaft of the motor bent.

-Overheating of the saw blade;

cooling water not sufficient.

-Check that the machine is properly

connected to the power supply.

-Have the power cord checked,

replace if necessary.

-Have the main power switch

checked and replace if necessary by

a qualified electrician.

-Have the whole electric system of

the machine checked by a qualified

electrician.

-Have the motor checked and

replaced if necessary by a qualified

technician.

-Exert less pressure when cutting.

-Use a saw blade which corresponds

to the material being cut.

-Have the electric system of the saw

checked by a qualified technician.

-Use a power cord/extension cable

of the rated length, use a cable

drum with cable fully extended.

-Observe the electrical ratings of the

machine and connect it only to a

power network which complies with

these ratings.

-Have the motor checked by a

quilified electrician and have it

replaced if necessary.

-Fill the container with water.

-Clean the filter of the pump.

-Disassemble the immersion pump

and clean.

- Return the saw blade to the

manufacturer.

-Have the saw blade aligned/

flattened.

-Clean the receiving flange.

-Solder the diamond segments of

the old blade onto another saw

blade or use a new blade.

-Replace the saw blade flange.

-Replace the electric motor.

-Have the diamond segment

soldered on the blade again; ensure

optimum flow of cooling water.

MACHINE DOES NOT RUN WHEN

SWITCHED ON

MOTOR STOPS

(POWER CUT OUT)

POOR MACHINE PERFORMANCE

LITTLE POWER

INSUFFICIENT FLOW OF COOLING

WATER OR NO COOLING WATER

AT ALL

IRREGULAR RUN OF THE

SAW BLADE

SAW BLADE WOBBLES WHEN

RUNNING

DIAMOND SEGMENT BECOMES

LOOSE

– 19 –

– 20 –

PROBLEM POSSIBLE CAUSE SOLUTION

-Wrong type of saw blade.

- Shaft of motor causes wobbling.

- Overheating.

- Saw blade type is unsuitable for the

material being cut.

-Saw blade ype is unsuitable for the

machine performance.

-Saw blade too hard.

-Diamond segments are blunt.

-Poor tension in the blade material.

-Too much load placed on the saw

blade.

-Diamond segments are blunt.

-The saw blade has slipped on the

motor shaft when running.

-Saw blade overheating due to a lack of

cooling water.

-Lateral friction when cutting.

-Material is not being fed parallel to the

saw blade

-Poor tension in the blade material.

-Too much load on the saw blade.

-Use harder saw blades.

-Have bearings of the motor or the motor

replaced.

- Ensure optimum flow of cooling water.

- Use appropriate type of saw blade.

-Sharpen the diamond saw blade.

-Return the saw blade to the manufacturer.

-Use a suitable saw blade.

-Sharpen the saw blade.

-The arbor of the saw blade must be fitted

with an appropriate adator ring.

-Check the receiving flange and have it

replaced if necessary.

-Ensure an optimum flow of cooling water.

-The material feed is too high; proceed

more slowly.

-Ensure that the direction of feed is

absolutely parallel to the saw blade.

-Adjust the roller table or have it adjusted.

-Have the saw blade tensioned.

-The material feed is too high, proceed

more slowly.

EXCESSIVE WEAR

SAW BLADE IS BLUNT

APPEARANCE OF CUT IS

NOT OPTIMAL

THE CENTER HOLE IN THE SAW

BLADE HAS BECOME WIDER DUE TO

WEAR

SAW BLADE SHOWS BLOOMING

COLORS

GRINDING MARKS ON THE

SAW BLADE

xxii. HOW TO ORDER PARTS

Please have the following information ready before calling: Model Number of the Tile Saw and Part Description

For warranty purpose, please have the following ready: Serial Number and When purchased and where

All parts listed may be ordered from your Local warehouses. If the part is not stocked locally, call our Corporate office and ask for

our Customer Service Department. For Technical Support call 1-800-969-5561. In Canada, call 1-800-387-0008. There is a $25.00

minimum order.

Return Policy: Return goods for credit or exchange on the basis of the following terms: (1) They must be current products;

(2) Items returned for replacement or refund should be in original cartons and must be accompanied by a packing slip with the

following information: Returned Goods Authorization (RGA) number obtainable from Customer Service Department • List of items

returned • Reason(s) for return(s) • Copy of original invoice(s); (3) Freight charges must be assumed by sender; (4) Returning goods

are subject to a 15% handling charge to cover our cost of repacking and restocking. All Prices are subject to change without notice.

Disclaimer: Pearl Abrasive Co. reserves the right to make changes or improvements on its products without incurring an additional

obligation including any obligation to make corresponding changes or improvements to products previously manufactured or sold.

Pearl reserves the right to discontinue products at any time without notice.

All illustrations displayed in this manual are the property of Pearl Abrasive Co. and shall not be duplicated or reproduced without the

express written consent of Pearl Abrasive Co.

xxiii. CUSTOMER SERVICE

AFTER SALE SERVICE

All customer service (technical questions, re-order of parts, etc.) will be provided by our company. All spare parts for after sales

service will be stocked and shipped from our warehouse. If requested, we may arrange for our sales representatives to hold a training

class for product knowledge at dealer’s location.

This manual suits for next models

1

Table of contents

Other Pearl Saw manuals

Pearl

Pearl PA7TTR Owner's manual

Pearl

Pearl PA7TT Owner's manual

Pearl

Pearl VX10RSPRO Owner's manual

Pearl

Pearl VX141MS User manual

Pearl

Pearl VX10.2XLPROR Owner's manual

Pearl

Pearl PA-7 Owner's manual

Pearl

Pearl VX RSPRO VX1048RSPRO Owner's manual

Pearl

Pearl PA-10 User manual

Pearl

Pearl VX5WV Owner's manual

Pearl

Pearl VX141MSD Owner's manual