1

VSP |

TABLE OF CONTENTS

GENERAL INFORMATION .................................................................................................................................................... 2

SAFETY RULES..................................................................................................................................................................... 2

SYMBOLS............................................................................................................................................................................ 2

WARNINGS ......................................................................................................................................................................... 3

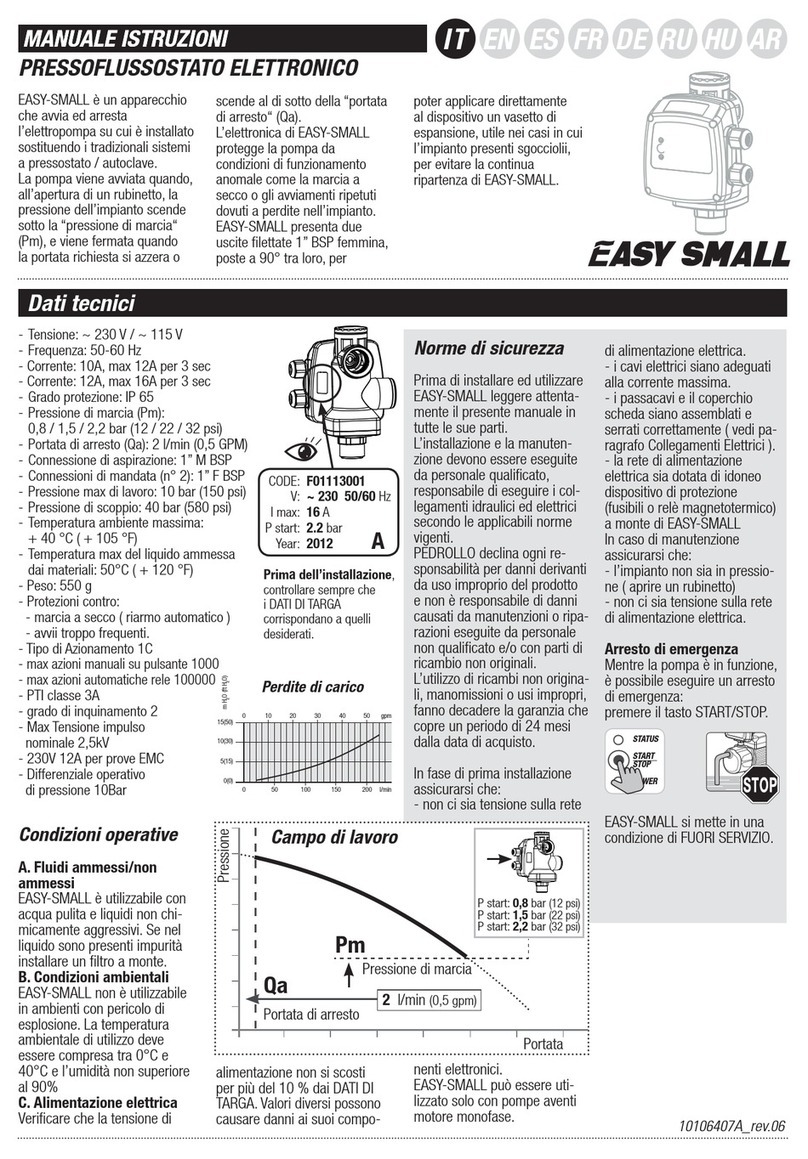

PRODUCT DESCRIPTION ..................................................................................................................................................... 4

TECHNICAL DATA................................................................................................................................................................. 4

POWER AND ABSORPTION.................................................................................................................................................. 4

USE LIMITATIONS................................................................................................................................................................ 5

AUTO-LIMITATION FOR OVERLOAD...................................................................................................................................... 5

PARTS LIST.......................................................................................................................................................................... 5

THE CONTROLS ................................................................................................................................................................... 5

DISPLAY SYMBOLS.............................................................................................................................................................. 6

INSTALLATION..................................................................................................................................................................... 6

PRESSURE SENSOR ............................................................................................................................................................. 7

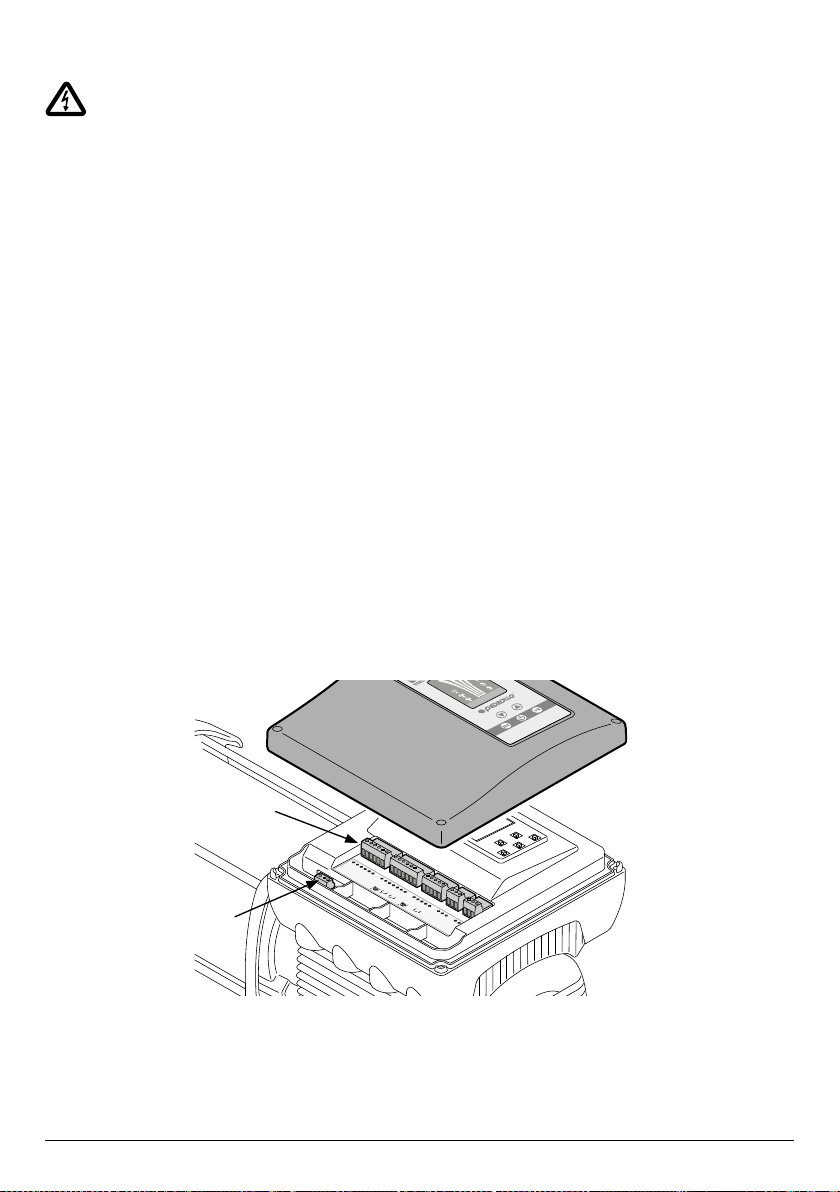

ELECTRICAL CONNECTION ................................................................................................................................................... 8

CONNECTIONS DIAGRAM..................................................................................................................................................... 8

POWER SUPPLYTERMINAL BOARD...................................................................................................................................... 9

INPUTS/OUTPUTS TERMINAL BOARD................................................................................................................................... 9

PUMPS CONNECTION IN PARALLEL.................................................................................................................................... 11

START-UP........................................................................................................................................................................... 11

PUMP PRIMING ................................................................................................................................................................ 11

FUNCTIONING PARAMETERS ............................................................................................................................................. 12

ADVANCED PARAMETERS MENU ....................................................................................................................................... 14

ALARMS............................................................................................................................................................................. 21

TROUBLESHOOTING.......................................................................................................................................................... 23

MAINTENANCE ................................................................................................................................................................. 26

DISPOSAL........................................................................................................................................................................... 26

DECLARATION OF CONFORMITY....................................................................................................................................... 26