4

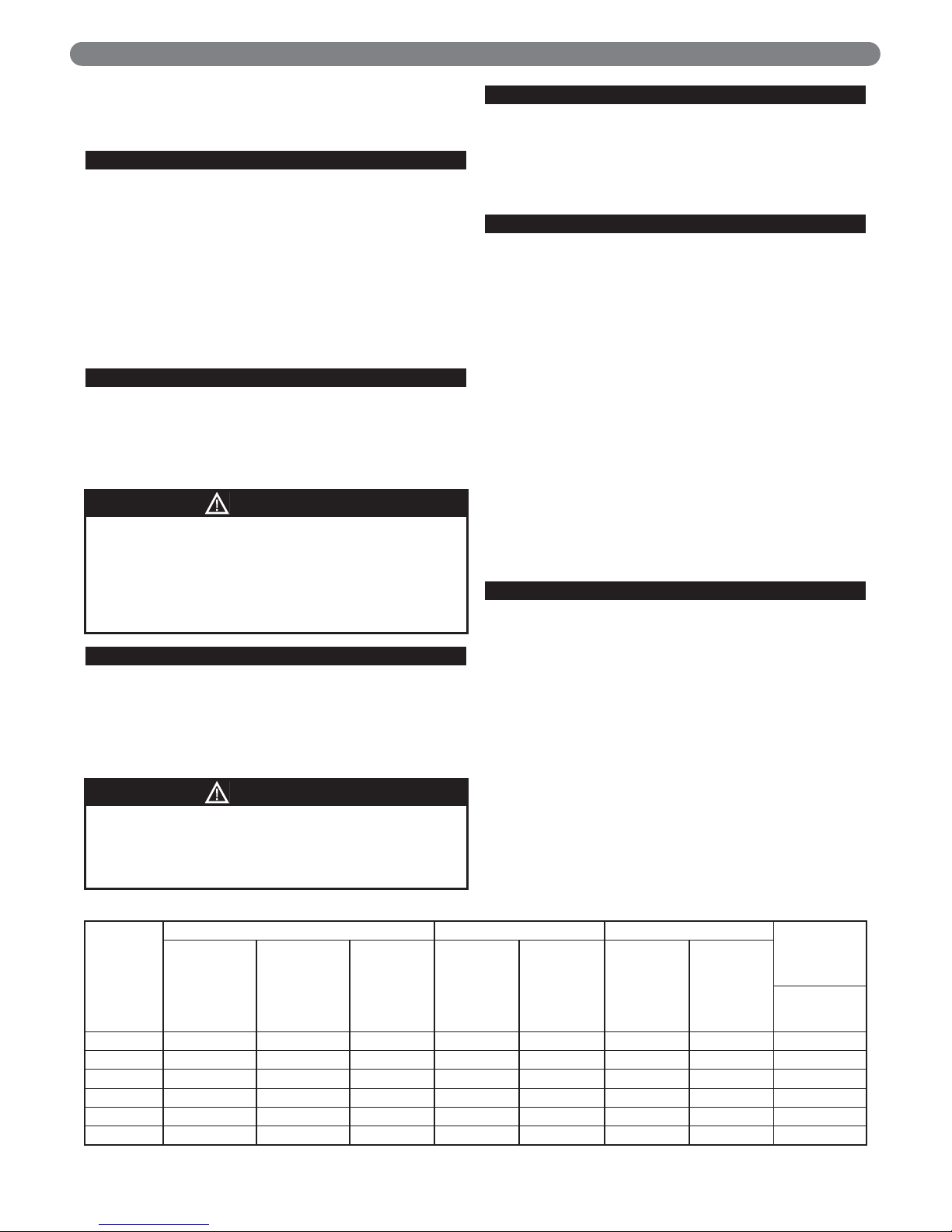

E. PRODUCT SELECTION

1. The following guidelines apply to residential systems

only. For commercial or institutional installations

contact your local PB Heat, LLC representative.

2. Determine the quantity of domestic hot water

required. Factors to consider:

a. Estimate typical peak hour demand. Determine

the general time of day (morning, noon, evening)

when the most hot water is used. Use chart below

to determine potential maximum usage.

b. Estimate unusual peak draw demand.

Whirlpool baths, hot tubs, and multiple head

showers require large quantities of hot water in a

short period of time. Contact fixture manufacturer

for quantity of water required. Generally speaking,

these circumstances can only be met with larger

storage volumes.

c. Domestic Water Temperature. Most residential

usage will be satisfied with 119°F water, the

temperature setting recommended by the

Consumer Product Safety Commission. Some

applications such as laundry and dishwashers may

require a higher temperature.

Ratings can be improved by increasing Peerless®

Partner®thermostat setting and using a mixing

valve to temper the hot water to the proper

temperature. When temperatures greater than

119°F are required, use a mixing valve at the

outlet of the water heater or anti-scald fittings at

point of use.

d. Domestic water priority. First hour ratings may

be less than published when boiler output is

shared with space heating. Generally a consumer

will notice a drop in domestic water temperature

before a drop in space heating temperature.

Giving domestic water production priority by

directing entire boiler output to Peerless®Partner®

will maximize domestic water output. However,

prioritization controls could result in an

unacceptable drop in space heating temperature

when large quantities of domestic hot water are

used, and a prioritization control malfunction

could result in loss of space heating.

3. Multiple Water Heaters. Peak domestic water

usage (first hour rating) or unusual peak draw may

not be met with a single water heater. Multiple units

can be installed as either a bank of tanks acting as a

single unit, or as multiple individual units sized and

located for specific draw situations.

PREINSTALLATION

Estimate of Peak Domestic Hot Water Usage

Average Gallons of Times Used During Gallons Used in

Use Hot Water per Usage One Hour One Hour

Shower 20 x _____________ = _____________

Bath 20 x _____________ = _____________

Shaving 2 x _____________ = _____________

Hands and Face Washing 4 x _____________ = _____________

Hair Shampoo 4 x _____________ = _____________

Hand Dish Washing 4 x _____________ = _____________

Automatic Dish Washing 14 x _____________ = _____________

Food Preparation 5 x _____________ = _____________

Wringer Clothes Washer 26 x _____________ = _____________

Automatic Clothes Washer 32 x _____________ =

Total Peak Hour Demand = __________

The Peerless®Partner®indirect-fired water heater is

deemed to be used in a "commercial setting" if at

any time the unit is operated at a temperature over

150°F. Refer to warranty for additional information.

NOTICE

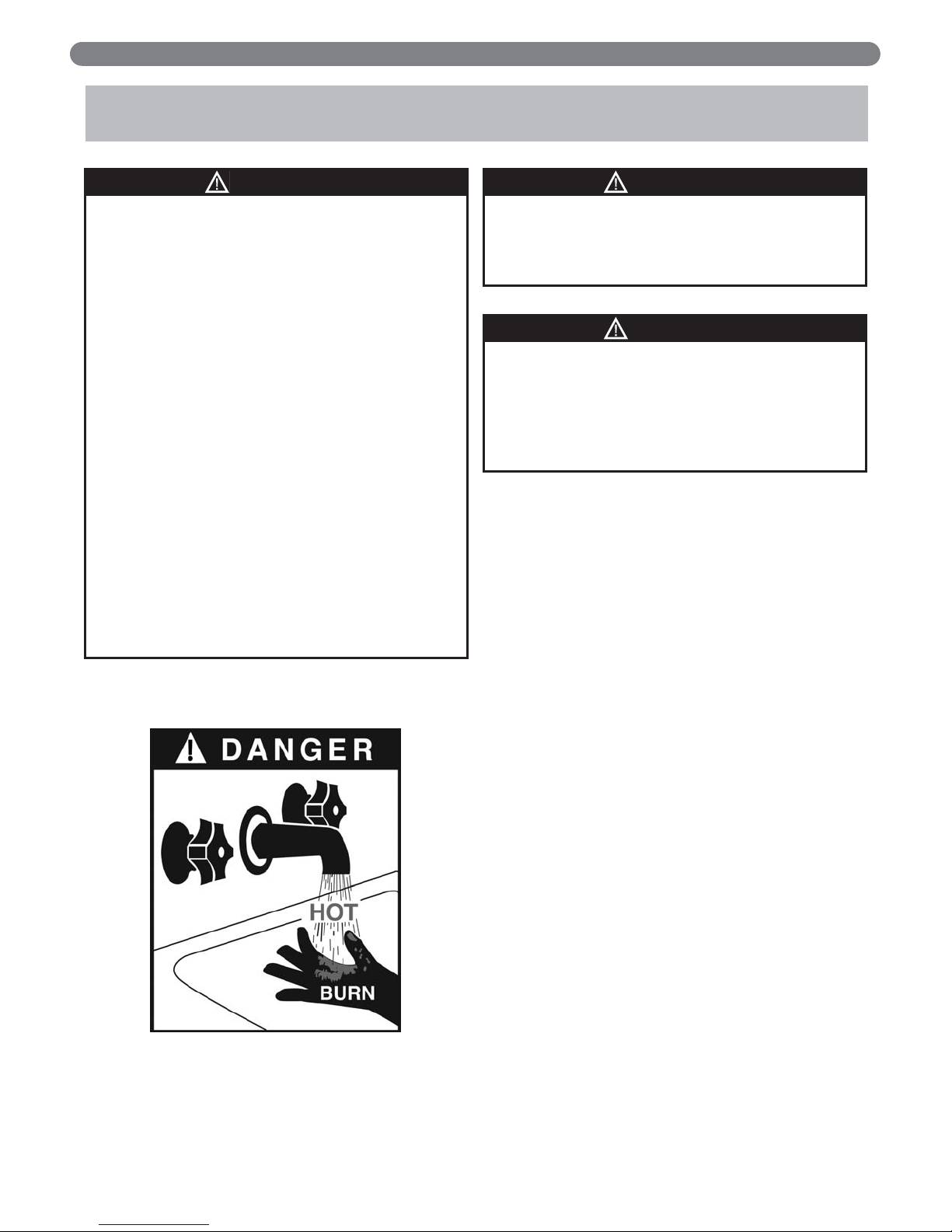

DANGER

Water temperatures over 125°F

can cause severe burns instantly,

or death from scalds.

Children, disabled, and elderly are

at the highest risk of being

scalded.

See instruction manual before

setting temperature at water

heater.

Feel water before bathing or showering.

Temperature limiting valves are available, see

manual.