Installaon and Operang Manual Page 9

INSTALLATION

VENTILATION / EXTRACTION SYSTEMS

To prevent the build-up of heat and moisture within the room, it

is recommended that a ventilation system is connected to the

cabinet. This can generally be achieved by using one of the

two options detailed below.

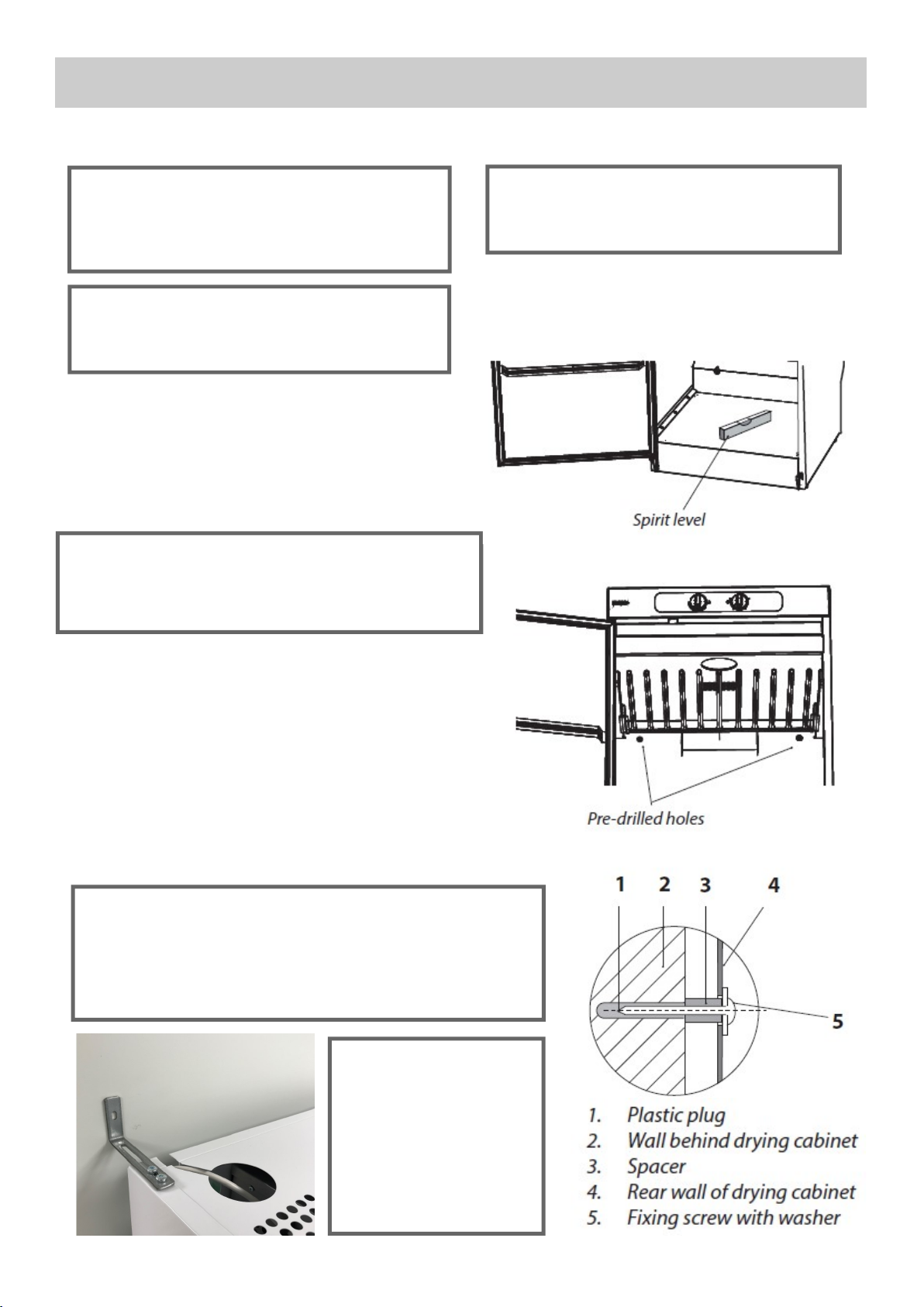

Requirements for all installations: Fit the spigot adaptor (1) to

the top of the cabinet by placing it over the cut-out and rotating

clockwise until the lugs of the spigot click into place.

The cabinet requires an optimum airflow of 95m3 per hour.

The location of the cabinet must ensure that replacement air is taken into consideration, especially in a

closet installation or where the cabinet is built-in to bespoke cupboard furniture.

1. CONNECTION TO AN EXISTING MECHANICAL SYSTEM

(Existing air conditioning / climate control system)*

This method is only suitable for buildings that have an existing

mechanical ventilation system, or where the room has a

dedicated extraction fan with a capacity of at least 95m3 /

hour. In both cases, the ducting must terminate to outside

atmosphere.

Fit the supplied white plastic ventilation adaptor (3) over the

existing wall or ceiling mounted extractor fan grille (fixing

screws for this ‘tripod’ type fitting are not supplied). This fitting

allows for both room and cabinet ventilation. Connect to the

cabinet outlet spigot with the flexible hose or other appropriate

ducting material.

*Please consult with a ventilation engineer before connecting the cabinet to a centralised building

ventilation system.

NOTE. The exhaust ducting should not be

connected into an existing chimney, boiler flue

or tumble dryer system.

2. CONNECTION TO A NATURALLY ASPIRATED SYSTEM

(Direct ducting system to outside air)

This is the preferred method of providing ventilation for the

cabinet. The ducting can be routed through an outside wall

or glazed window pane. Core cut a 105mm. diameter hole in

the outside wall, or alternatively cut a hole in a fixed pane of

window glass. Connect the flexible hose (2) to the cabinet. A

coupling fitting (4, not supplied) may be required to adapt to

the terminal fitting or ducting. Fixed open louvre fittings are

preferred complete with an integral insect mesh screen. The

ducting can also be installed with a vertical duct pipe termi-

nating on the roof.

Additional guidance notes on page 10.