Installaon and Operang Manual Page 6

INSTALLATION

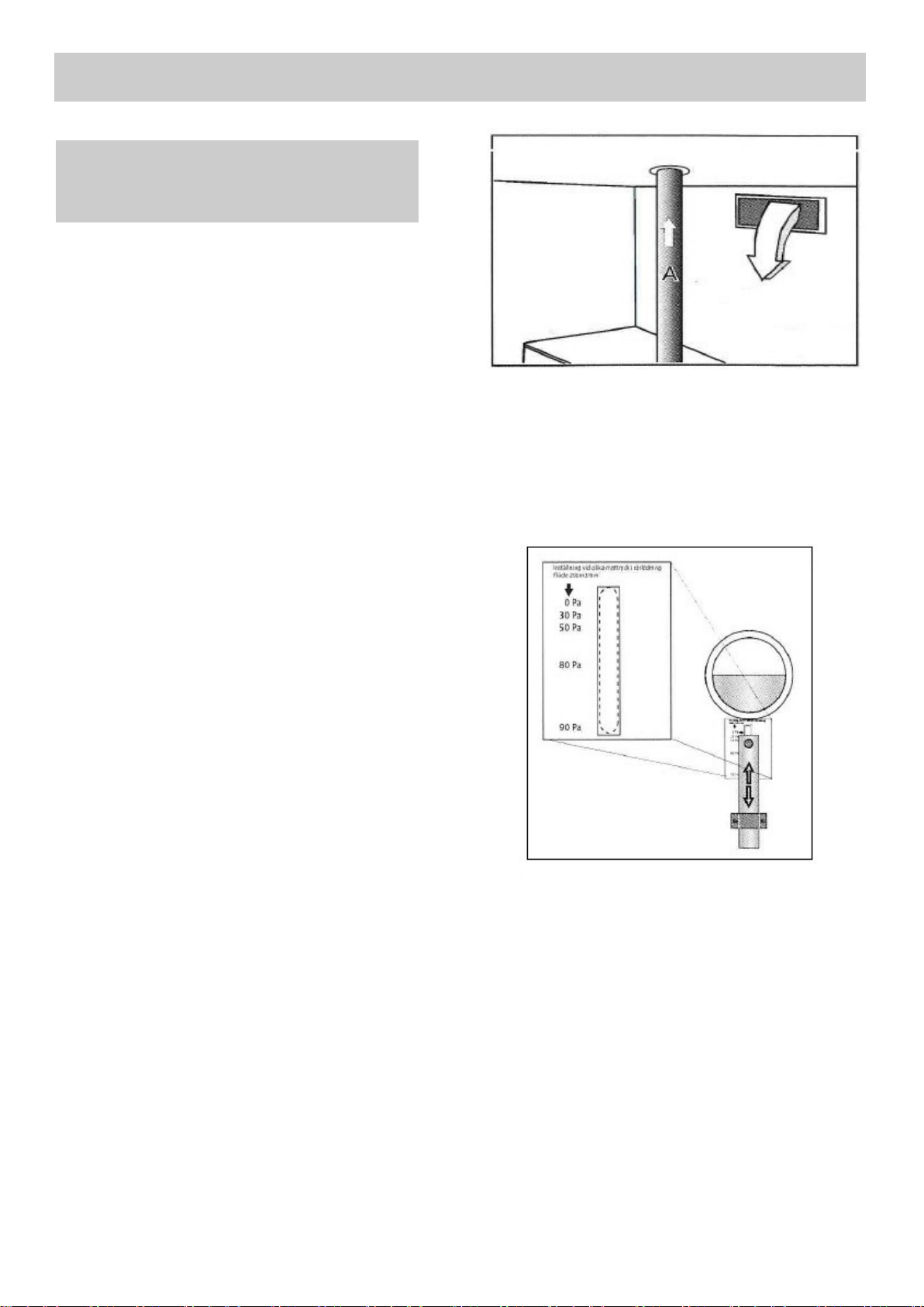

EXHAUST CONNECTION

The exhaust ducting should not be connected

into an existing chimney, boiler flue or tumble

dryer system.

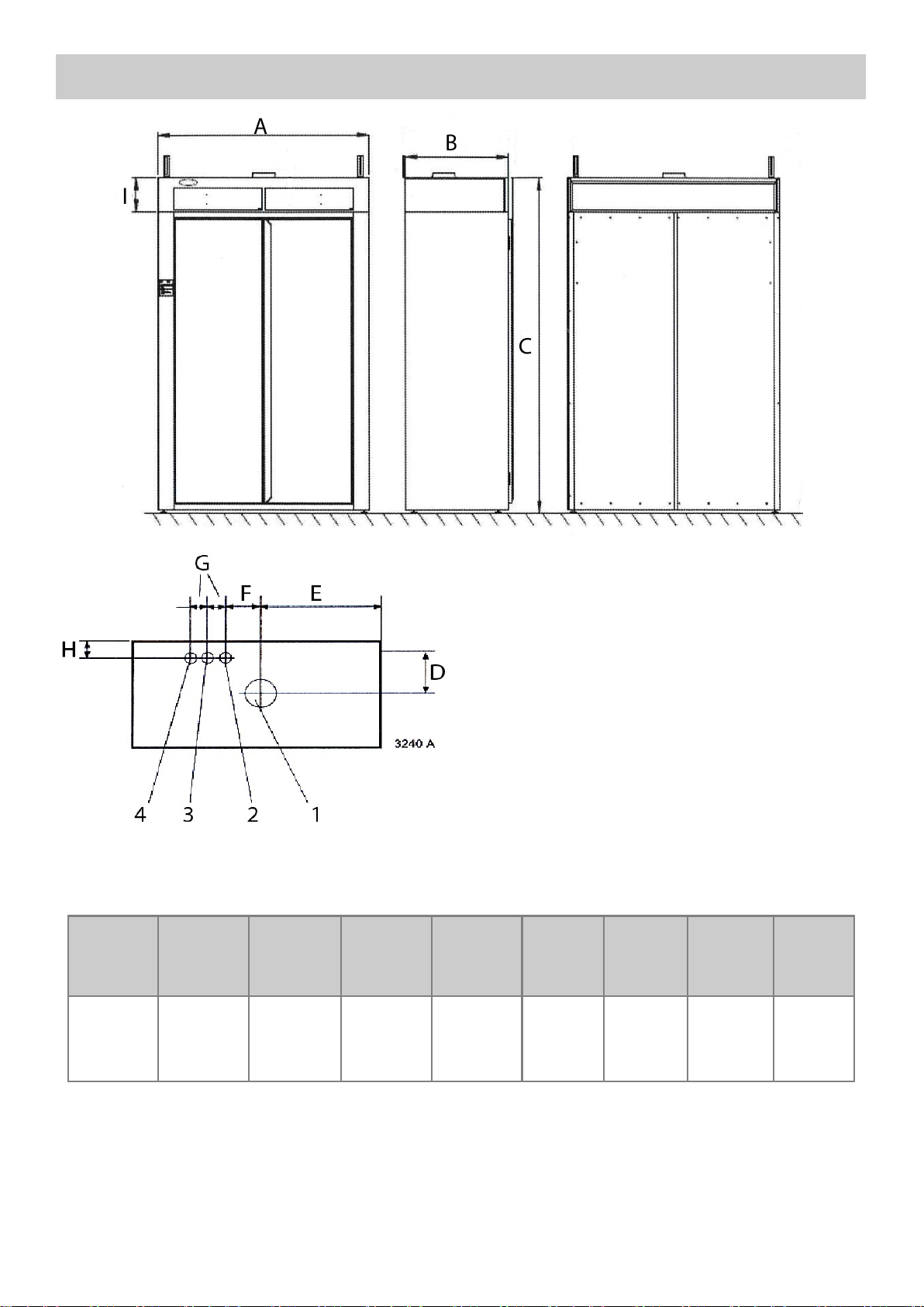

The dryer must be connected directly to an exhaust

ducting system that terminates on the outside of

the building. This could be through the roof or on

an external wall. The outlet spigot on top of the

cabinet is 125mm diameter. The effective length of

the ducting ‘A’ is 23m of straight pipe. If the

diameter of the pipework is increased to 160mm,

the effective length is 70m. The effective length of

the system will vary depending on the type of

ducting material and the number of bends used.

The cabinet operates more efficiently with the

minimum length of ducting and the unit should be

positioned on an external wall if possible.

Notes:

· Rigid metal or plastic pipe is preferred although

flexible ducting can be used for some

installations within close proximity to an outside

wall.

· Wall vented systems, including fixed window

pane applications, should terminate with an

open louvre grille.

· Roof vented systems should be fitted with a

weather cowl or a downward facing bend.

· Standard tumble dryer back draught shutters

should not be used.

· Ensure that the ducting and terminal fittings are

cleaned on an annual basis.

ROOM VENTILATION

The cabinet has an exhaust airflow of up to 250

cubic metres per hour. This air has to be sourced

initially from within the room where the dryer is

installed. It is important to ensure that there is a

continuous supply of fresh air into the room. The

air intake into the cabinet is via the door surrounds

- sealing gaskets are not fitted for this reason. The

recommended free area of the air intake into the

room must not be less than 142cm2. The resistance

caused by grilles or shutters must not exceed:

10 Pa (0.1 mbar).

Commissioning the ducting system

To optimise the efficiency of the cabinet the

damper situated on top of the unit should be ad-

justed to a setting that corresponds with the pres-

sure drop in the ducting. The maximum permissi-

ble pressure drop is 70pa.

If the pressure drop is greater than this, an exter-

nal fan must be installed. The dryer has electri-

cal terminals inside the control console suitable

for connecting an external fan. The fan would

then operate only when the cabinet is in use.

If several cabinets are installed adjacent to each

other it is advisable to fit a separate ducting sys-

tem to each unit. If a single ducting pipe is to be

considered for a multi unit installation, it would be

advisable to seek professional advise from a spe-

cialist heating and ventilation engineer as back

draught devices may be required for each cabi-

net.