InstallaonandOperangManual Page10

START-UP

WARNING! Read the safety advice on

page 3 before using the drying cabinet.

1. Check that the cabinet is firmly attached to the wall. See page 7 of this manual.

2. Check that no packaging material has been left behind.

3. Use a mild detergent with warm water and wash the inside and outside of the drying

cabinet. See the CARE section on page 14 of this manual.

HOW TO LOAD THE WASHING

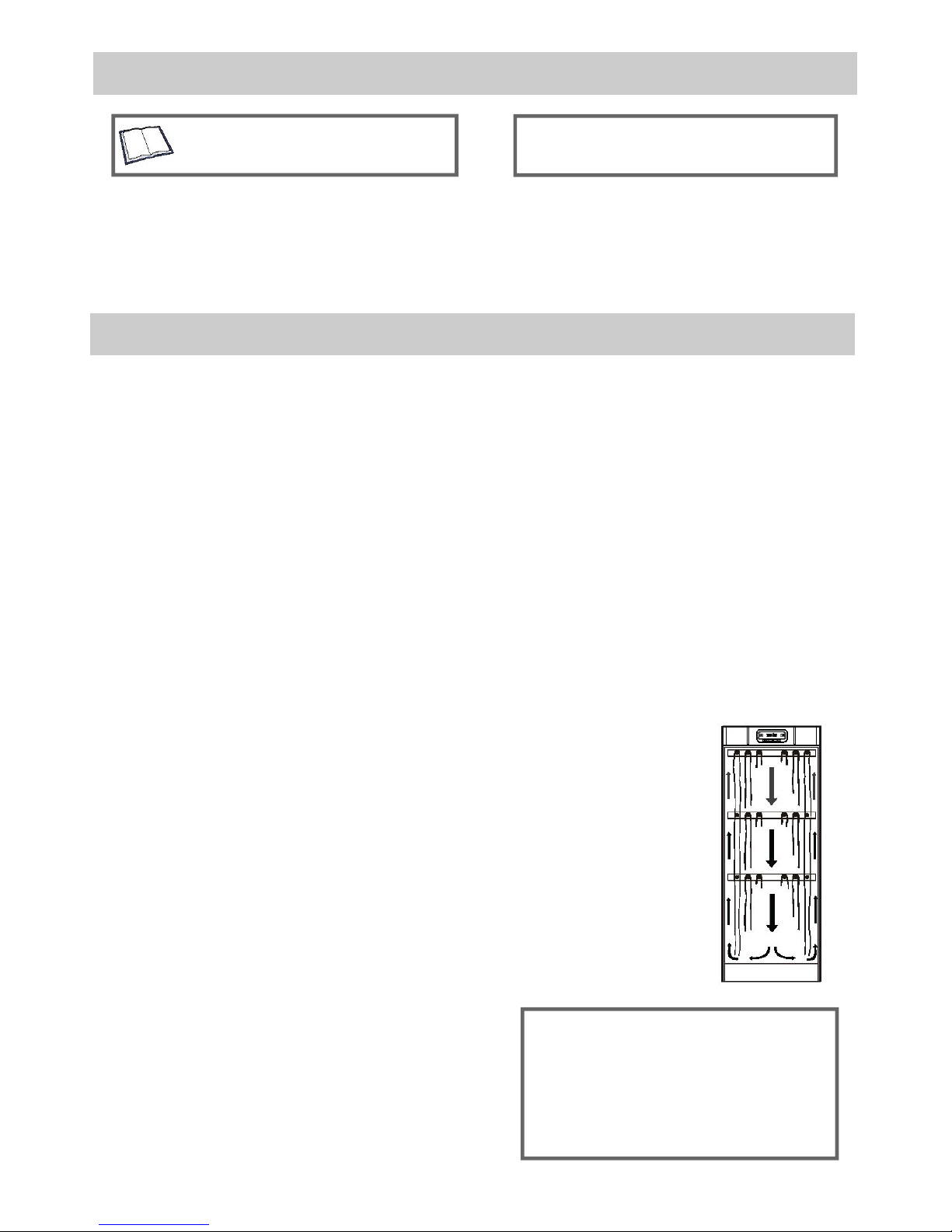

The cabinet contains three sets of hanging rails.

Each set has 10 bars on which to hang the washing.

Hang items in the drying cabinet according to

how much space they require – not according to

their weight.

Fold back the middle and bottom sets of rails if

long garments are to be hung from the top set.

Hang gloves, hats, scarves and similar items on

the hangers attached to the inside of the door.

Slide the hanging rails forward to facilitate the

loading process. Push them back when not in

use and before closing the door.

Do not overload the drying cabinet. If you do, the

washing will become creased and dry unevenly.

Instead, leave space between the garments if

possible.

Avoid drying heavy items of clothing together

with lighter items as they have very different

drying times.

Make sure not to hang knitted items. These will

stretch as they are heavy when wet. Instead, lay

these items flat on top of the middle or lower set

of hanging rails.

For optimum efficiency, do not lay items flat on

the top set of hanging rails.

Avoid hanging textiles that are dripping or

soaking wet, as the drying cabinet is not

intended to collect large volumes of water. This

also leads to unnecessarily long drying times.

To avoid any potential transfer of colours, keep

light and dark/ coloured materials separate.

CAUTION! Do not dry articles that have

been previously cleaned in, washed,

soaked or splashed with petrol, or other

flammable/ explosive substances, as they

give off vapours that could ignite or

explode.

Drying tips:

Always follow the washing machine

instructions on garment care, if they are

provided.

If fabric softener or an antistatic product is

used, follow the manufacturer’s instructions

on their use.

Remove washing that is already dry. This

will reduce the drying time for the remaining

items.

Hang longer items nearest to the cabinet

walls and shorter ones towards the centre.

This allows for efficient airflow within the

cabinet and delivers the most effective

drying results.

Read this user manual before using

the drying cabinet for the first time.

This figure shows

how the air flows

within the cabinet.