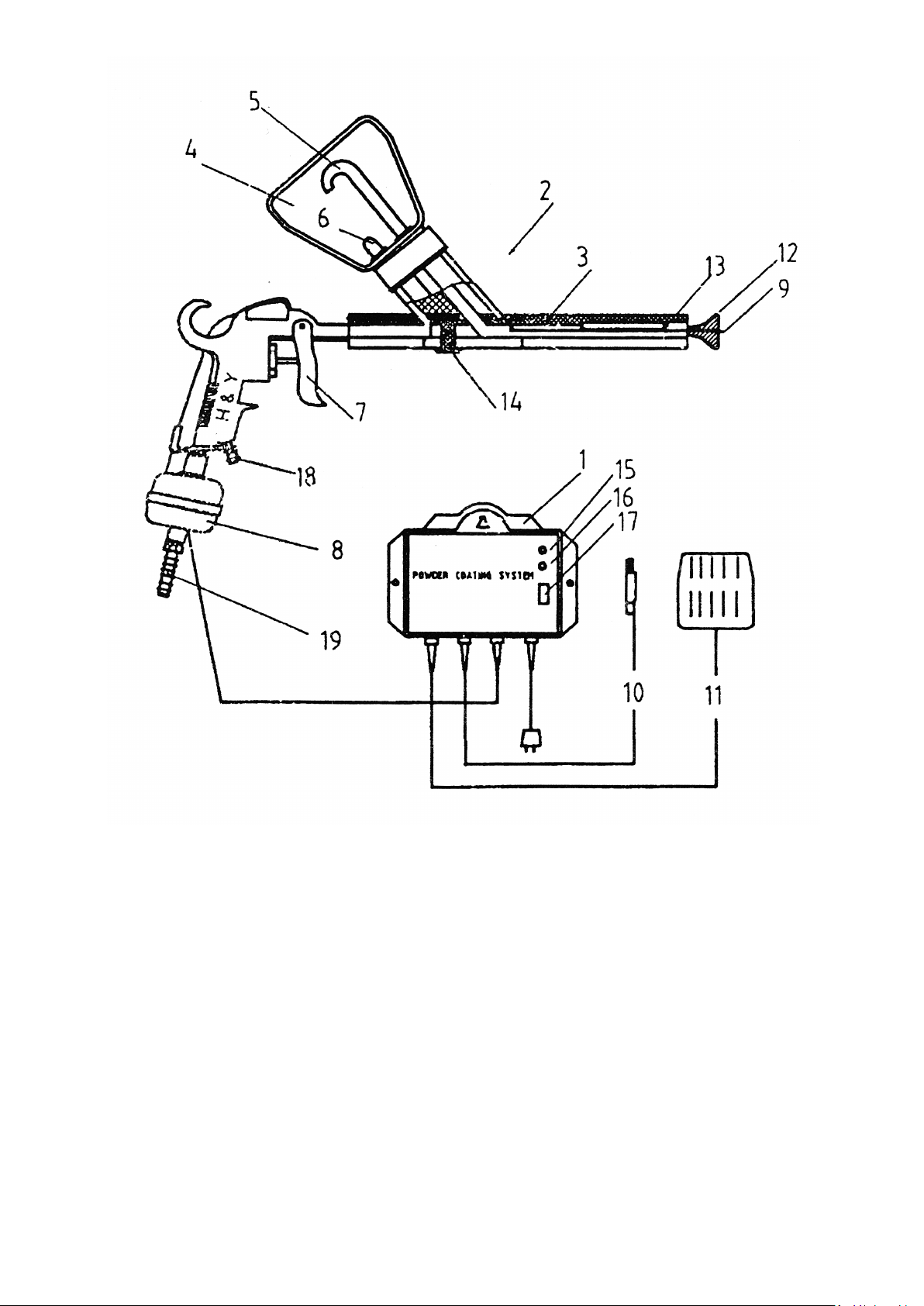

• Strive to have the object to be coated

hanging. The distance between the gun

and the object should be about 20 cm.

Activate the high voltage by pressing the foot

controller (11), and the green indicator (16)

lights up. Now you can cover the object with

powder from different directions and with

varying angles. Adjust the air pressure with

the adjusting screw (18) if necessary.

• The gun loses efciency if toner accumulates

on the emitter (13). Solve this by rst

switching off the switch (17), discharging

the emitter by touching the earth terminal,

aspark discharges the high voltage. Then

wipe the emitter clean with a clean cloth.

• When you have applied the desired amount of

powder, switch off the switch (17), discharge

the emitter (9) by touching the earth terminal,

a spark will discharge the high voltage.

Bake the object

Make sure that the oven is prepared and that it

has reached the correct temperature. Wear suit-

able gloves when placing the item in the oven,

avoid bumping into or scratching the surface of

the item. Bake the item according to the pow-

der manufacturer’s recommendations (usually

15minutes). Larger objects may need longer, the

powder gradually melts, from a dull at surface,

to a soft glossy nish. When baking manifolds or

rims, check every 5 minutes until you see that the

powder begins to take on a glossy surface over

the entire object, add another 10 minutes. If the

object has not been nished after 30 minutes,

you should look for a cause of error. Be careful

when baking, if the item is in the oven for too

long, the surface will be rough and may need to

be removed or redone.

Be sure to bake the items in a well-ventilated area

and use activated carbon respirators. Allow the

item to cool gradually when done by turning off

the oven and opening the door ajar. Note Too fast

cooling can cause the gloss to fade.

Clean the gun

When you are done with one colour, the gun must

be cleaned before using another colour. Start by

turning off the power switch (17). Touch the emit-

ter (9), the ground terminal (10) to discharge the

high voltage. You can now safely remove the paint

container (4). Unplug the power cord from the wall

outlet. Wipe the diffuser (12), the inlet pipe (6), the

outlet pipe (5) and the container (4), blow clean

with 3 kg of compressed air. Never use organic

solvents when cleaning the container.

The toner

Keep toner stored in a tight container to prevent

itfrom absorbing moisture. Mixtures between dif-

ferent powders, dusts and dusts can cause pits

in the surface. Never use solvents when cleaning,

only compressed air. You can reuse powders that

have been collected from a clean surface in a

spray can and that have not been contaminated

by anything. In certain concentrations, the toner

can be ammable and explosive, never use a

vacuum cleaner to suck up discarded powder.

Troubleshooting

Grooved surface:

Make sure the gun is properly cleaned of previous

toner. Some colours are made of polyurethane

other polyester, if you mix these the result can be

bumpy. Make sure the item is properly cleaned.

Porous surface:

If this occurs, remove the powder coating with

paint removal (may take a long time, cover with

plastic to reduce evaporation). Rinse with water

and prepare with a primer. Parts in cast iron, die-

cast, cast aluminum and magnesium can give off

precipitates that give a porous surface. This can

be remedied by preheating the object.

Preheating:

The time the object needs to be preheated varies

with the size. Preheat in temperatures between

95 - 200 ° C. Wipe with a white cloth until no pre-

cipitates appear. Allow the item to cool to room

temperature before powder coating.

Orange peel:

The fact that the surface has a light appearance

of orange peel is almost inevitable when it comes

to polyester-based powders. You can usually x

the surface by wet sanding it with a 400 paper

and nishing with chrome polish. Another cause

can be supercharged powder, which stands

on edge, like hair. Stop applying powder if this

occurs and try to blow away the cumbersome

grains with a light jet of air. If the powder settles

unevenly, it may be due to moisture, then replace

the water separator and rell the powder. Baked

powder can be post-treated in the same way as

liquid surface treatments.

Bad spray image:

If the gun does not spray properly, it may be due to

too low air pressure, water in the water separator

both cause malfunctions. Adjust the air pressure

or replace the water separator. Also check the

paint container so that there is enough space for

the powder to ow properly. There should be at

least 25 mm free space from the bottom.