([SORGHG47<

3$5725

,'(17,),<,1*12

120(1&/$785(

25'(6&5,37,21

0$7(5,$/

63(&,),&$7,21

,7(0

12

%207DEOH

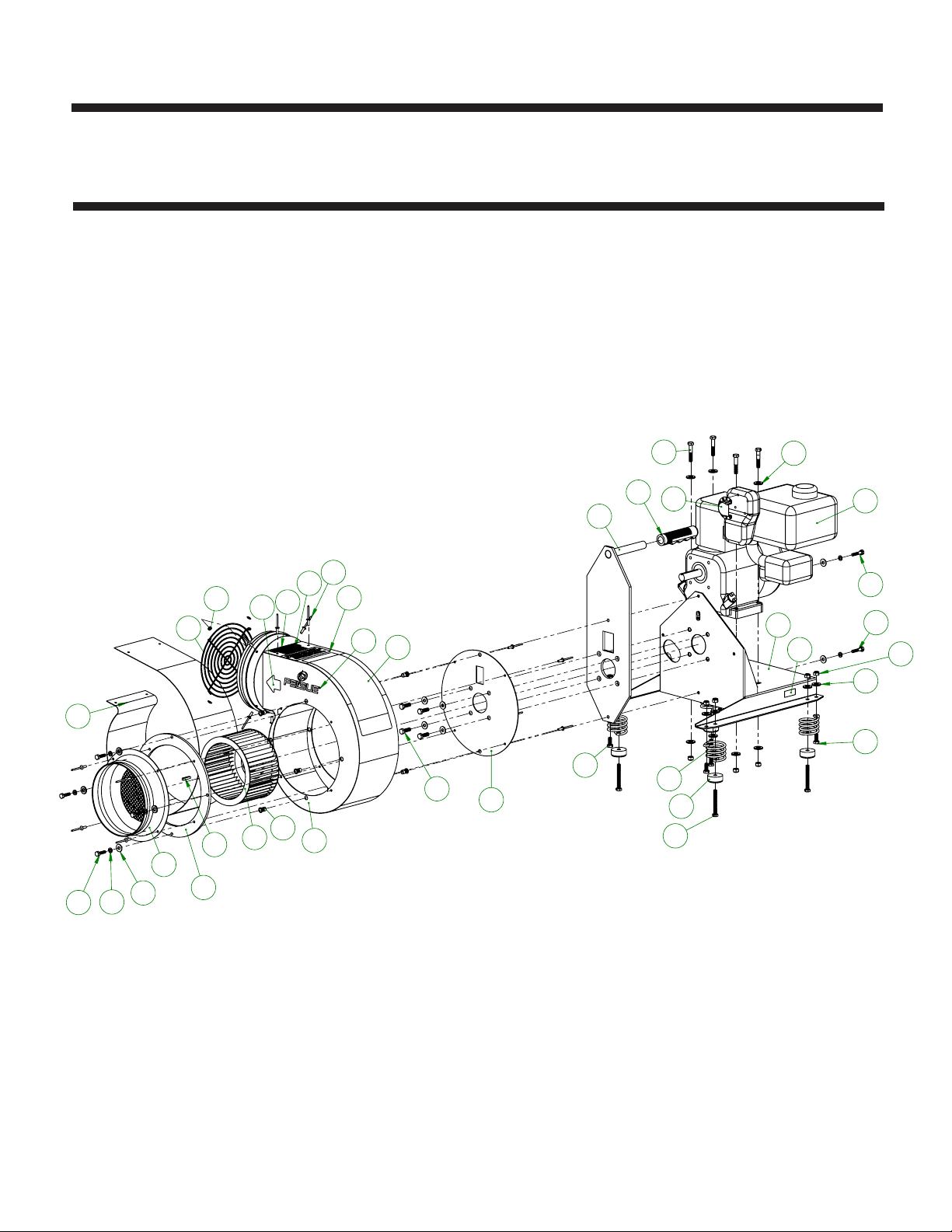

6&5(:+(;+'81&;3/$7('*5$'(

385&+$6('

:$6+(55,9(7%$&.83,';2'66

385&+$6('

'(&$/,163(&7('%<'$7($'+(6,9(%$&.;

385&+$6('

1876(577+,16+((781&&5,03,167</(

385&+$6('

'(&$/3(/68(:,7+3/2*2+;:%/$&.

385&+$6('

'()/(&72508))/(5%5,**6$1'675$7721(1*,1(

385&+$6('

$'$37(55,1*)2560$//(568&7,21$'$37(56

0)'5()':*

'(&$/&$87,21)25287'22586(21/<;

385&+$6('

'(&$/:$51,1*'212729(563(('530

:+75('

3&+5()':*

'(&$/,'(17,),&$7,216(5,$/,16758&7,216

3&+5()':*

'(&$/',5(&7,21$/$552:%/$&.

385&+$6('

'(&$/:$51,1*&+(&.2,//(9(/35,2572($&+

86(

3&+5()':*

:$6+(5/2&.,1+(/,&$/63*3/$7('

385&+$6('

:$6+(5)/$7,17<3($:3/$7('

385&+$6('

6&5(:&$3+(;+'81&;3/$7('*5$'(

385&+$6('

6&5(:&$3+(;+'81&;3/$7('

385&+$6('

1876729(581&*5$'(

385&+$6('

6&5(:+(;+'81&;/21*3/$7('

385&+$6('

,16(57)25%/2:(5:+((/)250('$/80,180

0)'5()':*&

(1*,1(%5,**6675$7721+36+$)7$/&</

385&+$6('

:$6+(5)/$77<3($:3/$7('

385&+$6('

6&5(:+(;+'81&;/21*3/$7('

385&+$6('

6&5(:+(;+'81);/*3/$7('

385&+$6('

<

:(/'0(17%/2:(5+$1'/(7+,&.3/$7(

:,7+%$5

0)'5()':*

5,9(767$9(;%/,1')/$1*('20(%/$&.',$

385&+$6('

*5,//(,17$.(287/(7*$67((/:,5(%/$&.

),1,6+ 3&+5()':*

68&7,21$'$37(5)256(5,(63(/3257%/2:(56

0)'5()':*

$'$37(53$1(/02817,1*3$77(51)25(1*,1(6

0)'5()':*%

)22758%%(52':5(&:$6+(5

385&+$6('

*5,36/,'(215281'*5,35,%%(':),1*(5*5,3

),762'

385&+$6('

+

635,1*(1*028179,%5$7,21,62/$725

385&+$6('

.(<%/2:(56+$)764;/*

385&+$6('

:+((/%/2:(5%25(;

385&+$6('

:(/'0(17&(175,)8*$/%/2:(5+286,1*)25

+26(

0)'5()':*

<

:(/'0(17*$67((/$//&(175,)8*$/%/2:(56

0)'5()':*%