ment.

([SORGHG$OO47<

3$5725

,'(17,),<,1*12

120(1&/$785(

25'(6&5,37,21

0$7(5,$/

63(&,),&$7,21

,7(0

12

%207DEOH

(

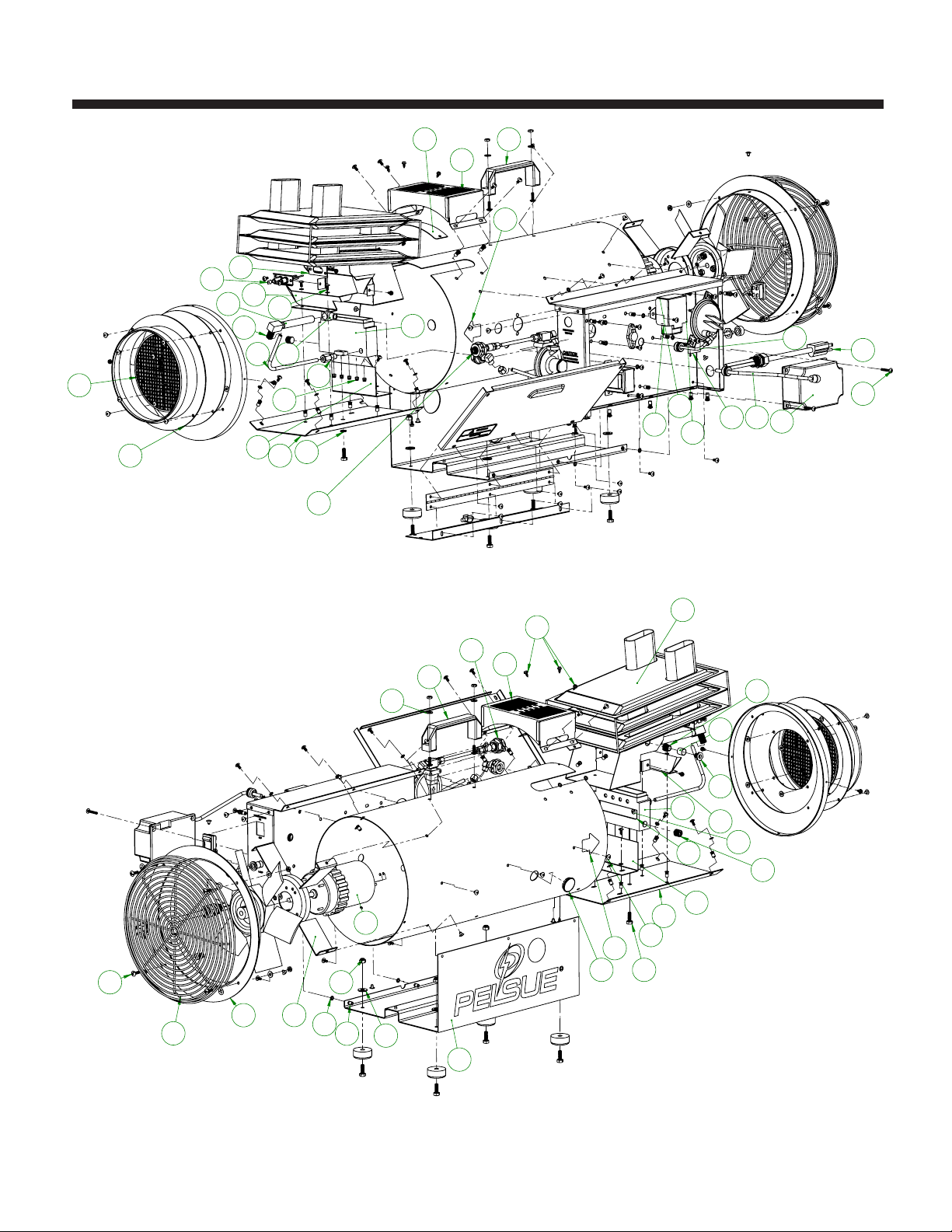

*5200(758%%(5,';2'

385&+$6('

5,9(767$9(;%/,1')/$1*('20(%/$&.',$ 385&+$6('

&$3'867<(//2:58%%(5:5(7$,1(5,'

385&+$6('

) ),77,1*$'$37(5/+:,19)/$5(;0137

385&+$6('

6&5(:0$&+,1(3+,/75866+';/21*%/$&.

385&+$6('

'(&$/+($7(5&203$570(17

3&+5()':*

'(&$/(/(&75,&$/6&+(0$7,&/(*(1')25

+($7(5%/2:(5

3&+5()':*

'(&$/:,5,1*',$*5$0+($7(5%/2:(5

3&+5()':*

'(&$/:,5,1*',$*5$0)25&21752/%2;'225

3&+5()':*

/($'+,*+7(16,21$66(0%/<

0)'5()':*

(

&$%/($66<&,5&8,7%2$5':*$:,5(6

385&+$6('

&,5&8,7%2$5'*$6,*1,7(5&21752/9$&5(027(

6(16,1*

385&+$6('

(

75$16)250(59$,13879$&287387

385&+$6('

78%(&233(52';/21*

385&+$6('

),77,1*'(*(/%2:&2032'78%(;

0137%5$66

385&+$6('

6:,7&+$,535(6685(9$&6(772&

1250$//<23(1

385&+$6('

78%(&233(52';/21*

385&+$6('

(

9$/9(62/(12,'0$*1(7,&9$&

385&+$6('

)

),77,1*1,33/(&/26(0137;/21*%5$66

385&+$6('

*

5(*8/$7253523$1(:,7+3,1.635,1*5$7('72

:&

385&+$6('

78%(&233(52';/21*

385&+$6('

),77,1*5('8&(5%86+,1*0137;)137

%5$66

385&+$6('

),77,1*7((0$/(%5$1&+)137;)137;

0137

385&+$6('

78%(&233(52';/21*

385&+$6('

),77,1*0$/(&211(&7250137;

&2035(66,21%5$66 385&+$6('

6:,7&+7+(50$/&872))23(1#&/26(#

385&+$6('

&$3$&,725%5$&.(70)'9$&+=

0)'5()':*

&29(558%%(5&$3$&,725&211(&7,21

385&+$6('

&$3$&,7250)'9$&+=

385&+$6('

6:,7&+52&.(563679$&$9'&$12

/,*+7

385&+$6('

)86($03;*/$6678%( 385&+$6('

)86(+2/'(53$1(/07':0$/(63$'(7(50,1$/

385&+$6('

)XVH:DVKHU

(

&25'6(7:02/'('3/8*6-72:5$7('

385&+$6('

675$,15(/+8%',$01276+2:1

385&+$6('

'225&21752/%2;)25+($7(5%/2:(5

0)'5()':*

+,1*(3,$12:,5(&21752/%2;'225+($7(5

%/2:(5

0)'5()':*

)86(&/,37<3()25017*$*)86(6

385&+$6('

02817,1*3$1(/&21752/%2;)25+($7(5

%/2:(5

0)'5()':*

%277203$1(/&21752/%2;$/80,180

0)'5()':*

7233$1(/&21752/%2;)25+($7(5%/2:(5

0)'5()':*

%5$&.(76833257$,535(6685(78%(35(6685(

',))

0)'5()':*

),77,1*3,3(3/8*0137&2817(5681.+(;+'

385&+$6('

),77,1*187&2035(66,21)2578%,1*

385&+$6('

),77,1*&2035(66,21(/%2:2'78%(;

0137%5$66

385&+$6('

) ),77,1*1,33/(0137;/21*67((/

385&+$6('

)8(//,1(67$,1/(6667((/78%(2';

:$///*

0)'5()':*

),77,1*0$/(&2112'78%(&2035(66,21;

0137

385&+$6('

),77,1*137;78%('(*)(0$/(

385&+$6('

),77,1*(//675((7

/2:352),/(137%5$66

385&+$6('

),77,1*&283/,1*$1&+25)137$1&+25

187

385&+$6('

'(&$/',5(&7,21$/$552:%/$&.

385&+$6('

'(&$/1277+,6+($7(5+$6$6(&21',*1,7,21

'(/$<

3&+5()':*

:$6+(5/2&.,1+(/,&$/63*3/$7('

385&+$6('

'(&$/&(57,),('$,5'(/,9(5<+($7(5%/2:(5

385&+$6('

'(&$/:$51,1*81,786$*(+($7(56

3&+5()':*

'(&$/5$7,1*3/$7(,'6(5,$/)25

385&+$6('

'(&$/23(5$7,1*,16758&7,216)25

385&+$6('

'(&$/(/(&75,&$/*5281',1*,16758&7,216

3&+5()':*

'(&$/127,&(:+(186,1*+($7(5+26(0867

3&+5()':*

'(&$/&$87,21)$16+28/'%(23(5$7,1* 3&+5()':*

'(&$/&$87,21:+(15(029,1*)25,167$//,1*

3&+5()':*

'(&$/:$51,1*+$=$5'286&21',7,216

3&+5()':*

&+,01(<:(/'0(17)25+($7(5

0)'5()':*

(

3/8*61$3,1%/$1.%87721',$

385&+$6('

6&5(:75866+($'3+,//,36;%/. 385&+$6('

1

:$6+(5/2&.,17(51$/7227+3/$7('

385&+$6('

:$6+(5)/$76$(=,1&3/$7('

385&+$6('

06+;187

'6

6&5(:0$&+,1(3+,/75866+'81&;%/.

385&+$6('

1876(577+,16+((7&5,03,167</(

385&+$6('

)$1%/$'(32/<3523</(1(',$;%25( 385&+$6('

5,1*287(5,17$.(287/(763,11,1*)25

3855()':*

5,1*,11(5287/(763,11,1*)25

0)'5()':*

5,1*5(675,&725',$0(7(5

0)'5()':*

6&5((1287/(7)256(5,(6

0)'5()':*

5,9(767$9(;%/,1')/$1*('20(%/$&.',$ 385&+$6('

/2&.187+(;1</21,16(57

385&+$6('

:$6+(5)/$7,17<3($:3/$7('

385&+$6('

6&5(:&$3+(;+'81&;3/$7('

385&+$6('

)22758%%(52':5(&:$6+(5

385&+$6('

3$1(/+($7(5%$6(6,/.6&5((1('+($7(5

%/2:(5

0)'5()':*3

6&5(:6+((70(7$/;+(;+'6/277('

%/$&.

385&+$6('

25,),&(%5$6681)'5,//('72

3&+5()':*

6+877(5$,5)25+($7(56

0)'5()':*

3/$7(+($7(;&+$1*(5%$6(+($7(56

0)'5()':*

'()/(&725$,5)/2:+($7(56

0)'5()':*

%851(5&$67,1*)25+($7(56

0)'5()':*

1

6&5(:0$&+,1(3+,/75866+'81&;3/$7('

385&+$6('

63$5.,*1,7(5,*1,7(5)/$0(6(1625(/(&752'(

385&+$6('

*$6.(763$5.,*1,7(5)/$0(6(1625

3&+5()':*

%$))/(0$,1%851(56(5,(6

0)'5()':*

&283/(50(5&+$17136)7+58*$/9

385&+$6('

),77,1*$'$37(5137+(;+'7+58+2/(

0)'5()':*

6,*+7*/$66137&/($5/(16+(;+'

385&+$6('

+($7(;&+$1*(5+($7(5%/2:(5

0)'5()':*

&/2685(3$1(/

0)'5()':*

*5,//(,17$.(''$632:'(5&2$7('%/.

3&+5()':*

1

:$6+(5/2&.,17(51$/7227+3/$7('

385&+$6('

:$6+(5)/$77<3($:3/$7('

385&+$6('

02725(/(&75,&9$&+3

385&+$6('

0272502817&837<3()25)$6&202725

0)'5()':*

63,11,1*,17$.($602',):017*+2/(6

0)'5()':*

+$1'/(38//7<3(%/.3/$67,&)25

6(5,(6

385&+$6('

+286,1*6,/.6&5((1('+($7(5%/2:(5

0)'5()':*