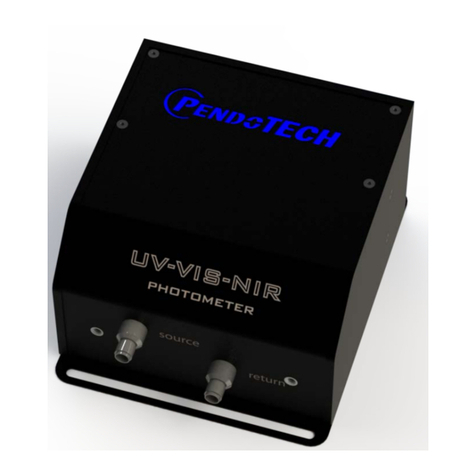

PendoTECH PM2 Photometer for UV Absorbance and Turbidity

Measurements User’s Manual Revision 0

www.pendotech.com Tel: +1-609-799-2299

Copyright © 2022 PendoTECH 1 | Page

Safety Instructions

Definition of Equipment and Documentation Symbols and Designations

WARNING: POTENTIAL FOR PERSONAL INJURY

CAUTION: Possible instrument damage or malfunction

NOTE: Important operating information

On the transmitter or in this manual text indicates Caution and/or other possible hazards, including the risk of electric

shock (refer to accompanying documents).

Each prospective user must test the measurement unit for its proposed application to determine its suitability for

the purpose intended prior to incorporating the sensor to any process or application. Proper safeguards must be

put into place for the process in which the unit is used.

The functioning and operational safety of the product can only be ensured if the user observes the usual safety

precautions as well as the specific safety guidelines stated in these operating guidelines:

The PM2 Photometer must only be operated under

the specified operating conditions.

The PM2 Photometer should be installed and

operated only by personnel familiar with the

Photometer and who are qualified for such work.

Before connecting the device to a supply unit, ensure

its output voltage cannot exceed 48 VDC. Do not use

alternating current or a main power supply!

Warning: Only use a power supply with double

insulation or reinforced insulation to supply this

product.

Warning: Do not submerge this product. Protect the

product before cleaning with any liquids by covering

openings that expose the internal components.

Install equipment as specified in this instruction

manual. Follow appropriate local and national codes.

Power supply must be disconnected before servicing.

The safety of the user may be endangered if the

instrument:

•is visibly damaged

•no longer operates as specified

•has been damaged in transport

Process upsets: because process and safety

conditions may depend on the consistent operation

of this transmitter, provide appropriate means to

maintain operation during sensor cleaning,

replacement, or sensor or instrument calibration.

Except for routine maintenance and cleaning procedures,

the PM2 Photometer must not be tampered with or altered

in any manner.

Maintenance and repair work must only be carried out by

PendoTECH.

METTLER TOLEDO/PendoTECH accepts no

responsibility for damage caused by unauthorized

modifications to the Photometer.

Follow all warnings, cautions, and instructions indicated

on and supplied with this product.

Electrical installation must be per the National Electrical

Code and/or any other applicable national or local codes.

If this equipment is used in a manner not specified by the

manufacturer, its protection against hazards may be

impaired.

Relay action: the PM2 Photometer relays will always de-

energize on the loss of power, equivalent to a normal

state, regardless of the relay state setting for powered

operation. Configure any control system using these

relays with fail-safe logic accordingly.

The terminals are suitable for single wires / flexible leads

0.2 mm2 to 1.5 mm2 (AWG 16 – 24).