Penico Rotary Grinding Attachment User manual

Penico Rotary Grinding Attachment

Page 1 of 4

UNPACKING YOUR MACHINE

Take care when removing your machine from the packaging. It weighs in excess of 25

kilos depending on the model. Seek assistance to lift it from the carton.

Your machine will arrive in two packages if you have ordered it with a magnetic chuck. For

safety reasons the chuck is packed separately from the Rotary Grinding Unit.

Inside the larger package is the Rotary Grinding Attachment, the Speed Control and there

are assorted small parts. Take care not to dispose of the small parts with the packaging.

Please re-cycle the packaging.

ASSEMBLY INSTRUCTIONS

To assemble the Chuck to the machine clean the top surface of the deflector & the

underside of the chuck. Lightly smear the cleaned surfaces with a light oil.

Remove the 3 pcs of 8mm grub screws from the deflector (these 3 pcs of 8mm screws are

for dust protection).

Gently lower the chuck onto the deflector top.

When the two ground surfaces meet gently turn the chuck to ensure good contact.

Use the supplied 3mm Allen key to evenly tighten 3 grub screws which are at the bottom of

the holes where the 8mm grubs screws were.

Use only moderate torque do not over tighten.

Replace the 3 pcs of 8mm grub screws in the deflector. Tighten them until they stop. These

screws protect the grub screws that secure the magnetic chuck from dust ingress.

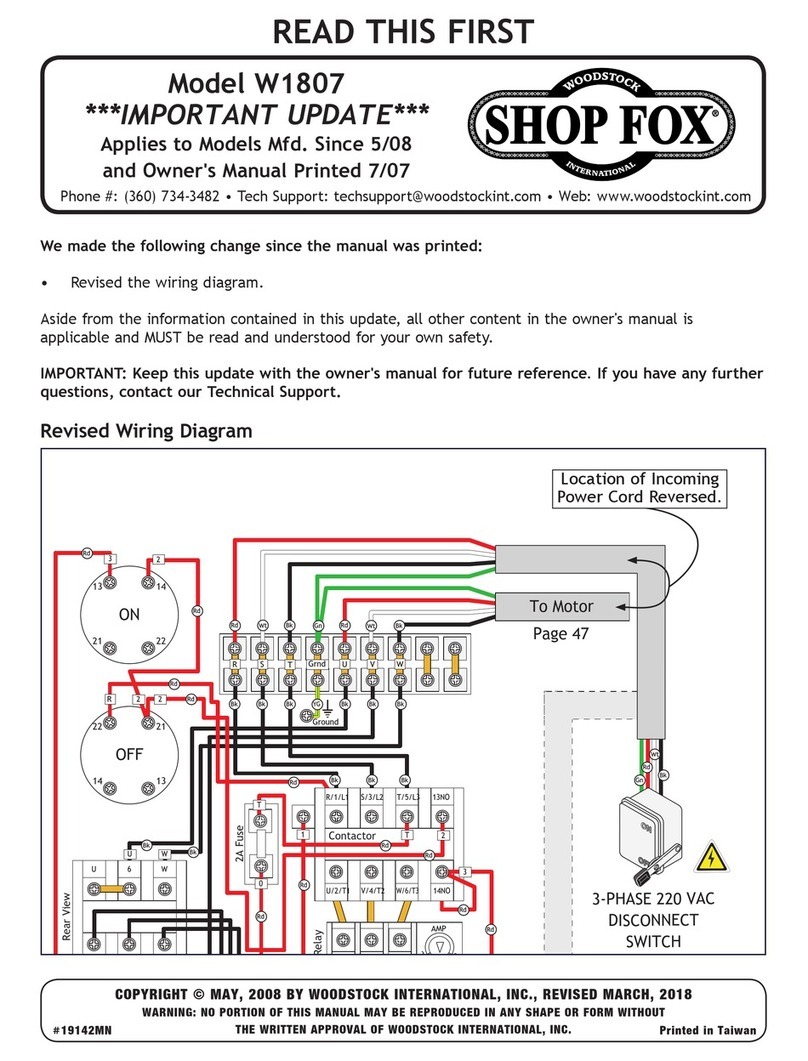

Ensure your Electric supply is suitable for the Sprint Control. The supply required is single

phase. A qualified Electrician must inspect the electrical connections to the control.

A Sprint Electrical control diagram is supplied with your machine for reference.

Plug your motor in to the speed control. Your Motor control can then be connected to your

power supply.

There are two Rocker Switches and one Rotary Switch. The switched are labelled to

indicate their function.

The on/off switch illuminates when power is available to the motor.

The Direction Rocker Switch has 3 positions. The center position is off and the other 2

positions rotate the chuck in alternate directions.

The speed control regulates how fast the chuck rotates.

It is recommended that the machine is not started on full speed. Turn the rotary speed

control down to stop the machine then turn the machine on and increase the speed on the

rotary speed control.

Penico Rotary Grinding Attachment

Page 2 of 4

MAGNETIC CHUCK

To operate the Magnetic Chuck insert the 6mm Allen Key into the Actuator and turn.

The magnet may be partially applied for thin work pieces.

Never leave the Allen Key in the magnet whilst the chuck rotates.

FIRST USE OF MACHINE AFTER DELIVERY

Check that the oil level is halfway up the sight glass. Connect the machine to the power

supply as described in the assembly instructions.

The magnetic chuck will require grinding true.

FLAT BASE MODEL

Contact the chuck face with a course dressed wheel and remove sufficient material to fully

clean up the face of the chuck. (Note: ensure the reversible chuck rotates contrary to the

grinding wheel). The use of coolant is recommended. Consult with your safety officer

concerning personal protection equipment.

SINE BASE MODEL

Remove the 8mm transit screw from the quadrant and replace it with the locking lever. The

'slip block' must be placed between the Sine Roller and the slip pad, ensure correct contact

is made.

Contact the chuck face with a course dressed wheel and remove sufficient material to fully

clean up the face of the chuck. (Note: ensure the reversible chuck rotates contrary to the

grinding wheel). The use of coolant is recommended. Consult with your safety officer

concerning personal protection equipment.

Refer to your inspection report for the sine centers for your model.

ANGLE GRINDING

The Sine Base Model can be set at any angle between 0-46°. A Sine Bar is fitted. It has

150mm centers. For quick angle setting a scale is engraved on the locking quadrant.

Please note that when grinding an angle the chuck will require rotating in the opposite

direction to flat grinding. When grinding on an angle it is also important that your grinding

wheel is on the center of your component. If the wheel is not on the centreline a true grind

cannot be achieved.

Penico Rotary Grinding Attachment

Page 3 of 4

CARE OFYOUR MACHINE

The unit is coolant proof, apply as much coolant as required to grind your component.

However you must not allow coolant to flood up to the level of the motor cover. Ensure the

drains on your grinding machine are free off debris to allow coolant to drain away.

Change the Gearbox oil every six months with a good quality Gearbox Oil. Clean grit &

coolant from machine when not in use. Lightly oil the base & chuck prior to storage.

WARRANTY

Your machine is guaranteed parts & labor for 12 months from dispatch date.

For your warranty to remain valid all operating & care instructions must have been adhered

to.

ROTARY TABLE SPECIFICATION

Electrical supply: 240V single phase

Motor: Parvalux PM6 VENT, Voltage 200/220 DC, Amp 1.6, Reversible, Continuous

Motor Control, Sprint 370E

Rotational accuracy: 0.005mm maximum error @ 80mm rad

RPM of Table 0-150 infinitely variable

Sine table range: -1° to 45°

Sine table. 150mm or 5” (customer option)

Length: 480mm, Width: 220mm, Height: 130mm No Chuck fitted

Height with Ø 200 mm Chuck fitted: 200m

Weight without Chuck (Flat Base): 24 kg

Weight Ø 200mm magnetic chuck: 16 kg

Penico Rotary Grinding Attachment

Page 4 of 4

SPARE PARTS & ADVICE

Penico Systems Ltd

Albion Works

Keighley Road

Bingley

West Yorkshire, BD16 2RD

United Kingdom

Tele: +44 (0) 1274 511044

Fax: +44 (0) 1274 510770

email: penicogauges@yahoo.co.uk

USA & North America

Precision International Corp

105 Old Windsor Road

P O Box 605

Bloomfield, CT 06002

U S A

Tele: +001 860 243 0341

Fax: +001 860 243 3150

Email [email protected]

Table of contents