PennBarry iPlume User manual

iPlume

Laboratory Exhaust System

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Please read and save these instructions. Read carefully before attempting to

assemble, install, operate or maintain the product described in this document.

Protect yourself and others by observing all safety information noted in this

document. Failure to comply with these instructions could result in personal

injury to others and/or property damage.

IMPORTANT! Read before proceeding!

2www.PennBarry.com

TABLE OF CONTENTS

GENERAL SAFETY INFORMATION 3-4

GENERAL INFORMATION 5

LIFTING INFORMATION 6-7

DUCT INSTALLATION FOR iPLUME 8

iPLUME SYSTEM ASSEMBLY 9-12

iPLUME DRAINAGE PIPE/TRAP DETAIL (BY OTHERS) 13

PRE-START-UP CHECKS 14-15

MAINTENANCE 16-17

DAMPER AND DAMPER ACTUATORS 18

CONTROLS AND SINGLE POINT WIRING PANEL 19

PIEZOMETER RING 20

JIB CRANE MOUNTING INSTRUCTIONS 21

iPLUME WITH MIXING BOX 22

EXPLODED VIEW OF FAN FOR iPLUME ASSEMBLY

& EXPLODED VIEW OF MIXING BOX 23

3

www.PennBarry.com

GENERAL SAFETY INFORMATION

Only qualied trained personnel should install or maintain equipment described in this document. Improper installation can result

in electric shock, possible injury due to high speed moving parts, or other potential hazards. Special circumstances such as high

winds or wet surfaces must be considered when installing the unit. Contact a PennBarry engineer if any questions or issues arise or

if any other information is needed before installing or maintaining the fan.

1. Follow all local, state and federal electrical and safety codes, as well as the National Electrical Code (NEC), and the National Fire

Protection Agency (NFPA), where applicable. Follow the Canadian Electrical Code (CEC) in Canada.

2. Make sure that the wheel spins freely without hitting or rubbing on any parts or objects.

3. The motor must be grounded; failure to ground a motor can result in a serious safety hazard.

4. The fan impeller should not be operated at RPM’s exceeding the rated RPM. If fan speed is higher than rated, the motor may

over amp, causing serious damage to the motor and other moving parts of the fan.

5. Power cord must be free of any kinks or pinches and must not come into contact with grease, oil or other liquids, ammable

or otherwise.

6. Verify that incoming power to the unit is of the correct voltage stated on the unit and/or motor nameplate.

7. Turn unit o before opening any access panels.

Receiving

PennBarry fans are carefully inspected and tested before leaving the factory. When the unit is received, inspect the packaging for

any signs of tampering. Inspect the unit for any damage that may have occurred during transit and check for loose, missing or

damaged parts. Mishandled units can void the warranty provisions. If units are damaged in transit, it is the responsibility of the

receiver to make all claims against the carrier. PennBarry is not responsible for damages incurred during shipment. Avoid severe

jarring and/or dropping. Handle units with care to prevent damage to components or nishes. If the unit is scratched due to

mishandling, the protective coating may be damaged. Incorrect lifting may damage the fan and void the warranty.

Unpacking

Upon reception, verify that all required parts and the correct quantity of each part have been received. If any items are missing,

report these to your local PennBarry representative. Due to variation in shipping carriers and availability, some items are shipped

separate from one another. Conrmation of shipment(s) must be limited to only items on the bill of lading.

Always disconnect power before working on or near a fan. Lock and tag the service switch or breaker to prevent

accidental power up.

DANGER

When servicing the fan, motor may be hot enough to cause pain or injury. Allow motor to cool before servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

CAUTION

4www.PennBarry.com

GENERAL SAFETY INFORMATION

Storage

Store in a dry, protected area being sure fan shaft, bearings and impeller are protected against dust and corrosion. If it is necessary

to store outdoors or within a building under construction, special care must be taken to prevent moisture, corrosion, dirt or

dust accumulation. Coat the shaft with grease or rust preventative compound. Cover and seal bearings to prevent entrance of

contaminants. Impeller should be rotated at least once a month to circulate the grease in bearings. If stored outdoors over seven

(7) days, cover completely with a tarp or heavy waterproof paper. Electrical connections and leads must be protected from moisture.

Block impeller to prevent natural rotation. Do not allow material of any kind to be piled on top or inside of fan.

Inspection and Maintenance during Storage

Long-term storage is dened as storage for period exceeding one month from the date the equipment was received. Fans and

motors should be stored in a dry, low humidity area indoors. Equipment which is to be installed, but not operated for several

months, should rst be blocked to take the weight o of the vibration isolators (if provided) and then given the same protection,

periodic inspection and maintenance as a unit in storage. To prevent puddle corrosion of fan bearings that undergo long-term

storage, the following preventive maintenance must be performed

1 Fan bearings must be re-lubricated every month until the fans are put into service. A clear 1/16” bead of grease must appear

on each side of the bearings. Fan wheels are to be rotated manually while the bearings are re-lubricated. Refer to the specic

bearing lubrication instructions located on the fan housing for the type of lubricant to use.

2 Motor bearings should be lubricated as recommended by the motor manufacturer.

Removing from Storage

Fans should be hoisted with slings placed around the fan housing. When a single hoist is used, a “spreader” will keep the sling from

slipping on the housing. Fans must be protected and maintained from the time of storage to the time of assembly and installation.

Ensure that the fan is in working order before assembly and installation. Be sure that no damage has occurred between storage

and time of assembly.

1 Ensure that all fasteners, ttings, screws, etc. are tightened to recommended specications.

2 Make sure that no parts or objects are rubbing on the fan wheel as it is turned.

Notes:

This document is applicable for the following PennBarry models.

iPlume-122LV iPlume-165HV iPlume-245LV iPlume-330HV

iPlume-122MV iPlume-165XV iPlume-245MV iPlume-330XV

iPlume-122HV iPlume-182LV iPlume-245HV iPlume-365LV

iPlume-122XV iPlume-182MV iPlume-245XV iPlume-365MV

iPlume-135LV iPlume-182HV iPlume-270LV iPlume-365HV

iPlume-135MV iPlume-182XV iPlume-270MV iPlume-365XV

iPlume-135HV iPlume-200LV iPlume-270HV iPlume-402LV

iPlume-135XV iPlume-200MV iPlume-270XV iPlume-402MV

iPlume-150LV iPlume-200HV iPlume-300LV iPlume-402HV

iPlume-150MV iPlume-200XV iPlume-300MV iPlume-402XV

iPlume-150HV iPlume-222LV iPlume-300HV iPlume-445LV

iPlume-150XV iPlume-222MV iPlume-300XV iPlume-445MV

iPlume-165LV iPlume-222HV iPlume-330LV iPlume-445HV

iPlume-165MV iPlume-222XV iPlume-330MV iPlume-445XV

5

www.PennBarry.com

GENERAL INFORMATION

Unit identication tags

Each unit has a permanently axed nameplate with various identications including, but not limited to, the unit model and serial

numbers, motor ratings and voltages.

The gure below is an example of a PennBarry unit nameplate. It includes all of the specications of the unit, as referenced above.

When contacting your PennBarry representative, please have the information on the nameplate readily available, as this will help

to streamline your help request.

Fan components may arrive in pieces or assemblies depending on the fan conguration. Components of the fan will have matching

nameplates, and these components should not be mixed with other PennBarry fans. If mismatched components are installed in the

same fan, fan performance may be reduced.

Pre-Installation information

Ensure that the mounting surface where the unit is to be installed is completely level and free of debris. The mounting surface must

also be able to bear the entire weight of the fan. See roof curb installation instructions for additional details.

Electrical service switches

An electrical service switch must be installed either on the unit or in visual proximity to the unit, so that the unit can be easily turned

o for maintenance or trouble shooting. These must be locked out when the unit is being maintained or serviced.

Moving parts

Any moving parts on the unit must have covers or guards to protect any servicers or personnel. These guards are to be installed in

accordance with local codes. The fan wheel must be secured before performing any maintenance on the unit; damage to the wheel

is possible if this precaution is not taken.

Guards (Motor/Weather cover)

All parts of the unit, including guards and covers, must be installed before attempting to start the unit. Do not operate the unit with

any missing pieces, particularly any guards or covers; this includes any hardware including nuts and bolts, which hold these covers

in place.

Air pressure and suction

Fans moving at any speed create suction with varying degrees of strength. Special consideration needs to be taken when working

around these units. Do not leave any loose articles of clothing or materials in or around air intake or fan inlet.

Power Ventilator for Smoke Control Systems

(1000* F for 15 min/500* F for 4 hrs)

For installation in accordance with NFPA-204M.

Ventllateur de Puissance pour un systeme de controle de

fumme (537.78* C pour 15 minutes/280* C pur 4 hour)

L’Istallation doit stre conforme au bulletin NFPA-204M.

See Motor Nameplate for Electrical Rating and Motor Protection

Se referer a la plaque singaletique du moteur concermant la classification

electique ainsi que la protection requises pour ce moteur

TM

Tag# Model Serial Fan RPM

Fan RPM

HP

Puissance en Chevaux

Voltage/Phase/Cycle Motor RPM SO#

MO#

Moteur RPM

Voltage/Phase/Frequence

NumeralModeleNumero D’etiquette

6www.PennBarry.com

LIFTING INFORMATION

The following is a list of recommendations for lifting the various assemblies of your iPlume fan system:

Discharge nozzle and stack extension may be pre-assembled and lifted as one assembly, or each component can be lifted separately.

These lifting methods are recommended.

Fans should be hoisted with slings placed around the fan housing. When a single hoist is used, a “spreader” will keep the sling from

slipping on the housing. If it is necessary to use hooks placed in lifting holes of fan, BE CAREFUL NOT TO DISTORT OR BEND THE

HOUSING. Large units may have lifting lugs or holes which should be used only to stabilize the unit while using a sling to support

the weight. Chain or wire slings should be well-padded where they contact the fan, especially where special coatings and paints are

involved. Rubber, phenolic enamels, etc. require special care as they may easily be damaged by contact in lifting. Even a small chip

will destroy the corrosion prevention seal of the coating and allow corrosion to start. Always repair scratched surfaces with touch

up of like coating prior to installation. The unit discharge nozzle is to be lifted per handling recommendations provided above by

specied mounting points at the top of the cone, separately from the other sections of the unit.

A. Lifting windband and nozzle: Use a sling in conjunction with lifting lugs at top of nozzle.

B. Lifting fan section: Use a sling in conjunction with lifting lugs at top of fan.

C. Lifting plenum section: Use a sling in conjunction with lifting lugs located at corner gussets

of isolation damper box.

7

www.PennBarry.com

LIFTING INFORMATION

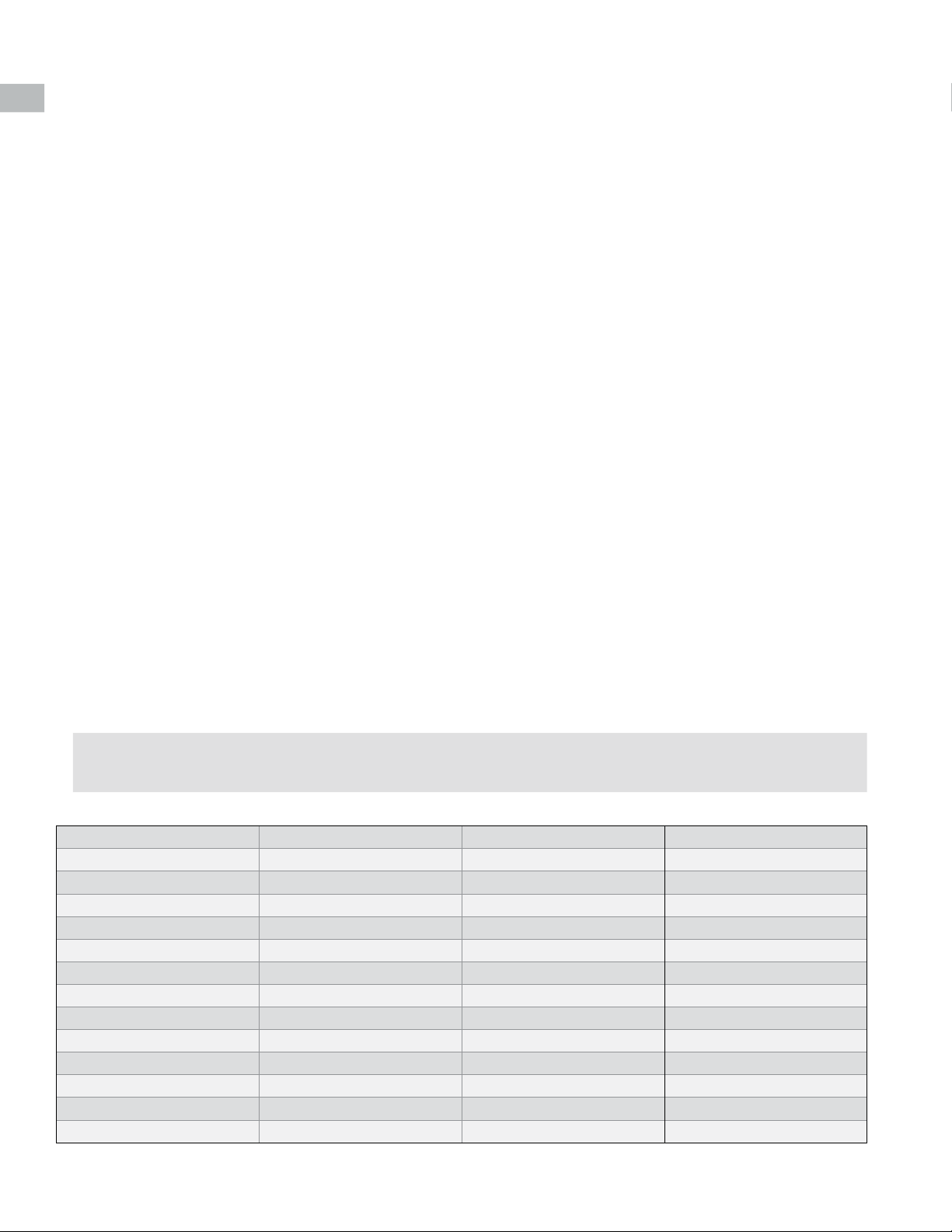

Size Nozzle &

Windband (lbs)

Belt Drive Fan

Section w/o

Motor (lbs)

Direct Drive Fan

Section w/o

Motor (lbs)

1x1 Mixing Box (lbs) 2x1 Mixing Box (lbs) 3x1 Mixing Box (lbs)

122 98 258 209 718 1436 2154

135 118 295 239 773 1546 2319

150 144 375 289 869 1738 2607

165 151 416 329 907 1814 2721

182 186 501 414 1441 2882 4323

200 220 571 481 1514 3028 4542

222 269 705 599 1640 3280 4920

245 254 818 709 1666 3332 4998

270 298 995 859 1644 3288 4932

300 366 1213 1060 1892 3784 5676

330 439 1429 1268 2063 4126 6189

365 390 1968 1773 2243 4486 6729

402 472 2294 2100 2373 4746 7119

445 574 2792 2559 2965 5930 8895

Size Fan Curb (lbs) 1x1 Plenum Curb (lbs) 2x1 Plenum Curb (lbs) 3x1 Plenum Curb (lbs)

12" 18" 24" 12" 18" 24" 12" 18" 24" 12" 18" 24"

122 228 263 356 342 395 541 571 659 895 735 851 1176

135 244 281 381 365 421 577 609 701 952 775 903 1248

150 259 298 405 459 436 736 758 881 1198 965 1135 1569

165 275 315 429 467 544 748 770 895 1217 981 1152 1593

182 298 341 465 521 605 833 861 995 1353 1094 1277 1765

200 345 399 544 576 671 924 951 1104 1502 1210 1420 1965

222 368 425 581 607 706 972 1003 1161 1580 1274 1491 2073

245 392 451 617 615 714 984 1015 1174 1598 1288 1507 2085

270 415 477 653 639 741 1021 1054 1217 1657 1337 1560 2170

300 486 560 768 709 824 1137 1170 1354 1846 1485 1739 2409

330 517 595 817 764 885 1221 1260 1454 1981 1597 1863 2580

365 556 638 877 787 911 1258 1298 1496 2038 1642 1914 2623

402 626 722 993 849 986 1361 1400 1618 2207 1774 2074 2878

445 673 774 1065 896 1038 1434 1477 1703 2322 1868 2179 3023

Windband and nozzle assembly can be lifted as one piece, the fan sections and plenums must be lifted separately.

CAUTION

8www.PennBarry.com

DUCT INSTALLATION FOR iPLUME

Notes:

Steel, concrete or wood roof support is per structural engineer and in accordance with load requirements and applicable building codes.

Bottom Inlet Duct Connection

If a customer supplied duct is to be installed on the unit, it is to be secured between the curb cap of the unit and the curb’s top

edge. If there is an isolation damper to be installed, it is to be installed between the duct and the unit.

Option 2

• No isolation damper in duct

• Side inlet on iplume with Bypass Air Plenum

Option 1

• No isolation damper in roof curb

• Bottom inlet on iplume

iPlume with curb

cap or iplume with

Bypass Air Plenum

Roof curb

Duct

Duct and

expansion joint

by others

Weatherhood

Bypass Air

Plenum Duct to bypass Air Plenum

iPlume

9

www.PennBarry.com

iPLUME SYSTEM ASSEMBLY

10 www.PennBarry.com

iPLUME SYSTEM ASSEMBLY

Sequence for Curb Installation to Roof

The roof curb is to be placed and fully secured to a level steel or concrete roof structure (by others) with 3/8-16UNC Gr. 5 cap

screws and washers (supplied by others) as depicted below. Fasteners must be centered on the curb ange and bolt spacing is

not to exceed 6”. It is important that a Structural Engineer is consulted to verify the support structure and attachment method can

adequately support the fan weight and wind loads.

In order to avoid structural resonance, the structure must be designed with adequate stiness so the natural frequencies are at

least 120% above fan maximum operating speed.

Notes:

An inadequately designed roof structure may impact fan performance, longevity, and/or result in injury. All roof structures should be in

accordance with all local building codes.

11

www.PennBarry.com

iPLUME SYSTEM ASSEMBLY

Sequence for Bypass Plenum or Fan to Roof Curb

Install the provided roof curb gasket by adhering it to the top of the roof curb. Rig and lift plenum or fan (if plenum not provided)

as per lifting information section of this manual and place carefully on top of roof curb ensuring not to damage gasket material.

Dill 0.348 pilot holes into roof curb using plenum or fan as a template and install provided 3/8 self-threading fasteners. Figures

below represent the typical installation of plenum and fan to curb.

For fans without a plenum, the fan is to be installed in a similar manner by using the fan slots as fastener pilot holes.

Flashing Detail

Typical installation of plenum onto roof curb

Typical installation of fan without plenum to roof curb.

12 www.PennBarry.com

iPLUME SYSTEM ASSEMBLY

Sequence for Fan to Bypass Plenum

Install gasket onto the top of the plenum, using the adhesive to adhere the gasket to the plenum.

Place the bottom of the fan onto the top of the plenum and secure with mounting hardware through the units mounting holes as

shown in diagrams.

Sequence for Discharge Nozzle to Fan

Install gasket onto the top of the fan section, using the adhesive to adhere the gasket to the fan.

Install discharge nozzle to the top of the fan section as shown in the diagrams, and secure with mounting hardware through the

units mounting holes; be sure to include gasket.

13

www.PennBarry.com

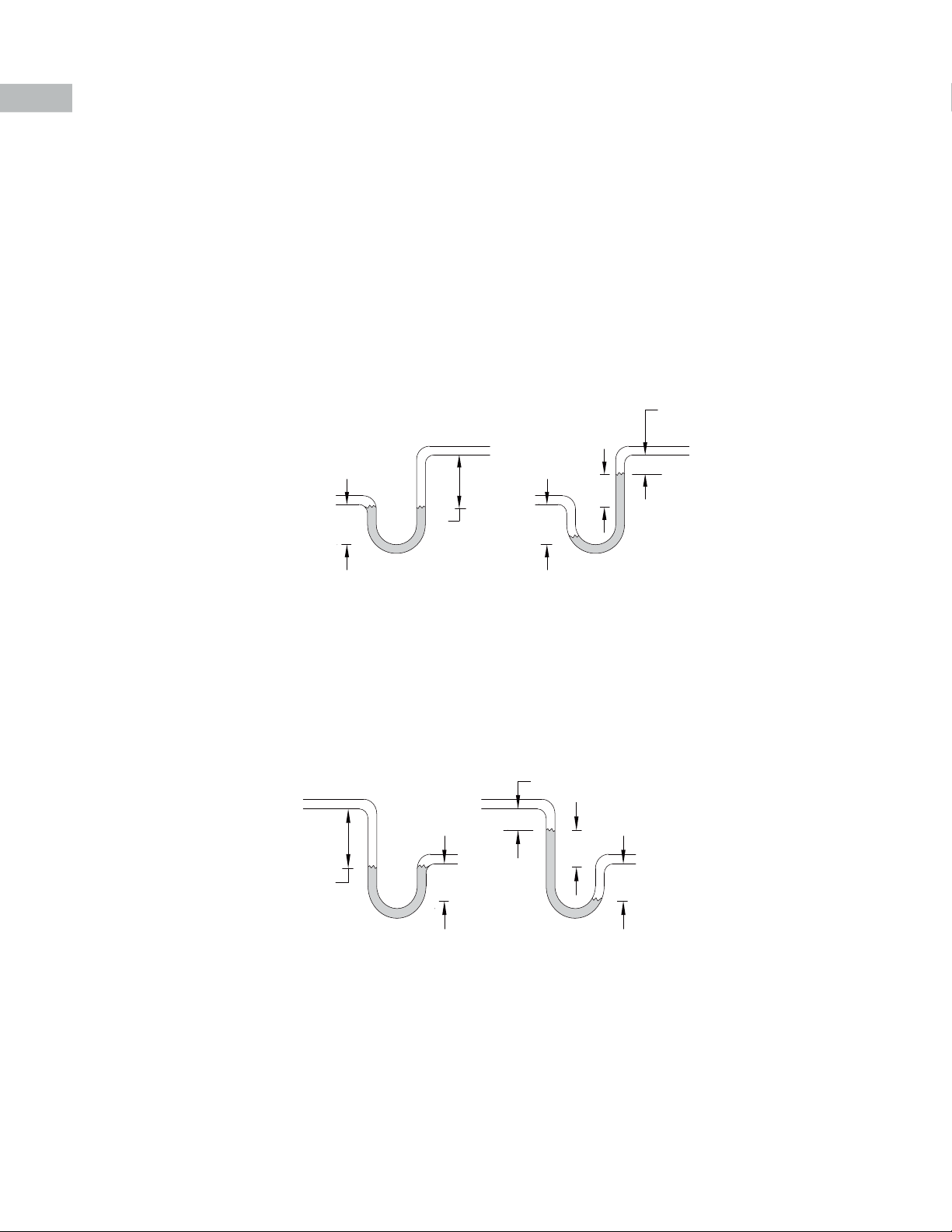

iPLUME

DRAINAGE PIPE/TRAP DETAIL (BY OTHERS)

Drainage ports are provided on both the fan housing and plenum box to provide drainage for the system. It is recommended that

these drains are piped to allow proper drainage of any condensation collected in the unit.

1. Drain connections are 3/4 inch NPT

2. Drain piping installed must have proper slope

3. P traps are to be lled to proper level prior to unit start up

Positive Pressure Trap on Tubular Fan Housing

Negative Pressure Trap on Bypass Air Plenum

N = Negative fan pressure (inches W.C.)

H = N - (0.5 inches minimum

H/2 H/2

H

1.25 inch minimum

N

FAN ON

FAN OFF

N = Negative fan pressure (inches W.C.)

H = N - (0.5 inches minimum)

H/2 H/2

H

1.25 inch

minimum

N

FAN ONFAN OFF

Connect

this end

to fan drain.

Rain Mitigation

Inline laboratory exhaust fans, such the iPlume, require mitigation of water below the fan if the fan is not running at all times. The

iPlume has drains in the nozzle and funnel but water entry is possible during heavy rain events. In bottom intake installations rain

mitigation must take place in the ductwork below the fan. A side intake mixing box is another solution, the side intake mixing box

will not allow water into the ductwork.

Fan should be selected at nozzle velocities of 3000 fpm or higher to prevent rain from entering during operation.

14 www.PennBarry.com

Ensure that all mounting hardware and fasteners are properly installed and tightened to recommended torque specications.

Ensure that the wheel is aligned and has the correct spacing in relation to the inlet venturi; it should be centered in the inlet venturi

as well. If adjustment is needed, loosen the inlet venturi bolts and shift the inlet venturi until the radial gap is the same at every point

across the circumference of the inlet venturi.

If adjustment of the overlap between the wheel and inlet venturi is needed, loosen the taper lock bushing, slide the wheel forwards

or backwards until the correct overlap is achieved, and then tighten the set screws back down.

There is a rotation sticker on the unit that species the direction the wheel should turn. Ensure that the wheel is rotating in the proper

direction before powering on the unit. In 3 phase units, simply switch two incoming leads to reverse rotation.

PRE-START-UP CHECKS

Airow

A

Notes: Any increase in fan speed represents a substantial increase in horsepower required from the motor. Always check motor load amperage

and compare to nameplate rating when changing fan speed.

Gap/ overlap dimensions

Size Inlet Venturi to Wheel Overlap Dimensions A (inches)

122

0.39

135

0.43

150

0.46

165

0.47

182

0.51

200

0.57

222

0.66

245

0.76

270

0.83

300

0.92

330

1.02

365

1.12

402

1.27

445

1.33

15

www.PennBarry.com

When the unit is removed from storage, all grease should be purged and replenished with fresh grease. The following check list should

be followed to ensure proper operation:

Operation Check List

Check fan mechanism components

• System connections are properly made and tightened.

• Impeller and fan surfaces are clean and free of debris.

• Impeller has been rotated by hand to verify it has not shifted in transit.

Check fan electrical components

• Motor is wired for proper supply voltage.

• Motor was properly sized for power.

• Motor is properly grounded.

• All leads are properly insulated.

PRE-START-UP CHECKS

Trial “bump”

• Turn on power just long enough to start assembly rotating.

• Check rotation for agreement with rotation arrow.

Perform checklist again until unit is operating properly. Verify

fastener tightness. These may have loosened during shipment or

installation.

• Bolts on inlet funnel.

• Motor bolt torque

• Nuts holding housing frame to base and base to

• Ground (customer specications)

• Bushing fastener torque

Ensure piezo tubing will not contact the impeller

A

B

C

A Hub

B Bushing

C Bushing screws

D Bushing set screw

C Bushing fastener torque

Bushing type Screw size Recommended toque

P2 5/16 - 18 192 in-lbs

Q2 3/8 -16 348 in-lbs

R2 3/8 -16 348 in-lbs.

S2 1/2 -13 840 in-lbs

16 www.PennBarry.com

MAINTENANCE

The benets of regular inspections and routine maintenance are well documented; regular service intervals keep the system

operating at peak eciencies, extend operational life and ensure safe product operation.

Notes:

In this section, routine service internals are recommended.

Scheduled maintenance must be performed on the unit after it is in operation to ensure that it runs eciently and reliably

BELTS

Improper belt tensioning is the most common cause of early

belt failures. As such, it is imperative to tension a belt down to

the correct tension, which is the lowest tension at which the belt

does not slip at peak running speed.

As a general rule, the belt should not deect any more than 1/64

inch for every inch of belt span.

It is advised to check the belt tension at least twice within 24

hours of installation and regularly with scheduled maintenance

thereafter. Adjust belt tension by loosening the bolts on the

motor plate to relieve the tension. Tighten belt tension by

tightening down the bolts on the motor plate.

Drive pulleys must be properly aligned, or belt slippage can

occur. If pulleys are not aligned, the unit will not run eciently,

and noise or premature failure can occur.

FASTENERS AND SET SCREWS

All hardware, screws and fasteners should be checked for torque at every scheduled maintenance

MOTORS

Most fractional horsepower motors provided with the unit do not require greasing or lubrication after they are installed. If motors

have grease ttings, then they should be re-lubricated according to motor manufacturer specications.

MOTOR FUSES

Fuses to be of the time delayed type.

REMOVAL OF DUST AND DIRT

The impeller and interior surfaces of the unit should be inspected and cleaned, if necessary, on a regular basis in accordance with

the maintenance schedule. Dirt and dust accumulation can throw the wheel o balance and cause other early failures in the unit.

Do not get water in bearings or motors when attempting to clean the unit.

FAN SHAFT BEARINGS

Bearings selected for Pennbarry fans are specially paired with the unit to achieve the maximum attainable eciency and performance

of the fan. As such, they are one of the most crucial parts of the fan and must be maintained and mounted accordingly.

BELT

ALIGNMENT

Ensure that all incoming power to the unit is switched o before attempting to service the unit. If this measure is not taken, serious

injury can occur to the servicer

CAUTION

17

www.PennBarry.com

MAINTENANCE

Ensure bearing set screws and collars are torqued to the correct specications upon installation and every scheduled maintenance

thereafter. Never mix lubricants or greases while re-greasing bearings; check bearing specications for the correct grease

recommended by the manufacturer.

• Lubrication intervals depend on many factors such as temperature, moisture, or dirt. Consult a local PennBarry representative

for lubrication recommendations.

• Lubricant should be selected based on the bearing manufacturer specications.

• If the unit is stored for longer than 3 months at a time, rotation of the shaft is recommended to free up grease in the bearing

* Lubrication interval is based on 12 hour per day operation and maximum 160°F. housing temperature. For 24 hour per day

operation, the interval should be cut in half.

** Lubricant should be added with the shaft rotating and until clean grease is seen purging from the bearing. The lubrication interval

may be modied based on the condition of the purged grease. If bearing is not visible to observe purged grease, lubricate with

number of shots indicated for bore size.

Shaft Size

OPERATING SPEED (RPM)

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

LUBRICATION FREQUENCY (Months)

0.50” - 1.00” 6666664422

1.06” - 1.44” 6 6 6 6 6 6 4 4 2 1

1.50” - 1.75” 6 6 6 4 4 2 2 2 1 1

1.88” - 2.19” 6 6 4 4 2 2 1 1 1 -

2.25” - 2.44” 6 4 4 2 2 1 1 1 - -

2.50” - 3.00” 6 4 4 2 1 1 1 - - -

3.06” - 3.50” 6 4 2 1 1 1 - - - -

3.56” - 4.00” 6 4 2 1 1 - - - - -

18 www.PennBarry.com

DAMPER AND DAMPER ACTUATORS

Notes: Disconnect power to damper before attempting any maintenance.

Fan Size Bypass Damper Size ID (in) Max Flow per Damper (CFM)

122 14 4900

135 16 6200

150 18 7900

165 18 8700

182 20 10600

200 22 12800

222 24 16000

245 24 16000

270 24 16000

300 30 25000

330 30 25000

365 36 36000

402 36 36000

445 48 55000

If access is required to a gravity isolation damper, remove the panel adjacent to the weatherhood on the bypass air plenum section

and slide the damper straight out toward you.

When performing maintenance on a motorized isolation damper, unbolt the panel with the isolation actuator. Then, pull the panel,

actuator and damper assembly out.

Damper actuators, when supplied by PennBarry, are designed to be maintenance free. No lubrication is required.

Isolation damper

Bypass damper

Weatherhood

Pull Isolation

Damper in

this direction

19

www.PennBarry.com

CONTROLS AND SINGLE POINT WIRING

PANEL

Reference the iQ-LFC-Lab Fan Controller installation manual for details on PennBarry lab fan control system installation.

The optional single point wiring panel allows all of the dampers to be wired to one location for easy eld wiring.

Single Point

Wiring Box

20 www.PennBarry.com

PIEZOMETER RING

Dierence in the cone surface pressure and fan inlet pressure (∆p) can be correlated to the volumetric air ow rate (Q) using

equation shown below to an accuracy of 5%.

Q = K * √(∆p)

Q = Volumetric ow rate (CFM)

∆p= Dierential Pressure (inWC)

K = Fan constant, as noted in table below:

Fan Size K

122 2512

135 3336

150 4286

165 5236

182 6313

200 7453

222 8847

245 10304

270 11887

300 13787

330 15688

365 17905

402 20248

445 22972

HIGH-PRESSURE

SIDE

LOW-PRESSURE

SIDE

TUBE

TO DIFFERENTIAL

PRESSURE TRANSUDER

HIGH-PRESSURE

SIDE HOLE

ON INLET CONE

LOW-PRESSURE

SIDE HOLE

ON INLET CONE

Table of contents

Popular Laboratory Equipment manuals by other brands

Macherey-Nagel

Macherey-Nagel NANOCOLOR VIS II quick start guide

Metrohm

Metrohm 917 Coulometer manual

artisan

artisan Germinator 500 operating manual

VERDER

VERDER Carbolite Gero HTMA 4/220 Installation, operation and maintenance instructions

Globe Scientific

Globe Scientific GCM-24 user manual

Data Translation

Data Translation DT2802 user manual