vi

UltraTemp®Heat Pump Installation and User’s Guide

IMPORTANT WARNING AND SAFETY INSTRUCTIONS

General Installation Information

1. Installation and service must be performed by a qualified installer or service agency, and must conform to all

national, state, and local codes.

2. UltraTemp®heat pumps get electrical power from an external source and provide a dual electronic thermostat

control system for pool/spa combinations or preheat convenience.

3. This heat pump is specifically designed for heating fresh water swimming pools and spas. Do not use it as a general

service heater. Consult your dealer for the appropriate Pentair products for these applications.

General Specifications

Installation Location Certified for use:

OUTDOOR USE ONLY. Failure to provide the proper clearances outlined on page 5 will lower the

performance of the heat pump and void the warranty.

Water Pipe/Heater Connection — Plastic 2” PVC (Unions included)

Flow Rate

Maximum 100 gpm [380 lpm]

Minimum 30 gpm [110 lpm]

Maximum Working Water Pressure 50 psi

Electrical Supply – Voltage Requirements:

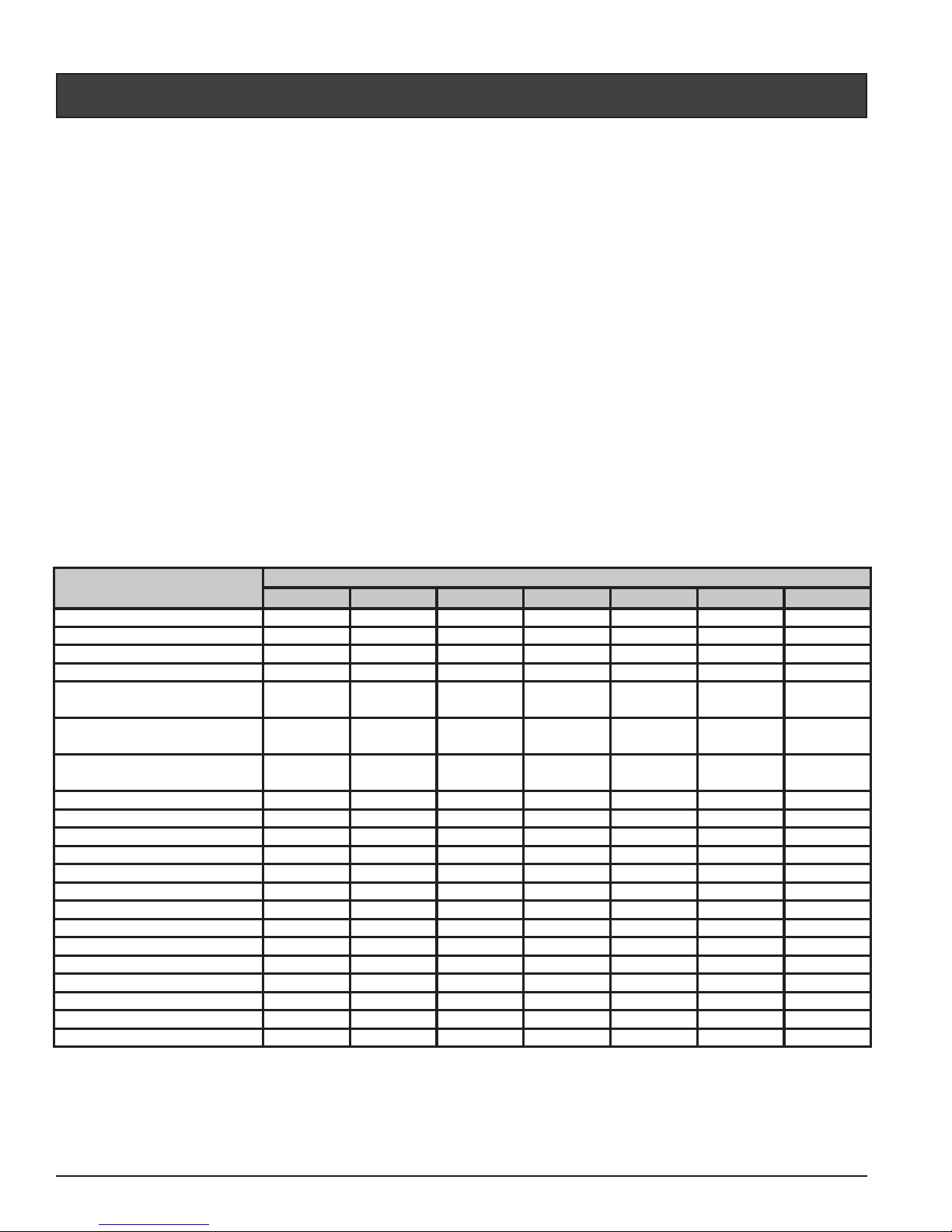

* 80A-80RH-80W: 80° F Air Temp, 80% RH, 80° F Water Inlet Temp.

** 80A-62RH-80W: 80° F Air Temp, 62% RH, 80° F Water Inlet Temp.

*** 50A-63RH-80W: 50° F Air Temp, 63% RH, 80° F Water Inlet Temp.

**** Add 50 lbs. for Pallet and Packaging.

COP = Coefficient of Performance

90 110 120 120 H/C 120C 100I 90I

Voltage/Phase/Hz 208-230/1/60 208-230/1/60 208-230/1/60 208-230/1/60 208-230/3/60 230/1/50 380-400/3/50

Min. Circuit Ampacity (Amp) 40 42 42 42 35 42 18

Recommended Fuse Size 50 50 50 50 50 50 30

Max Fuse Breaker Size 60 70 70 70 60 60 40

Compressor/Fan Motor/System

RLA

Compressor/Fan Motor/System

LRA

Compressor/Fan Motor/System

MCC

Capacity (Btu/h) 80A-80RH-80W * 90,000 108,000 125,000 125,000 125,000 102,000 85,000

COP 80A-80RH-80W * 5.8 5.8 5.5 5.4 5.7 5.95.7

Power Input (KW) 80A-80RH-80W* 4.5 5.5 6.7 6.8 6.4 5.1 4.4

Current (Amp) 80A-80RH-80W* 21 25 30 31 1925 9

Capacity (Btu/h) 80A-62RH-80W ** 84,000 101,000 117,000 117,000 115,000 96,000 81,000

COP 80A-62RH-80W ** 5.5 5.5 5.3 5.2 5.3 5.6 5.4

Power Input (KW) 80A-62RH-80W** 4.5 5.4 6.5 6.6 6.2 54.4

Current (Amp) 80A-62RH-80W** 20 25 2930 18 24 9

Capacity (Btu/h) 50A-63RH-80W *** 60,000 72,000 82,000 82,000 81,000 67,000 56,000

COP50A-63RH-80W*** 4444444

Power Input (KW) 50A-63RH-80W*** 4.2 5.3 6 6 5.94.94.1

Current (Amp) 50A-63RH-80W*** 1924 27 27 17 24 9

Weight (lbs) **** 250 270 270 278 280 280 250

Shipping Size (LxWxH) incl. Pallet 43"x34"x39" 43"x34"x51" 43"x34"x51" 43"x34"x51" 43"x34"x51" 43"x34"x47" 43"x34"x39"

26/2/28

19/NA/NA

Models

31/2/33 32/2/34 32/2/34

UltraTemp

®

32/2/34

87/3/90

32/2/34 12/1/13

178/4/182

49/NA/NA 50/NA/NA 50/NA/NA 50/NA/NA 39/NA/NA 50/NA/NA

148/4/152 185/4/189185/4/189190/4/194 130/4/134