Product Bulletin 96897

TM

CodeLine 40S Series

User’s Guide

DANGER - HIGH PRESSURE DEVICE

This vessel may cause loss of life, severe bodily harm, or property damage if not correctly installed, operated and

maintained. Read and understand all guidelines given in this bulletin before attempting to open, operate or service

this vessel. Failure to follow these guidelines and observe every precaution will result in malfunction and could

result in catastrophic failure. Misuse, incorrect assembly, or use of damaged or corroded components can result

in high-velocity release of the end closure. We recommend that only a qualified technician experienced in servicing

high-pressure hydraulic systems, open, close and service this vessel.

Important Safety Precautions

read, understand and follow every guide-

line in this bulleting. Failure to take every

precaution may void warranty and could

result in catastrophic failure.

Do...

install in an area where a vessel or piping

malfunction that result in water leakage

would not damage sensitive or expensive

equipment, such as electronic components.

Do...

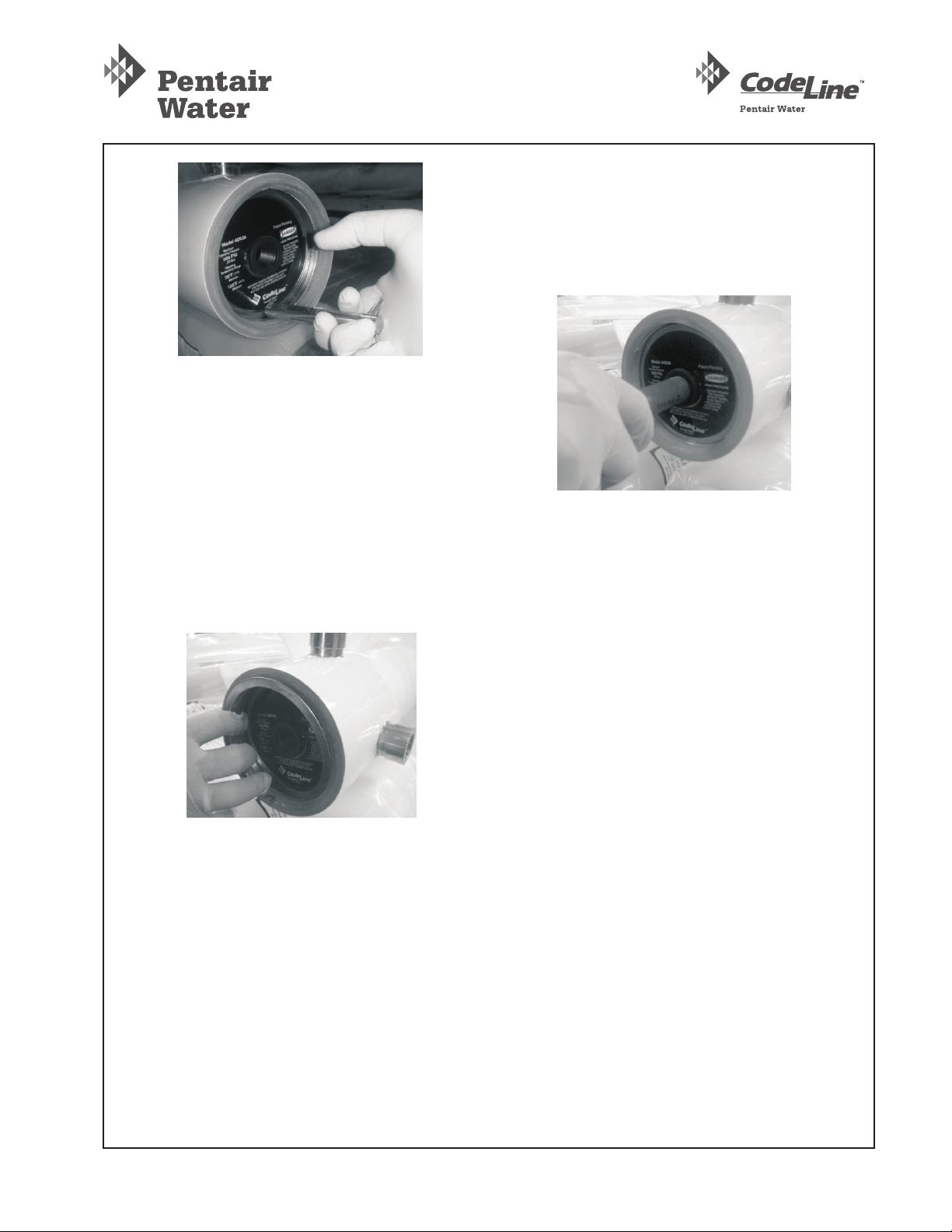

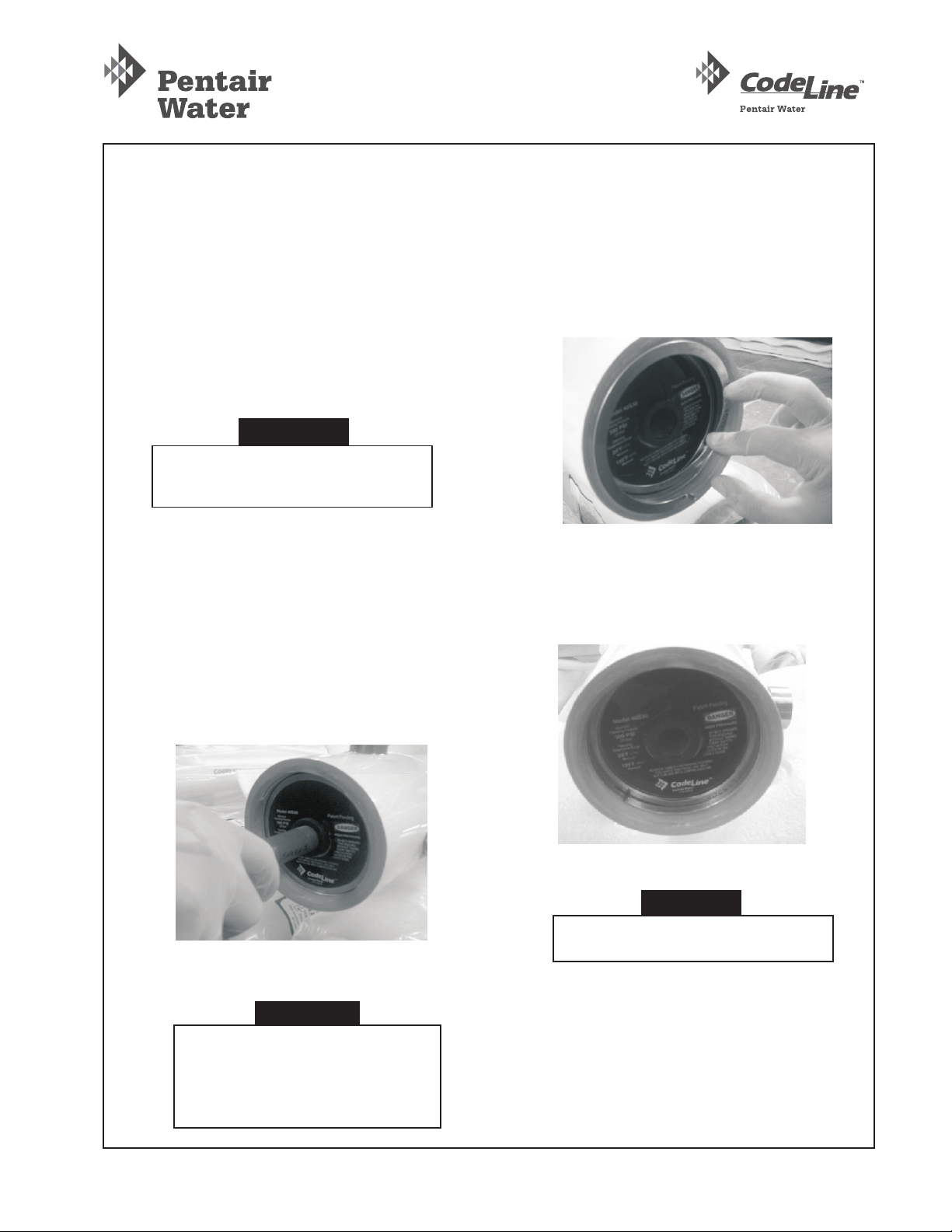

verify that head locking components are

properly placed and secured.

Do...

inspect end closures regularly, replace

deteriorated components and correct

causes of corrosion.

Do...

follow membrane element manufacturer’s

recommendations for loading elements into

the vessel (see Replacing Elements).

Do...

operate vessel at pressures and tempera-

tures in excess of their specific rating.

Do not...

service any component until you verify that

pressure is fully relieved from the vessel.

Do not...

use corroded components. Use of such

components may result in catastrophic

failure.

Do not...

pressurize vessel until after visually

inspecting to ensure that the spiral retaining

ring is correctly installed.

Do not...

tolerate leaks or allow end closures to be

routinely wetted in any way.

Do not...

use excessive silicone lubricant.Do not...

pressurize vessel without element in place

unless permeate ports are plugged

internally.

Do not...

overtighten fittings in ports.Do not...

General Information

The 40S Series Fiberglass RO/UF Pressure Vessel is

designed for continuous, long-term use as a housing

for reverse osmosis and ultrafiltration elements in

typical industrial water treatment systems at pressures

of 300, 450 & 600 psi..

The information and guidelines incorporated in this

User’s Guide are intended only as a supplement to

good industrial practice. Full responsibility for correct

operation and maintenance of vessel remains with the

user.

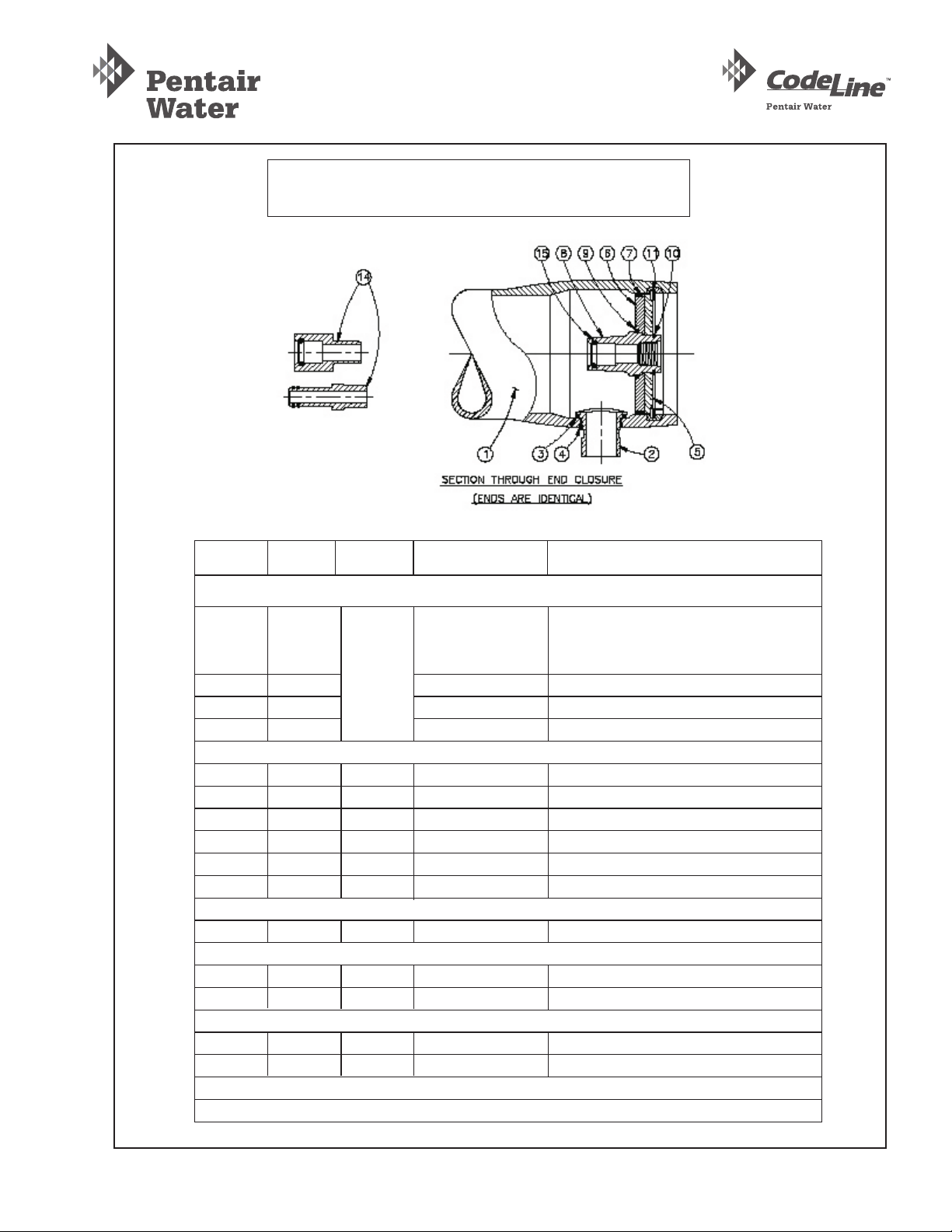

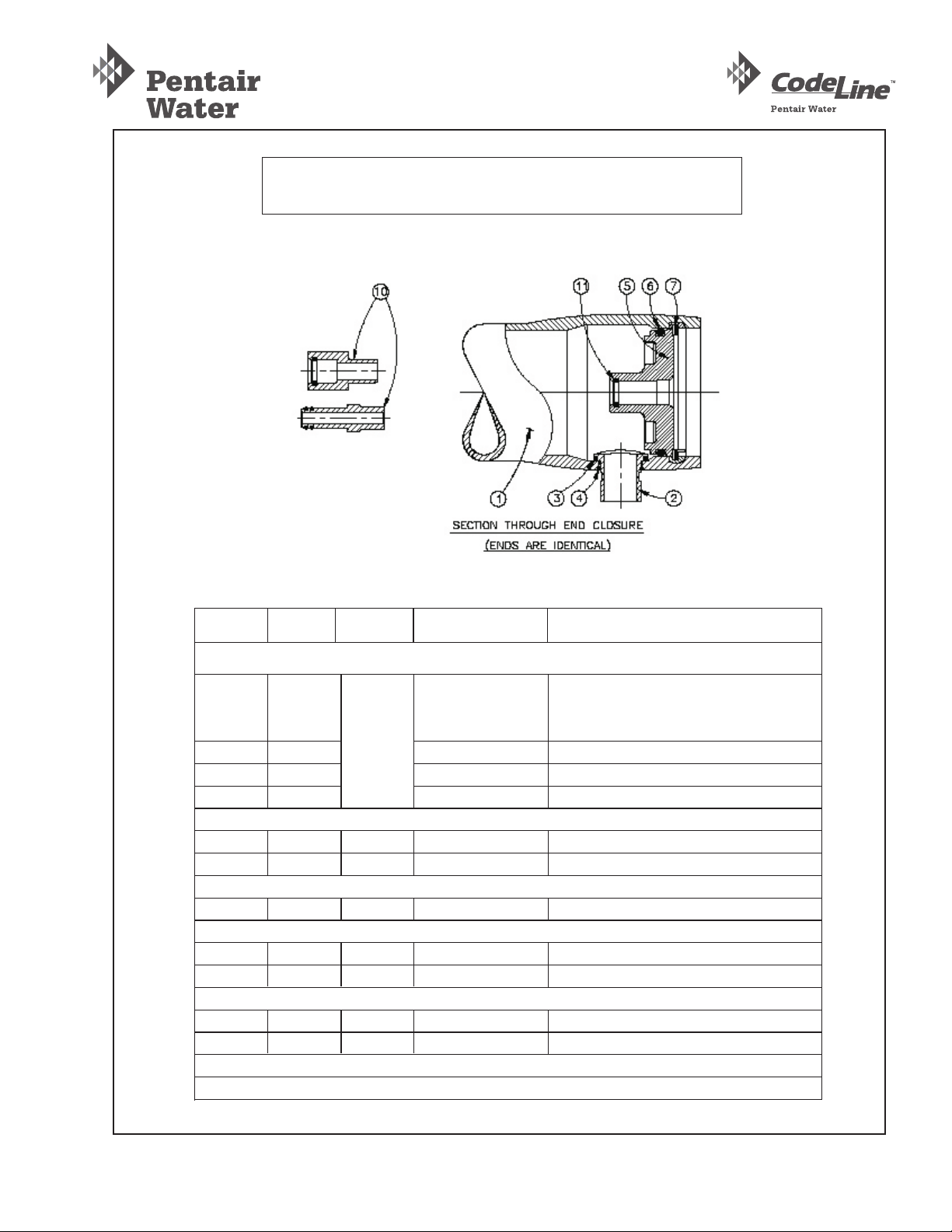

This guide should be used in conjunction with drawing

numbers 40S30(C):#99311; 40S30(NC):#99312;

40S45(C):#99315; 40S45(NC):#99316, 40S60(C):#99313;

40S60(NC):#99314

When properly installed and maintained, the 40S Series

vessels can be expected to provide safe operation over

a long service life.

User Guide 40S Series Rev. B Updated 07/03/11 Page 1 of 13

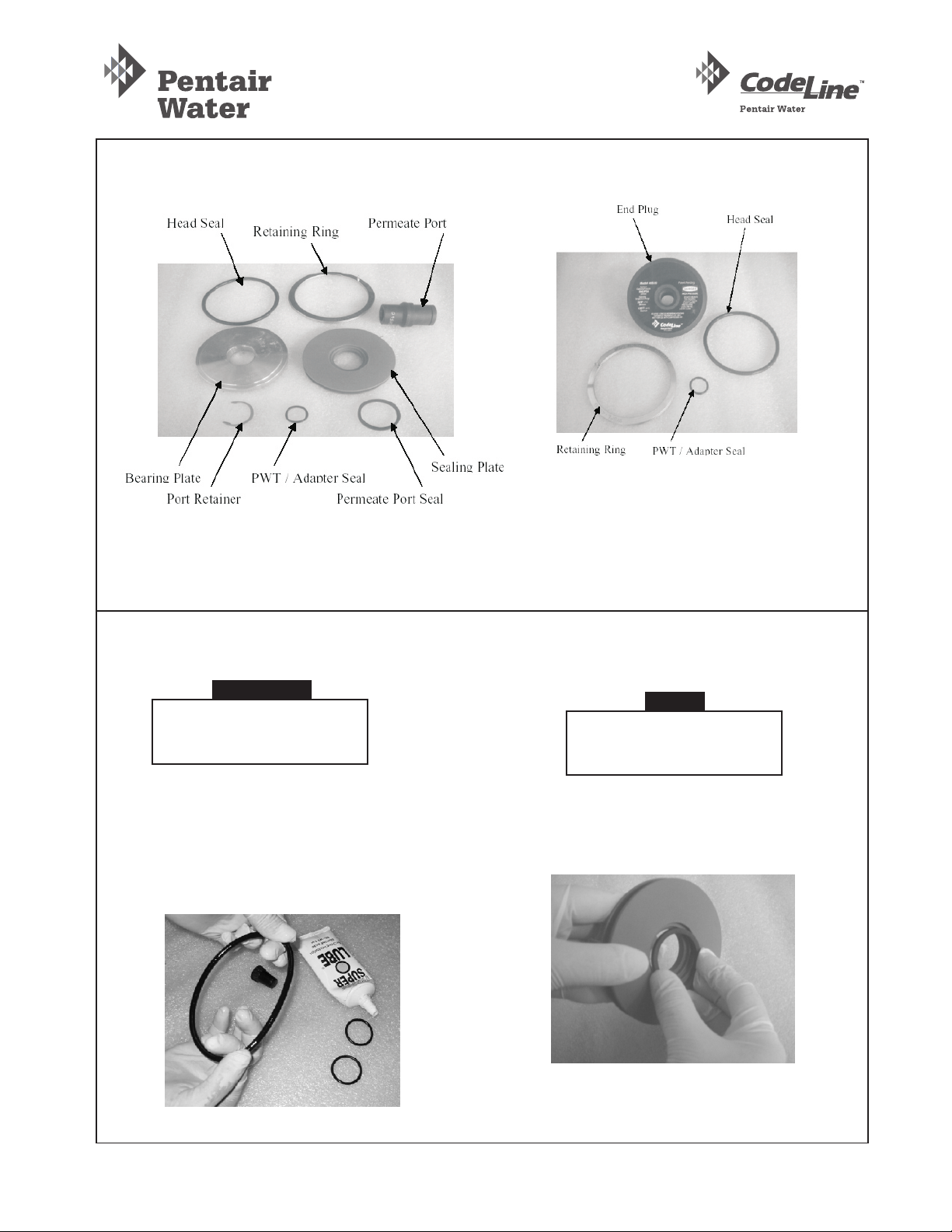

RO Pressure Vessels

The 40S Series is designed to accommodate any make

of 4-inch nominal diameter element.

The fiberglass shell can be damaged by rigid clamping,

impact, scratches or abrasion. Metal parts must be

maintained free of corrosion to eliminate potentially

unsafe conditions due to corrosion.

Do not... Use petroleum products on Noryl components.

Do not...

Allow petroleum or silicone based products to

come in contact with membrane elements during

installation or maintenance.

Use the vessel at negative pressureDo not...

Stand or climb on the pressure vessels, or theDo not...

feed / concentrate or permeate ports.