2019-10

10

Mechanical specifications

Degree of protection IP66 (individual components and entire system with housing)

Material Internal:

Panel: anodized aluminum (TCU, PCU, PSU), powder coated

aluminum (DPU)

External:

Bezel: stainless steel AISI 304 (1.4301) System housing: stainless

steel AISI 304

(1.4301), beat blasted, typical surface roughness Ra = 0.8 µm

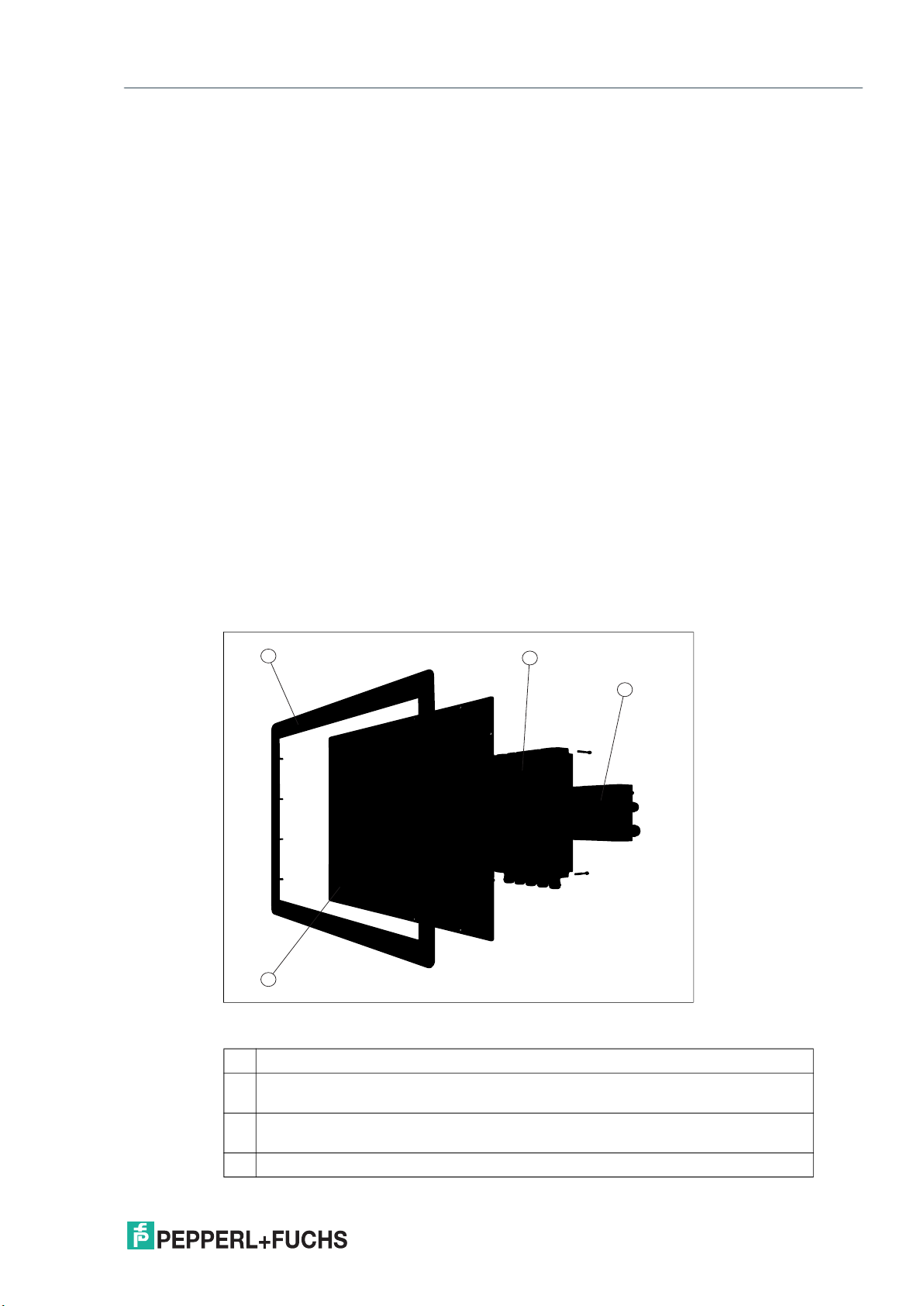

Installation Flush-mount installation (requires customized mounting kit)

Panel-mount installation into system housing with bezel

Panel-mount installation into cabinet with Bezel and standard

mounting kit

Mass Zone 1/21:

Panel (DPU with bezel, TCU, PSU DC): appx. 23 kg

Panel (DPU with bezel, TCU, PSU AC): appx. 24 kg

Zone 2/22:

Panel (DPU with bezel, TCU, PSU DC): appx. 17.5 kg

Panel (DPU with bezel, TCU, PSU AC): appx. 18 kg

Dimensions Panel with DC: 625 mm x 459 mm x 120 mm

Panel with AC: 625 mm x459 mm x137 mm

Panel with system housing: 625 mm x 459 mm x 173 mm

Panel cut-out: 583 mm x 417 mm (installation surface)

Data for application in connection with hazardous areas

EU-type examination certificate BVS 17 ATEX E 036 X

Directive conformity

Directive 2014/34/EU EN 60079-0:2012+A11:2013, EN 60079-

5:2015, EN 60079-7:2015, EN 60079-

11:2012, EN 60079-31:2014

International approvals

UL approval E492874

IECEx approval IECEx BVS 17.0029X

Standards IEC 60079-0:2011, IEC 60079-5:2015, IEC

60079-7:2015, IEC 60079-11:2011, IEC

60079-31:2013

VisuNet GXP

Technical Specifications

Zone 1/21

Data for application in connection with hazardous areas

EU-type examination certificate BVS 17 ATEX E 037 X

Directive conformity

Directive 2014/34/EU EN 60079-0:2012+A11:2013, EN 60079-

5:2015, EN 60079-7:2015, EN 60079-

11:2012, EN 60079-31:2014

Zone 2/22