Pulscon LTC

Table of Contents

DOCT-0094A 06/2009 120782

3

Brief overview . . . . . . . . . . . . . . . . . . . . . . . . 2

1 Notes on use . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using the table of contents to locate

a function description . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Using the graphic of the function menuto

locate a function description . . . . . . . . . . . . . . . . . . 5

1.3 Using the index of the function menuto

locate a function description . . . . . . . . . . . . . . . . . . 5

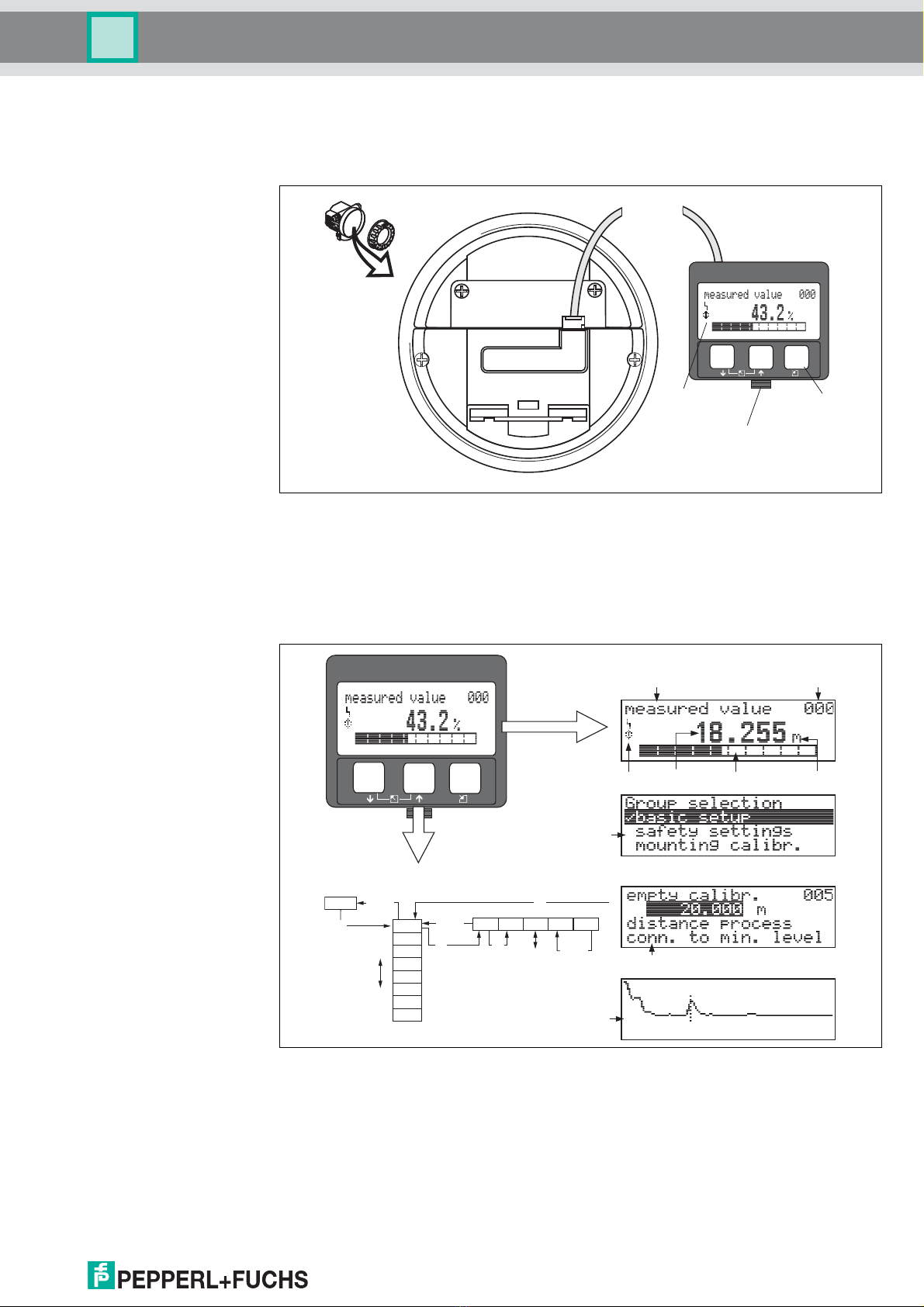

1.4 General structure of the operating menu. . . . . . . . . 6

1.5 Display and operating elements . . . . . . . . . . . . . . . 7

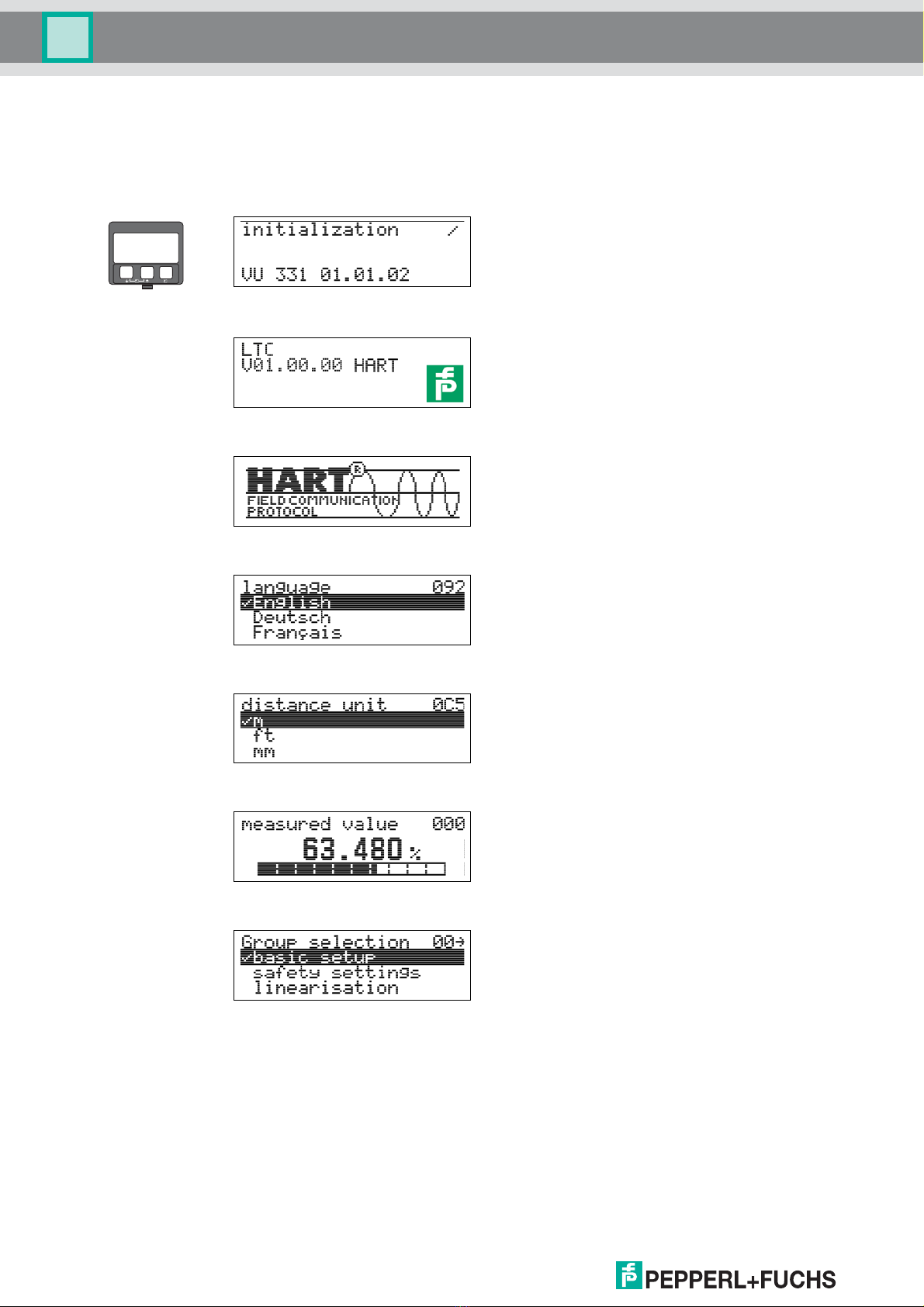

1.6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Function Pulscon LTC . . . . . . . . . . . . 11

3 Function group "basic setup" (00). . . 13

3.1 Function "measured value" (000) . . . . . . . . . . . . . 13

3.2 Function "tank properties" (002) . . . . . . . . . . . . . . 13

3.3 Function "medium property" (003). . . . . . . . . . . . . 14

3.4 Function "process propert." (004) . . . . . . . . . . . . . 15

3.5 Function "end of probe" (030) . . . . . . . . . . . . . . . . 15

3.6 Function "probe length" (031) . . . . . . . . . . . . . . . . 16

3.7 Function "probe" (032). . . . . . . . . . . . . . . . . . . . . . 16

3.8 Function "probe length" (033) . . . . . . . . . . . . . . . . 16

3.9 Function "determine length" (034) . . . . . . . . . . . . . 17

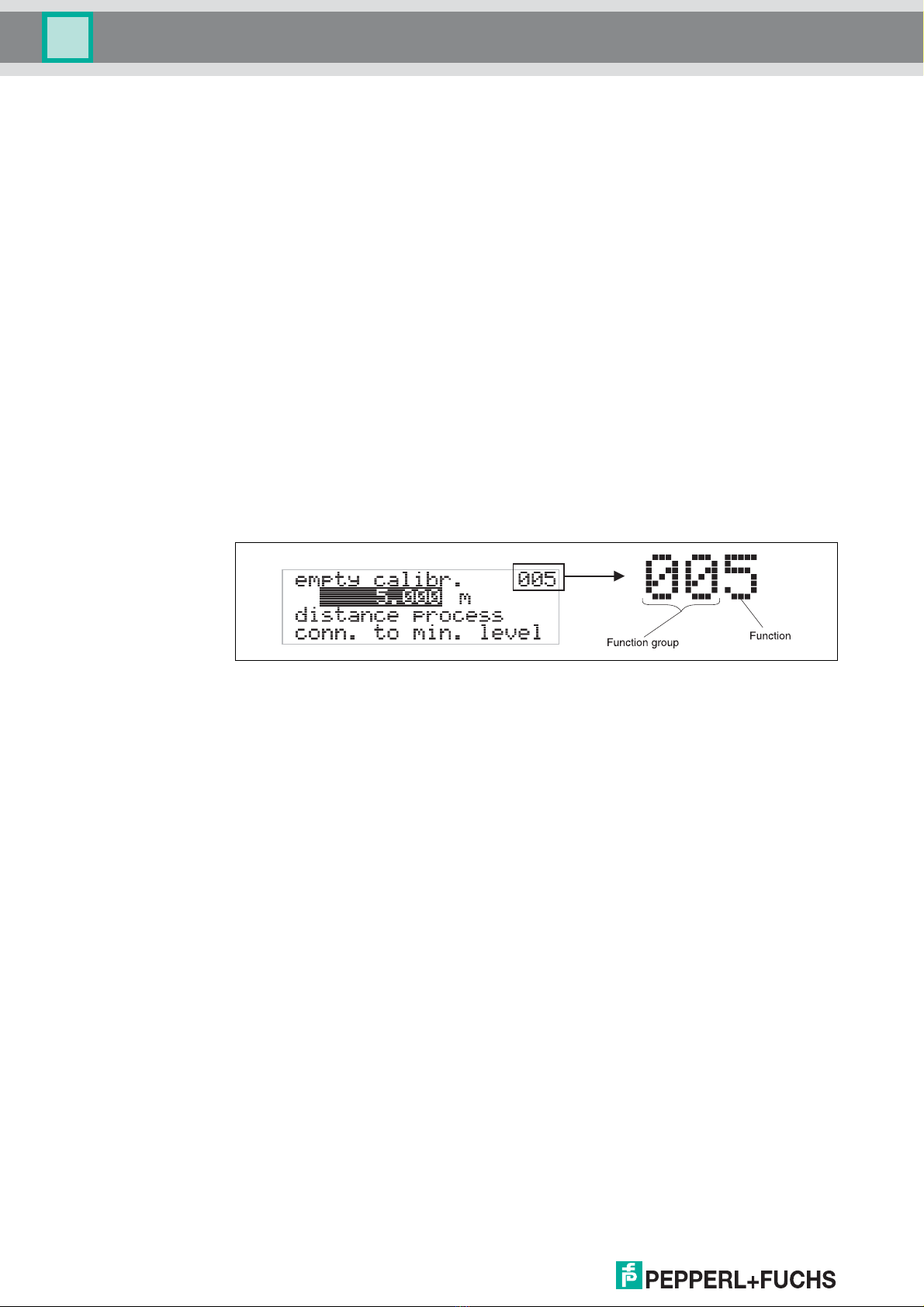

3.10 Function "empty calibr." (005) . . . . . . . . . . . . . . . . 17

3.11 Function "full calibr." (006). . . . . . . . . . . . . . . . . . . 18

3.12 Display (008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.13 Function "check distance" (051) . . . . . . . . . . . . . . 19

3.14 Function "range of mapping" (052) . . . . . . . . . . . . 20

3.15 Function "start mapping." (053). . . . . . . . . . . . . . . 20

3.16 Display (008) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Function "safety settings" (01) . . . . . 22

4.1 Function "output on alarm" (010). . . . . . . . . . . . . . 22

4.2 Function "output on alarm" (011), HART only . . . . 24

4.3 Function "outp. echo loss" (012) . . . . . . . . . . . . . . 24

4.4 Function "ramp %span/min" (013). . . . . . . . . . . . . 25

4.5 Function "delay time" (014) . . . . . . . . . . . . . . . . . . 26

4.6 Function "safety distance" (015) . . . . . . . . . . . . . . 26

4.7 Function "in safety dist." (016). . . . . . . . . . . . . . . . 26

4.8 Function "ackn. alarm" (017) . . . . . . . . . . . . . . . . . 28

4.9 Function "overspill prot." (018) . . . . . . . . . . . . . . . 28

4.10 Function "broken probe det" (019). . . . . . . . . . . . . 28

5 Function group

"length adjustment" (03). . . . . . . . . . . 29

5.1 Function "end of probe" (030) . . . . . . . . . . . . . . . . 29

5.2 Function "probe length" (031) . . . . . . . . . . . . . . . . 29

5.3 Function "probe" (032). . . . . . . . . . . . . . . . . . . . . . 29

5.4 Function "probe length" (033) . . . . . . . . . . . . . . . . 30

5.5 Function "determine length" (034) . . . . . . . . . . . . . 30

6 Function group "linearisation" (04) . . 31

6.1 Function "level/ullage" (040). . . . . . . . . . . . . . . . . . 31

6.2 Function "linearisation" (041) . . . . . . . . . . . . . . . . . 32

6.3 Function "customer unit" (042) . . . . . . . . . . . . . . . . 36

6.4 Function "table no." (043) . . . . . . . . . . . . . . . . . . . . 37

6.5 Function "input level" (044). . . . . . . . . . . . . . . . . . . 37

6.6 Function "input volume" (045) . . . . . . . . . . . . . . . . 38

6.7 Function "max. scale" (046) . . . . . . . . . . . . . . . . . . 38

6.8 Function "diameter vessel" (047) . . . . . . . . . . . . . . 38

7 Function group "extended calibr." (05) 39

7.1 Function "selection" (050). . . . . . . . . . . . . . . . . . . . 39

7.2 Function "check distance" (051) . . . . . . . . . . . . . . . 39

7.3 Function "range of mapping" (052). . . . . . . . . . . . . 40

7.4 Function "start mapping" (053). . . . . . . . . . . . . . . . 41

7.5 Function "pres. map dist." (054) . . . . . . . . . . . . . . . 41

7.6 Function "delete mapping" (055) . . . . . . . . . . . . . . 41

7.7 Function "echo quality" (056) . . . . . . . . . . . . . . . . . 42

7.8 Function "offset" (057) . . . . . . . . . . . . . . . . . . . . . . 42

7.9 Function "output damping" (058) . . . . . . . . . . . . . . 42

7.10 Function "upper block. dist" (059). . . . . . . . . . . . . . 43

8 Function group "output" (06),

- "profibus param." (06),

PROFIBUS PA only . . . . . . . . . . . . . . . 45

8.1 Function "commun. address" (060), HART only. . . 45

8.2 Function "instrument addr." (060),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 45

8.3 Function "no. of preambels" (061), HART only. . . . 45

8.4 Function "ident number" (061),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5 Function "low output limit" (062), HART only . . . . . 46

8.6 Function "set unit to bus" (062),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 46

8.7 Function "curr. output mode" (063), HART only . . . 47

8.8 Function "out value" (063), PROFIBUS PA only . . 47

8.9 Function "fixed cur. value" (064), HART only . . . . . 48

8.10 Function "out status" (064), PROFIBUS PA only . . 48

8.11 Function "simulation" (065). . . . . . . . . . . . . . . . . . . 49

8.12 Function "simulation value" (066) . . . . . . . . . . . . . . 50

8.13 Function "output current" (067), HART only . . . . . . 50

8.14 Function "2nd cyclic value" (067),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 50

8.15 Function "4mA value" (068), HART only . . . . . . . . 50

8.16 Function "select v0h0" (068),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 51

8.17 Function "20mA value" (069), HART only . . . . . . . 51

8.18 Function "display value" (069),

PROFIBUS PA only . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Function group

"envelope curve" (0E) . . . . . . . . . . . . . 52

9.1 Function "plot settings" (0E1) . . . . . . . . . . . . . . . . . 52

9.2 Function "recording curve" (0E2) . . . . . . . . . . . . . . 52

9.3 Function "envelope curve display" (0E3) . . . . . . . . 53