MR76 77GHz MMW Radar User Manual

MR76(v1.1)2020-3-10 Hunan Nanoradar Science and Technology Co., Ltd

4

CONTENT

1. Introduction..............................................................................................................................................................................5

1.1 Features....................................................................................................................................................................................5

1.2 Application examples.............................................................................................................................................................. 5

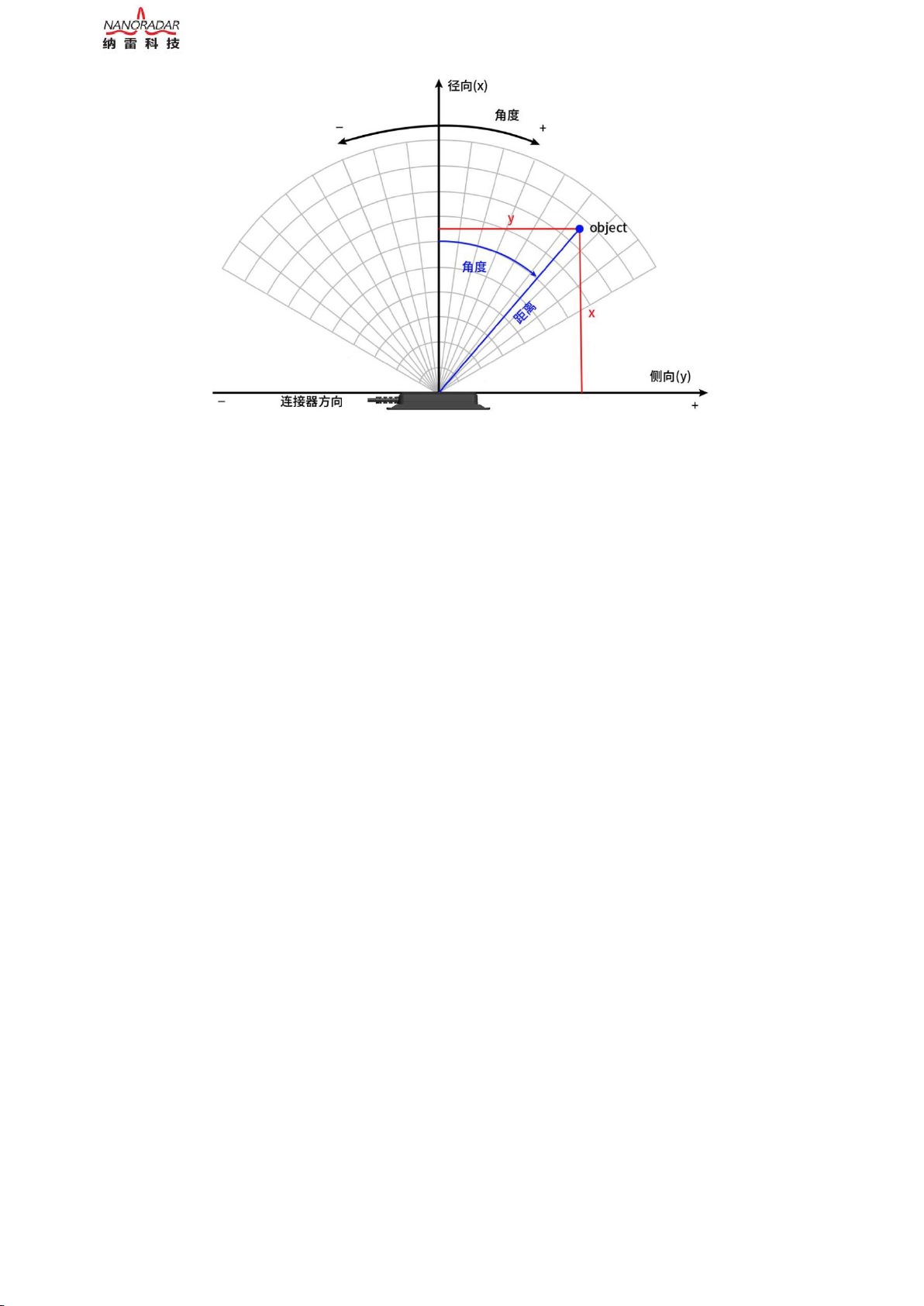

1.3 Radar principle.........................................................................................................................................................................6

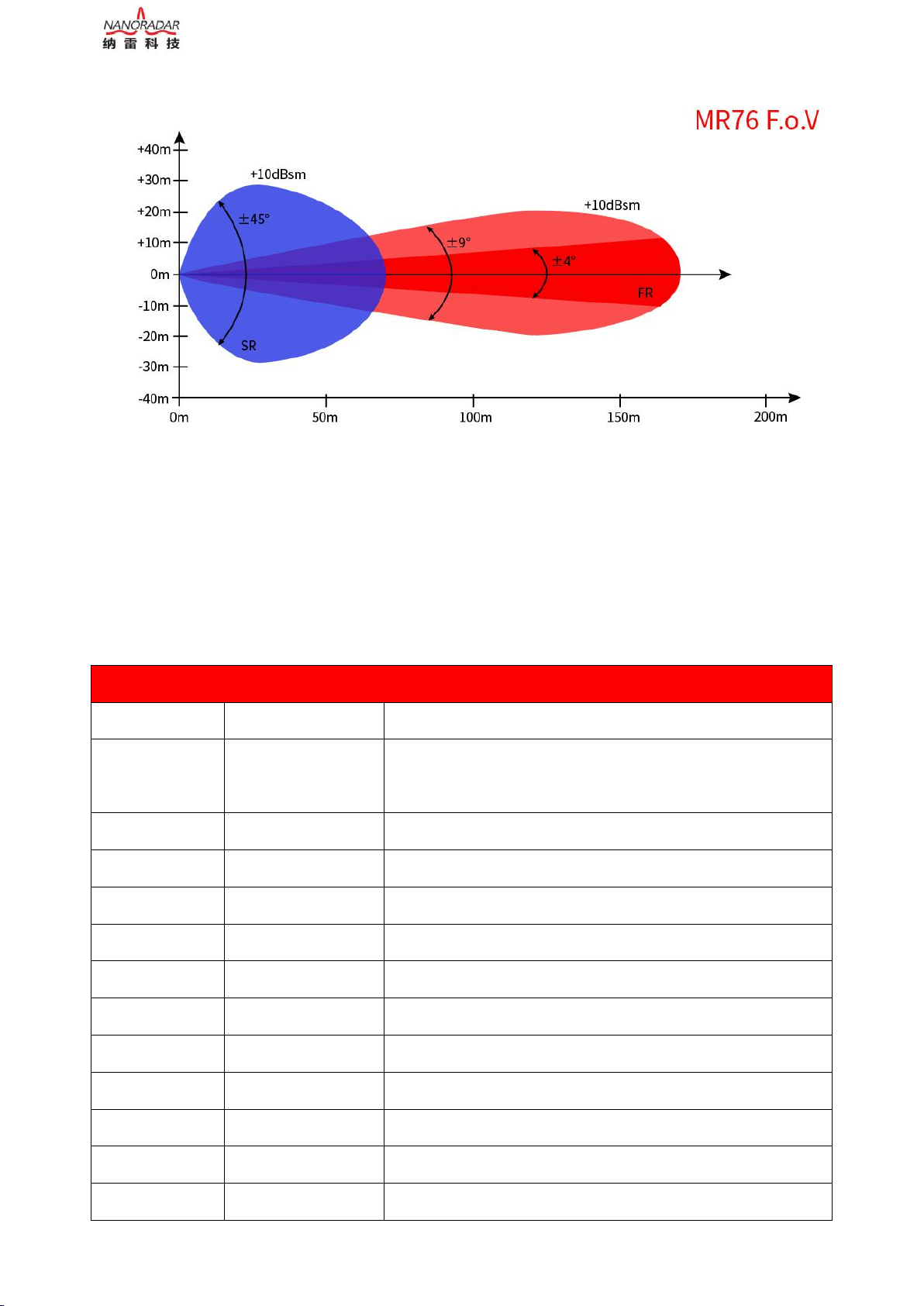

1.4 Radar FOV...............................................................................................................................................................................6

1.5 Technical Parameter................................................................................................................................................................ 7

2. Radar Connection....................................................................................................................................................................8

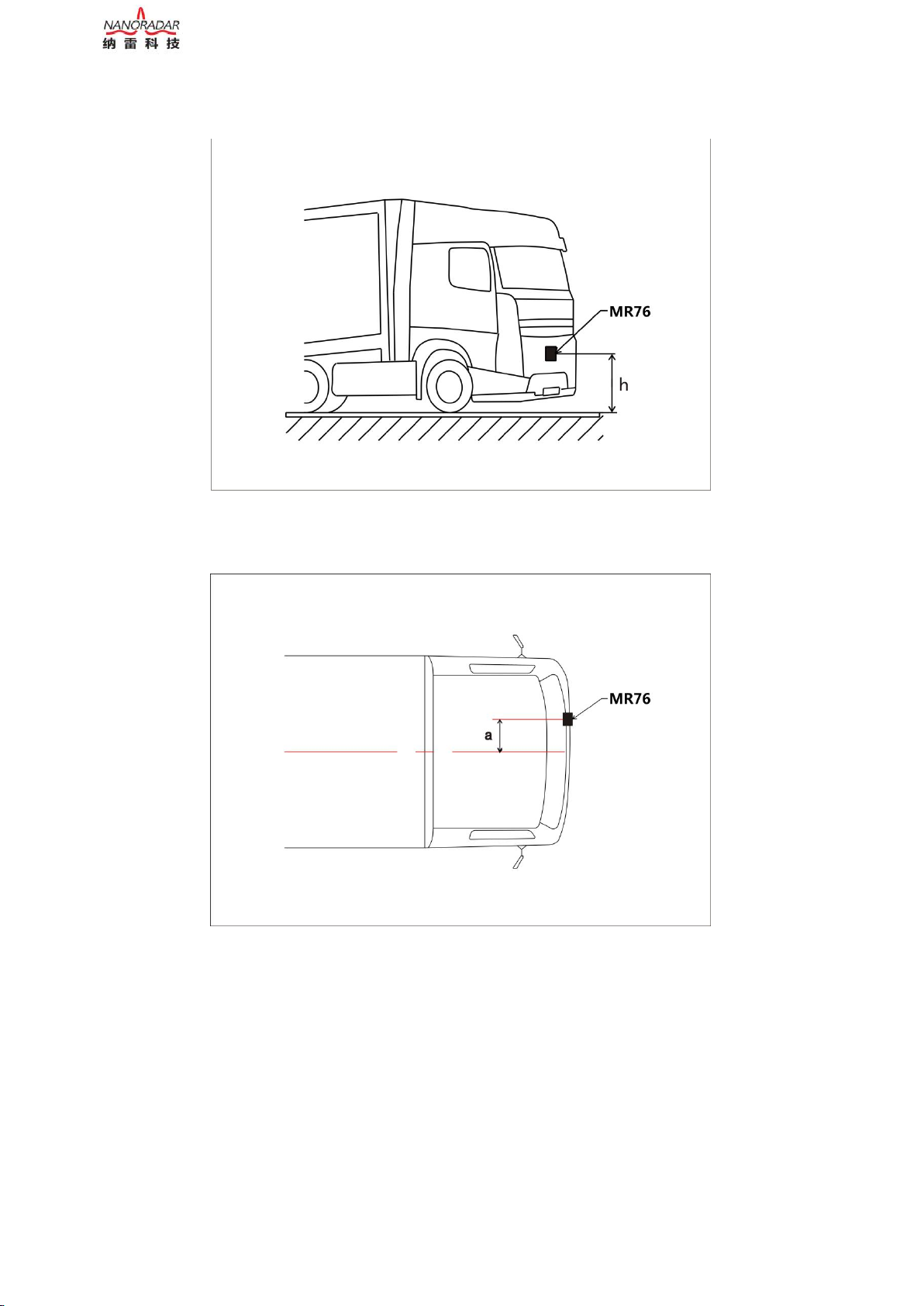

2.3.1 Mounting on Vehicle............................................................................................................................................................ 8

a. Thickness:............................................................................................................................................................................. 12

b. Spraying................................................................................................................................................................................... 12

c. Alignment................................................................................................................................................................................ 13

3. Electrical Conditions............................................................................................................................................................. 13

3.1 Cable Connection...................................................................................................................................................................13

3.2 CAN Interface........................................................................................................................................................................14

3.3 Test and Use.......................................................................................................................................................................... 14

4. Influence on Human Health..................................................................................................................................................16

5. Technical Parameter............................................................................................................................................................. 18

5.1 The Field of View (FoV)....................................................................................................................................................... 18

5.2 Cable Connection...................................................................................................................................................................19

6. Interfaces................................................................................................................................................................................ 20

6.1 CAN interface........................................................................................................................................................................20

6.2 Input Signals- Possible Dynamic Parameters........................................................................................................................ 21

7. Device Dimensions................................................................................................................................................................. 21

7.1 Dimensions......................................................................................................................................................................... 21

8. Notes on Safety and Risks..................................................................................................................................................... 21

8.1 Areas of responsibility........................................................................................................................................................... 22

9. Common faults and solutions............................................................................................................................................... 22