same as decreased stability) or through increasing the radius of inertia (putting

weights farther from the axis of rotation). Here are examples how these factors can

be used to effectively dampen

a

boat's movements in a seaway:

1.

On sailing yachts you can hoist a heavy anchor up the rigging (decreasing meta-

centric height and increasing radius of inertia without increasing weight).

2. On an Atlantic passenger ship the motion in

a

seaway was unsuitable for pas

-

sengers. The cure was 200 tons of stone on top of the upper deck.

The same effect has been measured on the Albin 25. The period of roll was measured

with an empty boat, with one man (85 kilograms) positioned in different places. The

following times were measured:

low position

...............................

2.05seconds

at thehelmsmans place

.....................

2.15 seconds

on top ofthe cabin

.........................

2.40seconds (anincrease of 25%)

Ballast and movements in a seaway

The above technical discussion on the period of roll has been given to give

a

back

-

ground to the following advice regarding ballast or no ballast. Several owners of the

Albin 25 think that the boat will have a calmer motion if ballast is used and many more

ask questions regarding ballast. One publication has advised that a ballast of 500

kilos be used down in the bilges. With conflicting advice it seems advisable to discuss

this question more thoroughtly. The reasons usually given as to why'ballast should be

used is the desire to obtain better stability and calmer motion in a seaway. Here we

have two conditions contrary to each other and where it will be necessary to choose

a suitable compromise.

Increased stability

is notnecessary. This is clearly shown inthestability curve fig. 5.

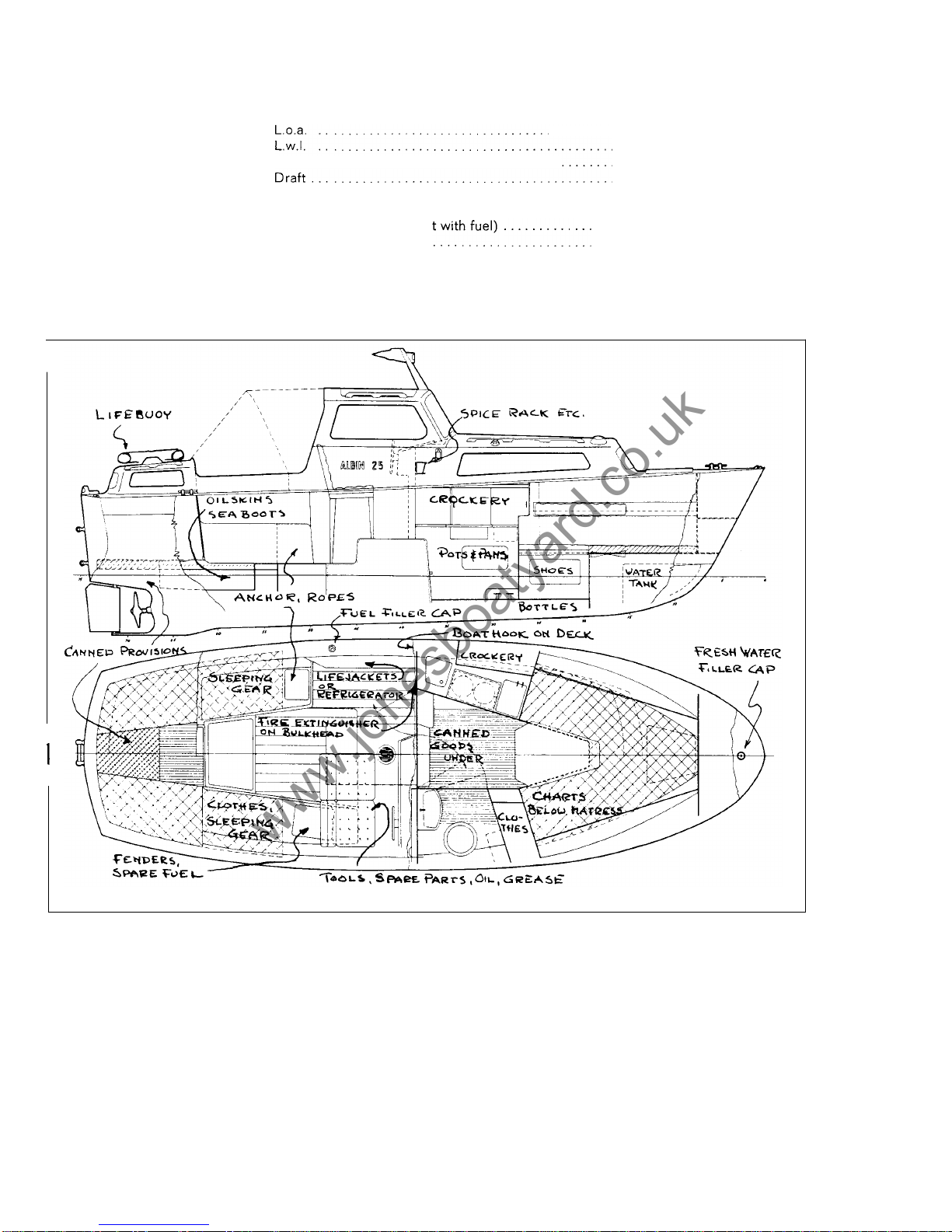

When the weight of the boat is increased with equipment, provisions etc., the stability

is increased and much more

so

if everything is stowed deep down in the boat.

Calmer movements in a seaway:

The main part of the discomfort experienced in a

motorboat in a seaway is caused by the athwarthship movements

-

the rolling.

There is the unhappy case where the period of the wave train is the same as the

boats natural period of roll and the motion of the boat therefore is increased. An

alteration of the course may change this. Each boat and each size of boat has a type

of sea which is especially uncomfortable.

Albin 25 has been designed for comfortable motion in normal use, loaded with a full

crew and all necessary equipment. The hull form gives a very comfortable movement

in a headsea. In certain types of seaways and also in open anchorages the boat can

develop relatively quick, uncomfortable athwarthship movements because of its form

stability. In open waters with a short and uncomfortable sea, calmer athwarthship

movements can be had through using:

1.

Sails.

A mast in itself is enough to increase the roll period and give a calmer

motion. With sails and a good wind the movement is considerably dampened.

2.

Mechanical stabilization.

There are several different systems, as a rule they are

too expensive.

3.

Lengthening the period

of

roll.

Through his own efforts the owner can increase

the period of

roll

by stowing all equipment and cargo (provisions, drink, etc.) as

high up and as far out to the sides as possible. A dinghy and anchor stored on

the deck helps for instance to give a better motion. An increase in the total weight

of the boat increases the radius of inertia if the increase of weight does not ride

on the axis of rotation.

To

use ballast is not advised if it is possible through other efforts to improve the

movement of the boat to satisfy your personal taste. If ballast is used to dampen the

movements it should be stowed high up and as far out to the sides as possible. Such

ballast must be fastened thoroughly

so

as not to come adrift in a seaway. If ballast

is

placed deep down, the meta

-

centric height is increased (which shortens the period

of roll). The radius of inertia is increased considerably if ballast is placed high up and

far out to the sides. It is a completely faulty use of ballast to place it far down hoping

for better motion, and the effect may be only 25% of what the right position will give.

Don't forget that every increase in weight also decreases the speed, increasing fuel

consumption. For instance

500

kilograms of ballast results in a reduction of maximum

speed byabout 3/4 ofaknot (10%) and a reduction of cruising speed by

about 1/3 of a

knot (5%).

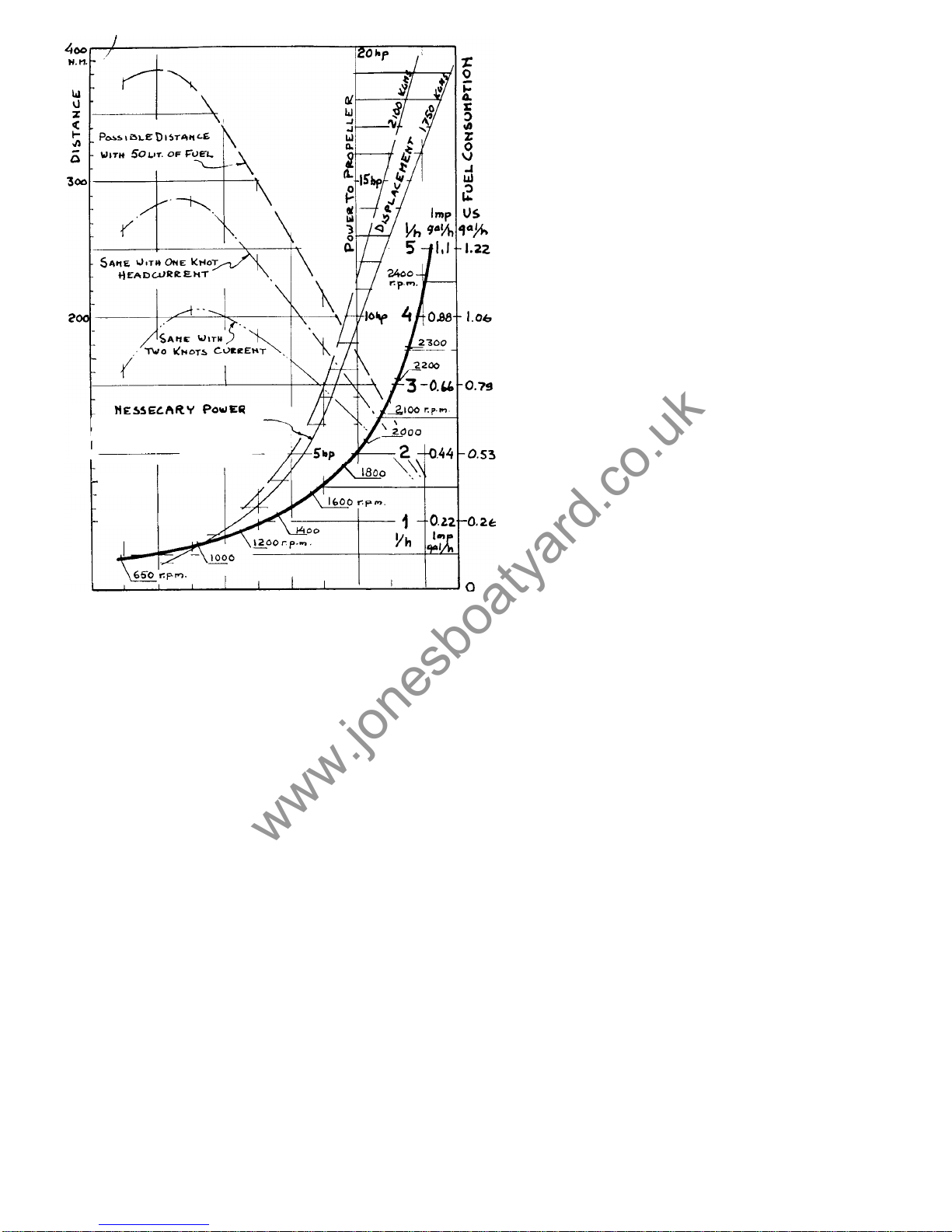

Fuel consumption and speed

Fig.

6

shows how much power must be delivered to the propeller to give the Albin 25

a certain speed. The power shown is about equal to the

DIN

power minus 5% to 10%

(losses in alternator, gearbox, shafts, bearings, etc). The efficiency of the propeller at

around

58%

is good. It follows that the thrust is a little more than half of the available

6