1. GENERAL CAUTION AND SAFETY RULES

We are very pleased with the choice of our brand product. In order for you

to enjoy it for a long time, we recommend that you follow the instructions for use

and maintenance of the device so that the selected product will last as long as

possible.

•All Peraqua products are made of top quality materials.

Careful manufacturing guarantees reliability and durability.

•The properties of the product will be maintained for a long period of time if

all recommendations for surface maintenance and cleaning are followed.

•Peraqua assumes no warranty and/or liability in the event of misuse or

improper installation, assembly or operation.

•The skimmer shall be used exclusively for the discharge of water from

swimming pools or bathing areas with associated treatment facilities, in

accordance with relevant national or international regulations.

•read and understand the installation and operating instructions carefully

before use, assembly and installation.

•Installation, assembly, installation and maintenance may only be performed by

trained and qualified personnel

DANGER!

Do not insert any body parts into the skimmer hole. Risk of the

skimmer grasping body parts, which may result in health damage and

injury.

•When unpacking and installing, be careful of edges and corners. Wear gloves

when unpacking to avoid potential injury.

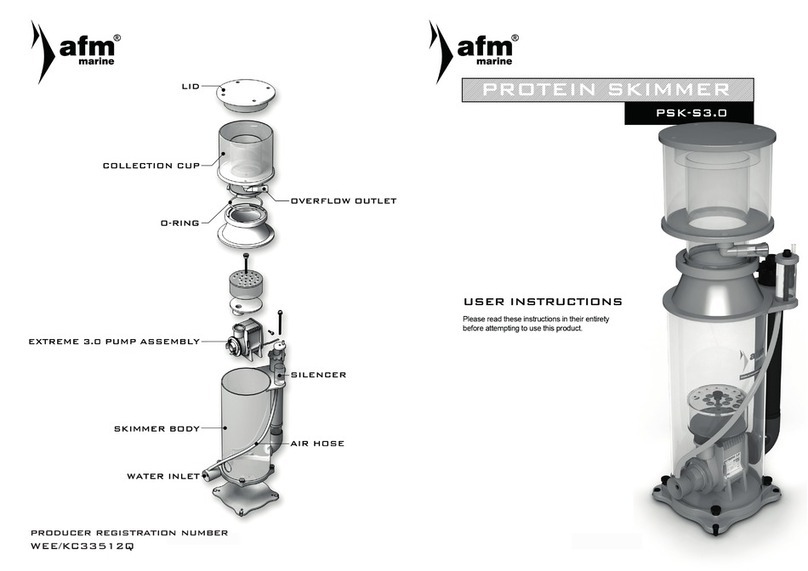

•Before installation, check that the delivered device contains all necessary

parts for completeness and check for potential damage.

•When working with stainless steel, use only stainless steel tools specially

designed for this purpose.

•During the warranty period, the equipment should not be repaired, tampered

with or modified on its own, except with the express consent of the

company. In case of failure to comply with the rules, the manufacturer has

the right to refuse the warranty rights of the customer.

•Make sure that the surface cleaner is working properly by checking it

regularly.

•The surface cleaner must be protected from frost and must not be installed

in the immediate vicinity of heat sources with high radiation temperatures.

The device itself is approved for a maximum water temperature of 40 and an

ambient temperature of 40.

6