IMPORTANT SAFETY INFORMATION

6.Dress properly. Do not wear loose clothing or jewelry.

Keep your hair, clothing and gloves away from mov-

ing parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

7. Work Safe. Operate tool a safe distance from yourself

and others in the work area. Keep proper footing and

balance at all times. Do not overreach, especially on

ladders. Be certain ladders being used are sturdy,

stable, on a rm surface and erected as safe work-

ing angles. Do not reach over or across running

machines, hoses, cords, etc.

8.Inspect tool before every use; do not use if parts are

loose or damaged.

9.Do not alter this product in any way.

10. Use the right tool for the job. Do not attempt to

force a small tool or attachment to do the work of a

larger industrial tool. Don’t use a tool whose perfor-

mance is not adequate for your work. Do not modify

this tool and do not use this tool for a purpose for

which it was not intended.

11. People with pacemakers should consult their

physician(s) before use. Electromagnetic elds in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure. In

addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with power switch locked on.

•

Properly maintain and inspect to avoid

electrical shock.

• Any power cord must be properly grounded.

Ground Fault Circuit Interrupter (GFCI) should

also be implemented – it prevents sustained

electrical shock.

12. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools.

Unmodied plugs and matching outlets will reduce

risk of electric shock. Do not use tool if plug is

damaged.

13. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

14. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

15.

Do not abuse the cord. Never use the cord for carry-

ing, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of

electric shock. Do not use tool if cord is damaged.

16.

When operating a power tool outdoors, use only

a 3-wire grounded cord with a wire size of 14

gauge or larger. We recommend they be listed

by Underwriters Laboratories (UL) in the USA or

(CSA) Canadian Standards Association in Canada

and be suitable for outdoor use. Cords marked for

outdoor use are also suitable for indoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

17. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

18. Use power tool ONLY on adequately rated circuits

to avoid overheating of electrical systems.

19. Prevent accidental starting. Ensure switch is in the

“OFF” position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch

or energizing power tools that have the switch “ON”

invites accidents.

20. Never let the power tool operate while unattended

and unplug when not in use or before servicing.

21.

Do not use the power tool if the switch does not

turn it on and off.Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

22. Never use this tool without the proper guard. The

grinding wheel could shatter during use. Make sure

the guard covers the side of the wheel facing you.

23. Never bounce the tool while grinding. This may

crack the wheel.

24. Grinding metal will cause sparks! Keep them di-

rected away from people and ammable materials.

Always keep the guard positioned so that as much

of the exposed disc as possible is pointing away

from you.

25. Keep children and pregnant women away from the

work area until the grinding is completed and the

area has been cleaned up.

26.

Always wear full eye, face and body protection.

Wire bristles may break off and y toward the

user. Always wear ear protection when grinding

in enclosed spaces. Noise level may be amplied

in such locations and may cause permanent

hearing loss.

27. Always wear an OSHA approved dusk mask or

respirator when inside the work area. Replace the

lter daily. NOTE: Not all dust masks offer protec-

tion from lead paint dust. Be sure to use the proper

mask for the job.

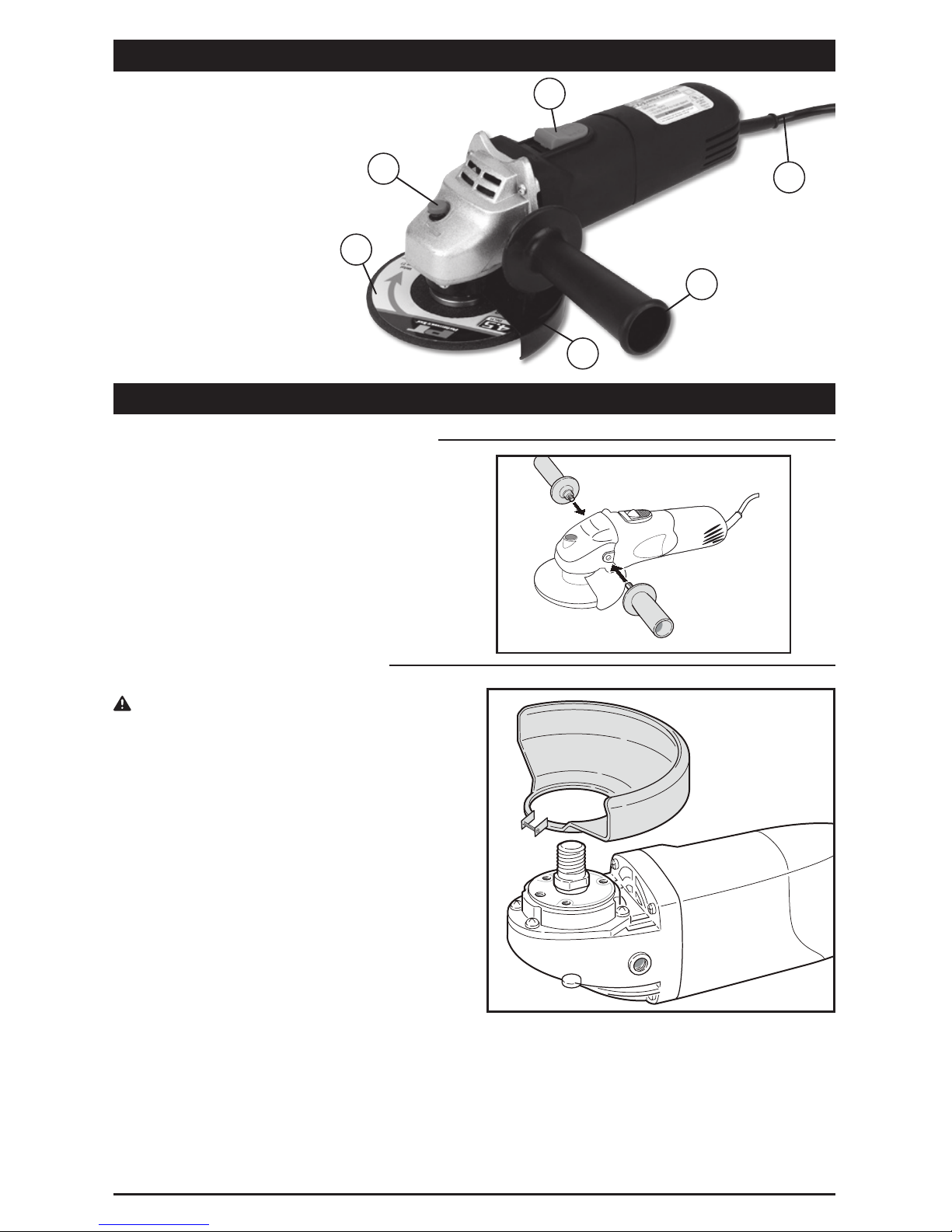

28. Before connecting the tool to the power supply fol-

low the safety instructions for installing the grinding

or cutting wheels. Do not lock the wheels too tight

or cracks may occur.

29. Only use grinding or cutting wheels with the correct

bore size for the spindle of the grinder.

30. Use standard parts. Do not use coolant or water

and do not use as a xed grinder.

31. Do not start the tool when the grinding or cutting

wheels are touching the work area.

32. Keep the power cord well away from the cutting

area during use. Always position the cord so that