WARNING

Always check the label for recommended applications before using a cleaning product. Using the incorrect product for the application may damage the

surface. Use only recommended car care products.

Never apply cleaner directly onto the surface to be polished. Apply to a clean soft cloth and then use the cloth to clean the surface.

Never use any type of abrasive cleaner as it may damage or scratch the surface.

BONNET INFORMATION & CARE

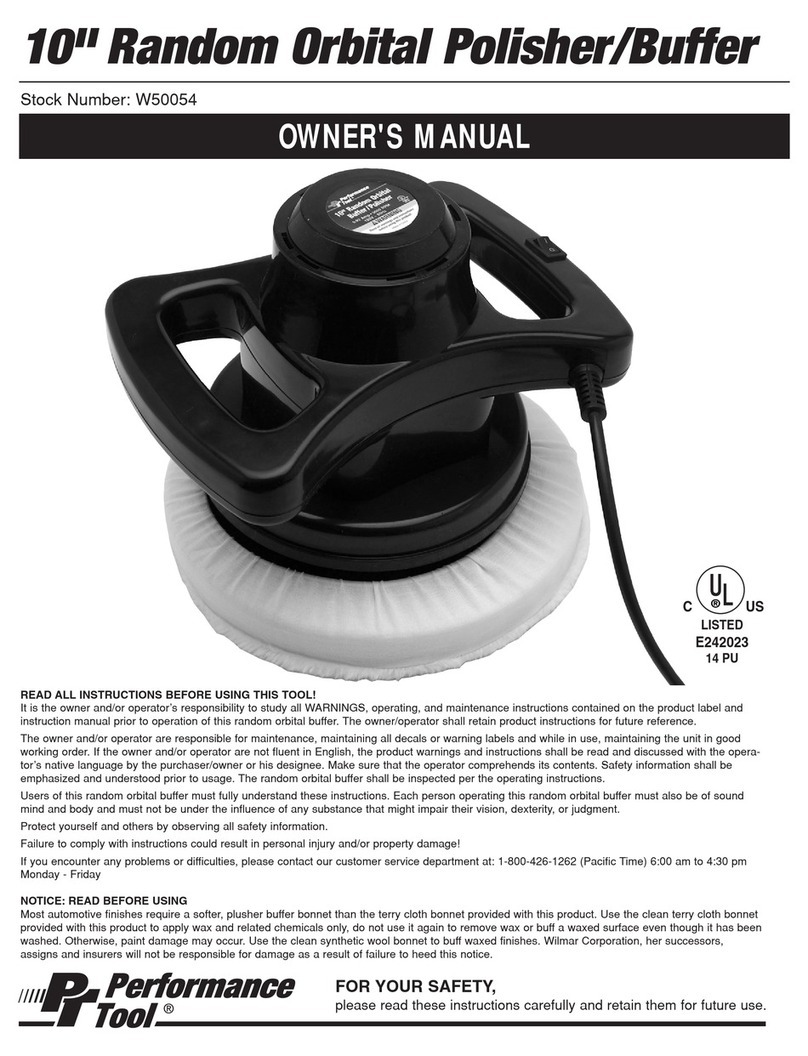

The Performance Tool Random Orbital Buffer is supplied with two (2) bonnets:

1. Terrycloth bonnet - used to apply wax / polish onto the surface.

2. Synthetic wool bonnet - used for fine buffing and to finish the surface.

CARING FOR YOUR BONNETS

1. Wash terrycloth bonnet and synthetic wool bonnet by hand in cold water with a mild detergent.

2. Remove excess moisture and allow bonnets to dry.

3. When not in use, remove the bonnets from the orbital buffer.

4. Wash bonnets after each use to prolong their life.

ATTACHING THE TERRYCLOTH APPLICATION BONNET

1. To install the terrycloth application bonnet, turn the orbital buffer upside down and rest the buffer on its motor housing (1).

2. Fit the terrycloth application bonnet over the top of the foam pad (4) and ensure that the outer edge of the elastic is drawn over the

top of the foam pad for a secure fit.

APPLYING POLISH TO THE TERRYCLOTH APPLICATION BONNET

1. Select a polish that is appropriate for your application. Be sure to read all directions carefully before using any polishing product.

2. For paste polish, use a putty knife or plastic spreader to apply approximately one heaping teaspoon of polish evenly over the entire

surface of the terrycloth application bonnet.

3. DO NOT APPLY POLISH DIRECTLY ONTO THE SURFACE BEING POLISHED.

4. When using liquid polish, apply a small half dollar size circle of polish in the center of the terrycloth polishing bonnet.

5. Apply two additional concentric rings of liquid polish outside of the circle as shown.

6. Please note - after the first application, the bonnet will not absorb as much polish so apply a smaller quantity when reloading the bonnet.

APPLYING POLISH TO THE SURFACE

1. Hold the orbital buffer with two hands against the surface to be polished and push the ON/OFF switch to the "I" (ON) position.

2. ALWAYS STARTAND STOP THE ORBITAL BUFFER ON OR AGAINST THE SURFACE BEING POLISHED.

3. Begin polishing larger flat surfaces first such as the hood, truck and roof. Cover areas quickly with broad, sweeping motion in a criss-

cross pattern.

4. DO NOT PRESS DOWN ON THE SURFACE WITH THE ORBITAL BUFFER. Allow the machine's random orbital action of the pad

and bonnet, not pressure, to do the work.

5. After flat surfaces have been covered, polish curved surfaces such as car doors, quarter panels and fenders. Use small circular

motions for these areas.

6. After applying polish to the surface, turn orbital buffer off by pushing the switch to the "O" (OFF) position while holding the orbital

buffer against the surface being polished.

7. WAIT UNTIL THE PAD STOPS ROTATING BEFORE LIFTING THE ORBITAL BUFFER FROM THE SURFACE BEING POLISHED.

8. UNPLUG THE ORBITAL BUFFER WHEN NOT IN USE AND WHEN INSTALLING OR REMOVING BONNETS.

9. Apply polish by hand for hard to reach areas, such as bumpers, side mirrors, etc.

ATTACHING THE BUFFING BONNET

1. To install the synthetic wool buffing bonnet, turn the orbital buffer upside down and rest the buffer on its motor housing (1).

2. Fit the synthetic wool buffing bonnet over the top of the foam pad (4) and ensure that the outer edge of the elastic is drawn over the

top of the foam pad for a secure fit.

USING THE BUFFING BONNET

1. Hold the orbital buffer with two hands against the surface to be polished and push the ON/OFF switch to the "I" (ON) position.

2. ALWAYS STARTAND STOP THE ORBITAL BUFFER ON OR AGAINST THE SURFACE BEING POLISHED.

3. Begin buffing larger flat surfaces first such as the hood, truck and roof. Cover areas quickly with broad, sweeping motion in a criss-cross pattern.

4. DO NOT PRESS DOWN ON THE SURFACE WITH THE ORBITAL BUFFER. Allow the machine's random orbital action of the pad

and bonnet, not pressure, to do the work.

5. After flat surfaces have been covered, buff curved surfaces such as car doors, quarter panels and fenders. Use small circular motions

for these areas.

6. After buffing the entire surface, turn orbital buffer off by pushing the switch to the "O" (OFF) position while holding the orbital buffer

against the surface being polished.

7. WAIT UNTIL THE PAD STOPS ROTATING BEFORE LIFTING THE ORBITAL BUFFER FROM THE SURFACE BEING POLISHED.

8. UNPLUG THE ORBITAL BUFFER WHEN NOT IN USE AND WHEN INSTALLING OR REMOVING BONNETS.

9. Buff hard to reach areas by hand. (i.e. bumpers, side mirrors, etc).

6.