49

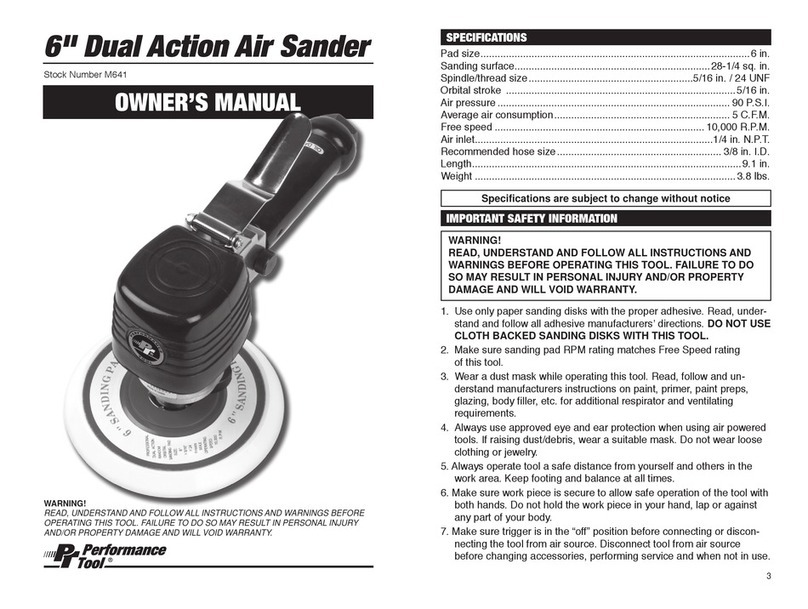

IMPORTANT SAFETY INFORMATION

34. Do not use a damaged accessory. Before each use inspect

the accessory such as abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess wear, wire brush for

loose or cracked wires. If power tool or accessory is dropped,

inspect for damage or install an undamaged accessory.After

inspecting and installing an accessory, position yourself and

bystanders away from the plane of the rotating accessory and

run the power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this

test time.

35. Hold power tool by insulated gripping surfaces only, when

performing an operation where the accessory may contact

hidden wiring or its own cord. An accessory contacting a “liveˮ

wire may make exposed metal parts of the power tool “live”

and shock the operator.

36. Do not use accessories that require liquid coolants. Using

water or other liquid coolants may result in electrocution or

shock.

37. Do not depress the spindle lock when starting or during

operation.

38. Use clamps (not included) or other practical ways to secure

and support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may lead

to loss of control and personal injury.

39. WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities, contains

chemicals known [to the State of California] to cause cancer,

birth defects or other reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement or other masonry

products.

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to lter out microscopic particles.

(California Health & Safety Code § 25249.5, et seq.)

40. WARNING: Handling the cord on this product will expose you

to lead, a chemical known to the State of California to cause

cancer, and birth defects or other reproductive harm. Wash

hands after handling. (California Health & Safety Code §

25249.5, et seq.)

41. KICKBACK WARNING: Kickback is a sudden reaction to a

pinched or snagged rotating wheel, backing pad, brush or any

other accessory. Pinching or snagging causes rapid stalling of

the rotating accessory which in turn causes the uncontrolled

power tool to be forced in the direction opposite of the acces-

sory’s rotation at the point of the binding. For example, if an

abrasive wheel is snagged or pinched by the workpiece, the

edge of the wheel that is entering into the pinch point can dig

into the surface of the material causing the wheel to climb out

or kick out. The wheel may either jump toward or away from

the operator, depending on direction of the wheel’s movement

at the point of pinching. Abrasive wheels may also break

under these conditions. Kickback is the result of power tool

misuse and/or incorrect operating procedures or conditions

and can be avoided by taking proper precautions as given

below.

1. Maintain a rm grip on the power tool and position your

body and arm to allow you to resist kickback forces. always

use auxiliary handle, if provided, for maximum control over

kickback or torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper precau-

tions are taken.

2. Never place your hand near the rotating accessory.Acces-

sory may kickback over your hand.

3. Do not position your body in the area where power tool

will move if kickback occurs. Kickback will propel the tool in

direction opposite to the wheel’s movement at the point of

snagging.

4. Use special care when working corners, sharp edges etc.

avoid bouncing and snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the rotating

accessory and cause loss of control or kickback.

5. Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of

control.

42. VIBRATION WARNING: This tool vibrates during use.

Repeated or long-term exposure to vibration may cause tem-

porary or permanent physical injury, particularly to the hands,

arms and shoulders. To reduce the risk of vibration-related

injury:

1. Anyone using vibrating tools regularly or for an extended

period should rst be examined by a doctor and then have

regular medical check-ups to ensure medical problems are

not being caused or worsened from use. Pregnant women

or people who have impaired blood circulation to the hand,

past hand injuries, nervous system disorders, diabetes, or

Raynaud’s Disease should not use this tool. If you feel any

medical or physical symptoms related to vibration (such as

tingling, numbness, and white or blue ngers), seek medical

advice as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood

supply to the hands and ngers, increasing the risk of

vibration-related injury.

3. Wear suitable gloves to reduce the vibration effects on the

user.

4. Use tools with the lowest vibration when there is a choice

between different processes.

5. Include vibration-free periods each day of work.

6. Grip tool as lightly as possible (while still keeping safe

control of it). Let the tool do the work.

7. To reduce vibration, maintain the tool as explained in

this manual. If any abnormal vibration occurs, stop use

immediately.

43. The warnings, precautions, and instructions discussed in

this instruction manual cannot cover all possible conditions

and situations that may occur. It must be understood by the

operator that common sense and caution are factors which

cannot be built into this product, but must be supplied by the

operator.

WARNING: Some dust created by power sanding, sawing, grind-

ing, drilling and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm.

WARNING: This product and its packaging contain a chemical

known to the State of California to cause cancer, birth defects, or

other reproductive harm.

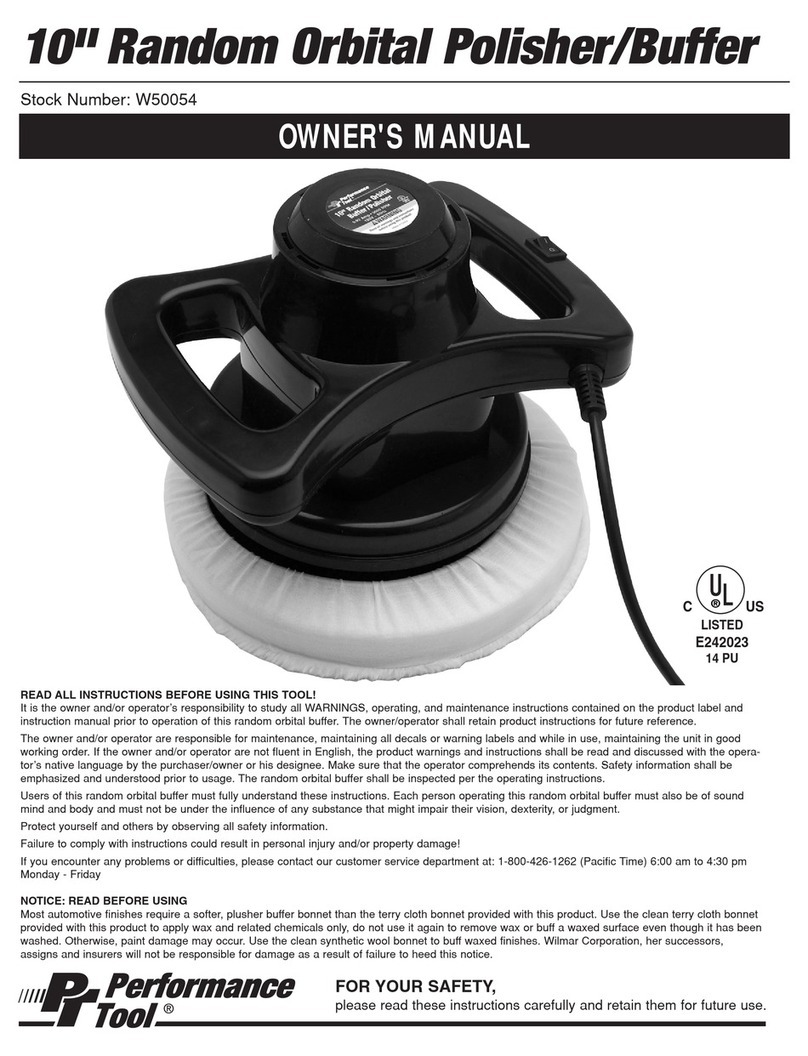

OPERATION

3. Rotate the Speed Dial to select the

desired speed setting.

4. Plug the Power Cord of the Polisher/

Sander into a grounded 120 volt,

electrical outlet.

5. To start, grip the Polisher/Sander rmly

with both hands and press the Trigger.

Release the Trigger to stop. To use the

Lock on button, while holding in the

Trigger, press the Lock On Button, then

release the Trigger. The Polisher/Sander

will stay on. Press and release the

Trigger to stop.

6. Wait until the Polisher/Sander has

reached full speed, then gently contact

the surface.

7. Keep heavy pressure off of the Polisher/

Sander when operating. Allow the

sanding disk to do the work.

8. Move the Polisher/Sander in a uniform

pattern up and down or side to side as

you sand to ensure even sanding.

9. Periodically, stop the Polisher/Sander

and check for possible disc wear.

Replace used or worn sanding discs

when necessary.

10. When nished, turn off and unplug the

Polisher/Sander.

11. Allow the tool to come to a complete

stop before setting it down.

12. To prevent accidents, turn off the tool

and disconnect its power supply after

use. Clean, then store the tool indoors

out of children’s reach.

CARE & MAINTENANCE

NOTICE

Procedures not specifically ex-

plained in this manual must be performed

only by a qualified technician.

WARNING

TO PREVENT SERIOUS

INJURY FROM A ACCIDENTAL OPERA-

TION: Release the trigger and unplug

the tool from its electrical outlet before

performing any inspection, maintenance,

or cleaning procedures.

WARNING

TO PREVENT SERIOUS

INJURY FROM TOOL FAILURE: Do not

use damaged equipment. if abnormal

noise or vibration occurs, have the prob-

lem corrected before further use.

1. BEFORE EACH USE, inspect the

general condition of the tool. Check for:

• loose hardware,

• misalignment or binding of

moving parts,

• cracked or broken parts,

• damaged electrical wiring, and

• any other condition that may

affect its safe operation.

2. AFTER USE, wipe external surfaces of

the tool with clean cloth.

3. Periodically blow dust and grit out of the

motor vents using dry compressed air.

WearANSI-approved safety goggles and

NIOSH-approved breathing protection

while doing this.

4. Periodically recheck all nuts, bolts, and

screws for tightness.

5. Remove Foam Pad from Backing Pad

when Polisher/Sander is not in use. This

will allow Backing Pad to dry and retain

its original shape. Wash with mild soap

and water before storing.

6. The Polishing Bonnet may be machine

washed in cold water with mild

detergent. Do not put in the dryer.

7. Use only a clean cloth and mild

detergent to clean the body of the

Polisher. Do not use solvents. Do not

immerse any part of the tool in liquid.

8. CARBON BRUSH MAINTENANCE.

The carbon brushes may require

maintenance when the motor

performance of the tool decreases or

stops working completely. To maintain

the brushes:

a. Remove the Carbon Brush Cover on

each side of the motor housing.

b. Remove the carbon brushes from the

housing. Keep track of which

orientation the old carbon brushes

were in to prevent needless wear if