10

Introduction

Target groups

Contractors

These Instructions for Use are intended

for contractors who either

assemble, modify and dismantle the

PERI products, or

use them, e.g. for concreting, or

who have them used, e.g. for forming

operations.

Construction site coordinator

The Safety and Health Protection Coordi-

nator*

is appointed by the client,

must identify potential hazards during

the planning phase,

determines measures that provide

protection against risks,

creates a safety and health plan,

coordinates the protective measures

for the contractor and site personnel so

that they do not endanger each other,

monitors compliance with the protec-

tive measures.

* Valid in Germany: Regulations for Occupational

Health and Safety on Construction Sites 30

(RAB 30)

Competent persons

Due to the specialist knowledge gained

from professional training, work experi-

ence, and recent professional activity, the

competent person has a reliable under-

standing of safety-related issues and can

correctly carry out inspections. Depend-

ing on the complexity of the test to be

undertaken, e.g. scope of testing, type of

testing or the use of certain measuring

devices, a range of specialist knowledge

is necessary.

When handling our products, ensure

that the relevant national guidelines

and regulations in the respective

current version are complied with!

If no country-specific regulations

are available, it is recommended to

proceed according to German

guidelines and regulations.

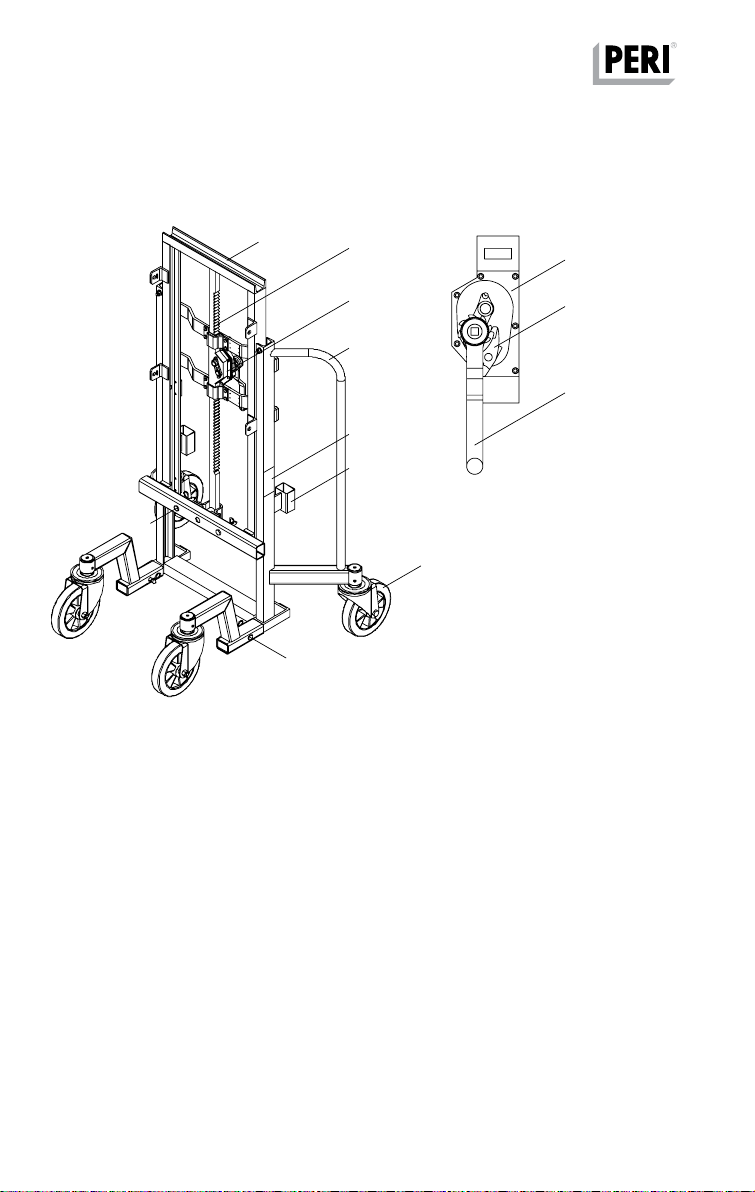

Trolley with Winch

Translation of the Original Instructions for Use