6SENR9977

Systems Operation Section

Each cylinder has a piston cooling jet that is installed

in the cylinder block. The piston cooling jet sprays

engine oil onto the inner surface of the piston in

order to cool the piston. The pistons have a Fastram

combustion chamber in the top of the piston in order

to provide an efficient mix of fuel and air. The piston

pin is off-center in order to reduce the noise level.

The pistons have two compression rings and an

oil control ring. The groove for the top ring has a

hardened insert in order to reduce wear of the ring

groove. The skirt has a layer of graphite in order to

reduce wear. The correct piston height is important in

order to ensure that the piston does not contact the

cylinder head. The correct piston height also ensures

the efficient combustion of fuel which is necessary in

order to conform to requirements for emissions.

A piston and connecting rod are matched to each

cylinder. The piston height is controlled by the

length of the connecting rod. Six different lengths

of connecting rods are available in order to attain

the correct piston height. The different lengths of

connecting rods are made by machining the small

end bearing off-center in order to form an eccentric

bearing. The amount of the eccentricity of the bearing

creates the different lengths of the connecting rods.

The crankshaft has five main bearing journals. End

play is controlled by thrust washers which are located

on both sides of the center main bearing.

The timing case is made of aluminum. The timing

gears have holes which align with holes in the front

flange of the crankshaft and the camshaft in order

to ensure the correct assembly of the gears. When

the number 1 piston is at the top center position

on the compression stroke, a temporary timing pin

is inserted through the crankshaft gear and the

hole in the front flange of the crankshaft. A second

temporary timing pin is inserted through the camshaft

gear and the hole in the timing case.

The crankshaft gear turns the idler gear which then

turns the following gears:

•the camshaft gear

•the fuel injection pump

•aloweridler gear which turns the gear of the

lubricating oil pump

The camshaft and the fuel injection pump run at half

the rpm of the crankshaft. The cylinder block has an

open top deck. The cylinders are only connected to

the cylinder block at the bottom.

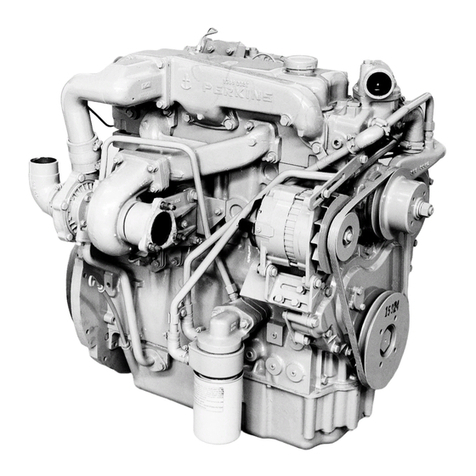

g00910750

Illustration 3

The Bosch VP30 fuel injection pump is installed on

the engine. The fuel injection pump conforms to

currentemissions.Boththepumptimingandthehigh

idle are preset at the factory. The fuel injection pump

is not serviceable. Adjustments to the fuel injection

pump timing and high idle should only be made by

personnel which have had the correct training. The

fuel injection pump uses the engine ECM to control

the engine RPM.

For the specifications of the 1104C electronic engine,

refer to the Specifications, “Engine Design”.

Engine Operation

i02242513

Basic Engine

Cylinder Block and Cylinder Head

The cylinder block for the 1104 engine has four

cylinders which are arranged in-line.

The cylinder block for the 1104 engine has five

main bearings which support the crankshaft. Thrust

washers on both sides of the center main bearing

control the end play of the crankshaft.

A cylinder head gasket is used between the

engine block and the cylinder head in order to seal

combustion gases, water, and oil.