DA 7440 User Manual v.1.1 Aug 2015

6 (48)

3. Table of contents

1. Safety Instructions.............................................................................................................3

2. General description ...........................................................................................................4

2.1 Introduction .......................................................................................................................................4

2.2 System features overview .................................................................................................................4

2.3 Copyright and liability.......................................................................................................................5

2.4 Declaration of conformity................................................................................................................5

3. Table of contents...............................................................................................................6

4. Setting up the instrument .................................................................................................8

4.1 Environmental conditions................................................................................................................8

4.2 Overview of installation pre-requisites...........................................................................................8

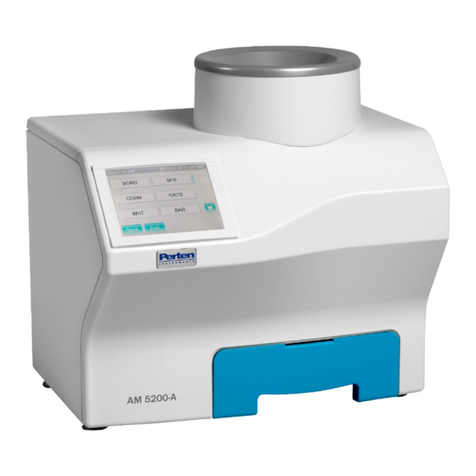

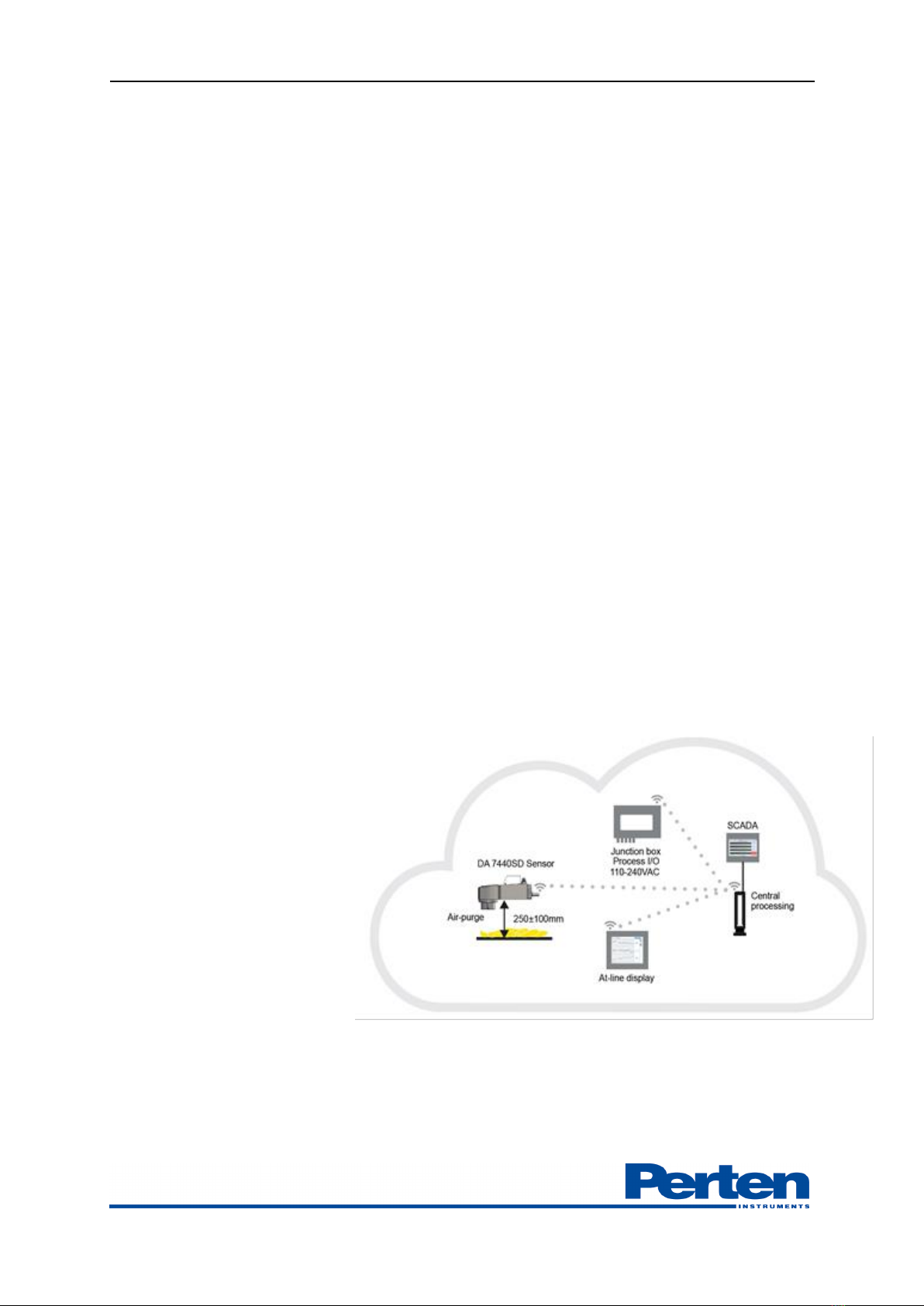

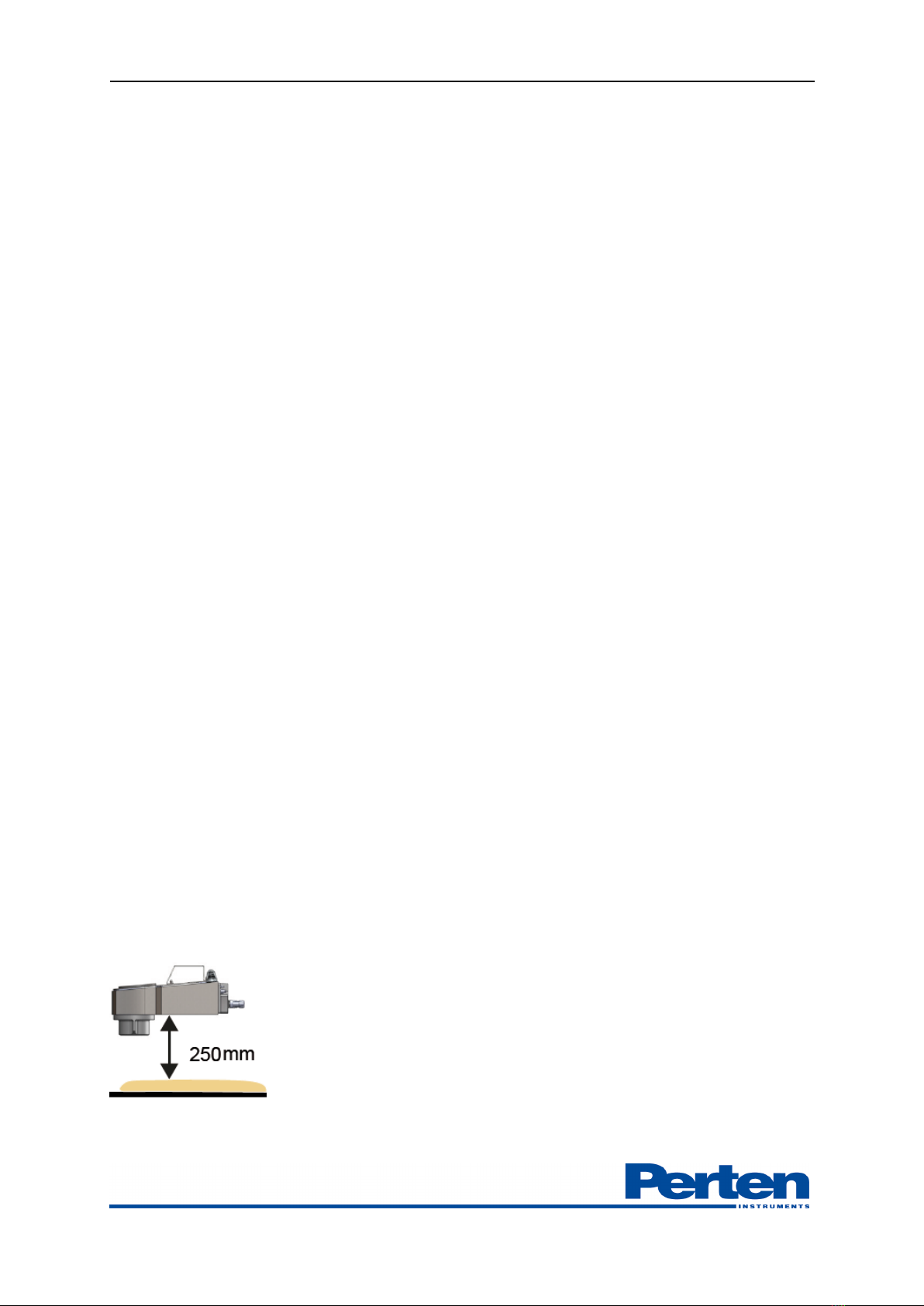

4.3 DA 7440 NIR Sensor .......................................................................................................................9

4.4 Junction box and instrument PC...................................................................................................10

4.5 At line display...................................................................................................................................10

4.6 Network set-up................................................................................................................................11

5. Process Plus Operational Overview ...............................................................................................12

5.1 Overview...........................................................................................................................................12

5.2 Logging in.........................................................................................................................................12

5.3 View measurement results..............................................................................................................13

5.4 Select product setting to use ..........................................................................................................15

5.5 Following measurement trends .....................................................................................................15

5.7 Grab sample collection...................................................................................................................18

6. Measurement set-up........................................................................................................20

6.1 Overview Setting menu ..................................................................................................................20

6.2 Analysis Profiles settings ................................................................................................................21

6.3 Sample collection settings ..............................................................................................................23

6.4 Bias adjustment................................................................................................................................23

7. Reporting and Data export .............................................................................................24

7.1 Data export overview......................................................................................................................24

7.2 Exporting grab samples results and corresponding measurement spectra.............................25

7.4 Exporting measurement results.....................................................................................................27

7.4 Exporting measurement spectra....................................................................................................27

7.3 Batch reports....................................................................................................................................28

8. Maintenance....................................................................................................................30

8.1 DA 7440 Maintenance overview...................................................................................................30

8.2 Maintenance checklist.....................................................................................................................30

8.3 Instrument cleaning.........................................................................................................................31

8.4 Replacing the lamp..........................................................................................................................32

8.5 External check sample ....................................................................................................................35

8.6 Spare parts list..................................................................................................................................37

9. Extended configuration ..................................................................................................38

9.1 Connecting DA 7440 sensor..........................................................................................................38

9.2 DA 7440 sensor IP configuration.................................................................................................39

9.3 Product Detection...........................................................................................................................40

9.4 Product Movement Detection.......................................................................................................41

9.5 Updating Calibration models.........................................................................................................42

9.6 Integration of measurement results ..............................................................................................43