Perun Technologies LARA-100 COMM User manual

PERUN

Technologies

LARA-100 MOTHERBOARD

USER MANUAL

Power Electronics Research Unified Technologies

www.perun-power.com

1

PERUN Technologies

CONTENTS

1 First things first: LARA-100 platform..................................................................................................... 2

1.1 Why LARA-100?............................................................................................................................. 2

1.2 What is LARA-100?........................................................................................................................ 2

2 LARA 100 MOTHERBOARD .................................................................................................................... 7

3 Technical data ..................................................................................................................................... 39

3.1 PWM outputs circuit ...................................................................................................................42

3.2 Protection logic –error signal generation circuit........................................................................ 43

3.3 Overcurrent protection circuit ....................................................................................................47

3.4 DC-link under/overvoltage protection circuit ............................................................................. 49

3.5 Manual error trigger circuit......................................................................................................... 51

3.6 Error signal reset circuit ..............................................................................................................52

3.7 PWM pulses enable circuit.......................................................................................................... 53

3.8 Current measurement circuit...................................................................................................... 54

3.9 DC-link voltage measurement circuit.......................................................................................... 56

3.10 Pre-charge thyristor and braking chopper turn on/off circuit .................................................... 58

3.11 Communication circuits ..............................................................................................................60

3.12 Power Supply circuits ..................................................................................................................63

4 Connection examples..........................................................................................................................65

5 Document history................................................................................................................................ 68

Power Electronics Research Unified Technologies

www.perun-power.com

2

PERUN Technologies

1FIRST THINGS FIRST: LARA-100 PLATFORM

Before we give detailed information about LARA-100 Motherboard, let us make a brief introduction in

LARA-100 system in order to get a bigger scope.

If you have been already familiar with LARA-100 concepts you can skip this first chapter and go

immediately to the second.

1.1 WHY LARA-100?

The vision behind LARA-100 is to serve its users as a sort of a LAunch RAmp for Power Electronics

control development, research and education. It emerged as the comprehensive answer to the

permanent need for flexibility and comfortable performance in the PE laboratory.

So, how LARA-100 serves you? Instead of building and maintaining a new test-bench whenever dealing

with new project or application PERUN brings you LARA-100 platform which can be re-configured and

re-used according to your present needs.

Therefore, LARA-100 is designed to solve the following:

1. It replaces standard inflexible laboratory test benches and their exhausting modifications with

the platform which can be configured to cover a variety of applications (motor drives, active

filters, PV converter, FACTS, as well as to support some larger research projects, e.g. micro-grids

and smart grids).

2. LARA-100 interfaces with popular controllers such as Texas Instruments C2000 series following

the simple plug and play principle

3. User’s control algorithm is tested directly from an intuitive software suite called PERUN Power

Desk (PPD) which facilitates:

Embedded oscilloscope function which reduces the need for the external oscilloscope

Supervisory control over the system operation

Tag Explorer with the on-line access (read and write) to all variables and parameters

defined by a user

Signal Analysis Desk which processes and analyzes measured results and

Control Design Desk which helps user to design the new control algorithm or modify the

existing one

1.2 WHAT IS LARA-100?

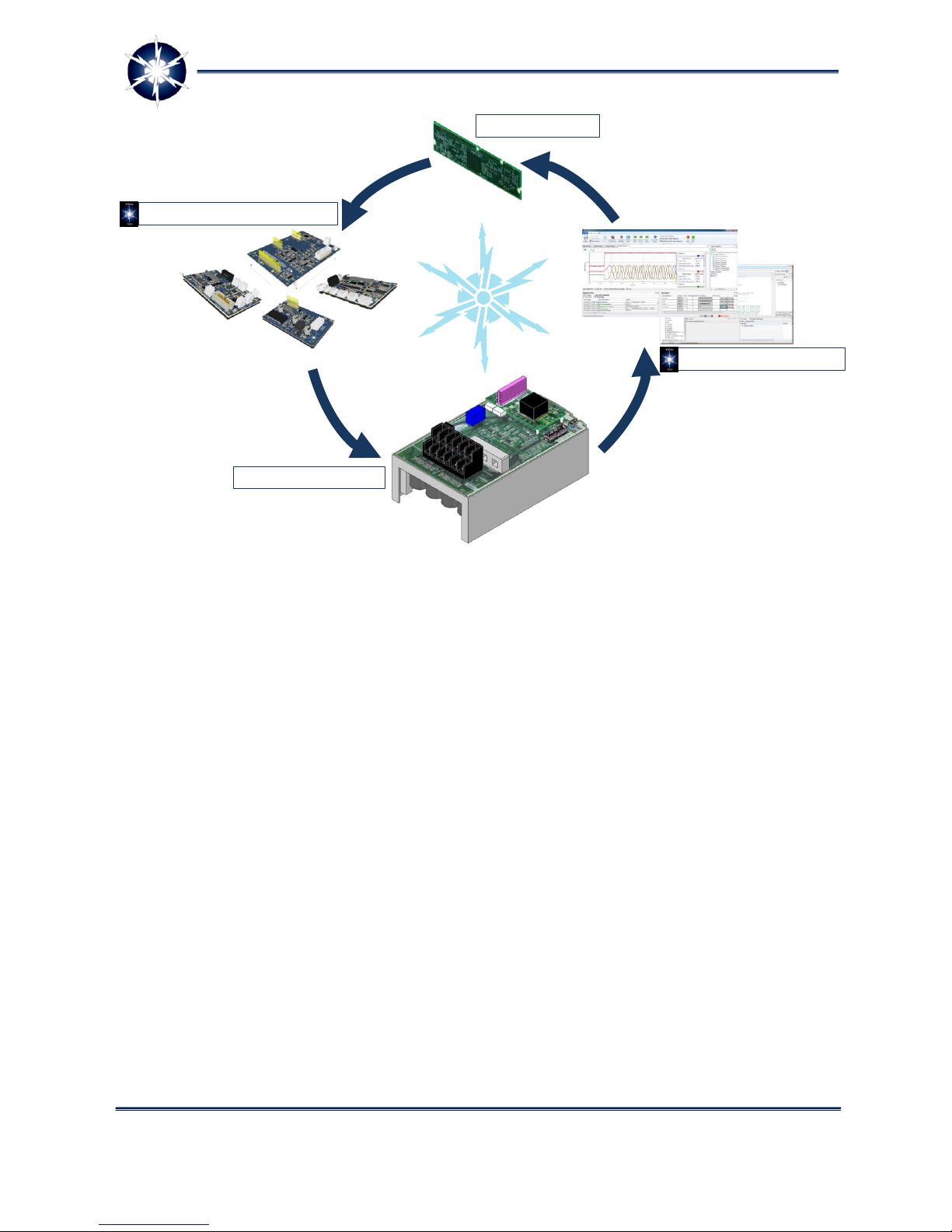

The idea behind LARA-100 is very simple and it can be summarized as follows (Figure 1): let us take

one standard, market available power electronics converter and transform it into the open and re-

configurable platform. How are we supposed to do so?

Power Electronics Research Unified Technologies

www.perun-power.com

3

PERUN Technologies

Figure 1: LARA-100 concept - reconfigurable platform to support applications in your focus

Simply, we will employ the industrial converter's power stage and combine it with LARA's PowerBox

which contains:

LARA's Expansion Boards and

PERUN PowerDesk software suite.

The role of LARA's Expansion Boards together with the PERUN PowerDesk SW is crucial in the concept

of LARA-100 as the open and configurable platform. The role of Expansion Boards is:

interfacing with popular controllers such as Texas Instruments C2000 series

expanding the scope of possible LARA's applications (motor drives, renewables, automotives,

etc.)

communication with variety of external devices such as encoders, resolvers, PLCs, other LARAs,

etc. through CAN, USB, Ethernet, JTAG and RS485.

LARA-100 Expansion Boards are:

LARA-100 Motherboard as the main component together with -

Application Boards

Communication and

GPIO Boards.

Power Electronics Research Unified Technologies

www.perun-power.com

4

PERUN Technologies

LARA-100 Motherboard has two main functions: the

first one is to enable easy plug-in of controllers (Texas

Instruments C2000 series) and the second one is to

host other Expansion boards based on plug-in

principle. You might think of it in similar way as of PC

motherboard.

The role of LARA-100 Application Boards (APP

Boards) is to extend the LARA-100 system

functionalities and features related to specific power

electronics applications. There are two main types of

Application boards: Motor drive and Grid-Connected.

The first one enables direct interfacing with

incremental/absolute encoders, resolvers or tachogenerators. The second one supports interfaces

with grid voltage lines, photovoltaic (PV) strings, currents measurements, etc. i.e. supports grid-

connected applications.

LARA-100 Communication Boards or simply COMM Boards are compact boards for extension of

LARA-100 system with a variety of standard communication interfaces such as Ethernet, CAN or RS-

485 communication buses. Application note: COMM Boards are ideal solution for expanding LARA-

100 power converters in order to form complex systems such as micro- and smart-grids, where

COMMs are connected with supervisory controllers and several LARAs that stand for different grid

elements.

LARA-100 GPIO (General Purpose Input/Output) comes with all sorts of digital and analog input

and output circuitries. Suitable GPIO Board directly interfaces switches, buttons, power relays,

power contactors, power LEDs, meters, or industrial PLCs with LARA-100 system controller and

quickly build power electronics hardware platform immediately ready for control development and

testing.

LARA's software suite PERUN PowerDesk is responsible for

system configuration

supervisory control

data acquisition

real time access to all controller variables

analysis of measured signals (real time filtering, Fourier)

mathematical manipulations over signals in real time

control design tools (Bode plots, etc.)

Very important fact is that PERUN PowerDesk can be utilized as an integral part of LARA-100 system as

described above, but also it can be employed as a standalone software package. In this scenario a user

can develop and test a control code on Texas Instruments C2000 controller using Perun PowerDesk for

all mentioned purposes except for system configuration (since there is no LARA's hardware). What do

you need in this case? Clearly you need some kind of a docking board to plug in controller and a PC with

installed PERUN PowerDesk. You can use either LARA-100 Motherboard or TI's Experimenter's kit in the

role of the docking board.

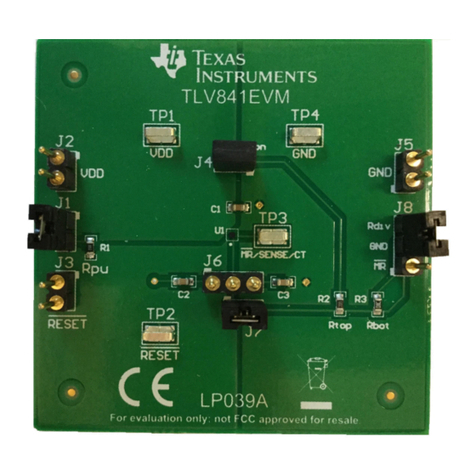

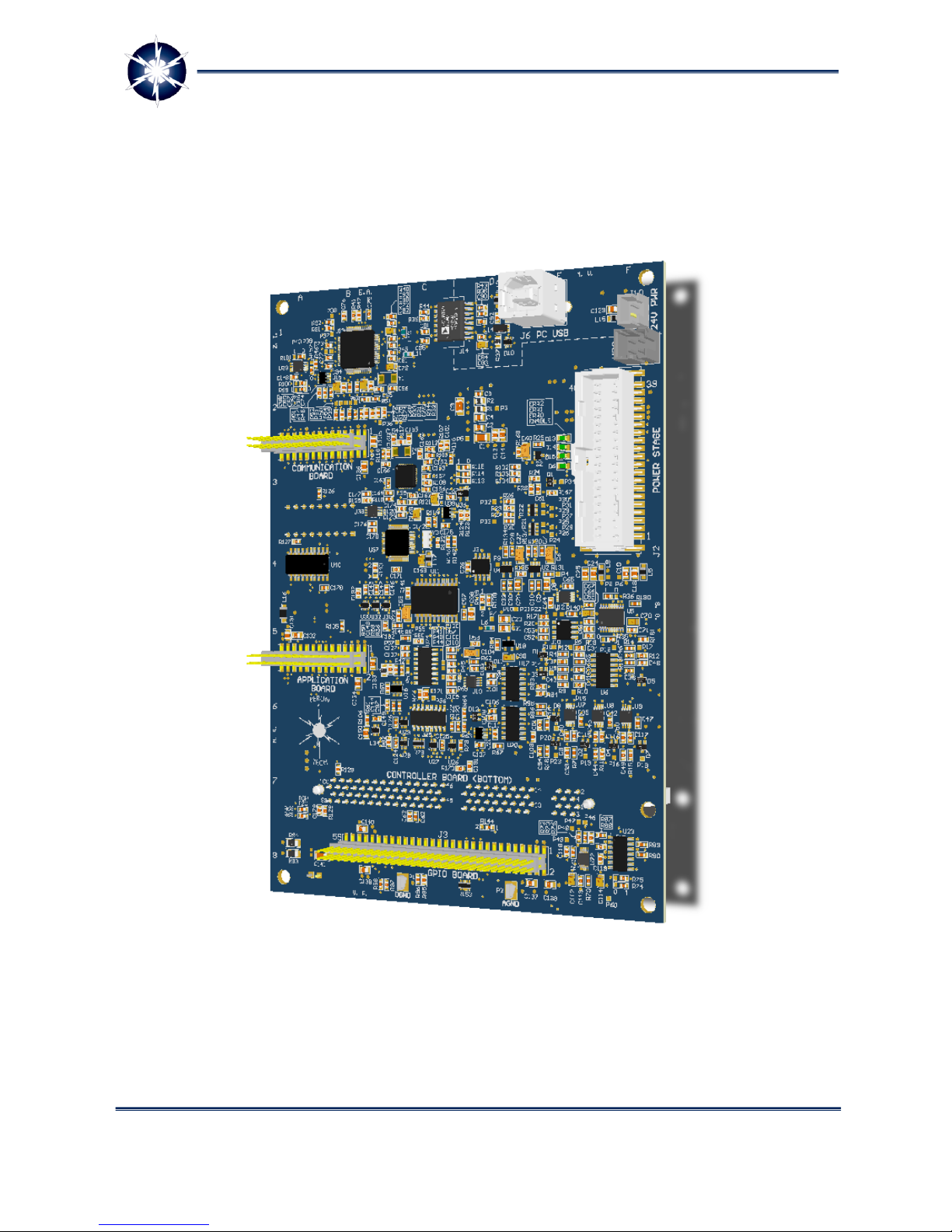

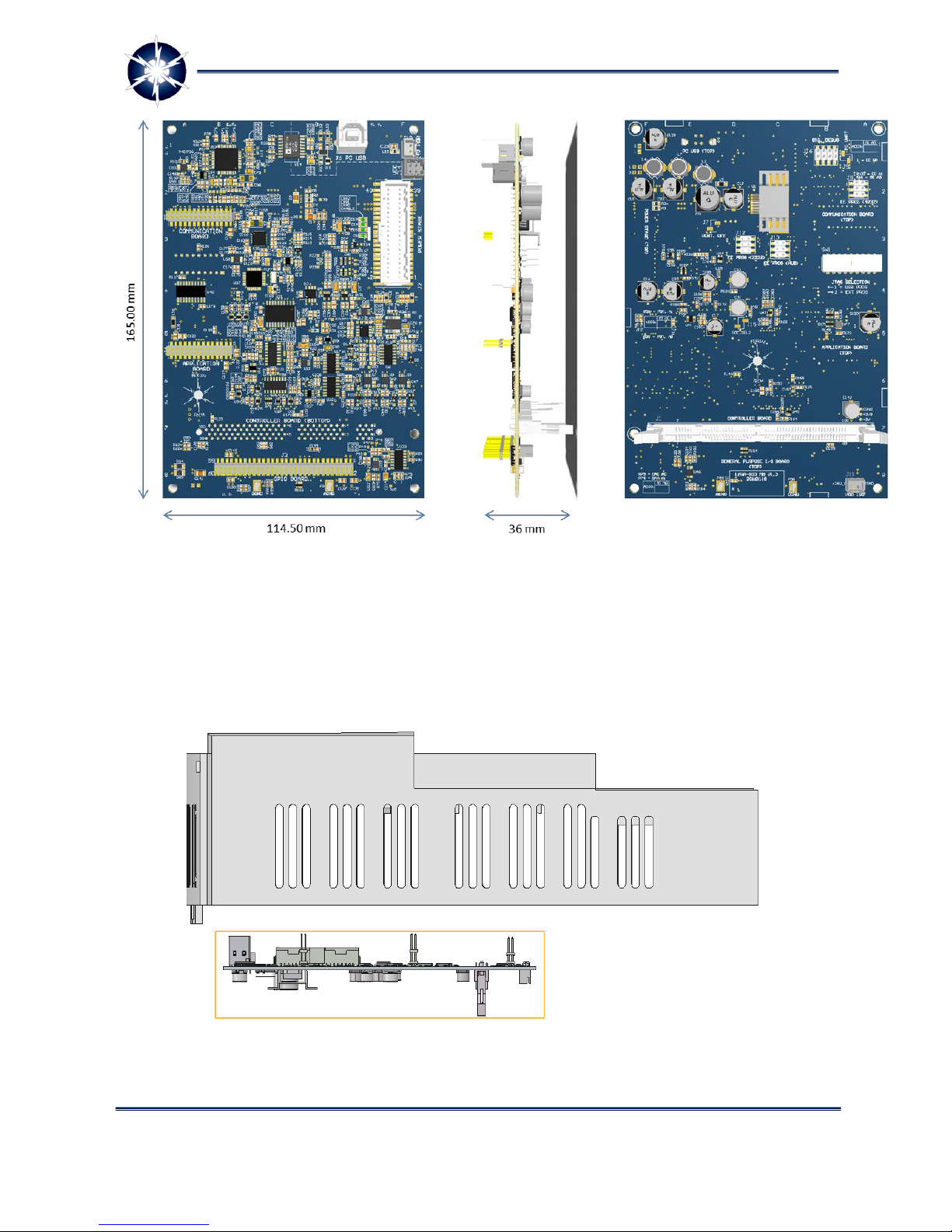

Figure 2: LARA-100 Motherboard

Power Electronics Research Unified Technologies

www.perun-power.com

5

PERUN Technologies

Automatic code generation (auto-coding) from Matlab Simulink is supported in PERUN PowerDesk

which makes the process of control design much easier and comfortable. Simply, auto-coding is here to

generate the designed algorithm and PERUN PowerDesk tools proceed with evaluation, testing and re-

design.

LARA-100 with its HW and SW components presents well rounded and open re-configurable platform

(Figure 3).

Frequently asked questions related to PERUN PowerDesk software suite:

Can I use PERUN PowerDesk without LARA-100 hardware?

The answer is yes. You can use PPD for in a standalone version. In that case you can test and debug

your control code for any kind of application. All you need is Texas Instruments C2000 DSP, a PC with

installed PERUN PowerDesk, a docking board for DSP such as TI’s Experimenter Kit or LARA’s

Motherboard

Can I write a control code directly from PERUN PowerDesk?

The answer is no. The writing of control code is performed with the tool which provides controller

manufacturer, for instance Code Composer Studio if you use Texas Instruments Controller. The role of

PERUN PowerDesk is to assist you in Comfortable higher level debugging and testing through Tag

Explorer, Oscilloscope function and real time signal manipulations and analysis.

What is the difference between PPD Standalone and version which comes with LARA-100?

Both versions have the same key features (PERUN Tag Explorer, Oscilloscope and Signal Analysis Desk.

The version which comes with LARA has a link to LARA HW and therefore enables supervisory control

of LARA configured in one of required Power Electronics applications

Power Electronics Research Unified Technologies

www.perun-power.com

6

PERUN Technologies

Figure 3: LARA-100 main components

In the continuation of this document the focus is set to LARA-100 Motherboard.

Industrial Converter

PERUN’s Expansion Boards

User’s controller

PERUN PowerDesk SW

LARA-100

Power Electronics Research Unified Technologies

www.perun-power.com

7

PERUN Technologies

2LARA 100 MOTHERBOARD

LARA-100 MOTHERBOARD is a main board interfacing power electronics stage (Power Stage) and its

controller (Controller Board). Making and putting together fully-functional power electronics devices

opened for control development and testing, have never been easier!

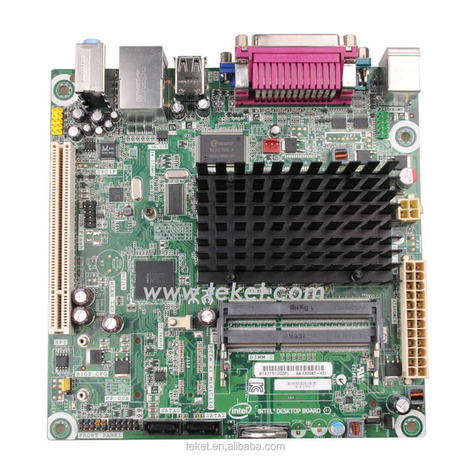

Figure 4: LARA 100 Motherboard

Figure 5 and Figure 6 gives overview of external connection interfaces.

Power Electronics Research Unified Technologies

www.perun-power.com

8

PERUN Technologies

Figure 5: LARA 100 Motherboard connectors –upper side

Power Electronics Research Unified Technologies

www.perun-power.com

9

PERUN Technologies

Figure 6: LARA 100 Motherboard connectors –bottom side

Connectors have the following meaning:

1 –Communication Board interface –Connect supervisory and power stage controller over different

communication buses, such as RS-232, RS-485, CAN or Ethernet, with just plugging suitable PERUN’s

Communication Board.

2 –Application Board interface –Adapt the LARA-100 system to the specific power electronics

application, using one of the PERUN’s Application Boards. Go ahead and work with motor drives, grid-

connected converters or solar boost converters right away.

Power Electronics Research Unified Technologies

www.perun-power.com

10

PERUN Technologies

3 –Controller Board interface (on bottom side) –See note 7.

4 –USB interface –Configure, monitor and control your power electronics device through PERUN’s

PowerDesk software suite.

5 –Power Stage interface –Interface all control, feedback and protection signals of power stage in

appropriate and safe manner with your controller.

6 –GPIO Board interface –Take advantage of PERUN’s GPIO Boards, and expand functionality of your

power electronics device through different digital and analog inputs and outputs.

7 –Controller Board interface –LARA-100 Motherboard has DIMM100 socket for connecting the power

stage controller. This makes it plug-and-play compatible with wide range of Texas Instruments C2000

control cards. Just plug TMS320F28335 controlCARD, upload appropriate PERUN’s example code and

you are ready to control your power stage.

8 –JTAG selection switch –Select between on-board XDS100 JTAG programmer / debugger or external

programmer / debugger connected to the corresponding connector on PERUN’s Communication Board.

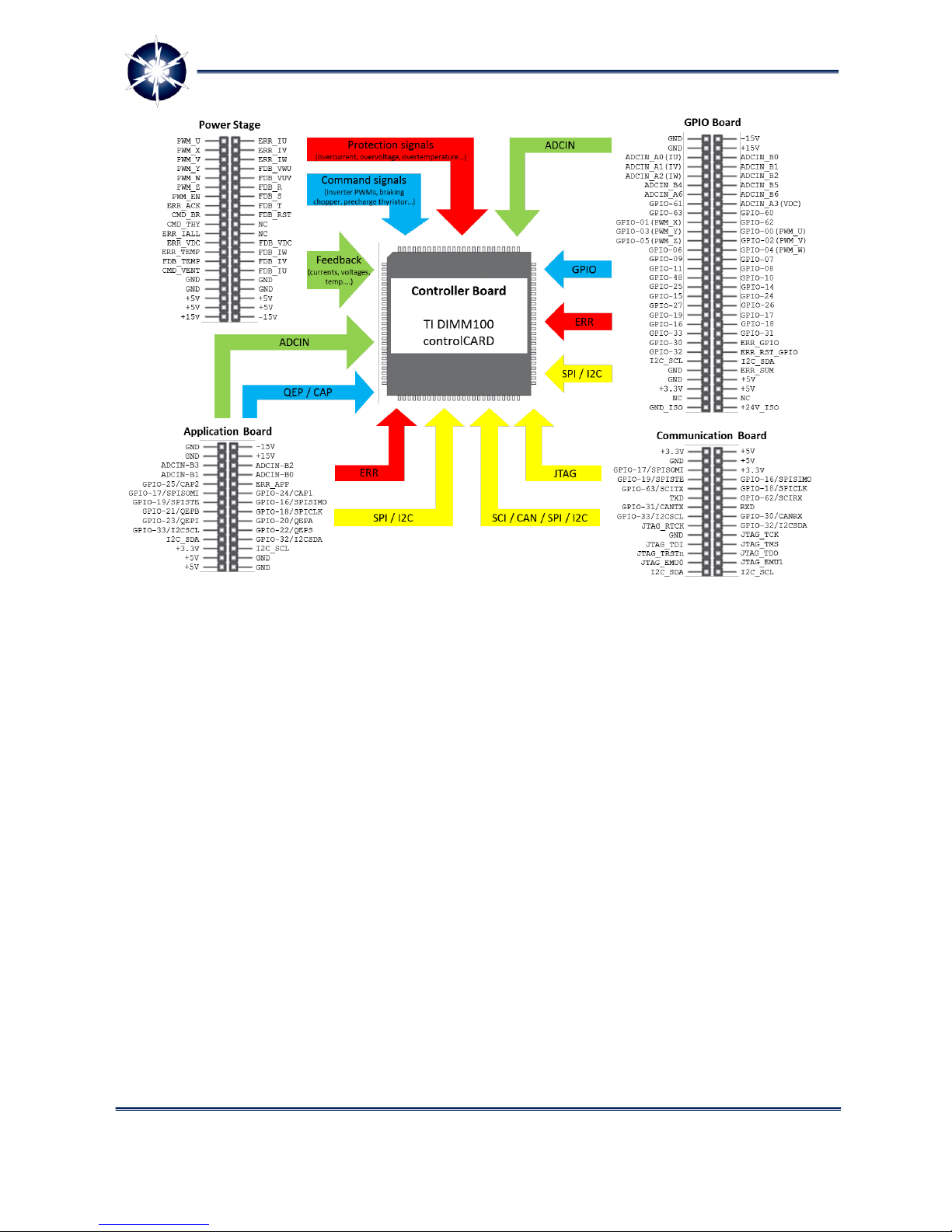

LARA-100 Motherboard is plug-and-play solution compatible with all Texas Instruments industry-

standard DIMM100 controlCards, such as TMDSCNCD28335 with TMS320F28335 high-performance

floating-point controller that operates at 150 MHz, has 256K x 16-bits Flash, 34K x 16-bits SRAM, and

I/O peripherals optimized for power electronics applications. Having sockets for Power Stage,

Application, GPIO and Communication Boards, LARA-100 Motherboard utilizes all of the controller’s

peripheral I/Os important for LARA-100 power electronics system control. This makes LARA-100 system

easy adaptable to various power electronics applications and different supervisory controllers.

Motherboard functionalities can be extended by using various PERUN’s Application, GPIO and

Communication Boards. Figure 6 gives an overview of connections between TI DIMM100 Control Cards

and Motherboard’s main connectors.

Power Electronics Research Unified Technologies

www.perun-power.com

11

PERUN Technologies

Figure 7: Pinout of LARA 100 Motherboard connectors and overview of controller

connections

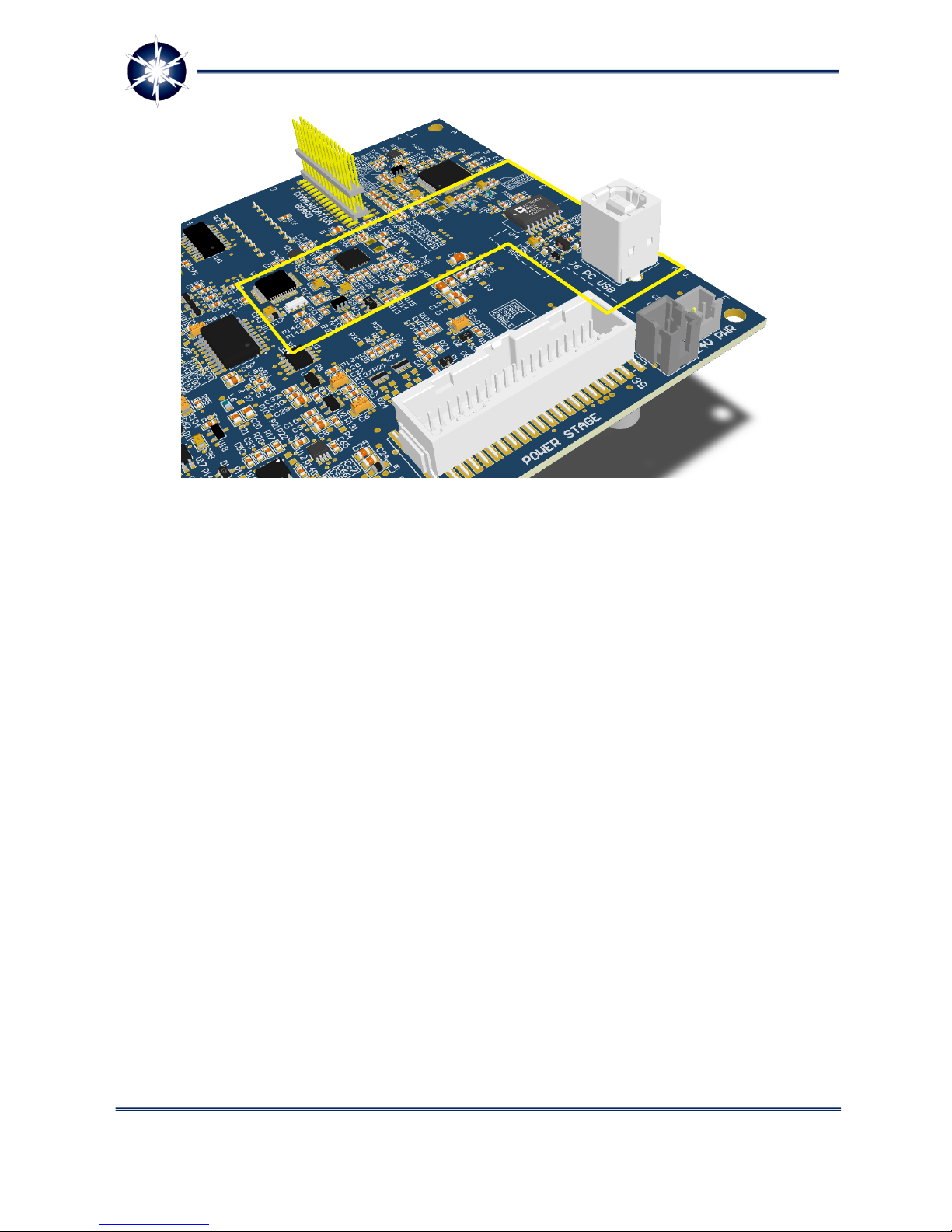

Controller on-board JTAG programmer/debugger

To make your control prototyping experience as convenient as possible, LARA-100 Motherboard has

built-in XDS100 v1 JTAG programmer/debugger. User can use standard programming/debugging

environment, such as Texas Instruments Code Composer Studio, or directly program and debug his

controller with PERUN PowerDesk software. He just needs to connect Motherboard with dedicated USB

link to the programming environment and he is ready to upload control code. Optionally, desired

external JTAG programmer/debugger can be used by connecting it to the controller through our

Communication Boards. Motherboard’s USB/JTAG interface, and moreover JTAG interface on

Communication Boards, are galvanically isolated from user’s programming/debugging device.

Power Electronics Research Unified Technologies

www.perun-power.com

12

PERUN Technologies

Figure 8: Controller on-board JTAG programmer/debugger interface

Control code debugging

By using PERUN PowerDesk software user can efficiently eradicate mistakes and iron out control code in

various applications, such as motor drive, PV boost converter or grid-connected converter in order to

work according to set requirements. It’s project-organized easy-to-use software environment used for

configuration, monitoring and high-level control of whole LARA-100 system. It’s special features are

Scope function allowing user to monitor any of controller’s real-time variables and Tag Explorer for

setting control variables and parameters reference values, turning the PERUN PowerDesk into ideal

platform for high-level debugging of power electronics applications. Motherboard’s USB/UART

debugging interface is galvanically isolated from user’s programming/debugging device (PC with PERUN

PowerDesk software). Moreover, you can use PERUN PowerDesk for control code high-level debugging

of any embedded microcontroller system with integrated USB/UART bridge.

Power Electronics Research Unified Technologies

www.perun-power.com

13

PERUN Technologies

Figure 9: Control code debugging

Technical specification for Motherboard

LARA-100 Motherboard dimensions and fixture holes are carefully designed in order to fit into the

original cover box of the industrial power converter. Just replace original controller board with PERUN

Motherboard, connect Motherboard and Power Stage with dedicated connector, and Power Stage is

ready for use. There is no need for multitude of long wires connecting the controller and power stage

units, controller is nicely packed locally where the power stage is, making the whole LARA-100 system

much less sensitive to signal noise typical for power electronics devices switching nature. In that way,

complete LARA-100 system have external layout as industrial drives, which is not usual case with open

development platforms.

www.perun-

power.com

Power Electronics Research Unified Technologies

www.perun-power.com

14

PERUN Technologies

Figure 10: LARA 100 Motherboard dimensions

Following figures represent process of mounting Motherboard on the industrial power stage (only

mechanical cover is shown).

Power Electronics Research Unified Technologies

www.perun-power.com

15

PERUN Technologies

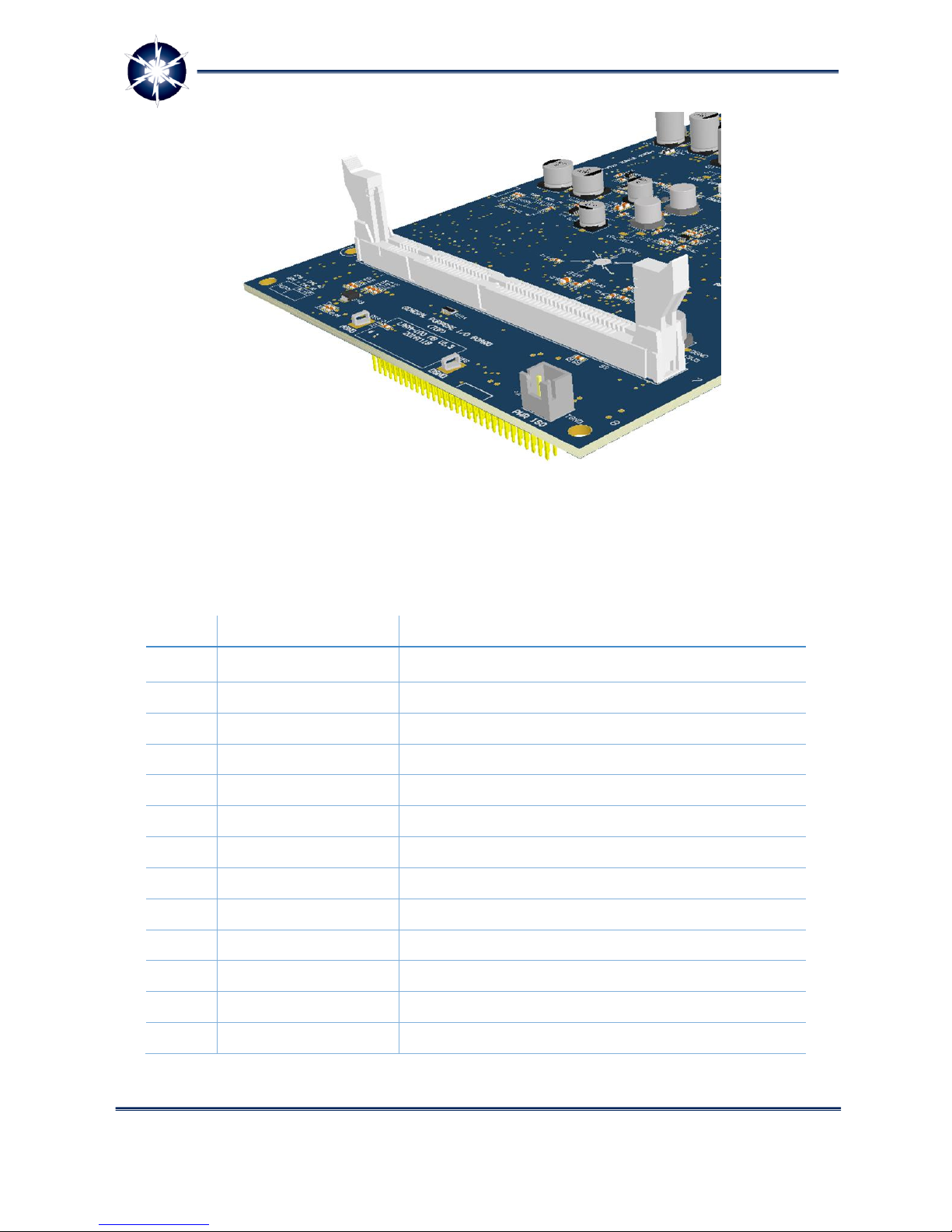

Figure 11: Power Stage cover box and LARA-100 Motherboard aligned for mounting –look

from the left (upper figure). Power Stage cover box and mounted LARA-100 Motherboard –

look from the front (bottom figure).

Figure 12: Power Stage cover box and mounted LARA-100 Motherboard. Look from the top

and bottom.

Power Electronics Research Unified Technologies

www.perun-power.com

16

PERUN Technologies

Figure 13: Power Stage cover box and mounted LARA-100 Motherboard, ready for

connection to Power Stage, LARA-100 Expansion Boards (GPIO, APP, COMM) and PC with

PERUN PowerDesk software.

Motherboard’s top side connectors are properly aligned with cover box holes, and at the bottom side

there is a connector (J1) for Controller Board.

Connections –Controller Board (J1)

LARA-100 Motherboard has DIMM100 connector (TE Connectivity part number 5390213-1, standard

MO-161) for direct use with compatible Texas Instruments controlCARDs or custom made Controller

Boards. It is placed on the bottom side of Motherboard, in the slot shown in Figure 14.

Power Electronics Research Unified Technologies

www.perun-power.com

17

PERUN Technologies

Figure 14: Controller board connector (J1)

A pin assignment of controller board connector is given in following table:

Table 1: Pin assignment of controller board interface (J1)

Pin

Signal

Description

1

N.C.

Not used

2

N.C.

Not used

3

N.C.

Not used

4

N.C.

Not used

5

N.C.

Not used

6

N.C.

Not used

7

N.C.

Not used

8

N.C.

Not used

9

N.C.

Not used

10

N.C.

Not used

11

N.C.

Not used

12

N.C.

Not used

13

ADCIN-B0

Controller analog input B0

Power Electronics Research Unified Technologies

www.perun-power.com

18

PERUN Technologies

Pin

Signal

Description

14

DSP_IU/ADCIN-A0

Measured inverter line current IU

15

GND

Electronics ground reference

16

GND

Electronics ground reference

17

ADCIN-B1

Controller analog input B1

18

DSP_IV/ADCIN-A1

Measured inverter line current IV

19

GND

Electronics ground reference

20

GND

Electronics ground reference

21

ADCIN-B2

Controller analog input B2

22

DSP_IW/ADCIN-A2

Measured inverter line current IW

23

GND

Electronics ground reference

24

GND

Electronics ground reference

25

ADCIN-B3

Controller analog input B3

26

DSP_VDC/ADCIN-A3

Measured DC-link voltage

27

GND

Electronics ground reference

28

GND

Electronics ground reference

29

ADCIN-B4

Controller analog input B4

30

DSP_TEMP/ADCIN-A4

Measured heatsink temperature

31

N.C.

Not used

32

N.C.

Not used

33

ADCIN-B5

Controller analog input B5

34

VREF/ADCIN-A5

Reference offset voltage (for currents)

35

PPD_RST/GPIO-58

Reset PERUN PowerDesk (PPD) scope

36

ERR_RST_DSP/GPIO-59

Error reset/acknowledgment

37

ADCIN-B6

Controller analog input B6

38

ADCIN-A6

Controller analog input A6

39

GPIO-60

Controller general purpose input/output 60

40

GPIO-61

Controller general purpose input/output 61

41

ADCIN-B7

Controller analog input B7

42

ERR_CODE/ADCIN-A7

Error code in analog format

43

GPIO-62/SCIRX-C

Controller GPIO or SCI pin 1)

Power Electronics Research Unified Technologies

www.perun-power.com

19

PERUN Technologies

Pin

Signal

Description

44

GPIO-63/SCITX-C

Controller GPIO or SCI pin 1)

45

DSP_GU/GPIO-

00/EPWM-1A

PWM signal for upper switch phase U

46

DSP_GX/GPIO-

01/EPWM-1B

PWM signal for lower switch phase U

47

DSP_GV/GPIO-

02/EPWM-2A

PWM signal for upper switch phase V

48

DSP_GY/GPIO-

03/EPWM-2B

PWM signal for lower switch phase V

49

DSP_GW/GPIO-

04/EPWM-3A

PWM signal for upper switch phase W

50

DSP_GZ/GPIO-

05/EPWM-3B

PWM signal for lower switch phase W

51

GPIO-06/EPWM-4A

Controller GPIO or PWM pin 1)

52

GPIO-07/EPWM-

4B/ECAP-2

Controller GPIO or PWM or CAP pin 1)

53

GND

Electronics ground reference

54

+5V

Power supply +5V for Controller Board

55

GPIO-08/EPWM-5A

Controller GPIO or PWM pin 1)

56

GPIO-09/EPWM-

5B/ECAP-3

Controller GPIO or PWM or CAP pin 1)

57

GPIO-10/EPWM-6A

Controller GPIO or PWM pin 1)

58

GPIO-11/EPWM-

6B/ECAP-4

Controller GPIO or PWM or CAP pin 1)

59

DSP_VUV/GPIO-

48/ECAP-5

Measured inverter output voltage VUV

60

PWM_EN/GPIO-49

PWM enable signal

61

N.C.

Not used

62

N.C.

Not used

63

N.C.

Not used

64

+5V

Power supply +5V for Controller Board

65

ERR/GPIO-12/TZ-1

Error signal (indicating error state) 1)

66

ERR_DSP/GPIO-13

Controller error triggering signal

Other manuals for LARA-100 COMM

2

Table of contents

Other Perun Technologies Motherboard manuals

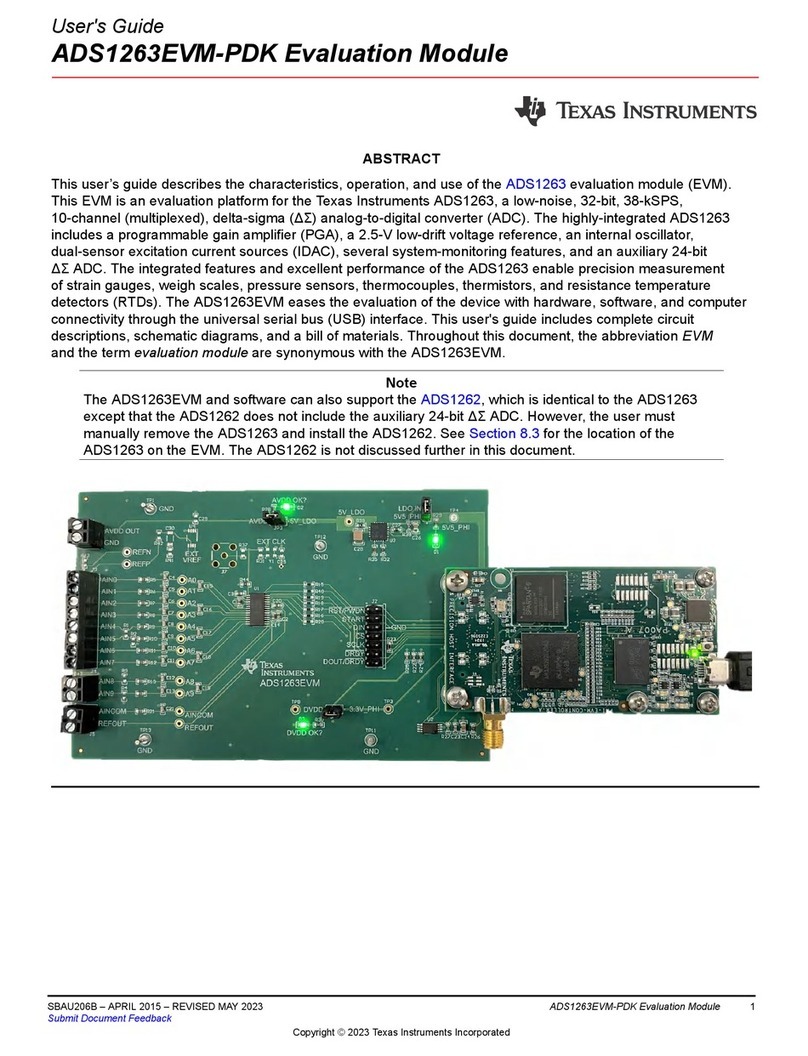

Popular Motherboard manuals by other brands

Texas Instruments

Texas Instruments ADS1263EVM-PDK user guide

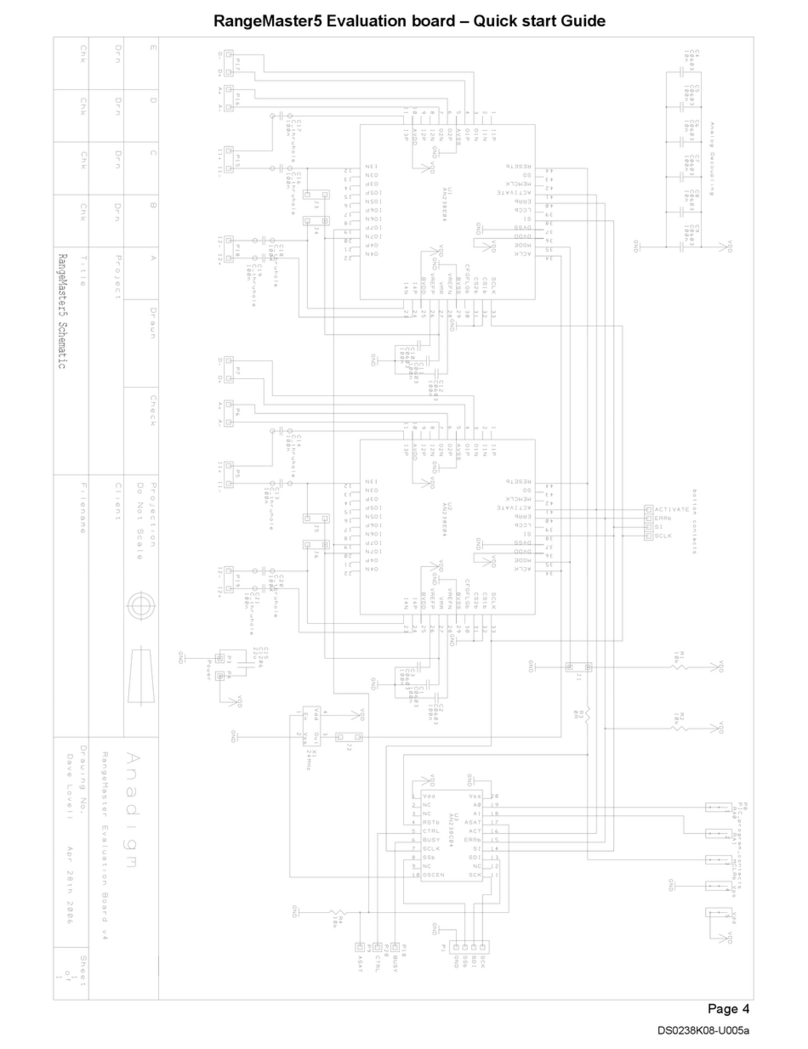

Anadigm

Anadigm RangeMaster5 quick start guide

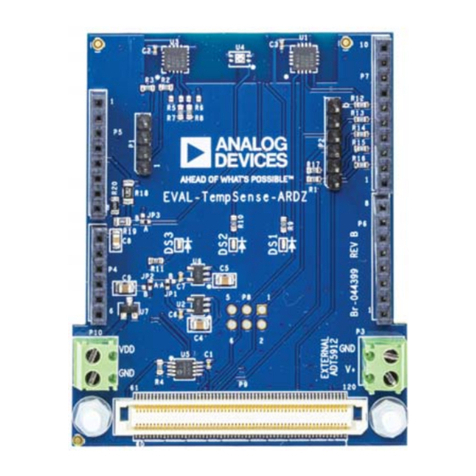

Analog Devices

Analog Devices EV-TEMPSENSE-ARDZ user guide

Linear Technology

Linear Technology Analog Devices DC1890A Demo Manual

Linear Technology

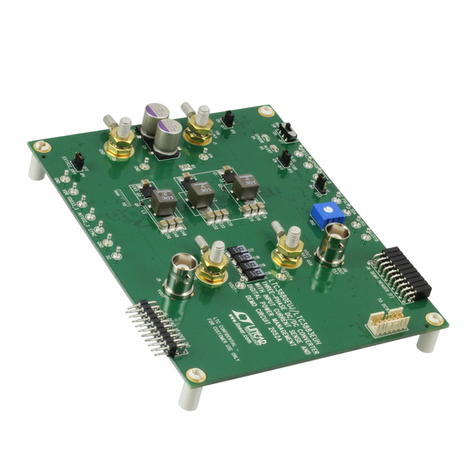

Linear Technology DC1472A Demo Manual

Linear Technology

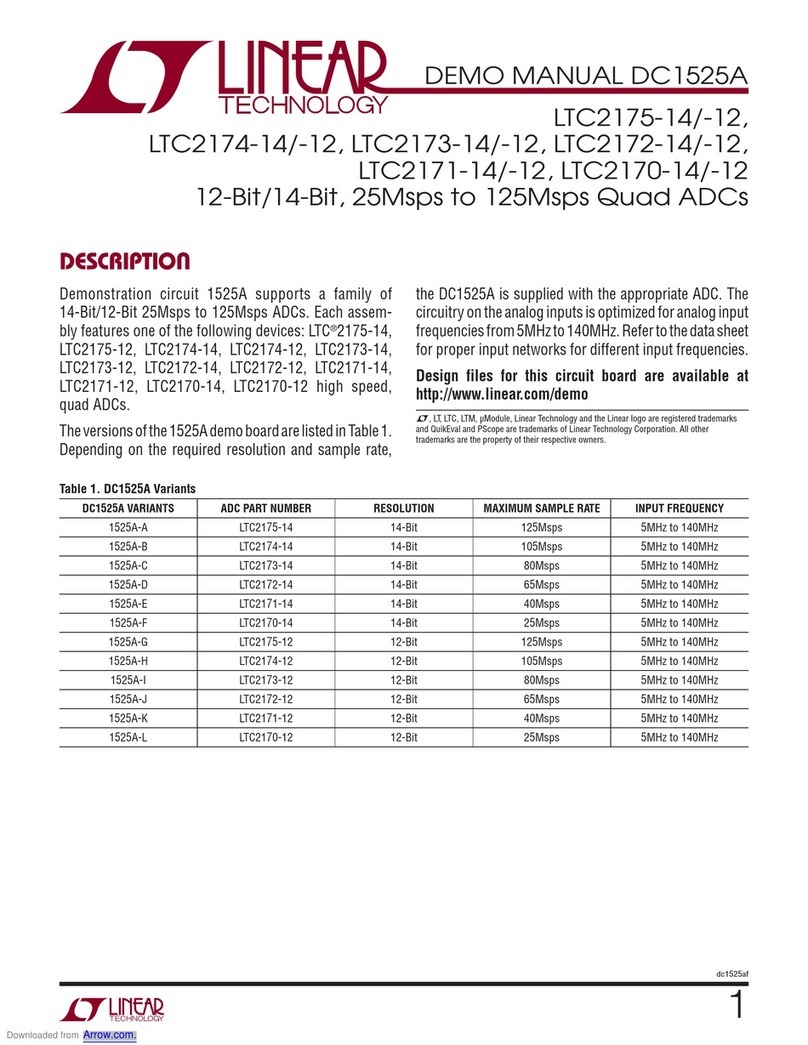

Linear Technology DC1525B-D Demo Manual