1.4. Framework:

Please refer to the layout drawings section of the installation manual.

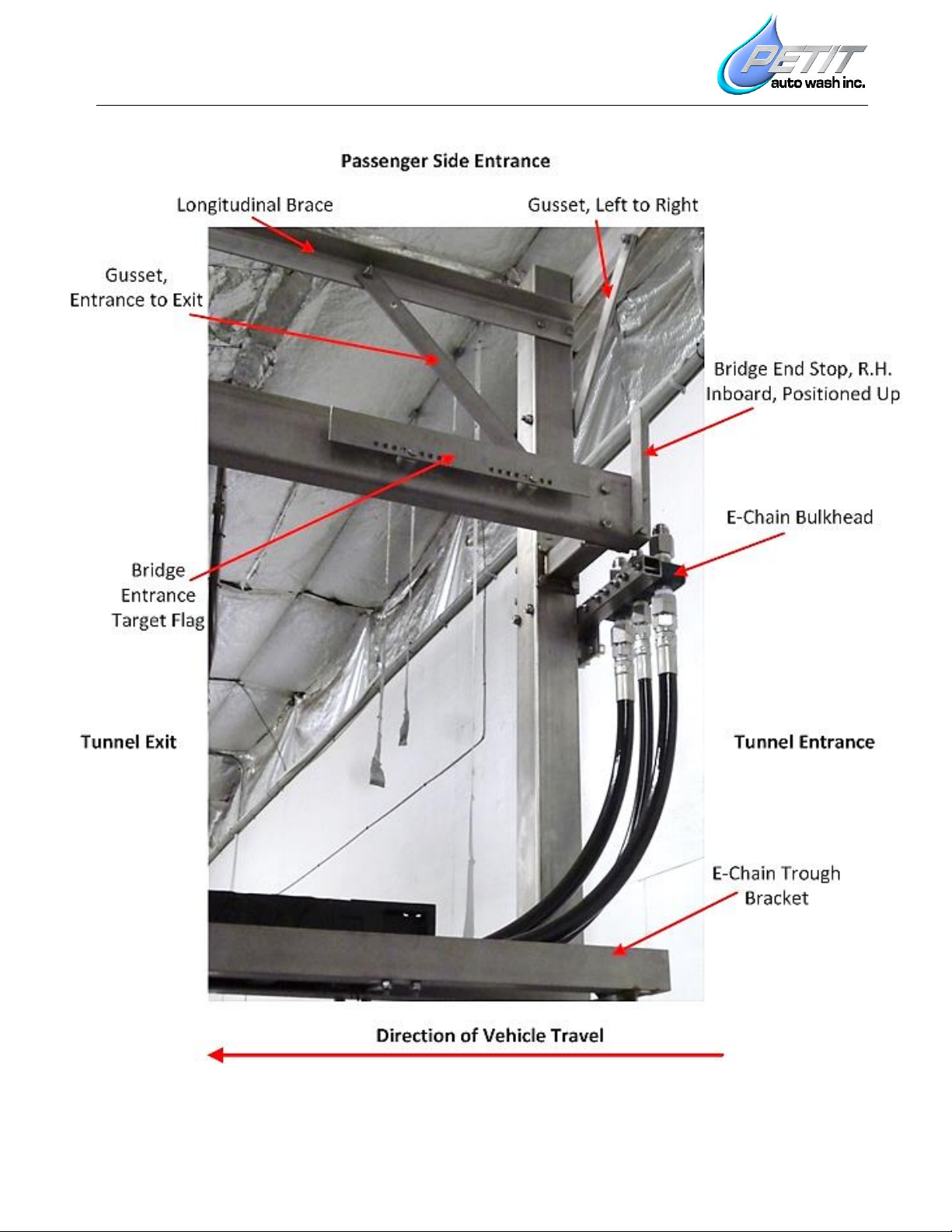

20” of clearance above the Bridge Rails is needed to unfold the Top Washer. T-Bars are held to their

mounting blocks with a shear bolt, do not replace with a regular bolt. Ensure the T-bars are parallel with

each other and perpendicular to the machine rails. Bridge Keepers bolt on to the outside of the Bridge

End Plates.

Legs are universal but are also directional. Orient all the legs with the drain holes facing inboard or

toward the center of the bay. All bolts should be inserted from inboard to outboard, so nuts are on

outside of legs.

Note that the P.S. Main Rail has two Proximity Switch Target Flags each on the inboard side of the

rail located at the entrance & exit end of the rail. The D.S. Main Rail has one Proximity Switch

Target Flag on the inboard side of the rail. Both Main Rails mount w/ the 4-bolt flange holes

toward the bottom.

When installing the Framework, it is important to fasten the legs to the floor exactly as depicted in

the drawing. Leave the entire framework and floor anchors slightly loose, then use a level to

insure the legs are plumb vertically (front/rear and left/right), before tightening all framework

fasteners. Fully tighten the floor anchors last.

Alternately: If enough man power and Genie Lifts are available wait until the entire framework is

assembled to fasten the legs to the floor. This will allow you to verify the correct position of the

legs.

Referring to the Rail Kit drawing, layout and mark the floor where each of the legs for the 360-t frame

will sit.

Assemble the Cross beams to the legs. If the factory Crossover Plumbing was purchased, one of the Top

Crossbeams already has channel strut & plumbing attached. This Crossbeam must be used on the

entrance legs. The Entrance Crossbeam is attached to the entrance side of the legs. The Exit Crossbeam

is typically attached to the exit side of the legs. Be sure to square the legs to the Beam when attaching

Left to Right Frame Gussets. Tighten the bolts until they are snug, but do not fully tighten at this time.

Stand up either the Exit or Entrance Cross Beam/ Leg assembly, position the legs EXACTLY as

dimensioned in the drawing. Use the corner-to-corner dimension in the drawing to verify squareness

and fasten loosely to floor.

Stand up the remaining Exit or Entrance Cross Beam/ Leg assembly and attach the two Longitudinal

Braces and the Entrance to Exit Gussets, then fasten loosely to the floor.