OPERATION

WARNING

Pressure Relief Procedure

To

reduce the risk

of serious bodily injury

, including

splashing in the eyes or on the skin or injury from

moving parts, always follow this procedure when

shutting

of

f the system, when

checking or servicing

any part of the spray system, when installing,

cleaning or changing fluid nozzles, and whenever

you

stop spraying.

1. T

urn of

f the air and fluid supply to the gun.

2. Trigger the gun into a grounded metal waste

container

to relieve fluid pressure.

Filter the Fluid

Filter the fluid to remove coarse particles and sediment

which

could clog the spray nozzle.

Select a Needle/Nozzle Set and Air Cap

Check the viscosity of your paint. Install the proper

needle/nozzle

set and air cap combination, selected from

the

charts on pages 5 and 6.

CAUTION

Trigger the gun whenever you tighten or remove

the nozzle. This keeps the needle seat away from

the nozzle seating surface and prevents the seat

from

being scratched.

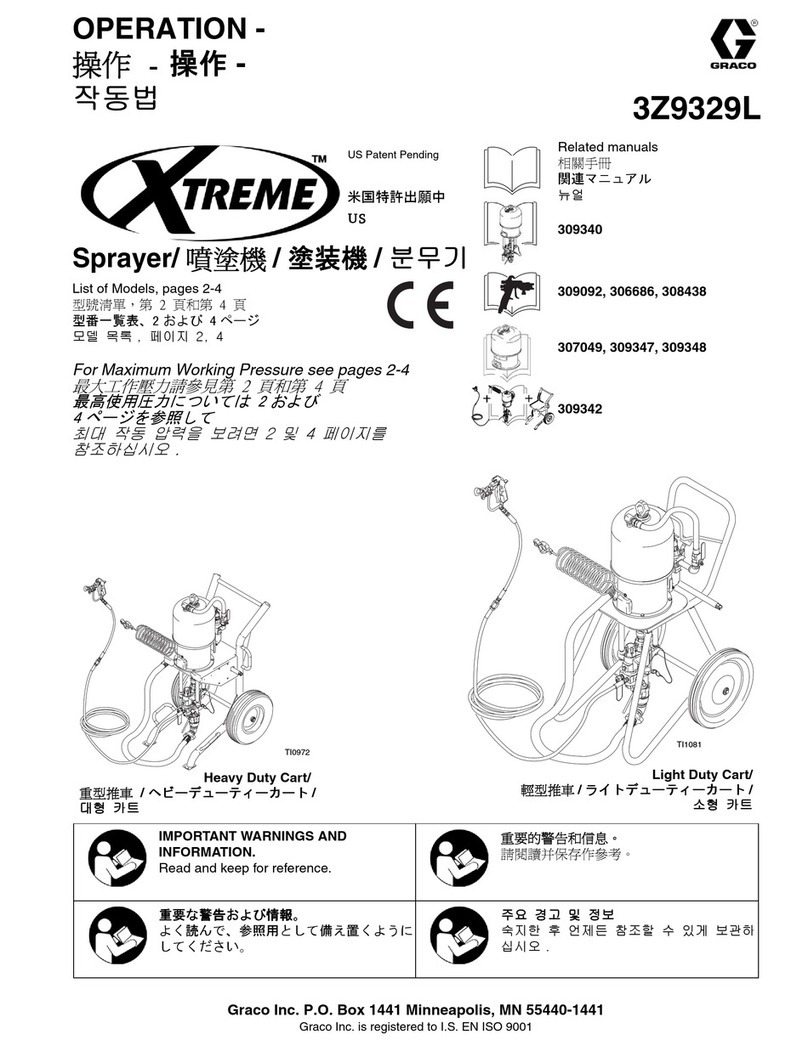

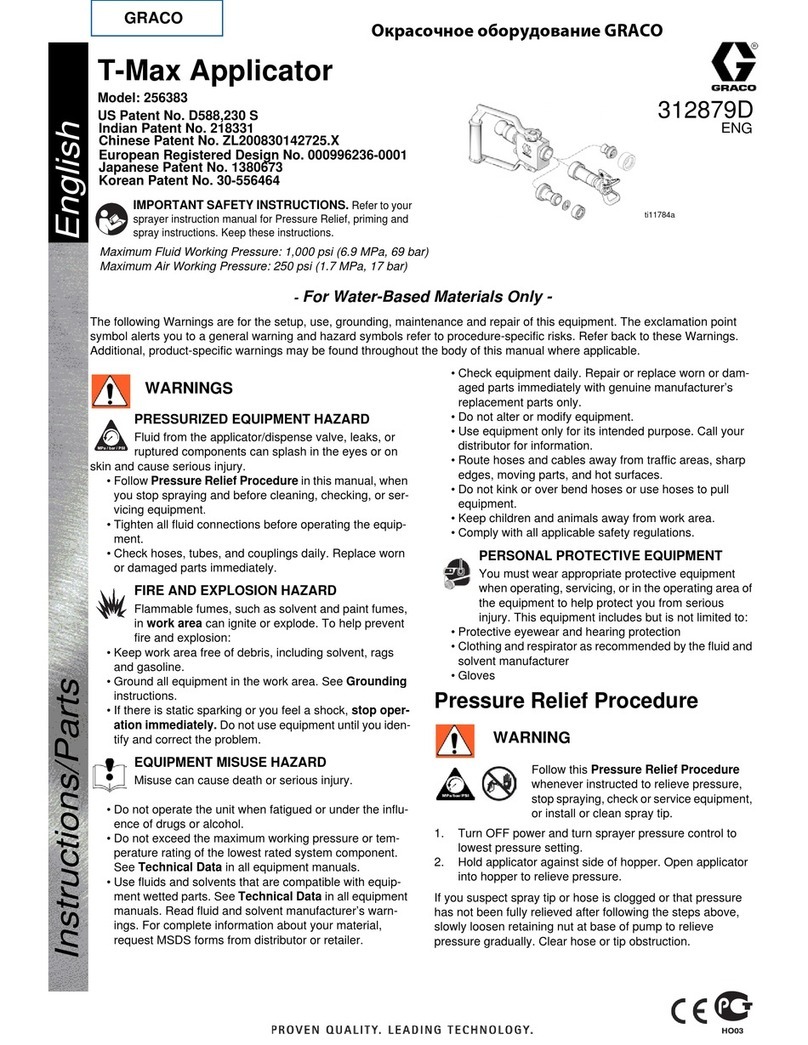

Position the Air Cap

Rotate

the air cap as needed to achieve the desired spray

pattern direction. See Fig 2. T o create a round pattern,

turn

the pattern air of

f.

Vertical Pattern

Horizontal Pattern

Fig

2

Adjust the Spray Pattern

Follow these steps to establish the correct fluid flow

and

air

flow:

1. Adjust the fluid flow by using the fluid pressure

regulator

installed in the fluid line.

2. The

spray gun has a 15 psi (1 bar) maximum recom

-

mended inlet air pressure. Using the air pressure

regulator, set the air line pressure according to the

fluid

manufacturer

’s

recommendations for a high vol

-

ume,

low pressure application. Local laws may limit

the air line maximum pressure to 10 psi (0.7 bar).

NOTE: The

H.E.L.P

. 1500 System is factory set to 10 psi

(0.7

bar) air pressure with 100 psi (7 bar) air pres

-

sure at inlet. The pressure can be reduced by

adjusting

the air supply adjustment knobs.

3. Adjust

the pattern size by turning the pattern adjust

-

ing

valve

OUT (counterclockwise)

for a wider pattern

or

IN (clockwise)

for a narrower pattern.

4. T

o adjust the volume of fluid output:

a. Turn the fluid adjusting knob out

(counterclock-

wise)

until no restriction of the trigger

movement

is

felt. Refer to Fig 1.

b. Then

adjust the air pressure at the pressure

pot

or

pump until the desired fluid flow is obtained.

WARNING

DO NOT

exceed the gun’ s 100 psi (7 bar) maxi-

mum fluid pressure. Higher pressures can cause

parts

to rupture and result in serious bodily injury

or

property

damage.

c. For

final adjustment, turn the fluid adjusting

knob

in

(clockwise)

to reduce the volume of fluid out-

put

and obtain the desired results.

CAUTION

Restricting the trigger and fluid needle travel by

continuously

spraying

with the fluid adjusting knob

turned

in

(clockwise),

will

cause accelerated abra

-

sive wear on the fluid needle and wear on the trig

-

ger/air

valve shaft interface.

For

the best results, adjust the fluid flow at the pres

-

sure pot or pump or use a dif ferent size needle/

nozzle set and air cap combination. See the

SELECTION

CHAR

TS on pages 5 and 6.

NOTE: If

the fluid adjusting valve is turned in all the way

the

gun will emit only air

.

d. The fluid flow can be feathered by partially trig-

gering the fluid needle, except when using the

smallest needle/nozzle/air cap size. See the

charts

on pages 5 and 6.

5.

For continuous spraying,

leave the fluid adjusting

valve in the full open position. This provides maxi-

mum

fluid flow and

prevents premature wear on the

fluid

nozzle.

6. Test

the spray pattern and atomization while

holding

the

gun about 6 to 8 inches (150 to 200 mm) from the

test

piece. Adjust as needed.