ПЛА150.208.010.100РЭ

3

Content

1. Description and work.........................................................................................................................................5

1.1. U-150 Description and work............................................................................................................................5

1.1.1. U-150 Purpose ............................................................................................................................5

1.1.2. Technical characteristics .......................................................................................................5

Table 1 –U-150 Main technical characteristics and parameters..........................................................................5

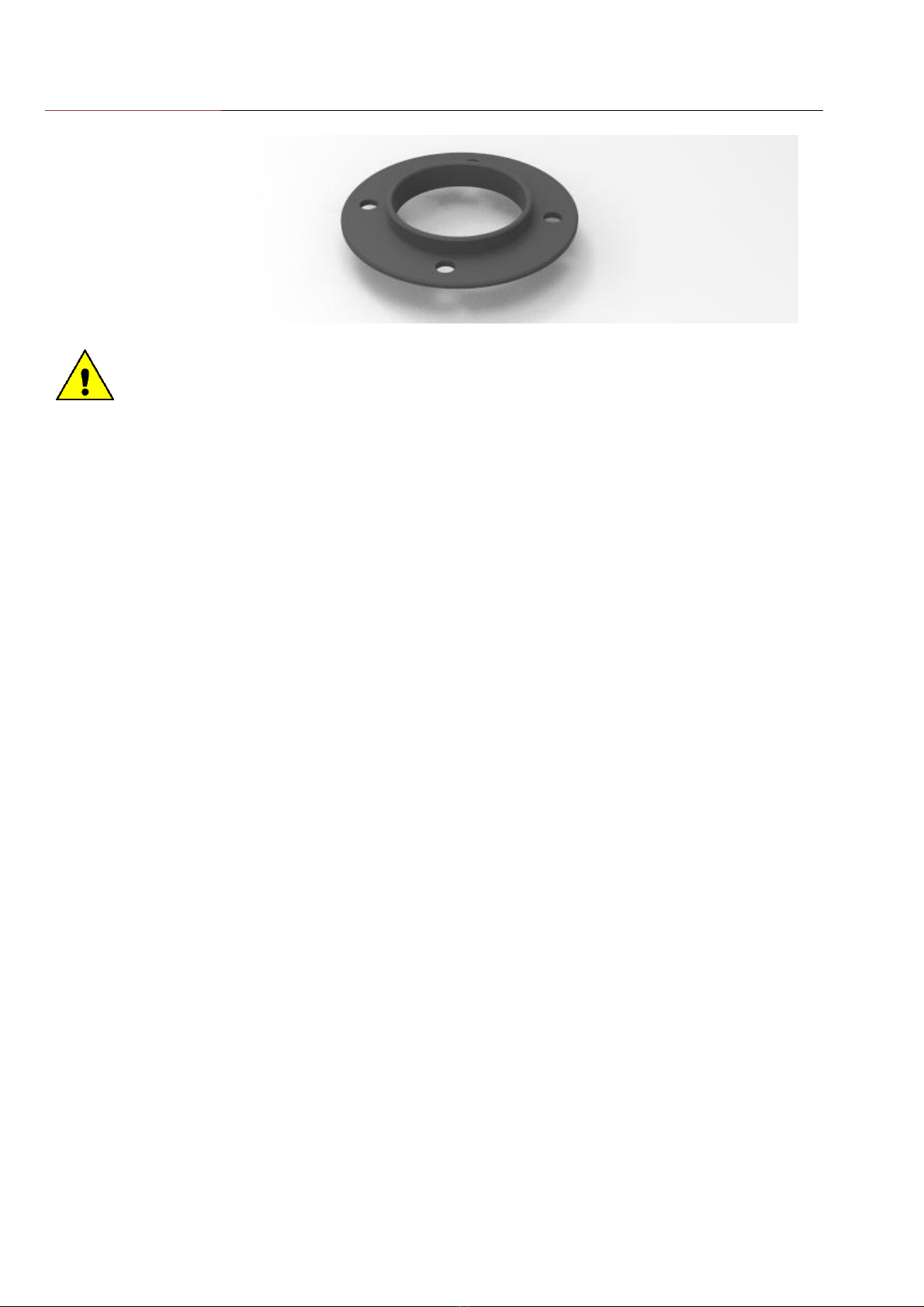

1.1.3. U-150 Content.............................................................................................................................5

1.1.4. Structure and operationing ...................................................................................................6

1.1.5. Measuring units and a tool ....................................................................................................6

Table 2 –Ex marking........................................................................................................................................7

1.1.7. Marking and sealing.................................................................................................................7

1.1.8. Packaging .....................................................................................................................................7

2. Usage ..................................................................................................................................................................7

2.1. Operational constraints...................................................................................................................................7

2.1.1. Ex rating in operating .............................................................................................................7

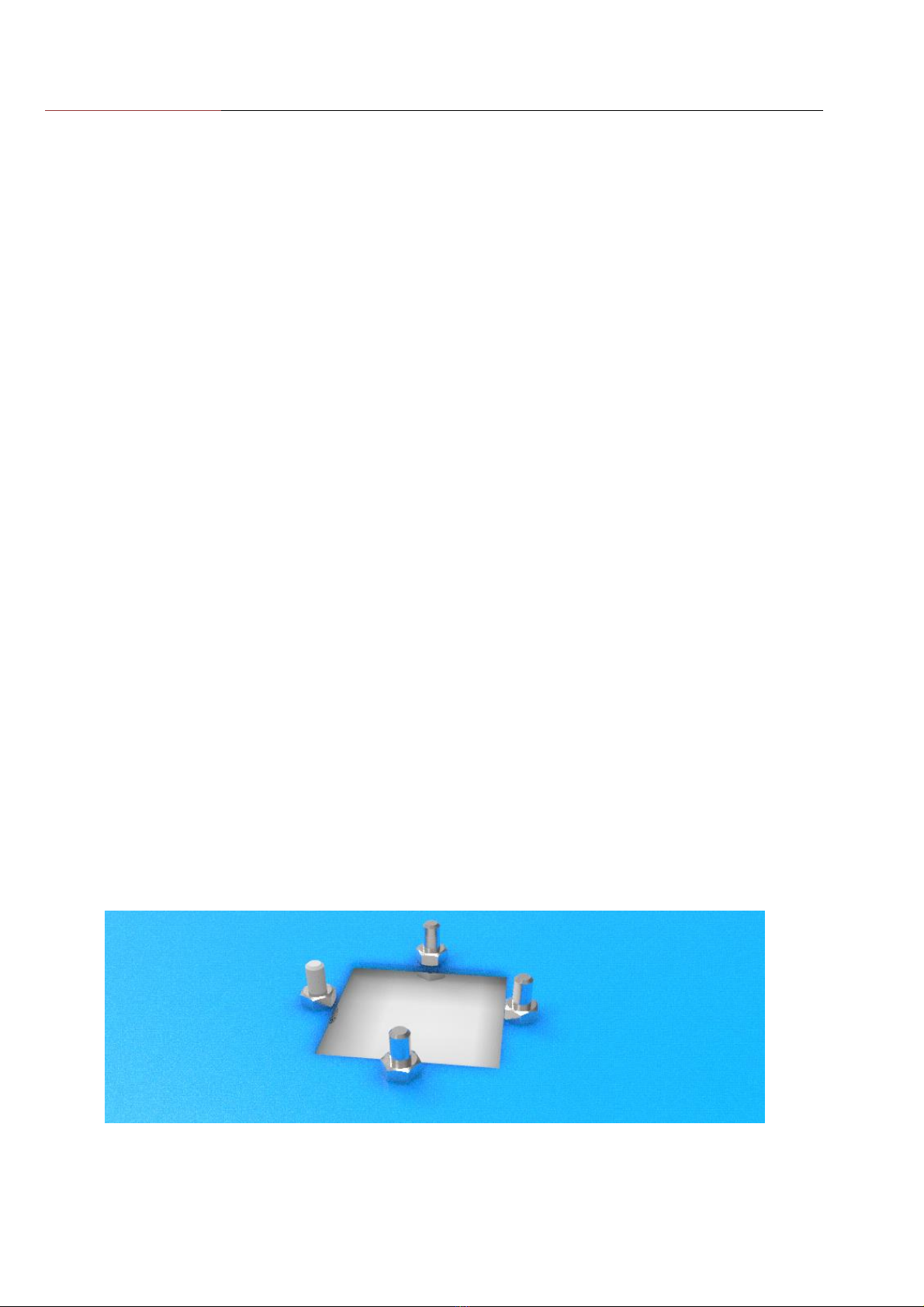

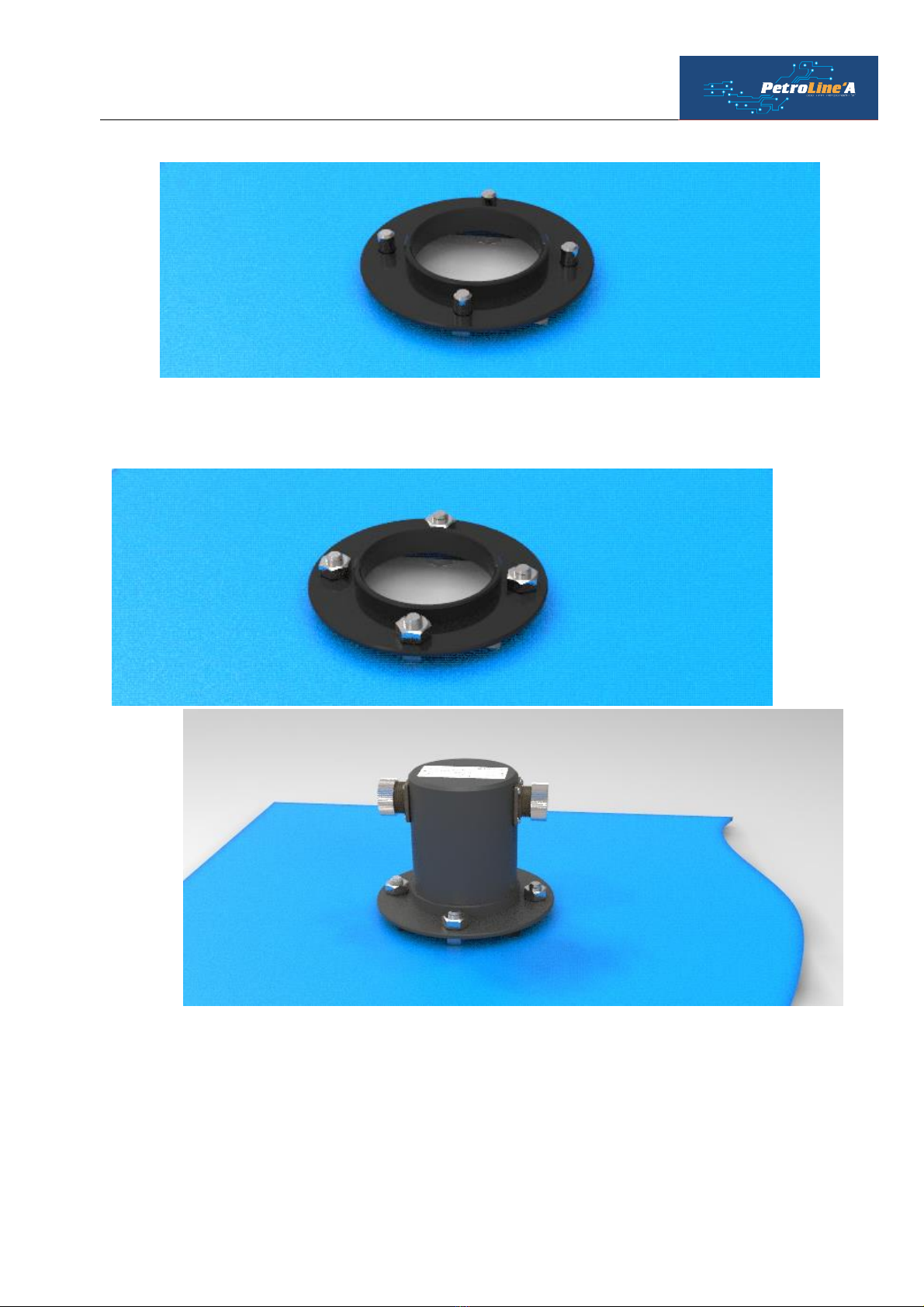

2.2. Preparation of U-150 usage ............................................................................................................................8

2.2.1. U-150 Safety rules.....................................................................................................................8

2.2.2. U-150 Volume and sequence ..................................................................................................8

2.2.3. Readiness checking for usage ...............................................................................................8

2.2.4. Setting description after preparation for a work..........................................................8

2.2.5. U-150 Orientation and Indication .......................................................................................8

2.2.6. Guideness about U-150 connection with other devices................................................9

2.2.7. Level sensor setting to work in a complex with DEL-150........................................10

2.2.8. Contractions for parameters display on a control module screen. .......................11

Table 3 –Contractions in DEL-150 system......................................................................................................11

Table 4 –Device addresses at RS-485 for DEL-150.........................................................................................11

2.2.9. U-150 Possible malfunctions while usage and recommendations for decoupling

them 12

2.2.11. Connection variants of a level sensor in a complex with DEL-150.......................12

2.3. Acts in emergency situations .........................................................................................................................14

3. Maintenance.................................................................................................................................................14

3.1.1. U-150 Maintenance .................................................................................................................14

3.1.2. Safety measures .......................................................................................................................14

3.1.3. U-150 Maintenance procedure........................................................................................................15

3.1.4. U-150 Work Capacity Check........................................................................................................... 15

4. Current Maintenance.......................................................................................................................................15

4.1. U-150 Current Maintenance..........................................................................................................................15

4.1.1. General information ........................................................................................................................15

5. Storage..............................................................................................................................................................15

5.1. Storage conditions ........................................................................................................................................15

6. Transportation.................................................................................................................................................16

6.1. Transportation requirements and conditions .................................................................................................16

7. Disposal ............................................................................................................................................................16